Professional Documents

Culture Documents

6la+r - P546

Uploaded by

Mohamed AwadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6la+r - P546

Uploaded by

Mohamed AwadCopyright:

Available Formats

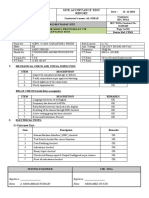

Respon

sibilities SITE TEST REPORT

Legend

CSD Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 1 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

1. GENERAL DATA AND INFORMATION.

Panel No: 6LA+R Designation 87L2

Make GE Rated current 1600/1 A

Serial No: 36183972/09/22 VT Ratio 115 KV/115 V

Model No: P54691RR7S0790M Aux: Voltage 110-250VDC/ 100-240VAC

Application DIFF. WITH DIST & DEF PROTN Software version P54691RR7S0790M

2. MECHANICAL CHECK AND VISUAL INSPECTION:

With relay de-energized condition

ITEM DESCRIPTION CHECKED

1 Inspect for any physical damage or defects. OK

2 Verify connections as per approved drawings. OK

3 Check that serial no. of relay matching with serial no. of display. OK

4 Check case earthing OK

5 Watchdog contacts (M11-M12 closed, M13-M14 open) OK

3. ELECTRICAL TEST:

1. Function Test: With relay energized condition

ITEM DESCRIPTION CHECKED

1 Watchdog contacts (M11-M12 open, M13-M14 closed) OK

Set Clock to local time OK

2 Date & time

Time maintained when Aux. Supply removed OK

Make Test Mode Enable under commissioning menu to check ALARM

3

LED (Yellow)

OK

Make Test Mode Enable under commissioning menu to check OUT OF

4

SERVICE LED (Yellow)

OK

5 Apply any fault condition to check TRIP LED (Red) OK

Apply Test LEDs under commissioning menu to check all 8 programmable

6

LEDs.

OK

Measured FIELD SUPPLY Between terminals M7 – M9 OK

7

Voltage Between terminals M8 – M10 OK

8 Disturbance report check OK

9 DC loss test OK

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 2 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

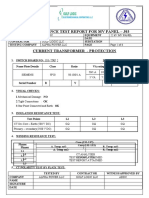

1. MEASURMENTS CHECK:

1.1 CURRENT INPUTS CHECK:

DISPLAYED DISPLAYED

INPUT APPLIED CT RATIO

SECONDARY VALUE PRIMARY VALUE

CURRENT VALUE (A) APPLIED

(A) (A)

IA 1.0 ∟0 ⁰ 1.002∟-0.198 1601∟-0.125

IB 1.0 ∟-120 ⁰ 1600/1 1.003∟-120.2 1602∟-120.1

IC 1.0 ∟120 ⁰ 1.003∟119.9 1605∟120.1

Limits: Typically ± 1%, but ± 0.5% between 0.2 - 2In/Vn; Current: 0.05 to 3 In ± 1% of reading as per TM Page: 16-17

1.3 VOLTAGE INPUTS CHECK:

APPLIED DISPLAYED

INPUT VT RATIO DISPLAYED

VALUE SECONDARY VALUE

VOLTAGE APPLIED PRIMARY VALUE(KV)

(V) (V)

VAB 115 ∟0 ⁰ 115.0∟30.1 115.0∟30.0

VBC 115 ∟-120 ⁰ 115.0∟-90.2 115.0∟-90.02

VCA 115 ∟120 ⁰ 115/√3 115.0∟150.1 115.0∟150.1

VA 66.4 ∟0 ⁰ /0.115/√3 Kv 66.38∟0.3 66.37∟0.02

VB 66.4 ∟-120 ⁰ 66.41∟-120.2 66.40∟-120.1

VC 66.4 ∟120 ⁰ 66.43∟120.0 66.42∟120.0

Accuracy: 1.0% of reading Voltage: 0.05 to 2 Vn

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 3 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

SETTING CHECK:

Ensure all the settings are applied for used functions and printout the enclosed setting [ ].

2. DISTANCE FUNCTION CHECK:

2.1 IMPEDANCE REACH CHECK:

Item Description Checked

1 Print out from FREJA attached OK

Impedance tolerance: +/- 10 % for all zones.

