Professional Documents

Culture Documents

Tutorial 3_Chapter 3

Tutorial 3_Chapter 3

Uploaded by

Fiz Mobile Gaming & MoreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial 3_Chapter 3

Tutorial 3_Chapter 3

Uploaded by

Fiz Mobile Gaming & MoreCopyright:

Available Formats

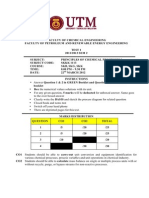

Material Balance For Non-Reactive System Chapter 3

3.0 MATERIAL BALANCE FOR NON-REACTIVE SYSTEM

3.1 Introduction

3.1.1 Discuss the differences between steady state process and transient process. Give

and example for each process.

(Final Exam Sep 2011)

3.1.2 Explain briefly and give an example for each of the following processes:

i. Batch process.

ii. Continuous process.

iii. Transient process.

iv. Steady state process.

(Final Exam Oct 2012)

3.1.3 State the characteristic of the following chemical processes: batch process,

continuous processes and semi batch processes.

(Final Exam Apr 2011)

3.1.4 Explain the differences between a batch process and a semi-batch process and

give examples for each process.

(Final Exam Mar 2012)

3.1.5 Write down a general material balance for a process and then simplify the

balance for a continuous steady state process with no reaction.

(Final Exam Sep 2011)

3.1.6 List four (4) independent equations that could be used to analyze the degree of

freedom (DOF) in solving the material balance problems.

(Final Exam Mar 2012)

3.1.7 A young engineer works in a factory which produces sulfuric acid using several

mixing tanks. He does some quick material balance calculation to determine

whether the total mole is conserved or not for these mixing tanks that is total

mole in = total mole out. Surprisingly, the total mole is not balance. Suggest four

(4) reasons for the imbalance.

(Final Exam Mar 2012)

3.2 Balance On Single Unit Process

3.2.1 A stream containing 25 wt% methanol in water is to be diluted with a second

stream containing 10 wt% methanol to form a product containing 17 wt%

methanol.

i. Choose a convenient basis of calculation, draw and label a flowchart of

this process and calculate the ratio (kg 17 wt%/kg 25 wt% solution)

ii. What feed rate of 10% solution would be required to produce 1250 kg/h

of product.

18 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

Ans: Basis 100 kg/h at feed stream (i) F2 = 114.29 kg/h, F3 = 214.29 kg/h, 2.143 kg F3/kg F1

(ii) F2 = 666.67 kg

3.2.2 A waste acid stream from a nitration process contains 35 wt% H2SO4, 32 wt%

HNO3 and 33 wt% H2O is to be concentrated to 38 wt% H2SO4, and 40 wt%

HNO3 by mixing with a stream of 98 wt% H2SO4 and a another stream of 72 wt%

HNO3. If 1000 kg of the acid product is to be produced:

i. Draw and label the flow diagram for the process.

ii. Calculate the number of degree of freedom (DOF) for the process.

iii. Calculate the mass of three acid streams to be mixed.

(Final Exam Oct 2012)

Ans: (iii) 285.6 kg, 286.1 kg, 428.3 kg

3.2.3 A paint mixture containing 25% of a pigment and the balance water sells for

RM18.00/kg, and a mixture containing 12% pigment sells for RM 10.00/kg. If a

paint retailer produces a blend containing 17% pigment. How much (RM/kg) is

the cost for the new blending?

(Final Exam Apr 2007)

Ans: RM13.08/kg

3.2.4 A cereal product containing 55 wt% water is made at rate of 500 kg/h. Then, the

product is dried so that it contains only 30 wt% water. Determine :

i. The water has to be evaporated per hour.

ii. The amount of the dried product per hour.

Ans: (i) 178.57 kg/h (ii) 321.43 kg/h

3.2.5 A slurry contains of 70 wt% water and 30 wt% solid is to be concentrated to

60 wt% solid in an evaporator.

i. Sketch a flow diagram for the process and label it completely.

ii. Take 100 kg/s of slurry feed as a basis; calculate the ratio of water

removed to the product slurry.

(Final Exam Mar 2012)

Ans: (ii) 1 kg water removed/ kg product slurry

3.2.6 A cereal product containing 55 wt% water is made at the feed rate of 500 kg/h.

To ensure its taste, this cereal is added with the sugar at 1:0.25 (kg/kg) of cereal:

sugar ratio. Then this cereal has to dry up to contain only 30 wt% water.

i. Draw and label the flow diagram completely.

ii. Determine how much water has to be vaporized and the cereal product

can be produced.

