Professional Documents

Culture Documents

Vincotech TP 2018 05 The Challenges of Using SiC MOSFET-based Power Modules For Solar Inverters Tauer Matthias

Uploaded by

Can IlicaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vincotech TP 2018 05 The Challenges of Using SiC MOSFET-based Power Modules For Solar Inverters Tauer Matthias

Uploaded by

Can IlicaCopyright:

Available Formats

PCIM Europe 2018, 5 – 7 June 2018, Nuremberg, Germany

The Challenges of Using SiC MOSFET-based Power Modules for

Solar Inverters

Matthias Tauer, Vincotech GmbH, Unterhaching, Germany, matthias.tauer@vincotech.com

Abstract

This paper examines SiC MOSFETs as a viable

option for meeting the rising demand for faster

switching and greater efficiency in 1500 V solar

applications. It looks at their benefits – SiC

MOSFETs enable deeper integration and greater

power density – and their drawbacks in terms of

switching performance in power module

applications. The intrinsic properties of the latest

generations of devices appear to inhibit

performance and reliability. This paper analyzes

the root cause of these limitations and proposes

solutions to overcome them.

1. Electrical performance

1.1. Advanced Neutral Point Clamped

(ANPC) Solar Inverter Fig 1. Active neutral point clamped (ANPC)

The object of investigation is an ANPC (active The switching performance of various suppliers'

neutral point clamped) power module equipped SiC MOSFETs was investigated in a hard-

with Si IGBTs and SiC MOSETs as bare die. This switching, totem-pole half-bridge configuration. All

ANPC is an improved version of the three-level measurements were taken at a double-pulse

NPC inverter topology. Figure 1 depicts an ANPC characterization test station with a power module

schematic with four grid-frequency synchronized as shown in figure 1. The same DCB layout was

IGBTs (T1-T4), their anti-parallel diodes (D1-D4), used for all three measurements to ensure the

and two fast-switching MOSFETs (T5 and T6). parasitic inductance attributable to the layout,

The target application is a 1500 V string inverter wire bonding and distance between pins would

with high switching frequency (up to 64 kHz) and not affect the results. The only variable was the

high efficiency. Figure 1 shows one phase out of investigated type of SiC MOSFET. This

the three-phase inverter system, including the characterization test station's low-inductive drive

power module, dc-link capacitors (CDC1 and CDC2) circuit supports positive and negative multiple-

and inverter choke (LAC). ampere gate drive currents. One SiC MOSFET

was selected as an example for the in-depth

investigation conducted for this paper.

The double-pulse measurement assessed the

low-side MOSFET T6's switching waveform and

switching energies. This MOSFET formed a

commutation pair with the body-diode of the high-

side MOSFET T5. T6 stayed on for a prolonged

ISBN 978-3-8007-4646-0 975 © VDE VERLAG GMBH · Berlin · Offenbach

PCIM Europe 2018, 5 – 7 June 2018, Nuremberg, Germany

period to build up current, and was then switched

off for a short time to allow the current to

commutate fully in the body-diode of the opposite

MOSFET T5. Then the low-side MOSFET T6 was

turned on again and the MOSFET and diode's

switching waveforms and energies were

measured at that moment.

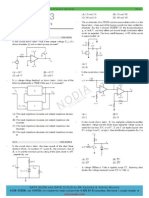

1.2. Double-pulse measurement result

The turn-on waveform of the low-side

MOSFET T6 shown in figure 2 indicates a sharp Fig. 3. The current path in hard-switched ANPC

spike of the drain current followed by ringing of

the drain current and gate voltage. This indicates

The voltage across Cds increases with high dv/dt.

a parasitic turn-on of the opposite device, also

The current then flows through Cgd and Cgs. The

called cross-conduction or shoot-through.

voltage on Cgs rises. If it reaches the turn-on

threshold, the MOSFET starts conducting current

in its channel.