2.2 OPERATING TIME TESTING:

Item Description Checked

1 Print out from FREJA attached OK

3. VTS FUNCTION TEST:

Setting:

VTS time delay = 5.0 Sec

VTS I> inhibit = 10.00 A

VTS I2> inhibit = 0.05 A

3.1 Loss of one or two phases test: (Under load Condition)

Fixed setting: V2 = 10 volt, I2> inhibit less than setting.

Set Time Measured Time

Phase Pick up Drop Off V2 = 10KV

(sec) (Sec)

AN 36.43 37.93 10.13 5.02

BN 36.42 37.93 9.999 5.02

CN 36.43 37.93 10.00 5.03

5.0

AB 36.42 37.92 10.00 5.02

BC 36.43 37.93 9.999 5.02

CA 36.43 37.93 10.00 5.03

Measured VTS I2> inhibit =0.049 A

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 4 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

3.2 Loss of all 3 phase voltages: (Under load condition test)

Fixed Setting: a- for fuse fail pick up; V1=10 volts.

b- for fuse fail reset; V1=30 volts.

Pick up measurement Reset measurement

voltage(v) voltage(v)

10.02 30.04

3.3 Absence of 3 phase volts on line Energization test :

1. Apply 3 phase current less than VTS I> inhibit with no volts and Check no tripping [ OK ]

2. Apply 3 phase current greater than VTS I> inhibit with no volts and Check zone 1 tripping occurred [ OK ]

Measured VTS I> = 9.992 A

Activate Binary Input( BI-1) connected to MCB/VTS address DDB-438 and check VTS Fail

Indication. [ OK ]

4. SOTF TEST:

SETTING:

-SOTF active with

FUNCTION SETTNG MEASURE TIME

TOC reset delay 0.5 sec 0.515 sec

TOC delay 0.2 sec 0.226 sec

Setting: All Zones Enabled

Apply fault condition and at the same time apply CB Manual Close Pulse within the time set in TOC Reset Delay,

relay shall be tripped by SOTF (Instantaneously). If CB Manual Close Pulse is received after TOC Reset Delay

time then, the relay shall be tripped on Zone timing’s..

Measured Time

SOTF IN External detection WITH OUT SOTF

(m sec) (m sec)

Zone 1 25 21

Zone 2 28 427

Zone 3 23 832

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 5 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

5. Scheme Communication Logic:

Setting:

Aid Dist delay = 0 m sec

TRev Guard = 117 m sec

I. Permissive Over Reach Scheme:

Send Logic : CS=ZM1&ZM2 : _____________

Trip Logic : Trip=ZM2+CR : _____________

Trip without CR : ___421 ___m Sec.

Trip with CR : ____21____m Sec.

Time Send : ____17_ __m Sec.

I. Current Reversal Logic Check (Permissive Over Reach Scheme):

Apply a reverse / forward fault to check: t rev guard:

Fault type t rev guard setting (m sec) t rev guard measured (m sec)

Reverse/ forward 100 121

6. Fault Locator Function:

Line Length: 14.2 km ФL: 83 degree

Fault Type Fault Impedance () Expected display (%) Actual display (%)

A-N 2.339 ∟80.25◦ 25 24.60

B-N 4.678 ∟80.25◦ 50 49.61

C-N 7.018 ∟80.25◦ 75 74.69

A-B 1.70 ∟83.0◦ 25 24.48

B-C 3.40 ∟83.0◦ 50 49.72

C-A 5.10 ∟83.0◦ 75 74.64

A-B-C 6.80 ∟83.0◦ 100 98.91

7. AIDED DEF TEST (INSTANTANEOUS)

Settings:

Vn> (3Vo) = 3 V

IN >FW (3Io) =220 mA Polarization = Zero sequence

IN >RV (3Io) = 130 mA RCA: -60° degree

DEF Start DEF Reset

Injection Angle Boundary Angle Limit

(mA) (mA)

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 6 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

FWD 330-150 0.221 0.215 330.4-150.1

REV 150-330 0.131 0.126 150.2-330.3

POLARIZING VOLTAGE (3V0) PICKUP AND DROP OFF TEST:

Note:

Apply 3phase volts healthy voltage inject only one phase current for this test to the phase under test and

reduce voltage of phase under test.

