Professional Documents

Culture Documents

Poster For Print V2

Poster For Print V2

Uploaded by

Ramesh Gopalan0 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

Poster for print V2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pagePoster For Print V2

Poster For Print V2

Uploaded by

Ramesh GopalanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

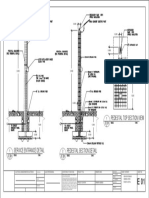

2022 7TH INTERNATIONAL ADVANCED RESEARCH WORKSHOP ON TRANSFORMERS (ARWTR) – BAIONA - SPAIN, (23)24-26 OCTOBER 2022

The Impact of the Use of Dry Lubricating Compound

on the Dielectric Properties of Solid and Liquid

Insulation of a Power Transformer

Gopalan Ramesh Senior Member, IEEE, Ashutosh Sharma, MCIGRE and Hemang Thakkar

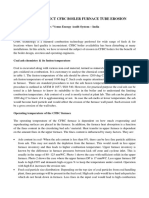

Insulation properties of power DNV in association with EGA conducted

transformers are affected by construction an experiment to study the effects of dry

materials used in power transformers. lubricating compound on the insulation

Dry Lubricants are used in power power factor and conductivity of solid

transformers for fasteners during insulation.

manufacture. One such dry lubricating

Experimental set up

compound is Molykote G Rapid Plus

®

Description Value for Molybdenum

Disulfide

Molecular 160.07

Weight

Appearance Black powder or solid in

various forms

Melting Point 1185 ° C (2165 ° F)

Density 5.06 g/cm3

Solubility in Insoluble Insulation Samples for testing. From the left, 1-A, 1-B, 2-A and 2-B

Water

Results

Dry lubricating compound affects 1.00E-05

Sample Reference

Ref-A Ref-B 1-A 1-B 2-A 2-B

0.035

insulation power factor of insulation if it 1.00E-06

0.030

Dissipation Factor or Tan Delta

falls on solid insulation during the

Front Side Conductivity- K Siemens

0.025

1.00E-07

manufacture. Increase in power factor 1.00E-08

0.020

results within a short span of service life 1.00E-09

0.015

(1-4 years). Moisture and contamination, 1.00E-10

0.010

aging, partial discharges affects the 1.00E-11

0.005

insulation power factor. 1.00E-12

0.000

1 2 3 4 5 6

Ref-A Ref-B 1-A 1-B 2-A 2-B

Reference Samples

Tan Delta at 23°C Tan Delta at 90°C

1.00E-13

Conclusion: Surface conductivity & Insulation Power factor of Insulation is affected by Dry

Lubricating Compound. Transformer manufacturers should use the compound with care and

study the effects of same during the service life of the transformer

DNV © 24 OCTOBER 2022

You might also like

- Fence ESTIMATE SampleDocument1 pageFence ESTIMATE SampleEvans Corp75% (4)

- Role of Polymers in Drug DeliveryDocument36 pagesRole of Polymers in Drug DeliveryMaoth Ahmed100% (1)

- Interactions Between Lubricants and CoatingsDocument23 pagesInteractions Between Lubricants and CoatingsBojan PodgornikNo ratings yet

- Directory IndustryDocument132 pagesDirectory IndustryShamsuddin HasnaniNo ratings yet

- Kumana - AIChE San Antonio (3-23-10) PresDocument19 pagesKumana - AIChE San Antonio (3-23-10) PresjkumanaNo ratings yet

- Hitech 35103 - PDS TasaDocument2 pagesHitech 35103 - PDS TasaPranit More Arabian Petroleum LimitedNo ratings yet

- Construction and Building MaterialsDocument10 pagesConstruction and Building MaterialsAriel VargasNo ratings yet

- 贴片二极管小集 (0 1-3 0A)Document2 pages贴片二极管小集 (0 1-3 0A)vetchboyNo ratings yet

- YD 90L 4 6 DatasheetDocument1 pageYD 90L 4 6 DatasheetLance AyoubNo ratings yet

- Model: G-070-VG: Direct Drive Centrifugal Roof Exhaust FanDocument2 pagesModel: G-070-VG: Direct Drive Centrifugal Roof Exhaust FanJoseph DavidNo ratings yet

- Bours07889 1Document2 pagesBours07889 1Marcos OliveiraNo ratings yet

- Warning !: Revisions Description Ecn No. Date RevDocument3 pagesWarning !: Revisions Description Ecn No. Date Revaw100% (1)