Ans: (ii) 154. 47 kg water/h, 401.78 kg cereal/h

3.2.7 Wardina Safia plans to make a jam tart cookie for raya’s day. In order to make

this cookie, she needs to prepare a pineapple jam. The 3 kg of pineapple fruit

that she bought contains 70 wt% solid and the balance is water. This pineapple is

mixed with the sugar at 1:1.5 (kg/kg) of pineapple : sugar ratio. This mixture is

fed to an evaporator. During the evaporation process, two-third of the water is

19 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

boiled off.

i. Draw the flowchart (Hint: Only one process unit is involved).

ii. Determine the amount of pineapple jam that can be prepared and its

composition.

Ans: (ii) 6.9 kg, 0.9565 kg sugar/kg, 0.0435 kg water/kg

3.2.8 In a production of apricot jam, apricots of weight compositions 30% solid and

70% water are mixed with sugar where the amount of sugar is 2.5 times the

weight of apricot. After the mixing process, the mixture is concentrated in an

evaporator where 70 wt% of water is boiled off. Calculate:

i. The jam production rate if 10 kg/h apricots are fed to the process.

ii. The feed rate of apricots (kg/h) required to produce 10 kg jam/h.

(Final Exam Apr 2008)

Ans: (i) 30.1 kg/h (ii) 3.3223 kg/h

3.2.9 A liquid stream containing 50 mol% of benzene and the balance toluene is fed to

a continuous single-stage evaporator at a rate of 1320 mol/s. In this process, 48%

of benzene in the feed is evaporated. The liquid and vapor streams leaving the

evaporator containing both toluene and benzene and the liquid stream contain

42.5 mol% of benzene.

i. Draw and label a flowchart of the process.

ii. Determine the composition leaving the evaporator as vapor.

(Final Exam Oct 2010)

Ans: (ii) 0.6182 mol B/mol, 0.3818 mol T/mol

3.2.10 A mixture of 1000 kg/h containing equal parts by mass of methanol and water is

distilled. Product streams leave the top and the bottom of the distillation

column. The flow rate of the bottom stream is measured and found to be

673 kg/h and overhead stream is analyzed and found to contain

96 wt% methanol.

i. Draw and label the flow diagram completely.

ii. Express DOF (Degree of Freedom) analysis for the overall system.

iii. Calculate the mass and mole fractions of methanol and the molar flow

rates of methanol and water in the bottom product stream.

(Final Exam Apr 2010)

Ans: (iii) 0.279 kg CH3OH/kg, 0.176 kmol CH3OH/kmol, 5.8 x 103 mol CH3OH/h,

2.71 x 104 mol H2O/h

3.2.11 1250 kilograms per hour (kg/h) of a mixture containing equal parts by mass of

ethanol and water is distilled. Product streams leave the top and the bottom of

the distillation column. The flow rate of the bottom stream is measured and

found to be 747 kg/h, and the overhead stream is analyzed and found to contain

96.0 wt% of ethanol (C2H5OH).

20 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

i. Draw and label a flowchart of the process and do the degree-of-freedom

analysis.

ii. Calculate the mass and mole fractions of ethanol and the molar flow rates

of ethanol and water in the bottom product stream.

(Final Exam Apr 2007)

Ans: (ii) 0.190 kg C2H5OH/kg, 0.084 mol C2H5OH/mol, 3.085 x 103 mol C2H5OH/h,

3.3.62 x 104 mol H2O/h

3.2.12 A gas stream contains 20 mole% hexane (C6H14) and the remainder nitrogen. The

stream flows to a condenser, where its temperature is reduced and some of the

hexane is liquefied. The hexane mole fraction in the gas stream leaving the

condenser is 0.05. Liquid hexane condensate is recovered at a rate of 1.5 L/min.

Data:

Molecular Weight of C = 12

Specific Gravity of C6H14 = 0.659

i. Draw and label a flowchart of the process.

ii. Determine the molar flowrate of liquid hexane condensate.

iii. Calculate the flowrate of the gas stream leaving the condenser in

mol/min.

iv. Determine the percentage of the hexane entering the condenser is

recovered as a liquid.