Vo=Vn/3= (Va+Vb+Vc)

Vn(3V0) setting Vn (3V0) measured (V)

(V) Pick up Drop off

3 2.97 2.94

I. SCHEME TEST:

DEF Scheme:

Aid DEF delay = 90.0 m sec

Scheme: permissive over reach

Send Logic : Forward Fault : ______________

Trip Logic : Forward Fault + CR : ______________

Trip Time Measured with CR : _____121.5____m Sec

Trip Time Measured without CR :_ NA ___mSec

Send Time : _____30.4____m Sec

II. Current Reversal Logic Check (Permissive Over Reach Scheme):

Apply a reverse / forward fault to check: t rev guard:

TR with t rev guard

Fault type

t rev guard setting Send Time

measured Time

(m sec) (m sec)

(m sec)

Reverse/ forward 100 215.6 128.1

8. Current differential bias characteristic (87-1)

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 7 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

Item Description Setting

1 IS1 0.30 A

2 Is2 2.0 A

3 K1 30 %

4 K2 150 %

5 T 0.0 Sec

I. Pick-up test

I min = [ Is1/ (1-0.5K1) ] x 0.5

Actual Trip

Expected Trip

Expected Pickup Actual Pickup Drop-off Time

Fault Type Time

In Amp In Amp In Amp in m-sec at

in m-sec

2 x I Pickup

A-N 0.180 0.129 <40 ms 27.9

B-N 0.176A 0.180 0.130 <40 ms 28.3

C-N 0.179 0.130 <40 ms 28.5

Limits: Pick-up: Formula ±10% ; Drop-off: 0.75 x Formula ±10% . P544&6/EN/TM/M Page: 16-10

II. Lower slope test (Injected current < Is2)

I Diff I > [ K1 * I bias) + Is1 ] x 0.5

Bias current Differential Expected

Measured Actual Trip

Injected in current inject differential Expected Trip

value of diff. Time

Phase (Amps) in phase current Time

current in m-sec at

for tripping in m-sec

(Amp) 2 x I Pickup

A B C A B C (Amp)

1.5 X 0.379 23 ms

1.5 X 0.375 A 0.377 <40 ms 26 ms

1.5 X 0.377 25 ms

III. Upper slope test (Injected current > Is2)

I Diff I > [ (K2 * I Bias – { (K2-K1) IS2 } + IS1 ]x 0.5

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

SITE TEST REPORT

Contractor’s name: Hitachi Energy

Sub.Contractor’s name: MRC

Name of Substation: Mobile Substation Semi-Trailer 115KV HV GIS-SS-01 Contract No.: 4500448311

LINE DIFFERENTIAL PROTECTION RELAY – MICOM P546 Page 8 of 8

Panel No: = 6LA+R Equip. No.: 87L2 Dwg. Ref.: XD-MOB107

Bias current Differential Expected

Actual Trip

Injected in current inject differential Measured value Expected Trip

Time

Phase (Amps) in phase current of diff. current Time

in m-sec at

for tripping (Amp) in m-sec

2 x I Pickup

A B C A B C (Amp)

3.0 X 1.212 23 ms

3.0 X 1.2 A 1.212 <40 ms 26 ms

3.0 X 1.210 22 ms

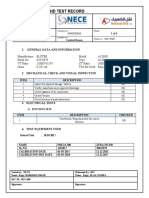

9. Breaker fails function:

Description Setting ( A ) Pick up Drop off

B.FAIL 1 TRIP 1 1.000 0.999

B.FAIL 2 TRIP 1 1.000 0.999

Description Setting ( m Sec ) Measured ( m Sec ) Remark

B.FAIL 1 TIMER 150 173

B.FAIL 2 TIMER 150 171

Limit: < 12 ms

10. Binary inputs and output checked: []

11. Test Equipment’s Used

Item Test Equipment Serial Number Calibration date Calibration due date

1 FREJA 300 1402796 23-SEP-2023 22-SEP-2024

2 Multimeter – Fluke 177 32560406 26-Oct-2023 25-Oct-2024

DATE: 23/11/ 2023

TESTING ENGINEER SEC- Engineer

Sec Id No: MRC – 006 Id. No.:

Signature: ________________ Signature: _____________________

Name : MALIK KHALID Name :

You might also like

- RMU Test ReportDocument3 pagesRMU Test ReportGANESH K75% (4)

- 7ss - Busbar Low Imp Relay Test-1Document17 pages7ss - Busbar Low Imp Relay Test-1Ravi100% (3)

- Site Inspection and Test Record: 1. General Data and InformationDocument13 pagesSite Inspection and Test Record: 1. General Data and InformationwazakifyNo ratings yet

- 6lb+r-Red 670Document15 pages6lb+r-Red 670Mohamed AwadNo ratings yet

- 6TB+R Micom P643-AcceptanceDocument16 pages6TB+R Micom P643-AcceptanceMohamed AwadNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument13 pagesSite Inspection and Test Record: 1. General Data and InformationwazakifyNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument13 pagesSite Inspection and Test Record: 1. General Data and InformationwazakifyNo ratings yet

- 6ta+r Micom P643-AcceptanceDocument16 pages6ta+r Micom P643-AcceptanceMohamed AwadNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument5 pagesSite Inspection and Test Record: 1. General Data and InformationSohail AhmedNo ratings yet

- 7SR1587 Voltage and Frequency RelayDocument4 pages7SR1587 Voltage and Frequency RelayAnonymous dH3DIEtzNo ratings yet

- Site Test Report Date: 29/5/2018 Contractor's Name: HADI HAIDER Customer: Sec-Eoa Jubail Commercial Port 115/13.8Kv Ss-2 Tapcon 260 Avr RelayDocument4 pagesSite Test Report Date: 29/5/2018 Contractor's Name: HADI HAIDER Customer: Sec-Eoa Jubail Commercial Port 115/13.8Kv Ss-2 Tapcon 260 Avr RelayMuhammad NasirNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- Non Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationDocument6 pagesNon Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationAnonymous dH3DIEtzNo ratings yet

- Lor Ri 16-Rp 94f-2 6rp2Document2 pagesLor Ri 16-Rp 94f-2 6rp2Humayun AhsanNo ratings yet

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocument2 pagesTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun Ahsan100% (1)

- CBP 1Document16 pagesCBP 1Vinod KumarNo ratings yet

- 6ta+r Ret670 AcceptanceDocument18 pages6ta+r Ret670 AcceptanceMohamed AwadNo ratings yet

- Non Dir. O/C Relay-7SR1102-1NA87-1CA0-ZDocument4 pagesNon Dir. O/C Relay-7SR1102-1NA87-1CA0-ZAnonymous dH3DIEtzNo ratings yet

- DIE 4B 115/13.8kV SS: Client SheetDocument5 pagesDIE 4B 115/13.8kV SS: Client SheetVinod KumarNo ratings yet

- Red670 Distance Line DifferentialDocument23 pagesRed670 Distance Line DifferentialRatheesh KumarNo ratings yet

- Line Differential Red670Document12 pagesLine Differential Red670Ashish ChughNo ratings yet

- J03 - TRF 2 CT TestDocument6 pagesJ03 - TRF 2 CT TestSaran SaravananNo ratings yet

- Transformer Diff - p643Document20 pagesTransformer Diff - p643rajeshNo ratings yet

- J02 - TRF 1 CT TestDocument6 pagesJ02 - TRF 1 CT TestGajendran SriramNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument5 pagesSite Inspection and Test Record: 1. General Data and InformationSohail AhmedNo ratings yet

- SEL-787 Transformer Protection Relay-REV02Document5 pagesSEL-787 Transformer Protection Relay-REV02Jayabal Gnanaprakasam100% (1)

- 6BB+BS Reb650 BDocument9 pages6BB+BS Reb650 BMohamed AwadNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- REF615 Over Current Test FormatDocument8 pagesREF615 Over Current Test FormatEssam AjamiNo ratings yet

- 7UT Relay XFMR PROTECTION RelayDocument9 pages7UT Relay XFMR PROTECTION RelayMoin KhanNo ratings yet

