Professional Documents

Culture Documents

Esd2100 Pib1020

Esd2100 Pib1020

Uploaded by

German E.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esd2100 Pib1020

Esd2100 Pib1020

Uploaded by

German E.Copyright:

Available Formats

ESD2100 Series

Speed Control Unit

1 OVERVIEW

The ESD2100 Series speed control unit is an all- electronic de-

vice designed to control engine speed with fast and precise re-

sponse to transient load changes. This closed loop control, when

connected to a proportional electric actuator and supplied with

a magnetic speed sensor signal, will control a wide variety of

engines in an isochronous or droop mode. It is designed for high

reliability and built ruggedly to withstand the engine environment.

◊ Multi-VDC

◊ Isochronous Operation

◊ Adjustable PID Functions

◊ Case Option Available

◊ Light Force Option Available

2 SPECIFICATIONS

Performance Environmental

Isochronous Operation ± 0.25 % or better Ambient Temperature -40° to 85 °C [-40 to 185 °F]

Speed Range / Governor 1 - 7.5 KHz Continuous Relative Humidity up to 90 %

Speed Drift with Temperature ±1% MAX All Surface Finishes Fungus-Proof

and Corrosion-Resistant

Speed Trim Range ± 450 Hz

PHYSICAL

Remote Variable Speed Range 500 Hz - 6 KHz

Dimension See Section 3, Installation

Terminal 9 Sensitivity 120 Hz. ±15 Hz./V

@ 250 K Impedance Weight 1.2 lbf (545 gf)

INPUT / OUTPUT Mounting Any position, Vertical Preferred

DC Supply 10 - 40 V DC RELIABILITY

Transient and Reverse

Voltage Protected* Vibration 5 g @ 20-500 Hz

Polarity Negative Ground Testing Functionally Tested

(Case Isolated)

Power Consumption 60 mA continuous

plus actuator current

Actuator Current

10 A Max Peak

@ 77°F (25°C)

Speed Sensor Signal 0.5 - 50.0 V RMS

* Reverse voltage is protected against by a parallel diode. A 15 A

fuse must be installed in the positive battery lead. See Section 4,

Wiring.

ESD2100 Electronic Governor 8-2021-C2 PIB1020

1 Governors America Corp. © 2021 Copyright All Rights Reserved

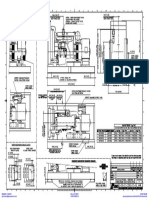

3 INSTALLATION

Vertical orienta-

tion allows for the

draining of fluids

in moist environ-

ments.

Mount in a cabinet,

engine enclosure,

or sealed metal

box.

Avoid Extreme Heat

Dimensions:

in

(mm)

Use an overspeed shutdown device, independent of the governor system, to prevent loss of engine control which

may cause personal injury or equipment damage.

Do not rely exclusively on the governor system electric actuator to prevent overspeed. A secondary shutoff device,

such as a fuel solenoid must be used.

ESD2100 Electronic Governor 8-2021-C2 PIB1020

2 Governors America Corp. © 2021 Copyright All Rights Reserved

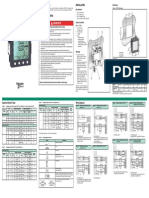

4 WIRING

TERMINAL DEFINITION NOTES

1

Actuator 16 AWG [1.3 mm2] or larger wire

2

3 • Wires must be twisted and/or shielded for their entire length

Magnetic Speed • Gap between speed sensor and gear teeth should not be smaller than 0.02 in (.51 mm)

4 Pickup

• Speed sensor voltage should be at least 1 V AC RMS during crank

5 Battery Power (-) 16 AWG [1.3 mm2] or larger wire

6 Battery Power (+) A 15 amp fuse must be installed in the positive battery lead to protect against reverse voltage

7

8

Variable speed isochronous operation can be obtained by connecting a 5K potentiometer to Terminals 8, 9, and

Speed Trim

9 10. To select the variable speed range, connect the appropriate resistor, R, to posts E4 and E5. See the Resistor

Control

Jumpers diagram below.

10

RECOMMENDATIONS

Shielded cable should be used for all external connections to the ESD control.

One end of each shield, including the speed sensor shield, should be grounded to a single point on the ESD case.

