Professional Documents

Culture Documents

Bracket Inspection Format

Uploaded by

Bindanna JoshiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bracket Inspection Format

Uploaded by

Bindanna JoshiCopyright:

Available Formats

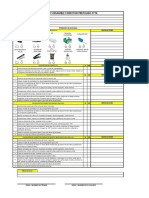

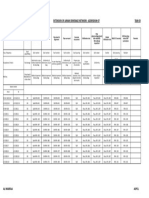

BRACKET INSPECTION REPORT

Bracket Inspection Criteria

Bracket Bracket Bracket Welding EPDM

Sl.No. Location Floor Floor Anchor Serated MS MS Washer

Mark Type Line & Packings of Sheet @

Levelling Fastener Washer Washer Welding

Level Packings Bottom

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Sl.No. Inspection Criteria Inspection Procedure

1 Floor Levelling Floor level at bracket location to be checked properly, if there is undulation more than 3mm it should be chipped or grinded

2 Bracket Line & Level Bracket line & level should be as per drawing

3 Packings Only GI Packings to be used if there is packing more than 10mm then solid plate packings to be used. Plastic & PVC packings not allowed

1.Packings more than 5mm thk to be tac welded to the bracket

4 Welding of Packings 2. After tac welding it should be ensured to remove flux and Galva Spray is done

3. Ensure there is no GI shim between Bracket & thick packings before tac welding

5 EPDM Sheet @ EPDM seperator to be put between Bracket & Concrtete

Bottom

1. Anchor fastener Embedment should be as per calculations

6 Anchor Fastener 2.Tightnig of fastener to be done as per required torque

3. Atleast three threads of faster shoud be exposed after tightning of fastener

7 Serated Washer Serated washer for Aluminium Brackets to be put properly

8 MS Washer MS Washer for brackets to be put neately(it should be parallel to sides of bracket)

Once Subcill/Panel is installed tac welding of brackets to be done, after tac welding it should be ensured to remove flux and Galva Spray is

9 MS Washer Welding

done

You might also like

- Welding InspectionDocument132 pagesWelding Inspectionlamia97No ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- 11.BMW - Check List Nghiem Thu Chat Luong Op Alu - EngDocument2 pages11.BMW - Check List Nghiem Thu Chat Luong Op Alu - EngPhong Ky Thuat Thi CongNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- U2 Knee CMA Baseplate BrochureDocument8 pagesU2 Knee CMA Baseplate BrochureOmar GarciaNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionRating: 5 out of 5 stars5/5 (2)

- Geothermal Drilling and Well Design (SE-830-DR2) : CementingDocument43 pagesGeothermal Drilling and Well Design (SE-830-DR2) : CementingERICK GUSTAVO QUINTANILLA GARCIANo ratings yet

- Splice SteelDocument28 pagesSplice SteelNacho Tomé100% (1)

- 19CEME801Document20 pages19CEME801Narayanan SubramanianNo ratings yet

- Check List Conector PrepulidoDocument1 pageCheck List Conector PrepulidoNoe MoralesNo ratings yet

- CSWIP 3 1 Welding Inspection NotesDocument102 pagesCSWIP 3 1 Welding Inspection NotesPavan KallempudiNo ratings yet

- Inspection Report of Rail Installation and Welding For WBXDocument2 pagesInspection Report of Rail Installation and Welding For WBXabdel mohamedNo ratings yet

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- Splicing Instruction For Trellex Steelcord Conveyor Belts: 1067 (42") ST 5700 14: 10 DIN XDocument6 pagesSplicing Instruction For Trellex Steelcord Conveyor Belts: 1067 (42") ST 5700 14: 10 DIN XnicolasNo ratings yet

- Section-05 RJT RJTWDocument2 pagesSection-05 RJT RJTWSandro gomez castroNo ratings yet

- Tab 7a - Completion Running Ops Update 01022012Document16 pagesTab 7a - Completion Running Ops Update 01022012Hassan MohamedNo ratings yet

- 1 in GEM CLAMP - 21-MEC - WITH PLATEDocument19 pages1 in GEM CLAMP - 21-MEC - WITH PLATEbubbacupcakeNo ratings yet

- Copper Piping Checklist VRVDocument1 pageCopper Piping Checklist VRVSkill IndiaNo ratings yet

- RO Presentation (Agung Widyanjaya)Document48 pagesRO Presentation (Agung Widyanjaya)Ferdik 69No ratings yet

- Ts Tpsodl Gi WireDocument1 pageTs Tpsodl Gi WireJainco Transmission LimitedNo ratings yet