- Ion Beam Analysis: Joele Mira From Uwc and Ithemba Labs Tinyiko Maluleke From Us Supervisor: Dr. Alexander KobzevDocument18 pagesIon Beam Analysis: Joele Mira From Uwc and Ithemba Labs Tinyiko Maluleke From Us Supervisor: Dr. Alexander Kobzevsajjad hussainNo ratings yet

- Sheathing, Light-Colored, DIN VDE 0207 EM1, 70 Shore A, EPDM, Sulfur Cure (E - 1 - 0 - 006)Document1 pageSheathing, Light-Colored, DIN VDE 0207 EM1, 70 Shore A, EPDM, Sulfur Cure (E - 1 - 0 - 006)andresmsantoshNo ratings yet

- Tuazon - Let's Analyze Spreadsheet-Ulo1bDocument3 pagesTuazon - Let's Analyze Spreadsheet-Ulo1bWilkenn TuazonNo ratings yet

- Solenoid Cam 2Document2 pagesSolenoid Cam 2Tim PearceNo ratings yet

- Adobe Scan 23 Apr 2023Document2 pagesAdobe Scan 23 Apr 2023Tanishk AgarwalNo ratings yet

- KRC102MDocument6 pagesKRC102MZoran IlićNo ratings yet

- Gauge Blocks: Product Catalogue Ver 1.0Document5 pagesGauge Blocks: Product Catalogue Ver 1.0Juliana chenNo ratings yet

- Loctite 641 enDocument3 pagesLoctite 641 engeorgeNo ratings yet

- Lyon2007 Friction Wear BoreDocument17 pagesLyon2007 Friction Wear BoreCLAUDIO RODRIGUES DA SILVA JUNIORNo ratings yet

- Sir fritz-PEDESTALDocument1 pageSir fritz-PEDESTALJayson Ayon MendozaNo ratings yet

- Ssi .308DPMS Ur V3.3Document2 pagesSsi .308DPMS Ur V3.3Ashley MolomoNo ratings yet

- Data Sheet - PORV 1500 - 2500 - 4500 (Power) .Document2 pagesData Sheet - PORV 1500 - 2500 - 4500 (Power) .KumarNo ratings yet

- ET1103 Medium Speed Torquemeter: Product Data SheetDocument2 pagesET1103 Medium Speed Torquemeter: Product Data Sheetja jaNo ratings yet

- Saudi Arabian Oil Company: SECTION 13300 InstrumentationDocument7 pagesSaudi Arabian Oil Company: SECTION 13300 InstrumentationMECHKARTHIKRAJNo ratings yet

- Overload Relays, Motor-Protective RelaysDocument22 pagesOverload Relays, Motor-Protective RelaysBahador YazdiNo ratings yet

- DS7405Document2 pagesDS7405mccornejo1617No ratings yet

- b1015 DatasheetDocument2 pagesb1015 DatasheetCharles DavisNo ratings yet

- Tablas de TermofluidosDocument2 pagesTablas de TermofluidosEmanuel SandovalNo ratings yet

- Circlip 13 X 1 N (Part 1)Document1 pageCirclip 13 X 1 N (Part 1)Cbh FastenersNo ratings yet

- 21.52mm Low IronDocument1 page21.52mm Low Ironrached abboudNo ratings yet

- Energyflo DatasheetDocument2 pagesEnergyflo Datasheetclazy8No ratings yet

- Denah Lantai 1Document1 pageDenah Lantai 1Surya BintangNo ratings yet

- Semiconductor KRC401 KRC406: Technical DataDocument7 pagesSemiconductor KRC401 KRC406: Technical DataPLSNo ratings yet

- PTV/PTT Series - 12 MM Potentiometer: FeaturesDocument6 pagesPTV/PTT Series - 12 MM Potentiometer: FeaturesFrankJoeNo ratings yet

- Epf10k10lc84 4Document2 pagesEpf10k10lc84 4api-3825669No ratings yet

- MMSS8050 Sot 23 - 3366058Document5 pagesMMSS8050 Sot 23 - 3366058florescu6969No ratings yet

- HB-3M-2 Nominal Performance Characteristic Curve Torque vs. CurrentDocument1 pageHB-3M-2 Nominal Performance Characteristic Curve Torque vs. CurrentPrathmesh MahajaniNo ratings yet

- Sample Progress Tracking Sheet For Equipment ErectionDocument2 pagesSample Progress Tracking Sheet For Equipment ErectionmarklesterNo ratings yet