Fig. 4. The SiC MOSFET's internal device

capacitances and gate resistance

Fig. 2. Cross-conduction at low-side SiC MOSFET

turn-on, Uds: light blue, Ids: dark blue, Ugs: yellow This renewed turn-on causes the current spike in

(Udc=600 V, Ids=140 A, Tj=150 C, Vg=-5/16 V) the low-side MOSFET’s drain shown in figure 2,

and therefore also high switching energies. The

operation junction temperature limits the highest

1.3. Explanation of the root cause acceptable power dissipation per MOSFET, which

means the high switching energy limits the

Before the low-side MOSFET T6 turns on, the maximum switching frequency.

current is freewheeling in the body diode of the

high-side MOSFET T5. During turn-on, the

current commutates from the high-side diode to 2. Proposed solutions

the low-side channel (figure 3). This causes the

diode to block and the voltage potential of the This chapter describes potential solutions,

midpoint to change with high dv/dt from DC+ to analyzes their effectiveness and looks at how

0 V. these are put into practice.

Figure 4 shows the position of the SiC MOSFET's

intrinsic capacitances. The Miller capacitance Cgd

is located between drain and gate, while Cgs is 2.1 Miller clamp circuit

between the gate and source, and Cds is between

the drain and source. A common way of removing the injected current

from the device is to install an external Miller

clamp circuit in the gate driver. The external

clamp circuit's effectiveness depends on the

ISBN 978-3-8007-4646-0 976 © VDE VERLAG GMBH · Berlin · Offenbach

PCIM Europe 2018, 5 – 7 June 2018, Nuremberg, Germany

inductance between the clamp circuit and the 2.3. ANPC with split output

MOSFET, and on the internal gate resistance.

The gate loop's inductance is below 4nH, Another proposed solution is to decouple the

including the module's pin, bond wires and DCB high- and low-side MOSFETs by splitting the

copper tracks. circuit into two parts with a separation inductance

In this case, the MOSFET's internal gate resistor in between.

limits effectiveness—the higher the gate resistor The module's pin stray inductance serves as the

value, the less effective the external Miller clamp separation inductance. No additional external

circuit. The gate resistor in this example has circuit components are necessary.

several ohms, which prevents the charge's Two additional diodes have to be added in the

removal. power module to keep the circuit functional

(figure 6).

2.2. Negative gate voltage bias

Another option is to increase the negative gate

voltage bias until any parasitic turn-on is

undetectable. However, most suppliers limit the

maximum negative gate voltage to a value of

around -5 V, including all transients. Experiments

show that a negative voltage spike appears when

the MOSFET is turning off. This spike imposes a

limit on the static negative gate voltage as the

sum of both may not exceed the maximum

ratings. In that case, this solution is not an option.

If the negative spike exceeds the given limits for

device reliability, this will cause the gate oxide to Fig. 6. ANPC with split output

degrade. This has a negative impact on long-term

reliability because the threshold voltage may The added inductance disables the given switch's

decrease to zero as the oxide deteriorates. output capacitance, thereby preventing exposure

to high dv/dt and Miller capacitance-induced

charging injected into the gate. This first step can

reduce the second current spike (figure 7), but not

eliminate it all together.

Fig. 5. Low-side SiC MOSFET turn-off, Uds: light blue,

Ids: dark blue, Ugs: yellow (Udc=600 V, Ids=140 A,

Tj=150 C, Vg=-6/16 V)

Fig. 7. Low-side SiC MOSFET turn-on with 50 nH

separation inductance, Uds: light blue, Ids: dark blue,

Ugs: yellow (Udc=600 V, Ids=140 A, Tj=150 C,

Vg=0/16 V)

ISBN 978-3-8007-4646-0 977 © VDE VERLAG GMBH · Berlin · Offenbach

PCIM Europe 2018, 5 – 7 June 2018, Nuremberg, Germany

2.4. ANPC with split-output and Timing is essential here. The gate voltage has to

integrated gate capacitor be stepped down to a more negative value and

back up to the nominal value after the high dv/dt

crosses the half-bridge's midpoint.

A further step can be taken to fully overcome the The negative gate voltage spike shown in figure 5

limitations imposed by the Miller effect: Install a can be used as the negative gate bias. This is

capacitor in the module between the MOSFET's done by turning on the opposite MOSFET at the

gate and source (figure 8). The absence of a moment the gate voltage is at its most negative

second current spike in figure 9 shows that this value. The voltage added to the gate by the Miller

prevents parasitic turn-on. effect increases the resulting voltage on the gate,

The gate capacitor reduces dv/dt, which has the but the absolute value will not reach the turn-on

added benefit of reducing EMC. threshold (figure 10). The high-side gate voltage

in this example was measured with a differential

probe, which is why the capacitive current

generated during low-side switching interfered

with the measurement as can be seen here.