RESISTOR JUMPERS

FREQUENCY RANGE (Hz) RESISTOR

850 NONE

1280 2M

1880 750 K

3400 300 K

5700 150 K

ESD2100 Electronic Governor 8-2021-C2 PIB1020

3 Governors America Corp. © 2021 Copyright All Rights Reserved

5 Starting The Engine

IMPORTANT Make sure the following adjustments are set before starting the engine.

Gain Middle Position

Stability Middle Position

Speed Trim Control Middle Position

The speed control unit governed speed setting is factory set at approximately engine idle speed (1000 Hz., Speed sensor signal or

600 RPM)

Crank the engine with DC power applied to the governor system. The actuator will energize to the maximum fuel position until the

engine starts. The governor system should control the engine at a low idle speed. If the engine is unstable after starting, turn the

GAIN and STABILITY adjustments counterclockwise until the engine is stable.

NOTE The governed speed set point is increased by clockwise rotation of the SPEED adjustment pot. Remote speed adjustment

can be obtained with an optional 5K Speed Trim Control. See Section 4, Wiring.

6 ADJUSTING FOR STABILITY

Once the engine is at operating speed and at no-load, the following governor performance adjustments can be made:

STABILITY ADJUSTMENT

1. Rotate the GAIN adjustment clockwise until instability develops. Gradually move the adjustment counterclockwise until stability

returns. Move the adjustment one division further counterclockwise to ensure stable performance (270° pot).

2. Rotate the STABILITY adjustment clockwise until instability develops. Gradually move the adjustment counterclockwise until

stability returns. Move the adjustment one division further to ensure stable performance (270° pot).

3. Gain and stability adjustments may require minor changes after engine load is applied. Normally, adjustments made at no load

achieve satisfactory performance.

NOTE If instability cannot be corrected or further performance improvements are required, see Section 7, System Troubleshooting.

ESD2100 Electronic Governor 8-2021-C2 PIB1020

4 Governors America Corp. © 2021 Copyright All Rights Reserved

7 SYSTEM TROUBLESHOOTING

SYSTEM INOPERATIVE

If the engine governing system does not function, the fault may be determined by performing the voltage tests described in Steps 1

through 4. Positive (+) and negative (-) refer to meter polarity.

Should normal values be indicated during troubleshooting steps, and then the fault may be with the actuator or the wiring to the actu-

ator. Tests are performed with battery power on and the engine off, except where noted. See your actuator publication for additional

testing and troubleshooting procedures.

STEP WIRES NORMAL READING PROBABLE CAUSE

1. DC battery power not connected. Check for blown fuse, switch off power.

Battery Supply Voltage 2. Low battery voltage

1 6(+) & 5(-)

(12, 24, or 32 V DC) 3. Wiring error

6.5-7.1 V with speed trim 1. Speed trim shorted or miswired.

2 8(+) & 10(-) 2. Defective unit.

7.1-7.9 V without speed trim

1. Low battery voltage

3 7(+) & 10(-) 1.8-2.6V 2. Defective Unit

1. Gap between speed sensor and gear teeth too great. Check Gap.

1.0 V AC RMS min. while 2. Improper or defective wiring to the speed sensor. Resistance between D and C should

4 3(+) & 4(-)

cranking be 160 to 1200 Ω. See specific mag pickup data for resistance.

3. Defective speed sensor.

1. SPEED adjustment set too low.

7(+) & 10(-) 2. Wiring error to actuator.

5 8.4-9.4 V

while cranking 3. Defective speed control unit.

4. Defective actuator.

1. Wiring error to actuator

6 6(+) & 2(-) 0.2-1.0 V while cranking 2. Defective speed control unit

3. Defective actuator

UNSATISFACTORY PERFORMANCE

SYMPTOM NORMAL READING PROBABLE CAUSE OF ABNORMAL READING

Engine 1. Do Not Crank. Apply DC power to the 1. After the actuator goes to full fuel, disconnect the speed sensor at

Overspeeds governor system. Orange and Green wires. If the actuator is still at full fuel-speed then the

speed control unit is defective.

2. If the actuator is at minimum fuel position and there exists an

erroneous position signal, then check speed sensor cable.

2. Manually hold the engine at the desired 1. If the voltage reading is 0.2 to 1.0 V DC:

running speed. Measure the DC voltage a. Speed adjustment is set above desired speed

between Terminal 2(-) & 6(+) on the speed b. Defective speed control unit

control unit.