(Final Exam Apr 2006)

Ans: (ii) 11.49 mol/min (iii) 61.28 mol/min (iv) 78.95%

3.2.13 A gas stream contains 20 mol% hexane and the remainder nitrogen. The stream

flows to a condenser, where its temperature is reduced and some of the hexane is

liquefied. The hexane mole fraction in the gas stream leaving the condenser is

0.04. Liquid hexane condensate is removed at a rate 2 mol/min.

i. Draw and label the flowchart of the process.

ii. Determine the molar flow rate of the gas stream leaving the condenser in

mol/min.

iii. Calculate percentage of the hexane entering the condenser recovered as

liquid.

iv. If all the hexane from the feed stream is liquefied, calculate the molar flow

rate of the gas and liquid streams leaving the condenser.

v. If 35% of the feed hexane is liquefied, determine the molar flow rate and

composition of the gas and liquid streams leaving the condenser.

(Final Exam Nov 2005)

Ans: (ii) 10 mol/min, 12 mol/min (iii) 83.33% (iv) 2.4 mol liq/min, 9.6 mol gas/min

(v) 7 mol gas/min, 93 mol liq/min, 13.98 C6H14 mol%, 86.02 mol% N2

3.2.14 A gas mixture containing 15 mol% of benzene (C6H6) and the balance air is

flowing at a rate of 100 kg/h to a dilution tower. The mixture is to be diluted

with pure air to reduce the benzene concentration to 5 mol%. The diluted

mixture flows out from the dilution tower for further processes.

21 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

Data:

Air consists of 21 mol% O2 and 79 mol% N2 and an average molecular weight of

Air is 29.0

i. Draw and label the flowchart of the process.

ii. Determine the average molecular weight of the initial gas mixture.

iii. Calculate the molar flow rate of the mixture, benzene and air before

dilution process.

iv. Determine the required amount of pure air in mol/h for the dilution

process.

v. Calculate the mass of the diluted mixture stream in kg.

(Final Exam Apr 2005)

3.2.15 In a production plant, 1000 kg per hour of a mixture containing 60 wt% of

methanol (CH3OH) and 40 wt% of water (H2O) is fed to the distillation column.

Product streams leave the top and the bottom of the distillation column. The

flow rate of the bottom stream is 500 kg/h and the overhead stream contains

96 wt% of methanol.

i. Draw and label a flowchart of the process.

ii. Calculate the mass flowrate of methanol and water in the bottom product

stream.

iii. Calculate the mole fraction of methanol and water in the feed stream.

iv. Calculate the molar flowrate of methanol and water in the bottom

product stream.

Data: Molecular weight C = 12, O = 16 and H = 1

(Final Exam Mar 2005)

Ans: (ii) 120 kg M/h, 380 kg W/h (iii) 0.4576 kmol M/kmol, 0.5424 kmol W/kmol

(iv) 3.75 kmol M/h, 21.11 kmol W/h

3.2.16 In a production plant, 5000 kg per hour of a mixture containing 50 wt% of

benzene (C6H6) and 50 wt% of toluene (C7H8) is fed to the distillation column.

The gas product goes to the top stream and the liquid product goes to the

bottom stream of the distillation column. The flow rate of the overhead stream is

3500 kg/h and the bottom stream contains 5 wt% of benzene.

i. Draw and label a flowchart of the process.

ii. Calculate the mass flow rate of the bottom product stream in kg/h.

iii. Calculate the mass flow rate of benzene and toluene in the bottom

product stream.

iv. Calculate the mole fraction of benzene and toluene in the feed stream.

v. Calculate the molar flow rate of benzene and toluene in the bottom

product stream.

vi. Calculate the weight composition of benzene and toluene in the top

stream.

22 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

Data: Molecular weight C = 12 and H = 1

(Final Exam Nov 2005)

Ans: (ii) 1500 kg/h (iii) 75 kg/h, 1425 kg/h (iv) 0.54 kmol C6H6/kmol, 0.46 kmol C7H8/kmol

(v) 0.96 kmol C6H6/h, 15.49 kmol C7H8/h (vi) 69.29 wt% C6H6, 30.071 wt% C7H8

3.2.17 Benzene, C6H6 an organic chemical compound which is colourless and highly

flammable has flammable limit of 4 mol %. A mixture of 10 mol % benzene and

air is flowing at a rate of 500 kg/hr is to be diluted with pure air to reduce

benzene concentration to the lower flammability limit. Note that air containing

21 mol% O2 and 79 mol% N2 and to have average molecular weight of 29.

i. Draw and label a flow chart of the process.

ii. Calculate the average molecular weight of the inlet mixture.

iii. Determine the required flow rate of air to dilute benzene.

iv. Calculate the percent by mass of oxygen in the product gas.