Low-side gate

High-side

gate

5V/div

Fig. 8. ANPC with split output and gate capacitor

Fig. 10. A smart gate driver's low- and high-side

gate timing

The smart gate drive may thus be a practicable

solution. However, the timing has yet to be

optimized and the solution's long-term reliability

and effectiveness remains to be proven.

Conclusion

The above paragraphs describe and discuss

Fig. 9. Low-side SiC MOSFET turn-on with various remedies to the root cause of the

50 nH separation inductance and 10 nF gate limitations of SiC MOSFETs operated in hard-

capacitor, Uds: light blue, Ids: dark blue, Ugs: yellow switched, totem-pole applications. A SiC

(Udc=600 V, Ids=140 A, Tj=150 C, Vg=0/16 V) MOSFET has to operate reliably throughout its

service life, so the main concerns to be taken into

account here are the gate oxide and therefore the

2.5. Smart gate driver maximum positive and negative gate voltages.

Exceeding the maximum device ratings in static

A smart gate drive may be used to dynamically or dynamic conditions may cause the gate

drain the gate voltage to a more negative value structure to degrade and the threshold voltage to

when the Miller charge surges into the gate. drift. This would eventually result in component

ISBN 978-3-8007-4646-0 978 © VDE VERLAG GMBH · Berlin · Offenbach

PCIM Europe 2018, 5 – 7 June 2018, Nuremberg, Germany

failure and, as a consequence, device failure. A References

split output paired with an integrated capacitor [1] B. Jayant Baliga, “The IGBT Device," William

between the gate and source as presented here Andrew, ISBN 978-1455731435

can help overcome the limitations in switching

[2] Qingzeng Yan, Xibo Yuan, et al.,

performance and enable the device to be

“Performance Evaluation of Split Output

operated to its specifications.

Converters with SiC MOSFETs and SiC Schottky

Diodes,” IEEE 2017

[3] Helong Li, Stig Munk-Nielsen, et al., “SiC

MOSFETs Based Split Output Half Bridge

Inverter: Current Commutation Mechanism and

Efficiency Analysis,” IEEE 2014

ISBN 978-3-8007-4646-0 979 © VDE VERLAG GMBH · Berlin · Offenbach

You might also like

- Designer's Guide To Isolation CircuitsDocument70 pagesDesigner's Guide To Isolation Circuitsrangerford100% (2)

- Wireless Power TransmissionDocument5 pagesWireless Power TransmissionNiranjan TawareNo ratings yet

- Switchgear and ProtectionDocument51 pagesSwitchgear and ProtectionAhad Silve90% (10)

- Resonance Energy by BelkiredDocument28 pagesResonance Energy by BelkiredAndres SiposNo ratings yet

- Stacking Power MOSFETs For Use in High Speed InstrumentationDocument3 pagesStacking Power MOSFETs For Use in High Speed InstrumentationTomas MullerNo ratings yet

- Research On High Power Density Sic Mosfet Driver Circuit: Shaokun Zhang, Guolin He, Dan Zheng, Tao Fan, Xuhui WenDocument6 pagesResearch On High Power Density Sic Mosfet Driver Circuit: Shaokun Zhang, Guolin He, Dan Zheng, Tao Fan, Xuhui WenghhNo ratings yet

- Lectura 3 M PDFDocument12 pagesLectura 3 M PDFFlakita S MelcOchitaNo ratings yet

- Unit 01Document21 pagesUnit 01mathanstar77No ratings yet

- Ecler Pam1400 1000 600 300Document183 pagesEcler Pam1400 1000 600 300Lluis Reparacion ElectronicaNo ratings yet

- My Notes - UnderstandingsDocument14 pagesMy Notes - UnderstandingsLubaba Bashar MomiNo ratings yet

- Parasitic Turn-On of Power MOSFETDocument7 pagesParasitic Turn-On of Power MOSFETBiswajit SinghNo ratings yet

- High PSRR Voltage Reference Circuit With Dual-Output For Low Power ApplicationsDocument4 pagesHigh PSRR Voltage Reference Circuit With Dual-Output For Low Power Applicationsmd istiyakNo ratings yet

- Modeling of SiC MOSFET in MatlabSimulinkDocument5 pagesModeling of SiC MOSFET in MatlabSimulinkDaniel Labiano AnduezaNo ratings yet

- High Voltage Pulser With A Fast Fall-Time For Plasma Immersion Ion ImplantationDocument4 pagesHigh Voltage Pulser With A Fast Fall-Time For Plasma Immersion Ion ImplantationAnonymous u5128WZ1KNo ratings yet