- Form, Test TardjoenDocument30 pagesForm, Test TardjoenDangolNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- Site Acceptance Test Report For MV Panel - J03: Al Hudayriyat Island Tmp4Document6 pagesSite Acceptance Test Report For MV Panel - J03: Al Hudayriyat Island Tmp4Gajendran SriramNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYDocument2 pagesCommissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYtajudeenNo ratings yet

- Mvaj101 - Trip RelayDocument2 pagesMvaj101 - Trip Relayratheeshkumard100% (1)

- Auxiliary Relay - AR111Document2 pagesAuxiliary Relay - AR111Santhosh Kumar VinayagamNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: HIGH IMP. DIFF PROT. - MFAC34Document5 pagesCommissioning Service Department Commissioning Standard Test Formats Description: HIGH IMP. DIFF PROT. - MFAC34saiNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Mcti - CBF Current Check RelayDocument2 pagesMcti - CBF Current Check RelayTHILAKKUMARNo ratings yet

- Micom p142 CBFDocument2 pagesMicom p142 CBFm khNo ratings yet

- Ccr3 Bus Pt1Document2 pagesCcr3 Bus Pt1Neeraj SinghNo ratings yet

- 6BB+BS Reb650 ADocument9 pages6BB+BS Reb650 AMohamed AwadNo ratings yet

- Fakoor Sanat Tehran: 1. General Data & InformationDocument6 pagesFakoor Sanat Tehran: 1. General Data & Informationkarimi-15No ratings yet

- Mvaj205 - Trip RelayDocument2 pagesMvaj205 - Trip Relayratheeshkumard100% (1)

- Ha02-Bus VT Unit#10Document4 pagesHa02-Bus VT Unit#10Asgher khkattakNo ratings yet

- 1VFSG036955V201: Sr. No Injected Voltage Expected Voltage Measured VoltageDocument3 pages1VFSG036955V201: Sr. No Injected Voltage Expected Voltage Measured VoltageAmir HabibNo ratings yet

- Ccr4 Bus Pt2Document2 pagesCcr4 Bus Pt2Neeraj SinghNo ratings yet

- 7ut - Transformer Diff Relay TestDocument25 pages7ut - Transformer Diff Relay TestAnoss Olier100% (2)

- Commissioning Service Department Commissioning Standard Test Formats Description: Rxma2 Aux. Relay TestDocument2 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Rxma2 Aux. Relay TestDinesh PitchaivelNo ratings yet

- Sec - Eoa Contract No: 4400003814 Sheet No: 1 of 5Document4 pagesSec - Eoa Contract No: 4400003814 Sheet No: 1 of 5Humayun AhsanNo ratings yet

- Record No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesRecord No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDinesh Pitchaivel100% (1)

- Ccr4 Bus Pt1Document2 pagesCcr4 Bus Pt1Neeraj SinghNo ratings yet

- Sper 1c1 - Trip CKT SupvnDocument3 pagesSper 1c1 - Trip CKT SupvnGunta Raviteja100% (1)

- Site Inspection and Test Record: 4. Electrical TestsDocument2 pagesSite Inspection and Test Record: 4. Electrical TestswazakifyNo ratings yet

- Service Manuals LG TV PLASMA 42PB4D 42PB4D Service ManualDocument59 pagesService Manuals LG TV PLASMA 42PB4D 42PB4D Service Manual邱政鋒100% (1)

- Group C Module 2 PracticalDocument10 pagesGroup C Module 2 PracticalLevi MuromboNo ratings yet

- Smart Grid in EthiopiaDocument47 pagesSmart Grid in EthiopiaYidnekachew Bereda WizirNo ratings yet

- Types of DiodeDocument3 pagesTypes of DiodeRyan HarrisNo ratings yet

- Low Voltage FuseDocument27 pagesLow Voltage FuseDE VERA, KENNETH GABRIEL D.No ratings yet

- UK Electrical Industry British Standards BSDocument19 pagesUK Electrical Industry British Standards BSvijaydev75100% (1)

- Manual TranstectorDocument6 pagesManual TranstectorHoku's NickNo ratings yet

- PP Starter VFD BasicsDocument51 pagesPP Starter VFD BasicsGerardo Zumbado MNo ratings yet