(Final Exam Oct 2006)

Ans: (ii) 33.9 kg/kmol (iii) 22.1238 kmol/h (iv) 76.7% N2, 23.3 % O2

3.2.18 A total of 4800 kg/h of fresh feed contains 35.0 wt% of crystalline sodium

carbonate (Na2CO3) and the balance is H2O is combined with a recycle stream

and fed into an evaporator. The concentrated streams leaves the evaporators

contains 80.0 wt% Na2CO3 is fed into crystallizer. The product crystal from the

crystallizer contains 98.2 wt% Na2CO3 and is collected as the final products. In

this system. The recycle ratio (mass of recycle/ mass of fresh feed) is 0.1.

i. Draw and label the process flow diagram.

ii. Express the DOF analysis for overall system and crystallizer.

iii. Calculate the amount of water removed in the evaporator and mass

flowrate of crystalline Na2CO3 product.

i. Calculate the feed flowrates to the evaporator and crystallizer.

ii. Calculate the composition for all components in the recycle stream and

the stream feeds into the evaporators (after mixing with the recycle

stream).

(Final Exam Apr 2009)

Ans: (ii) 3089.21 kg/h, 17110.79 kg/h (iii) 5280 kg/h, 2190.79 kg/h (iv) R − 0.1513 kg Na2CO3/kg,

0.8486 kg H2O/kg, E – 0.3319 kg Na2CO3 /kg, 0.6681 kg H2O/kg

3.3 Balance On Multiple Unit Processes

3.3.1 Fresh orange juice contains 10 wt% solids and the balance is water, and

concentrated orange juice contains 42 wt% solids. Initially a single evaporation

stage was used for the concentration, but volatile constituents of the juice

escaped with water, leaving the concentrated juice with a flat taste. This problem

is overcome by bypassing the evaporator with a fraction of the fresh juice. The

juice that enters the evaporator is concentrated to 55 wt% solid, and the

evaporator product stream is mixed with the bypassed fresh juice to obtain the

desired final concentration.

23 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

i. Draw and label a flowchart for the process.

ii. Determine the amount of product (42% concentrate) produced per 100 lbm

of fresh juice fed to the process.

iii. Determine the fraction of the feed that bypasses the evaporator.

iv. Most of the volatile ingredients that provide the taste of the concentrate

are contained in the fresh juice that bypasses the evaporator. You could

get more of these ingredients by evaporating to 90% solid (for example)

instead of 55% and then bypass a greater portion of the fresh juice to

obtain an even better tasting product. Criticize this proposal by giving

possible drawbacks.

(Final Exam Sep 2011)

Ans: (ii) 23.8 lbm, 76.2 Ibm (iii) 0.07

3.3.2 A liquid mixture containing 30 mole% benzene (B), 25 mole% toluene (T) and

45 mole% xylene (X) is fed at a rate of 1275 kmol/h to a distillation system which

consists of 2 distillation columns. The bottom product from the first column is to

contain 99 mole% X and no B and 98% of the X is to recover in this stream. The

overhead product from the first column is fed to a second column. The overhead

product from the second column contains 99 mole% B and no X. The benzene

recovered in this stream represents 96% of the B in the feed of this column.

i. Do degree of freedom analysis.

ii. The molar flowrate (kmol/h) in each product stream from both columns.

iii. The mole fractions of each component in each product stream.

3.3.3 In a factory, fresh orange juice which contains 12.0 wt% solids and the balance

water is fed to a two-stages (E1 and E2) evaporation unit where it is heated until

it is concentrated to 58 wt% solid. A portion of the fresh juice bypasses the

evaporator and combines with the concentrated juice to achieve the desired juice

composition of 42 wt% solid as shown in the figure below.

i. If the value of V is twice of W, B is quarter of F and the fresh juice feed

enters at 2000 kg/h, redraw and label the flowchart completely.

ii. Determine the DOF analyses for overall system, mixing point, E1 and E2.

iii. Determine the values of P, C, Q, B, M in kg/h and composition at M

stream.

24 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

Ans: (iii) P = 571.43 kg/h, C = 372.67 kg/h, Q = 1801.24 kg/h, B = 108.76 kg/h, M = 1325.05 kg/h,

0.1631 kg solid/kg, 0.8369 kg water/kg

3.3.4 Air consists of approximately 21 mol% oxygen and 79 mol% nitrogen. Liquid

nitrogen is produced by liquefying air and distilling it at low temperature. The

process uses two distillation columns as shown in Figure 1. All compositions are

reported in mole percent. On a basis of 150 kmol/h of liquid nitrogen produced,

calculate:

i. The molar flow rate of feed.

ii. The molar flow rate of stream 1.

iii. The percent recovery of nitrogen in the nitrogen-rich product stream.