- A Gate Driver of SiC MOSFET For Suppressing The Negative Voltage Spikes in A Bridge CircuitDocument15 pagesA Gate Driver of SiC MOSFET For Suppressing The Negative Voltage Spikes in A Bridge CircuitMahesh KulkarniNo ratings yet

- Choosing Power Switching Devices For SMPS Designs: Mosfets or Igbts?Document6 pagesChoosing Power Switching Devices For SMPS Designs: Mosfets or Igbts?RubenG200No ratings yet

- Mosfets BasicsDocument7 pagesMosfets Basicsodl_123No ratings yet

- Mosfet Switching PCB InductanceDocument5 pagesMosfet Switching PCB InductancerajeshNo ratings yet

- How To Drive Mosfets and Igbts Into The 21St Century: IXAN0009Document28 pagesHow To Drive Mosfets and Igbts Into The 21St Century: IXAN0009mmNo ratings yet

- Isolated Gate Driver For SiC MOSFETs With Constant Negative Off VoltageDocument4 pagesIsolated Gate Driver For SiC MOSFETs With Constant Negative Off VoltageHainan DingNo ratings yet

- Isolated Mosfet Gate Driver PaperDocument6 pagesIsolated Mosfet Gate Driver PapergenwittsNo ratings yet

- Latest Technology PT Igbts vs. Power Mosfets: Application Note Apt0302 Rev. A April 4, 2003Document6 pagesLatest Technology PT Igbts vs. Power Mosfets: Application Note Apt0302 Rev. A April 4, 2003Jyothsna VayyalaNo ratings yet

- Balancing Circuit For A 5-KV 50-Ns Pulsed-Power Switch Based On SiC-JFET Super CascodeDocument7 pagesBalancing Circuit For A 5-KV 50-Ns Pulsed-Power Switch Based On SiC-JFET Super Cascodemohsen feiziNo ratings yet

- Gate Drive For High Speed, High Power IgbtsDocument4 pagesGate Drive For High Speed, High Power IgbtsAhmadNo ratings yet

- IGBT & Sic MosfetDocument7 pagesIGBT & Sic MosfetNgọc Hưng TạNo ratings yet

- Mosoft Circuit ApplicationDocument16 pagesMosoft Circuit Applicationkaran007_mNo ratings yet

- Application Note AN-1005: Power MOSFET Avalanche Design GuidelinesDocument17 pagesApplication Note AN-1005: Power MOSFET Avalanche Design Guidelinesmetary4183No ratings yet

- Report MosfetDocument13 pagesReport MosfetaiswaryaNo ratings yet

- Switching Loss Estimation of Sic Mosfet in LtspiceDocument4 pagesSwitching Loss Estimation of Sic Mosfet in Ltspice劉育昇No ratings yet

- IGBT: A Solid State SwitchDocument9 pagesIGBT: A Solid State Switchnagaraj p sNo ratings yet

- A Hybrid-Switch-Based Soft-Switching Inverter For Ultrahigh-Efficiency Traction Motor DrivesDocument8 pagesA Hybrid-Switch-Based Soft-Switching Inverter For Ultrahigh-Efficiency Traction Motor DrivesraghuaadsNo ratings yet

- A Hybrid-Switch-Based Soft-Switching Inverter For Ultrahigh-Efficiency Traction Motor DrivesDocument8 pagesA Hybrid-Switch-Based Soft-Switching Inverter For Ultrahigh-Efficiency Traction Motor DrivesraghuaadsNo ratings yet

- A High-Frequency CMOS Based Driver For High-Power MOSFET ApplicationsDocument6 pagesA High-Frequency CMOS Based Driver For High-Power MOSFET ApplicationsNikolas AugustoNo ratings yet

- Project 1 FullDocument10 pagesProject 1 FullSaratul AkmaNo ratings yet

- Infineon-MOSFETs OptiMOS Selection For DC-DC converters-AN-v01 00-ENDocument6 pagesInfineon-MOSFETs OptiMOS Selection For DC-DC converters-AN-v01 00-ENLûtwàmä JôëNo ratings yet

- New 1600V BIMOSFET TransistorsDocument10 pagesNew 1600V BIMOSFET TransistorsCristian BandilaNo ratings yet