2. If voltage reading is above 1.5 V DC then check for:

a. actuator binding

b. linkage binding

3. If the voltage reading is below 0.2 V DC there is a chance of a defective

speed control unit

Actuator does 1. Measure the DC voltage between Termi- 1. Actuator wiring incorrect

not energize fully nals 2(-) & 6(+) on the speed control unit.

while cranking Should be 0.2 to 1.0 volts. If not: 2. If the voltage is less than:

a. 7 V for a 12 V system, or

b. 14 V for a 24 V system, Then:

3. Check or replace battery.

2. Momentarily connect Terminal 2 to 6. 1. Actuator or battery wiring in error

The actuator should move to the full fuel

position. 2. Actuator or linkage binding

3. Defective actuator

Engine remains 1. Measure the actuator output, Terminal 1 & 1. If voltage measurement is within 1.5 V DC of the battery supply voltage

below desired 2, while running under governor control. level, then fuel control is restricted from reaching full fuel position, pos-

governed speed sibly due to mechanical governor, carburetor spring, or linkage interfer-

ence.

2. Speed parameter set too low

ESD2100 Electronic Governor 8-2021-C2 PIB1020

5 Governors America Corp. © 2021 Copyright All Rights Reserved

7 SYSTEM TROUBLESHOOTING (CONTINUED)

INSTABILITY

INSTABILITY SYMPTOM PROBABLE CAUSE OF ABNORMAL READING

1. Readjust the Gain and Stability for optimum control.

The engine seems to 2. Turn off other electrical equipment that may be causing interference.

Fast Periodic jitter with a 3Hz or faster

irregularity of speed. 3. Cutting jumper from E1 to E2 should reduce the tendency to jitter.

4. If not, remove the jumper from E6 to E7

1. Readjust the Gain and Stability for optimum control.

2. Adjust Dead time compensation by adding a capacitor from posts E2 to E3 (negative on E2). Start

with 10 mfds and increase until instability is eliminated.

An irregularity of speed

Slow Periodic

below 3Hz.

3. Check fuel system linkage during engine operation for:

a. binding

b. high friction

c. poor linkage

1. Increasing the Gain should reduce the instability but not totally correct it. If this is the case, there is

most likely a problem with the engine itself. Check for:

a. engine mis-firings

b. an erratic fuel system

Non-Periodic Erratic Engine Behavior

c. load changes on the generator set voltage regulator.

2. If the throttle is slightly erratic, but the performance is fast, removing the jumper from E6 to E7 will

tend to steady the system.

Insufficient Magnetic Speed Signal

A strong magnetic speed sensor signal eliminates the possibility of missed or extra pulses. The speed control unit will govern well with

a 0.5VAC RMS speed sensor signal. However, a speed sensor signal of 3 V AC RMS or greater is recommended.

The amplitude of the speed sensor signal can be raised by reducing the gap between the tip of the speed sensor and the top land of a

tooth on the engine’s ring-gear. This gap should not be any smaller than 0.020 in. (0.45 mm).

With the engine stopped, turn the magnetic speed sensor CW until it touches the top land of a ring-gear tooth, then turn it CCW 3/4 turn.

This will provide an acceptable gap.

If unsuccessful in solving instability, contact GAC for assistance.

GAC@governors-america.com or call: 1-413-233-1888

ESD2100 Electronic Governor 8-2021-C2 PIB1020

6 Governors America Corp. © 2021 Copyright All Rights Reserved

You might also like

- Cable Sizing CalculationDocument15 pagesCable Sizing CalculationMaloni0192% (12)

- Mtu 18v2000 PartsDocument156 pagesMtu 18v2000 PartsGerman E.100% (1)

- 8801 Servohydraulic Fatigue Testing SystemDocument2 pages8801 Servohydraulic Fatigue Testing SystemAwan AJaNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Approach Boundaries NFPA 70E Table 130 2 (C)Document8 pagesApproach Boundaries NFPA 70E Table 130 2 (C)kamal_khan85100% (1)

- 3.2 - Electrical System, System Diagrams (OCR)Document320 pages3.2 - Electrical System, System Diagrams (OCR)mnbvqwertNo ratings yet