(Final Exam Apr 2008)

Ans: (i) 193.93 kmol/h (ii) 116.36 kmol/h, 77.58 kmol/h (iii) 97.4%

3.3.5 Seawater is to be desalinized by reverse osmosis using the scheme as indicated

in the figure below.

i. Express DOF (Degree of Freedom) analysis for the overall system and the

mixing point.

ii. Calculate the waste brine removal (W) and desalinized water production

(D).

iii. If the ratio of brine recycle (R) to cell feed (M) is 1:4, determine the brine

recycle (R)and the NaCI composition, x for this stream.

(Final Exam Oct 2008)

Ans: (i) 45.45 kg/h, 54.55 kg/h (ii) 33.33 kg/h, 133.32 kg/h, 0.1099 kg NaCl/kg

3.3.6 100 kg fresh feed strawberry juice contains 15.0 wt% solids and the balance is

25 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

water. At the end of the process, the product which is concentrated strawberry

juice contains 45.0 wt% solids. Initially a single evaporation process was used for

the concentration, but volatile constituents of the juice escaped with the water,

leaving the concentrate with a flat taste. In order to overcome the flat taste

problem, a new process has been developed which is by bypassing the

evaporator with a fraction of the fresh juice. The juice that enters the evaporator

is concentrated to 58 wt% solids. The evaporator product stream is mixed with

the bypassed fresh juice to achieve the desired final concentration. The flowchart

of the process is shown in the figure below.

i. Label the known and unknown values of this process.

ii. Perform the degree-of-freedom analysis for the overall system, the

evaporator, and the bypass-evaporator product mixing point.

iii. Calculate the amount of concentrated product produced per 100 kg fresh

juice fed to the process.

iv. Calculate the fraction of the feed that bypass the evaporator.

v. Calculate the amount of water evaporated from the evaporator.

vi. Calculate the ratio of water evaporated from the evaporator to water in

the feed entering the evaporator.

(Final Exam Apr 2007)

And: (iii) 33.33 kg (iv) 0.1008 (v) 66.67 kh/h (vi) 0.87

3.3.7 A process for the separation of a propelyne-propane mixture to produce

99 mol% propylene and 95 mol% propane is shown in the figure below. A liquid

mixture containing 50 mole% propylene and 50 mole% propane is fed to a

distillation column. The mixture of overhead product leaving the DC-1 is fed to

the column DC-2. The overhead product from the second column contains 97%

of propylene in the feed to this column. The bottom product come out from DC-2

is consisting of pure propylene and recycles back to DC-1.

i. Redraw and label a flowchart of this process.

ii. Assuming basis of calculation is 100 mol/h mixture fed to the DC-1,

calculate the amount of propylene recycles to DC-1.

26 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

(Final Exam Apr 2007)

Ans: (ii) 1.4658 mol

3.3.8 In the production of coconut oil, coconuts containing 15 wt% oil and 85 wt%

solids are crushed and fed to the extractor along with a recycled stream of liquid

solvent. The feed ratio is 5 kg solvent per 1 kg coconuts. The crushed coconuts

are suspended in the liquid, and essentially all of the oil in the coconuts is

extracted into the solvent. The extractor effluent passes to a filter. The filter cake

contains 65.0 wt% solids and the balance oil and solvent, the latter two in the

same ratio in which they emerge from the extractor. The filter cake is discarded

and the liquid filtrate is fed to a heated evaporator in which the solvent is

vaporized and the oil remains as a liquid. The oil is stored in drums and

shipped. The solvent vapor is subsequently cooled and condensed, and the

liquid solvent condensate is recycled to the extractor. A below figure illustrates

process flow of the production of coconuts oil.

i. Draw and label each component in every streams of the process

flowchart.

ii. Calculate the mass flow rate of each stream in the process.

iii. Calculate the yield of coconut oil product (kg oil produced/kg coconuts

fed).

iv. Calculate the ratio of recycle solvent to fresh solvent feed (kg solvent

recycled/kg fresh feed).