- G. Pulla Reddy Engineering College (Autonomous) : Kurnool Department of Electrical & Electronics Engineering Power Electronics (PEP) Laboratory (Scheme-2013)Document87 pagesG. Pulla Reddy Engineering College (Autonomous) : Kurnool Department of Electrical & Electronics Engineering Power Electronics (PEP) Laboratory (Scheme-2013)Sreenath SreenathNo ratings yet

- En CD00003897 PDFDocument7 pagesEn CD00003897 PDFJosias AndradeNo ratings yet

- Stacked High Voltage Switch Based S I C Vjfets: ISPSD 2003, April 14-17, UKDocument4 pagesStacked High Voltage Switch Based S I C Vjfets: ISPSD 2003, April 14-17, UKМилан ЛукићNo ratings yet

- Voltage References Consisting of Subthreshold MOSFETsDocument9 pagesVoltage References Consisting of Subthreshold MOSFETsChristian Ismaël Tcheutchoua TakamNo ratings yet

- Paper Final PDFDocument5 pagesPaper Final PDFmd istiyakNo ratings yet

- Modelling of Power MOSFET For The Analysis of Switching Chara in Half-Bridge ConvertersDocument10 pagesModelling of Power MOSFET For The Analysis of Switching Chara in Half-Bridge ConvertersMa SeenivasanNo ratings yet

- Mtw8n60e DDocument9 pagesMtw8n60e DAtiqurrehman UmairNo ratings yet

- Light Triggering Thyristor For HVDC and Other Applications.Document6 pagesLight Triggering Thyristor For HVDC and Other Applications.IDESNo ratings yet

- PEMD Paper - Walid Issa - AxchiveDocument5 pagesPEMD Paper - Walid Issa - AxchivePAL ROBOTNo ratings yet

- Ecler Pam2000 Pam2600 Power Amplifier Service ManualDocument107 pagesEcler Pam2000 Pam2600 Power Amplifier Service Manuallluissb92% (12)

- Double Pulse Testing 5 6 Series MSO Qorvo 48W 73984 0Document18 pagesDouble Pulse Testing 5 6 Series MSO Qorvo 48W 73984 0Issa PouyeNo ratings yet

- A Novel TFET StructureDocument23 pagesA Novel TFET StructureRohith ChowdaryNo ratings yet

- Ixys P-Channel Power Mosfets and Applications Abdus Sattar, Kyoung-Wook Seok, Ixan0064Document14 pagesIxys P-Channel Power Mosfets and Applications Abdus Sattar, Kyoung-Wook Seok, Ixan0064Kikuvi JohnNo ratings yet

- Assignment 2Document13 pagesAssignment 2UdaY BNo ratings yet

- Assignment 2Document13 pagesAssignment 2UdaY BNo ratings yet

- Design and Implementation of A Non-Destructive Test Circuit For Sic-MosfetsDocument6 pagesDesign and Implementation of A Non-Destructive Test Circuit For Sic-MosfetsHendi AfriyanNo ratings yet

- Design Considerations For A Fast Stacked-MOSFET SwitchDocument7 pagesDesign Considerations For A Fast Stacked-MOSFET SwitchBruna RibeiroNo ratings yet

- Reduction of Power MOSFET Losses in Hard-Switched ConvertersDocument2 pagesReduction of Power MOSFET Losses in Hard-Switched ConvertersWesley de PaulaNo ratings yet

- Mosfet: Huda Mohammed Stage 3Document11 pagesMosfet: Huda Mohammed Stage 3الزهور لخدمات الانترنيتNo ratings yet

- Pms Dei 062200Document4 pagesPms Dei 062200Afrizal ALANANo ratings yet

- Low Voltage Low Power Pipelined ADC For Video Applications: Hameed Zohaib Samad, Patri Sriharirao, K. SarangamDocument5 pagesLow Voltage Low Power Pipelined ADC For Video Applications: Hameed Zohaib Samad, Patri Sriharirao, K. SarangamGayathri SrinivasaNo ratings yet

- Application Note: Extremely Compact, Isolated Gate Driver Power Supply For Sic-Mosfet (6 - 10 W)Document5 pagesApplication Note: Extremely Compact, Isolated Gate Driver Power Supply For Sic-Mosfet (6 - 10 W)Wesley de PaulaNo ratings yet

- Understand Two-Switch Forward - Flyback ConvertersDocument3 pagesUnderstand Two-Switch Forward - Flyback ConvertersLitt Pang HiewNo ratings yet

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10From EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10No ratings yet