- Defect Catalogue - Galva .Document45 pagesDefect Catalogue - Galva .Suvro ChakrabortyNo ratings yet

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Document1 pageSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- Alignment Reports TriconDocument8 pagesAlignment Reports TriconPRATHAMESH PEBNo ratings yet

- 01 Track 2 - Armaki2 - 019 GDIS-Advantages of Fortiform 980 GI - Superior Weldability PDFDocument17 pages01 Track 2 - Armaki2 - 019 GDIS-Advantages of Fortiform 980 GI - Superior Weldability PDFSilverio AcuñaNo ratings yet

- IDPT - 05 - Casing Running & Cementing Volumes PDFDocument19 pagesIDPT - 05 - Casing Running & Cementing Volumes PDFMas KuncritNo ratings yet

- 16 MATERIAL HANDLING - MasterDocument55 pages16 MATERIAL HANDLING - MasterSinter PlanningNo ratings yet

- Draft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch LayoutDocument5 pagesDraft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch Layoutexam proNo ratings yet

- Fabric Manu FacDocument15 pagesFabric Manu FacStudent AkashNo ratings yet

- Bezdan Cable Framework Fitting and Tool GuideDocument3 pagesBezdan Cable Framework Fitting and Tool Guidedamienapril98No ratings yet

- 23-WIS5 Visual Inspection 2006Document38 pages23-WIS5 Visual Inspection 2006ahmed titoNo ratings yet

- Foundation Pavement and Anchor DetailsDocument1 pageFoundation Pavement and Anchor DetailsVictor TorresNo ratings yet

- Blast TrainingDocument180 pagesBlast TrainingPabloNo ratings yet

- Wire BondingDocument31 pagesWire BondingGiar Maulana SNo ratings yet

- TFA Barring Spec 33.02 Rev 0Document5 pagesTFA Barring Spec 33.02 Rev 0Anonymous cuOIjrLINo ratings yet

- Requirements BS7609Document3 pagesRequirements BS7609soryn_25No ratings yet

- Steel Connection DesignDocument81 pagesSteel Connection DesignAnkan SarkarNo ratings yet

- Effective Use of Gauges and Measuring InstrumentsDocument31 pagesEffective Use of Gauges and Measuring Instrumentsaizaz65No ratings yet

- Black Granite Surface PlatesDocument3 pagesBlack Granite Surface PlatesyoghereNo ratings yet

- Nylon Cavity Fastener: Specification DescriptionDocument1 pageNylon Cavity Fastener: Specification DescriptionYansen SuwantoNo ratings yet

- Barred Tee TFA Barring Spec 33.02 Rev 4Document5 pagesBarred Tee TFA Barring Spec 33.02 Rev 4varaNo ratings yet

- Cat Tubefittings enDocument208 pagesCat Tubefittings enДаниил СторчеусNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Plasma Dicing of Si Wafers With Panasonic APX300Document45 pagesPlasma Dicing of Si Wafers With Panasonic APX300Pretty ChenNo ratings yet

- Form - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageDocument2 pagesForm - Pre-Concrete Checklist: Fiche de Contrôle Avant Le BétonnageMvomoNo ratings yet

- Cross Cut Adhesion Test Kit cc2000 m44 1 14Document4 pagesCross Cut Adhesion Test Kit cc2000 m44 1 14OMATNo ratings yet

- Manual For EOT CranesDocument39 pagesManual For EOT CranesManish Jha67% (12)

- Rex DWC Catalogue IS-14930..Document2 pagesRex DWC Catalogue IS-14930..ajeetNo ratings yet

- Shaft Strain Gaging Guide v4Document11 pagesShaft Strain Gaging Guide v4craigNo ratings yet

- Fortec Brochure 2015Document4 pagesFortec Brochure 2015Hanuman BuildersNo ratings yet

- The Ultimate Splicing SystemDocument4 pagesThe Ultimate Splicing SystemKevin ArNo ratings yet

- Inspection Report-Hdpec BlankDocument2 pagesInspection Report-Hdpec BlankJoseph Perez100% (1)

- Mooring Line Management PlanDocument3 pagesMooring Line Management Planghonwa hammodNo ratings yet

- Sewer Check List Task-3Document1 pageSewer Check List Task-3csacas sacscNo ratings yet

- UM - MVG - SO60976 - Modificaton BucketDocument4 pagesUM - MVG - SO60976 - Modificaton Bucket1989vasu.pNo ratings yet