(Final Exam Apr 2006)

Ans: (ii) If Basis 100 kg coconut fed/h - 600 kg/h, 129.23 kg/min, 470.77 kg/h14.12 kg/h, 456.65

kg/h, 43.45 kg/h (iii) 0.14 (iv) 10.53

27 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

3.3.9 A widely employed method of gas purification is to selectively absorb

undesirable constituents of the gas into a specifically selected liquid medium.

The liquid medium is subsequently regenerated by chemical or heat treatment to

release the absorbed material. In a particular installation, the purification system

for the removal of sulfur compounds, designed to operate at a feed rate up to

820 mol/h, is temporarily subjected to a feed rate of 1000 mol/h. Since the

absorption system simply can accommodate only 82% of this flow, the overload

is bypassed and the exit H2S concentration of the absorption system is reduced

far enough so that the mixed exit stream contains only 1% H2S and 0.3% COS on

a mole basis. The feed stream consists of (mole basis) 15% CO2, 5% H2S,

1.41% COS, and the balance is CH4. The flow diagram for the process is given in

the figure below.

i. Redraw and completely label the flow diagram for the process.

ii. Make a table of Degree of Freedom Analysis for the absorption tower, the

mixing point,and the overall process. Which unit should you solve first?

Justify your answer.

iii. Determine flow rates of the streams D, E and F and their respective

compositions.

(Final Exam Oct 2007)

Ans: (iii) 51.77 mol/h D (0.783 mol D/mol) 948.23 mol/h F, 768.23 mol/h E (0.829 mol E/mol)

3.3.10 A feed of 10000 kg/h of soybean is processed in a sequence of three stages as

shown in the figure below. The soybean contains of 71.5 wt% meal, 10.5 wt%

moisture and the balance is oil. In first stage, the bean is crushed and pressed to

remove oil (assume no loss of other stream constituents with the oil stream). In

the second stage, the crushed bean contains 6.0 wt% of oil is extracted with

hexane. The oil-hexane stream is removed from the process while extracted

soybean with 0.5 wt% oil is dried in a dryer. The mixture is dried until the

residue contains 8.0% by mass.

i. Redraw the process flow diagram and label it completely.

ii. Determine the DOF (Degree of Freedom) analysis for the first stage.

iii. Calculate the flowrate of crushed bean (P kg/h) and oil (L kg/h) from the

first stage.

iv. Calculate the flowrate of extracted bean (M kg/h) from the second stage.

v. Calculate the flowrates of moisture that have been removed (W kg/h) and

final dried bean (D kg/h).

28 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

(Final Exam Oct 2009)

Ans: (iii) 8723.4 kg P/h, 1276.6 kg L/h (iv) 8240.82 kg M/h (v) 424.32 kg D/h

3.3.11 Figure 1 shows the process of a series of two distillations. In this process, liquid

mixture containing 50 mole% benzene (B), 15.0% toluene (T), and the balance

xylene (X) is fed to a distillation column. The bottom product contains 88.0

mole% X and no B, and 90% of the X is recovered in this stream. The overhead

product is fed to a second column. The overhead product from the second

column contains 98% of the B in the feed to this column. The composition of this

stream is 95 mole% B and the balance T.

n3 mol/h

100 mol/h n1 mol/h

C1 C2

n2 mol/h n4 mol/h

Figure 1 A series of two distillations

a) Based on the above description, redraw and label the mole fraction

accordingly on the flow diagram in Figure 1.

b) Perform a degree of freedom (DOF) in column 1 and 2.

c) Calculate the molar flow rate of streams n1, n2, n3 and n4 with their molar

fractions.

(Final Exam Sept 2013)

29 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

Material Balance For Non-Reactive System Chapter 3

3.3.12 A gas containing 80 mole% Butane (C4H10) and 20 mole% Helium (He) is

sent through a quarts diffusion tube to recover He as shown in Figure 1. 20%

by weight of the feed gas is recovered and its composition consists of 50

mole% He.

F (Feed gas) P2 (waste gas)

P1 (recovered gas)

Figure 1: Quarts diffusion tube

a) Redraw and label the flow diagram completely.

b) Express the degree of freedom (DOF) analysis of the process.

c) Calculate the composition of the waste gas if 100 kg of gas are processed per

minute.

d) If the waste gas stream (P2) is intended to be recycled and blended with the feed

gas stream (F), justify the reasons of using recycle process.