- Pib1010 Esc63c SeriesDocument4 pagesPib1010 Esc63c Serieszakie8008No ratings yet

- ESD5550 & ESD5570 Series: Speed Control UnitDocument8 pagesESD5550 & ESD5570 Series: Speed Control UnithedayatNo ratings yet

- Pib1025 Esd1000 1Document5 pagesPib1025 Esd1000 1soliscristopher1310No ratings yet

- ESD5100 Series: Speed Control UnitDocument7 pagesESD5100 Series: Speed Control UnitYazan HasanNo ratings yet

- Electronic Digital Governor: Performance EnvironmentalDocument8 pagesElectronic Digital Governor: Performance EnvironmentalMaxDalmiNo ratings yet

- Esd5500 IiDocument8 pagesEsd5500 Iioperaciones1 sesaNo ratings yet

- ESD5500E Series Speed Control Unit: SpecificationsDocument4 pagesESD5500E Series Speed Control Unit: SpecificationsAndres LopezNo ratings yet

- ESD5500E Series Speed Control Unit: SpecificationsDocument5 pagesESD5500E Series Speed Control Unit: SpecificationsMurilo FigueiredoNo ratings yet

- ESD5200 Series: Speed Control UnitDocument7 pagesESD5200 Series: Speed Control UnitFeri RinaldiNo ratings yet

- ESD2200 Series Speed Control Unit: SpecificationsDocument4 pagesESD2200 Series Speed Control Unit: SpecificationsMaxiSanchezNo ratings yet

- ESD5100 Series: Speed Control UnitDocument8 pagesESD5100 Series: Speed Control UnitCarlos RiveraNo ratings yet

- Pib1002 Esd5500eDocument5 pagesPib1002 Esd5500eAnonymous M0OEZEKoGiNo ratings yet

- Esd5500E Series Speed Control Unit: Model DescriptionDocument23 pagesEsd5500E Series Speed Control Unit: Model DescriptionEslam MahfouzNo ratings yet

- PIB5112 EEG7000 With Interface ToolDocument17 pagesPIB5112 EEG7000 With Interface ToolRogelio Reyes RomeroNo ratings yet

- Performance Input / Output: Impedance Impedance Impedance ImpedanceDocument9 pagesPerformance Input / Output: Impedance Impedance Impedance ImpedanceSalah AhmedNo ratings yet

- Pib4145 Edg5500 PDFDocument5 pagesPib4145 Edg5500 PDFUNIPOWER2013No ratings yet

- Enhanced Electronic Speed Controller: Gaconfig ToolDocument30 pagesEnhanced Electronic Speed Controller: Gaconfig ToolLuciano PereiraNo ratings yet

- LSM200 Series: Load Sharing ModulesDocument11 pagesLSM200 Series: Load Sharing ModulesHernando luis Fang pedrozaNo ratings yet

- Over Speed Control Esd5500eDocument9 pagesOver Speed Control Esd5500eferas rahilNo ratings yet

- SPHSA-152Document2 pagesSPHSA-152ravi010582No ratings yet

- DS StG-EC-250 Positioner eDocument2 pagesDS StG-EC-250 Positioner esxturboNo ratings yet

- Jin Kwang-Recloser-Mold Recloser (With R200C) Catalouge PDFDocument15 pagesJin Kwang-Recloser-Mold Recloser (With R200C) Catalouge PDFMd. zahidul IslamNo ratings yet

- FIO OverviewDocument42 pagesFIO OverviewNirmal K100% (1)

- Cordex 220-4.4kW Modular Switched Mode RectifierDocument36 pagesCordex 220-4.4kW Modular Switched Mode RectifierammelinoNo ratings yet

- ESD5500-II Fusion Series Speed Control Unit: SpecificationsDocument6 pagesESD5500-II Fusion Series Speed Control Unit: SpecificationsIgor TabulynskyNo ratings yet

- Manual Titan GS SeriesDocument144 pagesManual Titan GS SeriesPablo CesarNo ratings yet

- HCM634G - Winding 07: Technical Data SheetDocument7 pagesHCM634G - Winding 07: Technical Data SheetAtanasio PerezNo ratings yet