- Sisgeo S143 en 00 Easy Lock Inclinometer CasingDocument5 pagesSisgeo S143 en 00 Easy Lock Inclinometer CasingJamjamNo ratings yet

- DPRDocument9 pagesDPRhellfire8No ratings yet

- Quality Crimp HandbookDocument24 pagesQuality Crimp HandbookFlavia DogojieNo ratings yet

- Wire Rope InspectionDocument5 pagesWire Rope InspectionJan Weinans100% (1)

- BoQ Floc-Sed-Filtermodel 2021.07.03Document15 pagesBoQ Floc-Sed-Filtermodel 2021.07.03Po RaksmeyNo ratings yet

- BS en 10111-2008Document16 pagesBS en 10111-2008Martijn GrootNo ratings yet

- Guia Utilizador - Mooz 2 PlusDocument30 pagesGuia Utilizador - Mooz 2 PlusRafael Salas MuñozNo ratings yet

- HPM Steel For MoldDocument15 pagesHPM Steel For MoldcadcamtaiNo ratings yet

- Research Work No.1Document6 pagesResearch Work No.1Van Aeron ValdezNo ratings yet

- CENG 2111 - Course OutlineDocument2 pagesCENG 2111 - Course OutlinetrfuawlachewNo ratings yet

- Bab Ii Telaah PustakaDocument23 pagesBab Ii Telaah PustakaPak SulNo ratings yet

- Crown SpecsDocument16 pagesCrown SpecsGonçalo Filipe SousaNo ratings yet

- 316L Muchos Resultados FFF Tensile StrengthDocument10 pages316L Muchos Resultados FFF Tensile StrengthJuan JimenezNo ratings yet

- AMP ME5I Microproject. Join AICTE Telegram GroupDocument32 pagesAMP ME5I Microproject. Join AICTE Telegram GroupVivek SharmaNo ratings yet

- Zamak 5 Data SheetDocument1 pageZamak 5 Data SheetLittle ChimpunksNo ratings yet

- Axis Final BillDocument5 pagesAxis Final BillVikram KamathNo ratings yet

- 01 Al Munaif UPVC High Pressure FittingsDocument36 pages01 Al Munaif UPVC High Pressure FittingsmohammedNo ratings yet

- Fitter 2nd Year Set-04Document14 pagesFitter 2nd Year Set-04Jule PandeyNo ratings yet

- Application of Brushable Ceramic Coating and Superior Metal For Pipe SupportDocument2 pagesApplication of Brushable Ceramic Coating and Superior Metal For Pipe SupportSandeep gangulyNo ratings yet

- Jis G3445 STKM 11a MTCDocument1 pageJis G3445 STKM 11a MTCNgoc PhatNo ratings yet

- LLR08 Latex Thread ManufacturingDocument5 pagesLLR08 Latex Thread ManufacturingChalani NeranjanaNo ratings yet

- The Extrusion Press Maintenance ManualDocument3 pagesThe Extrusion Press Maintenance ManualrcNo ratings yet

- Sant Gadge Baba Amravati UniversityDocument6 pagesSant Gadge Baba Amravati UniversitySkillytek ServiceNo ratings yet

- Metals and Non MetalsDocument17 pagesMetals and Non Metalsarun ahujlaNo ratings yet

- Progress Tracking Sheet For Piping FabricationDocument1 pageProgress Tracking Sheet For Piping FabricationBrm MaminNo ratings yet

- Manufacturing CompanyDocument29 pagesManufacturing CompanyBhuvana RajendranNo ratings yet

- Machining of CompositesDocument5 pagesMachining of CompositesoussamaNo ratings yet

- Two Plate Three PlateDocument15 pagesTwo Plate Three PlateHarshvardhan KharatNo ratings yet

- Various Methods of Shoe ConstructionDocument16 pagesVarious Methods of Shoe ConstructionVishnu TejaNo ratings yet

- 2008-06-03 Spec Tenaris CrMoDocument10 pages2008-06-03 Spec Tenaris CrModanielNo ratings yet

- Mills List in BangladeshDocument25 pagesMills List in BangladeshJayaprakash Subban100% (1)

- MBR Membrane Bio ReactorDocument4 pagesMBR Membrane Bio ReactorecotechconsultantsNo ratings yet

- TiO2 (RC 635)Document1 pageTiO2 (RC 635)medo.k016No ratings yet

- MT-1 (English) - N SchemeDocument288 pagesMT-1 (English) - N SchemeKumar Subramanian100% (1)