- Sboa 558Document10 pagesSboa 558Can IlicaNo ratings yet

- Power Mosfet DetailsDocument66 pagesPower Mosfet DetailsCan IlicaNo ratings yet

- Sensor Signal Conditioning (Part 3)Document6 pagesSensor Signal Conditioning (Part 3)Can IlicaNo ratings yet

- MP1657 MPSDocument19 pagesMP1657 MPSCan IlicaNo ratings yet

- Hoyle-TIA BootstrappingDocument7 pagesHoyle-TIA BootstrappingCan IlicaNo ratings yet

- ECD II Presentation OP-AMP ApplicationsDocument30 pagesECD II Presentation OP-AMP ApplicationsUmaNo ratings yet

- Untitled DocumentDocument68 pagesUntitled DocumentLalit GaurNo ratings yet

- AN-1302 Application Note: Optimizing The For 4-Wire, Bioisolated Impedance Measurement ApplicationsDocument16 pagesAN-1302 Application Note: Optimizing The For 4-Wire, Bioisolated Impedance Measurement ApplicationssalemNo ratings yet

- 3rd Grading Physics 2022 Summative QuizDocument2 pages3rd Grading Physics 2022 Summative QuizOdessa SantosNo ratings yet

- Mk5pfc ArticleDocument24 pagesMk5pfc ArticleenzolnNo ratings yet

- Investigation of SVC and STATCOM Devices in Terms of Static and Dynamic Voltage StabilityDocument11 pagesInvestigation of SVC and STATCOM Devices in Terms of Static and Dynamic Voltage StabilityEduardo ZamoranoNo ratings yet

- NTB23N03 DatasheetDocument4 pagesNTB23N03 DatasheetingucvNo ratings yet

- Advanced Digital Controls Improve PFC PerformanceDocument18 pagesAdvanced Digital Controls Improve PFC Performancediablo diablolordNo ratings yet

- 212 - Problem Set #09Document2 pages212 - Problem Set #09everyoneMDNo ratings yet

- ECE Companies ListDocument9 pagesECE Companies ListPolaiah Geriki100% (1)

- 3 Overhead Transmission Switches CatalogDocument24 pages3 Overhead Transmission Switches CatalogihtishamuddNo ratings yet

- HV - Impulse CurrentDocument9 pagesHV - Impulse CurrentSaufiNo ratings yet

- ODE Lecture 15Document45 pagesODE Lecture 15Zainab BatoolNo ratings yet

- Whitepaper Switching of Filter Circuits With Vacuum SwitchesDocument8 pagesWhitepaper Switching of Filter Circuits With Vacuum Switchesvijayeee82No ratings yet

- Vol D 3 Maintenance Repair Manual of Wap5Document340 pagesVol D 3 Maintenance Repair Manual of Wap5rahul kumarNo ratings yet

- ECT AssignmnetDocument18 pagesECT AssignmnetJayanthiKathiresanNo ratings yet

- Bhel Paper For Electrical & Electronics: UndefinedDocument13 pagesBhel Paper For Electrical & Electronics: UndefinedAnkit SrivastavaNo ratings yet

- Analog CircuitsDocument33 pagesAnalog Circuitsafireon80% (1)

- LM350 DatasheetDocument12 pagesLM350 DatasheetOmarVelasquezC.No ratings yet

- EHVAC Objective Question Bank - Electrify Students1Document3 pagesEHVAC Objective Question Bank - Electrify Students1RitNo ratings yet

- Acoplador LDG Z 11ProII ManualDocument25 pagesAcoplador LDG Z 11ProII ManualyupiteruNo ratings yet

- Lpg/flammable Gas Leakage DetectorDocument41 pagesLpg/flammable Gas Leakage DetectorAkash Zad100% (1)

- Electrical Unit 5Document14 pagesElectrical Unit 5Mausam MallaNo ratings yet

- Wa0011Document45 pagesWa0011Vedhas WalimbeNo ratings yet

- ABB ACS880 Based Retrofit Handbook RevADocument37 pagesABB ACS880 Based Retrofit Handbook RevARomildo FernandesNo ratings yet

- LIN Transceiver With Voltage Regulator: Features Package TypesDocument38 pagesLIN Transceiver With Voltage Regulator: Features Package TypesPhạm Văn TưởngNo ratings yet

- Simulación de 21 y 87L Con SimulinkDocument72 pagesSimulación de 21 y 87L Con SimulinkLuis BriceñoNo ratings yet