- HVSI804X WGD 83Document6 pagesHVSI804X WGD 83mnezamiNo ratings yet

- Esd5500-II Ban Dich Tv1Document13 pagesEsd5500-II Ban Dich Tv1luanng2301No ratings yet

- HVSI804T WGD 83Document6 pagesHVSI804T WGD 83mnezamiNo ratings yet

- Synchronous Alternators: G Plus Line AG10 Line 60 HZDocument48 pagesSynchronous Alternators: G Plus Line AG10 Line 60 HZSeitec AssistenciaNo ratings yet

- SCD - BAP 319-125-48F4T-U5119 Ferney Gutierrez LtdaDocument1 pageSCD - BAP 319-125-48F4T-U5119 Ferney Gutierrez LtdaAbeiroNo ratings yet

- Gbelimo GGMB24-SRDocument5 pagesGbelimo GGMB24-SRcassioNo ratings yet

- Eeg 7500Document32 pagesEeg 7500Jorge Mario Perdomo PerdomoNo ratings yet

- Generator Stamford Ucm224dDocument9 pagesGenerator Stamford Ucm224dGrupo Alber SACNo ratings yet

- UCDI274K - Technical Data SheetDocument8 pagesUCDI274K - Technical Data SheetLeopoldo Godinez HernandezNo ratings yet

- Eeg 6500Document14 pagesEeg 6500Jorge Mario Perdomo PerdomoNo ratings yet

- WDG 51 - Technical Data Sheet MV 804 WDocument7 pagesWDG 51 - Technical Data Sheet MV 804 WPowerTechNo ratings yet

- Technical data sheet of generator 发电机技术数据表 UCM274H-311-TD-EN - Rev - ADocument9 pagesTechnical data sheet of generator 发电机技术数据表 UCM274H-311-TD-EN - Rev - ADanial AbdullahNo ratings yet

- Technical Data HVSI804X WDG 61 V9 TDSDocument6 pagesTechnical Data HVSI804X WDG 61 V9 TDSmohsen_cumminsNo ratings yet

- Alternador DataSheet HVSI804R WDG 91Document6 pagesAlternador DataSheet HVSI804R WDG 91Johann Fernandez De CastroNo ratings yet

- PM044F - Winding 17: Technical Data SheetDocument7 pagesPM044F - Winding 17: Technical Data SheetLeenaNo ratings yet

- En0c0830 Ge02r0198 PDFDocument4 pagesEn0c0830 Ge02r0198 PDFManuel RíosNo ratings yet

- PI044D - Winding 311: Technical Data SheetDocument10 pagesPI044D - Winding 311: Technical Data SheetthainarimeNo ratings yet

- UCM274G-Đầu PhátDocument9 pagesUCM274G-Đầu PhátVOLVO VPVNNo ratings yet

- HCKI 534D/544D - Technical Data SheetDocument8 pagesHCKI 534D/544D - Technical Data SheetMajo MolinaNo ratings yet

- Energy Meter 2.0 DatasheetDocument2 pagesEnergy Meter 2.0 DatasheetThai chheanghourtNo ratings yet

- Gs32q06k20-31e 001Document38 pagesGs32q06k20-31e 001Andy Kong KingNo ratings yet

- HCM434E - Winding 27: Technical Data SheetDocument7 pagesHCM434E - Winding 27: Technical Data SheetRenzo zuñiga ahonNo ratings yet

- HCM 434 CDocument8 pagesHCM 434 CCRIS SEDANTONo ratings yet

- Model Number Structure: Relays With Forcibly Guided ContactsDocument22 pagesModel Number Structure: Relays With Forcibly Guided Contactselkin mezaNo ratings yet

- Potentiometers and Trimmers: Resistive ProductsDocument5 pagesPotentiometers and Trimmers: Resistive ProductstchepssilveiraNo ratings yet

- Stamford Alternator Technical Data Sheet of Generator HCM5D-311-TD-EN Rev ADocument9 pagesStamford Alternator Technical Data Sheet of Generator HCM5D-311-TD-EN Rev ADanial AbdullahNo ratings yet

- Ucm274h 14 TD en Rev ADocument7 pagesUcm274h 14 TD en Rev Ateja sri rama murthyNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Denyo Euro Spec BrochureDocument16 pagesDenyo Euro Spec BrochureGerman E.No ratings yet