- Left Hand Console: Electrical System 313 and 313 GC ExcavatorDocument6 pagesLeft Hand Console: Electrical System 313 and 313 GC ExcavatorHenry Sergio HuayhuaNo ratings yet

- Noida Electricity UPPCLDocument1 pageNoida Electricity UPPCLDebjyoti BanerjeeNo ratings yet

- Midas Venice 160,240,320 PDFDocument46 pagesMidas Venice 160,240,320 PDFstari692002No ratings yet

- BPS-Solar Power System 100W To 20KW - BESTSUN 2015Document8 pagesBPS-Solar Power System 100W To 20KW - BESTSUN 2015ARUSCHELNo ratings yet

- 3 Phase Asyn. MachineDocument74 pages3 Phase Asyn. Machineabdul shaggyNo ratings yet

- Experiment No 09 Fault Scenario Simulation in A Feeder-1Document4 pagesExperiment No 09 Fault Scenario Simulation in A Feeder-1Kaustubh PatilNo ratings yet

- 3VA Manual Molded Case Circuit Breakers en en-US (1) D Conversion TablesDocument18 pages3VA Manual Molded Case Circuit Breakers en en-US (1) D Conversion TablesJOELNo ratings yet

- Physics Investigatory ProjectDocument19 pagesPhysics Investigatory ProjectYeshrun prakash Minz100% (3)

- CV Jose Luis Garcia Tucci (Eng)Document4 pagesCV Jose Luis Garcia Tucci (Eng)Jose Luis Garcia TucciNo ratings yet

- EE6009 PERES Unit IIIDocument301 pagesEE6009 PERES Unit IIIrivehappy1996No ratings yet

- Application Note: AN1989 Rev 0, 03/2004 MC3371 and MC33702 Components Selection GuidelinesDocument16 pagesApplication Note: AN1989 Rev 0, 03/2004 MC3371 and MC33702 Components Selection GuidelinesfabioboogNo ratings yet

- Rele AXICOM V23079-A1011-B301Document6 pagesRele AXICOM V23079-A1011-B301Bassman PopNo ratings yet

- API Eis Solutions Guide 2019Document8 pagesAPI Eis Solutions Guide 2019Dimitra KatsiorchiNo ratings yet

- Guideline For Solar PV System Installation For Solar Providers April 2019 PDFDocument82 pagesGuideline For Solar PV System Installation For Solar Providers April 2019 PDFJaliya ThilakawardaneNo ratings yet

- Product Data Sheet: Easergy BAT24Ah 12V 24ah 10 Years Life High Rate Industrial VRLA BatteryDocument2 pagesProduct Data Sheet: Easergy BAT24Ah 12V 24ah 10 Years Life High Rate Industrial VRLA BatteryPreditec PeruNo ratings yet

- M.E Ped - R2017 - X86077 (PS5092)Document2 pagesM.E Ped - R2017 - X86077 (PS5092)MR.R. JEBA RAJNo ratings yet

- Patch Panel Cat 5eDocument3 pagesPatch Panel Cat 5eJuan Pablo Caguana InchiglemaNo ratings yet

- FL-IPKIT Battery Calculation Chart: Regulated Load in StandbyDocument1 pageFL-IPKIT Battery Calculation Chart: Regulated Load in StandbyFire ChileNo ratings yet

- Leaflet UPS DPH-200-500-600kVA en V2-1Document2 pagesLeaflet UPS DPH-200-500-600kVA en V2-1Karina SolisNo ratings yet

- Sales Proposal 291KW Karachi Club Annex v1Document7 pagesSales Proposal 291KW Karachi Club Annex v1junaid ahmadNo ratings yet

- Study of Relay Protection On PT. PLN (PERSERO) P3B Jawa-Bali RJTB UPT KediriDocument4 pagesStudy of Relay Protection On PT. PLN (PERSERO) P3B Jawa-Bali RJTB UPT KediriMuhammad RafiNo ratings yet

- Underground Wire Fault Detector ProjectDocument4 pagesUnderground Wire Fault Detector Projectsrakhisharma41No ratings yet

- Cutler-Hammer ATS Parts ManualDocument70 pagesCutler-Hammer ATS Parts ManualTom LeonardNo ratings yet