(Final Exam Mac 2014)

30 Faculty Of Chemical Engineering, UiTM (Terengganu) Kampus Bukit Besi

You might also like

- Poettmann Carpenter BHPDocument5 pagesPoettmann Carpenter BHPcesar_d10% (1)

- Chemical Engineering Principles and Calculations Chapter I - Introduction To Chemical ...Document175 pagesChemical Engineering Principles and Calculations Chapter I - Introduction To Chemical ...Alex RomeroNo ratings yet

- Mass BalancesDocument40 pagesMass Balancesnazar9515100% (2)

- 400L Chemical Engr. Past Questions (2012/2013)Document52 pages400L Chemical Engr. Past Questions (2012/2013)ifiokNo ratings yet

- Separation Processes IDocument3 pagesSeparation Processes IAmesh Chiyogami100% (1)

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- HYSYS-Report Ammonia PlantDocument21 pagesHYSYS-Report Ammonia PlantDouglas Ross HannyNo ratings yet

- Budget of Work Chem 2 Midterm Curriculum MappiDocument23 pagesBudget of Work Chem 2 Midterm Curriculum MappiIm NaYeon TWICENo ratings yet

- Exercises in Polymer ChemistryDocument34 pagesExercises in Polymer ChemistryShirish Maheshwari100% (1)

- Batch Manufacture of Propylene GlycolDocument6 pagesBatch Manufacture of Propylene Glycolprassna_kamat1573No ratings yet

- The Framework of Solution ThermodynamicsDocument51 pagesThe Framework of Solution ThermodynamicsAljebre MohmedNo ratings yet

- Assignment 2 DR Azizul PDFDocument4 pagesAssignment 2 DR Azizul PDFjinNo ratings yet

- Process Enginnering FundamentalsDocument65 pagesProcess Enginnering FundamentalsMeng KiatNo ratings yet

- CBE 202 Homework #1: Introduction To Chemical and Biomolecular EngineeringDocument2 pagesCBE 202 Homework #1: Introduction To Chemical and Biomolecular Engineering김민성No ratings yet

- Mass Balance Tutorial 2 - 2021 Fin-StuDocument2 pagesMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanNo ratings yet

- Tutorial 4_Chapter 4Document13 pagesTutorial 4_Chapter 4Fiz Mobile Gaming & MoreNo ratings yet

- Tutorial 2_Chapter 2Document5 pagesTutorial 2_Chapter 2Fiz Mobile Gaming & MoreNo ratings yet

- CHE471Document5 pagesCHE471ShahrizatSmailKassimNo ratings yet

- Untitled DocumentDocument3 pagesUntitled DocumentRoxan MoraNo ratings yet

- HW #2Document4 pagesHW #2Rohit ReddyNo ratings yet

- LN Meb 3Document22 pagesLN Meb 3Siti Noranisa hidayahNo ratings yet

- SKKK1113 Tutorial Assignment-04-ReactiveDocument2 pagesSKKK1113 Tutorial Assignment-04-ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194No ratings yet

- PROBLEMARIO 2 BAL DE MAT.Document2 pagesPROBLEMARIO 2 BAL DE MAT.Blanca LopezNo ratings yet

- Lectut CHN-102 PDF ReactiveDocument4 pagesLectut CHN-102 PDF ReactiveTanmaysainiNo ratings yet

- Week 7 TutorialDocument4 pagesWeek 7 TutorialHua KhienNo ratings yet

- Assignment ReactiveDocument2 pagesAssignment ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET01940% (1)

- Cpe 420 Tutorial 2Document3 pagesCpe 420 Tutorial 2Muhamad Baihakhi ShamsudinNo ratings yet

- Revision - Mass BalanceDocument3 pagesRevision - Mass BalancePorkkodi SugumaranNo ratings yet

- Assignment Reaction EngineeringDocument6 pagesAssignment Reaction Engineeringnur hidayatiNo ratings yet

- Ejercicios.1-Varios Equipos, Multicomponentes, Sin RX PDFDocument4 pagesEjercicios.1-Varios Equipos, Multicomponentes, Sin RX PDFMafee VelezNo ratings yet

- Assisgnment-I - Material and Energy Balance - Autumn 2022Document2 pagesAssisgnment-I - Material and Energy Balance - Autumn 2022Konain Raza AnsariNo ratings yet

- CHE211 Problem Set 1Document3 pagesCHE211 Problem Set 1AlexNo ratings yet

- Assignment MEB - 2Document2 pagesAssignment MEB - 2Tuah Abadi RosmazamNo ratings yet