- GAC ActuadorDocument7 pagesGAC ActuadorGerman E.No ratings yet

- MOTORTECH SalesFlyer Valve Cover Conversion Kit MAN E32 Series 01.65.008 EN 2019 07Document4 pagesMOTORTECH SalesFlyer Valve Cover Conversion Kit MAN E32 Series 01.65.008 EN 2019 07German E.No ratings yet

- AMPS15599 - AMPS Power Magazine 2020, Issue 3 04e WebDocument44 pagesAMPS15599 - AMPS Power Magazine 2020, Issue 3 04e WebGerman E.No ratings yet

- MOTORTECH SalesFlyer SparkView 40kV 01.15.019 EN 2015 08Document2 pagesMOTORTECH SalesFlyer SparkView 40kV 01.15.019 EN 2015 08German E.No ratings yet

- MOTORTECH Manual SparkView 40kV 01.10.021 EN 2013 03 WEBDocument28 pagesMOTORTECH Manual SparkView 40kV 01.10.021 EN 2013 03 WEBGerman E.No ratings yet

- PGDLS310Document5 pagesPGDLS310German E.No ratings yet

- Volvo Generator 500 KW V500uc2 IIDocument1 pageVolvo Generator 500 KW V500uc2 IIGerman E.No ratings yet

- Field Terminal Outer Insulator Installation 37MT, 41MT and 42MTDocument1 pageField Terminal Outer Insulator Installation 37MT, 41MT and 42MTGerman E.No ratings yet

- MOTORTECH InstructionLeaflet Hall Effect Pickup 66.60.043 L 01.12.044 EN 2020 11Document2 pagesMOTORTECH InstructionLeaflet Hall Effect Pickup 66.60.043 L 01.12.044 EN 2020 11German E.No ratings yet

- Semi Solid Link Solenoid Replacement Instructions For 29MT, 38MT 39MT HD StartersDocument1 pageSemi Solid Link Solenoid Replacement Instructions For 29MT, 38MT 39MT HD StartersGerman E.No ratings yet

- Option h5 h7 h12 h13 Engine Communication Agc 4 4189341231 UkDocument118 pagesOption h5 h7 h12 h13 Engine Communication Agc 4 4189341231 UkGerman E.No ratings yet

- Agc 150 Engine Communication 4189341302 UkDocument178 pagesAgc 150 Engine Communication 4189341302 UkGerman E.100% (1)

- Apd631v 6Document4 pagesApd631v 6German E.No ratings yet

- Universal Spare Parts Instructions 37MT, 41MT 42MTDocument2 pagesUniversal Spare Parts Instructions 37MT, 41MT 42MTGerman E.No ratings yet

- Field Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTDocument4 pagesField Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTGerman E.No ratings yet

- Volvo Generator Silent V500uc2 IiDocument1 pageVolvo Generator Silent V500uc2 IiGerman E.No ratings yet

- Industrial Diesel Generator Set - 60 HZ: General Specifications KOHLER Premium QualityDocument7 pagesIndustrial Diesel Generator Set - 60 HZ: General Specifications KOHLER Premium QualityGerman E.No ratings yet

- More Performance Through Real-Time Monitoring: With The Digital Myplant Apm Solution From Innio JenbacherDocument7 pagesMore Performance Through Real-Time Monitoring: With The Digital Myplant Apm Solution From Innio JenbacherGerman E.No ratings yet

- Agc 150 Installation Instructions 4189341185 UkDocument30 pagesAgc 150 Installation Instructions 4189341185 UkGerman E.No ratings yet

- Caterpillar C9 D300 GC SubmittalDocument42 pagesCaterpillar C9 D300 GC SubmittalGerman E.No ratings yet

- 1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemDocument2 pages1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemGerman E.100% (1)

- Perkins Data Sheet PCS100-150PDocument4 pagesPerkins Data Sheet PCS100-150PGerman E.No ratings yet

- Specifications Systems Operation Troubleshooting Testing and AdjustingDocument44 pagesSpecifications Systems Operation Troubleshooting Testing and AdjustingGerman E.100% (1)

- Package Performance: Standby: 60 HZDocument30 pagesPackage Performance: Standby: 60 HZGerman E.No ratings yet

- Select Series: Standby GeneratorsDocument4 pagesSelect Series: Standby GeneratorsGerman E.No ratings yet