- Switching Over Voltages (SOV) : TrainingDocument31 pagesSwitching Over Voltages (SOV) : TrainingVigneswaran KNo ratings yet

- KRC101S KoreaElectronicsDocument6 pagesKRC101S KoreaElectronicsClay LanzarinNo ratings yet

- DatasheetDocument1 pageDatasheetUmar MahmudNo ratings yet

- pj2000171611 15Document1 pagepj2000171611 15karan singh solankiNo ratings yet

- Semiconductor KRC241S KRC246S: Technical DataDocument5 pagesSemiconductor KRC241S KRC246S: Technical DataAron OrtencioNo ratings yet

- Semiconductor KHB7D0N65P1/F1: Technical DataDocument7 pagesSemiconductor KHB7D0N65P1/F1: Technical DataDaniel DominguezNo ratings yet

- T1/CEPT Telecom Line Interface ApplicationsDocument1 pageT1/CEPT Telecom Line Interface ApplicationsRishikesh SaliNo ratings yet

- Ilovepdf MergedDocument12 pagesIlovepdf MergedSeptianNo ratings yet

- CELENIT-L3AB-A2 en Sound-Absorption 333110-A 201610Document1 pageCELENIT-L3AB-A2 en Sound-Absorption 333110-A 201610bobNo ratings yet

- 1SMB5 917BDocument3 pages1SMB5 917Bsansanyohan139875No ratings yet

- Third Angle Third AngleDocument1 pageThird Angle Third AngleMichael LedermanNo ratings yet

- KRC104S-RTK PDocument6 pagesKRC104S-RTK PGlam BarberiaNo ratings yet

- Presentation PosterDocument1 pagePresentation PosterMatthew Gary NesbittNo ratings yet

- 1St. FLR - LVL.: Section 1-1Document1 page1St. FLR - LVL.: Section 1-1Oseni MomoduNo ratings yet

- Side View Back View Recommended Footprint: CONSMA001 1.0Document1 pageSide View Back View Recommended Footprint: CONSMA001 1.0myfutn-re8512No ratings yet

- Series: Professional Pushbutton Switches - Threaded Bushing Ø 10 (.393)Document2 pagesSeries: Professional Pushbutton Switches - Threaded Bushing Ø 10 (.393)Sebastyan MártirNo ratings yet

- XFCN-T1201PS-00 C2839998Document1 pageXFCN-T1201PS-00 C2839998asdNo ratings yet

- Trip Curve IEC-RI-10PU: Rapid Inverse 3000TCDocument1 pageTrip Curve IEC-RI-10PU: Rapid Inverse 3000TCSergio aldoNo ratings yet

- 01 EF MS-UltraPleat-Coalescing-Particle-Filters 3pgDocument3 pages01 EF MS-UltraPleat-Coalescing-Particle-Filters 3pgNahbi Emilio PerezNo ratings yet

- Product Selection Guide - Electrical Insulating Resins VarnishesDocument4 pagesProduct Selection Guide - Electrical Insulating Resins VarnishesAjay AbrahamNo ratings yet

- 06 Pressure LossesDocument50 pages06 Pressure LossesDanian PrimasatryaNo ratings yet

- The Impact of The Use of Dry Lubricating Compound On The Dielectric Properties of Solid and Liquid Insulation of A Power TransformerDocument6 pagesThe Impact of The Use of Dry Lubricating Compound On The Dielectric Properties of Solid and Liquid Insulation of A Power TransformerRamesh GopalanNo ratings yet

- Frequent Questions & Answers ForDocument54 pagesFrequent Questions & Answers ForRamesh GopalanNo ratings yet

- Israel Barrientos, Prolecge, Nuevo León, México.: Dissolved Gas Limits in Transformers For Wind ApplicationDocument1 pageIsrael Barrientos, Prolecge, Nuevo León, México.: Dissolved Gas Limits in Transformers For Wind ApplicationRamesh GopalanNo ratings yet

- Rlswitcher: Southern States For Tertiary Reactor SwitchingDocument12 pagesRlswitcher: Southern States For Tertiary Reactor SwitchingRamesh GopalanNo ratings yet

- Compatibility Test For Mineral and Ester OilDocument6 pagesCompatibility Test For Mineral and Ester OilRamesh GopalanNo ratings yet

- Oils I:: Electrical Insulating Characterization and Pre-Treatment of Transformer OilsDocument13 pagesOils I:: Electrical Insulating Characterization and Pre-Treatment of Transformer OilsRamesh GopalanNo ratings yet

- Pre-Engineered Steel BuildingsDocument40 pagesPre-Engineered Steel BuildingsThilan SenarathneNo ratings yet

- Flashcards - CP6 Chlorination of 2-Methylpropan-2-Ol With Concentrated Hydrochloric Acid - Edexcel IAL Chemistry A-LevelDocument25 pagesFlashcards - CP6 Chlorination of 2-Methylpropan-2-Ol With Concentrated Hydrochloric Acid - Edexcel IAL Chemistry A-LevelTravel UnlimitedNo ratings yet

- Chapter 4 Chemical Reactions 4 3 To 4 6Document38 pagesChapter 4 Chemical Reactions 4 3 To 4 6api-313987777No ratings yet

- TEK Pan Head Self-Drill ScrewsDocument1 pageTEK Pan Head Self-Drill ScrewsdennisNo ratings yet

- Mechanical GalvDocument11 pagesMechanical GalvMehman NasibovNo ratings yet

- Factors That Affect CFBC Panel Erosion by K.K.parthibanDocument34 pagesFactors That Affect CFBC Panel Erosion by K.K.parthibanparthi20065768100% (2)

- Ormus DerivationDocument5 pagesOrmus Derivationextemporaneous100% (3)

- Report On Industrial TimberDocument31 pagesReport On Industrial TimberLakshya SharmaNo ratings yet

- SPINDO Catalogue New PDFDocument56 pagesSPINDO Catalogue New PDFTitus Deus PrizfelixNo ratings yet

- UK Water Approved ProductsDocument81 pagesUK Water Approved Productsmuhamadrafie1975No ratings yet

- Introduction To Fire Protection SystemDocument7 pagesIntroduction To Fire Protection SystemHiei ArshavinNo ratings yet

- Pro Honda Oils & Chemicals (Web Friendly)Document12 pagesPro Honda Oils & Chemicals (Web Friendly)fernando venacciNo ratings yet

- Fibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFDocument122 pagesFibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFA.Subin DasNo ratings yet

- Technical Data Sheet Gardobond G 4040Document5 pagesTechnical Data Sheet Gardobond G 4040jaymuscatNo ratings yet

- Toli Vinyl Tile Matico V TECHNICAL REPORT MV3mmDocument1 pageToli Vinyl Tile Matico V TECHNICAL REPORT MV3mmKelvin TjeongNo ratings yet

- HFD Catalog PvsDocument11 pagesHFD Catalog PvshadhisNo ratings yet

- Expansive Soil Stabilization Using Marble Dust and Bagasse AshDocument8 pagesExpansive Soil Stabilization Using Marble Dust and Bagasse AshArham SheikhNo ratings yet

- Stationery QuotationDocument4 pagesStationery Quotationsdr stationeryNo ratings yet

- A Guide To Grease Thickeners - Twin Specialties CorpDocument7 pagesA Guide To Grease Thickeners - Twin Specialties Corpbelkarroub mouradNo ratings yet

- ASTM E247-01 Standard Test Methods For Determinacion of Silica in Manganese Ores, Fe Ores, & Related Materials by GravimetryDocument3 pagesASTM E247-01 Standard Test Methods For Determinacion of Silica in Manganese Ores, Fe Ores, & Related Materials by GravimetryQuimica Grupo 3No ratings yet

- Free Float Steam Trap: Model Ductile Cast Iron Cast IronDocument2 pagesFree Float Steam Trap: Model Ductile Cast Iron Cast IronSamerNo ratings yet

- Asme Section II A Sa-202 Sa-202mDocument4 pagesAsme Section II A Sa-202 Sa-202mAnonymous GhPzn1xNo ratings yet

- Astm F1043 00Document3 pagesAstm F1043 00REHAN HASSANNo ratings yet

- Chapter 4 Sewer ConstructionDocument27 pagesChapter 4 Sewer Constructionsahle mamoNo ratings yet

- ASTM C 1038 - 01 Standard Test Method For Expansion of Hydraulic Cement Mortar Bars Stored in WaterDocument3 pagesASTM C 1038 - 01 Standard Test Method For Expansion of Hydraulic Cement Mortar Bars Stored in Waterfilipe100% (1)

- Intake Retaining Wall Take OffDocument9 pagesIntake Retaining Wall Take OffMesfin DerbewNo ratings yet

- Amscrew Part Numbering - Rev18 (11-2020) - SAPDocument43 pagesAmscrew Part Numbering - Rev18 (11-2020) - SAPValentina RojasNo ratings yet