- S6700E ESC Speed Controller ManualDocument3 pagesS6700E ESC Speed Controller ManualGerman E.No ratings yet

- Operation and Maintenance Manual: 1204F-E44TA and 1204F-E44TTA Industrial EnginesDocument148 pagesOperation and Maintenance Manual: 1204F-E44TA and 1204F-E44TTA Industrial EnginesGerman E.No ratings yet

- Gwta6Rp G Build Engines: Gamma SeriesDocument2 pagesGwta6Rp G Build Engines: Gamma SeriesGerman E.No ratings yet

- Bottom Mount Refrigerators ServiceDocument77 pagesBottom Mount Refrigerators ServiceaderlochNo ratings yet

- Xtrons Android Caraudio D766A-D714ADocument12 pagesXtrons Android Caraudio D766A-D714AredplayNo ratings yet

- Asaba - en 61558-2Document38 pagesAsaba - en 61558-2Vikki PatelNo ratings yet

- Motor Protection DevicesDocument35 pagesMotor Protection DevicesAli AhmadNo ratings yet

- Fuse EOTDocument29 pagesFuse EOTKushagr SinghNo ratings yet

- CPC 100 User ManualDocument77 pagesCPC 100 User ManualGabriel GarciaNo ratings yet

- Sinamics g180 ManualDocument197 pagesSinamics g180 ManualЧеловек ЧеловековNo ratings yet

- AFS 650-655 Installation PDFDocument36 pagesAFS 650-655 Installation PDFMatijaDebogovićNo ratings yet

- Technical Guidance For Customer Export Limiting SchemesDocument34 pagesTechnical Guidance For Customer Export Limiting SchemesDavid GarciaNo ratings yet

- NYC Electrical Advisory Board Rules - 1 - RCNY - 34-05Document3 pagesNYC Electrical Advisory Board Rules - 1 - RCNY - 34-05jouweitoNo ratings yet

- Unit 53 Electrical Installation PDFDocument12 pagesUnit 53 Electrical Installation PDFnadeem UddinNo ratings yet

- CLH-SC: Maintenance ManualDocument31 pagesCLH-SC: Maintenance Manualiberman PereNo ratings yet

- Sinus K r03.1 ManualDocument219 pagesSinus K r03.1 ManualVIJAYKAGRENo ratings yet

- Pressure Aging Vessel: Manuale Di Istruzioni Instruction ManualDocument68 pagesPressure Aging Vessel: Manuale Di Istruzioni Instruction ManualfabulosofigueroaNo ratings yet

- PM710Document2 pagesPM710A. IvanNo ratings yet

- Sopan Pems Nayara (P) : CommentsDocument7 pagesSopan Pems Nayara (P) : CommentssidharthNo ratings yet

- Electrical Control For Machines 7th Edition Lobsiger Solutions ManualDocument34 pagesElectrical Control For Machines 7th Edition Lobsiger Solutions Manualnicoledickersonwmncpoyefk100% (18)

- Power Supply NGMO1 and Power Supply NGMO2: Service ManualDocument76 pagesPower Supply NGMO1 and Power Supply NGMO2: Service ManualSebastian JoehnkNo ratings yet

- Model PUS400G Ultrasonic Oscillator: User's ManualDocument33 pagesModel PUS400G Ultrasonic Oscillator: User's ManualzaffarNo ratings yet

- Presentation Himel Company ProfileDocument27 pagesPresentation Himel Company ProfileDeni DendenNo ratings yet

- Bs 320 InstallationDocument84 pagesBs 320 InstallationBhavin DoshiNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- Ring Main Unit Type SF6, Gas-Insulated, 8DJH: SiemensDocument27 pagesRing Main Unit Type SF6, Gas-Insulated, 8DJH: SiemensXaxmx AgnsNo ratings yet

- Sumitomo Hc4a ManualDocument72 pagesSumitomo Hc4a ManualEn-Min Shih100% (1)

- ETC 600 ManualDocument22 pagesETC 600 ManualTroy AchillesNo ratings yet

- MAN 00187 Xylo mDiCRDe Wiring ManualDocument122 pagesMAN 00187 Xylo mDiCRDe Wiring ManualEduardo Antonio Barria OjedaNo ratings yet