- (I) Amount (In KG) of Water Evaporated and (Ii) Amount (In KG) of Thick Liquor ObtainedDocument2 pages(I) Amount (In KG) of Water Evaporated and (Ii) Amount (In KG) of Thick Liquor ObtainedDechenPemaNo ratings yet

- PCE - Chapter 4 - MASS BALANCE-47-73 PDFDocument27 pagesPCE - Chapter 4 - MASS BALANCE-47-73 PDFSchool Of Energy UTPNo ratings yet

- r05320801 Mass Transfer Operations IIDocument9 pagesr05320801 Mass Transfer Operations IISRINIVASA RAO GANTANo ratings yet

- Manual Experiment SMA TestDocument9 pagesManual Experiment SMA TestJair Ferreira JúniorNo ratings yet

- Stoichiometry Application - App.4 - 08.11.2023Document2 pagesStoichiometry Application - App.4 - 08.11.2023Poriya SharifaeeNo ratings yet

- Tutorial 2-Part 1Document3 pagesTutorial 2-Part 1Wan AmzarNo ratings yet

- BdeM Taller No. 2Document2 pagesBdeM Taller No. 2Luisfer PriceNo ratings yet

- Lista de ExerciciosDocument30 pagesLista de ExerciciosFrancine MartinsNo ratings yet

- Assignment CPP Jan 2020 PDFDocument5 pagesAssignment CPP Jan 2020 PDFNur Afifah IINo ratings yet

- Orca Share Media1567598084691Document10 pagesOrca Share Media1567598084691Kobe AcobNo ratings yet

- Homework #2 For Chemical Process Calculation PDFDocument2 pagesHomework #2 For Chemical Process Calculation PDFUrgen TamangNo ratings yet

- Tutorial 2 (2013)Document7 pagesTutorial 2 (2013)Shah AhmadNo ratings yet

- BdeM Taller No. 2 Una Sola Unidad 2018-VDocument4 pagesBdeM Taller No. 2 Una Sola Unidad 2018-VMarelbis RangelNo ratings yet

- A4 02-Aug-2016 Bit1008 EthDocument34 pagesA4 02-Aug-2016 Bit1008 EthsantoshNo ratings yet

- CHEN 201 Exam 1 Spring 2019 QuestionsDocument2 pagesCHEN 201 Exam 1 Spring 2019 QuestionsDiana BeirutiNo ratings yet

- Tute 3Document4 pagesTute 3ArunNo ratings yet

- Inorganic Catalysts Bronze Problem 2Document11 pagesInorganic Catalysts Bronze Problem 2joell2253h.01No ratings yet

- Assignment L01 (Thursday, 11.30 Am)Document9 pagesAssignment L01 (Thursday, 11.30 Am)MawareNo ratings yet

- For Student Test1 Version 3 SKKK1113 1112-1 PDFDocument3 pagesFor Student Test1 Version 3 SKKK1113 1112-1 PDFDon Jer Bear FirdausNo ratings yet

- Tutorial 2-Part 1Document2 pagesTutorial 2-Part 1Abdul AddaharyNo ratings yet

- Chapter 8 (Principle of Chemical Engineering) 1Document9 pagesChapter 8 (Principle of Chemical Engineering) 1Edmark Sienes Icalina50% (2)

- Simulation of The Production and Recovery Process of Butanol-ReportDocument15 pagesSimulation of The Production and Recovery Process of Butanol-ReportdanielNo ratings yet

- Int Confe Biote Bioen - TendsDocument8 pagesInt Confe Biote Bioen - TendsJosé Luis Nava RebollarNo ratings yet

- CHBE 241 (2020W1) (Material & Energy Balances) Assignment 02Document4 pagesCHBE 241 (2020W1) (Material & Energy Balances) Assignment 02SoumalyaNo ratings yet

- DR Nayak PPC Tutorials 19CH3DCPPCDocument12 pagesDR Nayak PPC Tutorials 19CH3DCPPCMABUKE NDINAINWI INNOCENTIANo ratings yet

- CPC QB Full 2013Document7 pagesCPC QB Full 2013Arul KamalakumarNo ratings yet

- Problem Set 3-1Document1 pageProblem Set 3-1Carlo Luis LeeNo ratings yet

- QPDocument3 pagesQPgood buddyNo ratings yet

- Assignment 2Document2 pagesAssignment 2Boy farhanNo ratings yet

- S F Assessment: Course Name: Mass Transfer IIDocument3 pagesS F Assessment: Course Name: Mass Transfer IIMani king100% (1)

- Chemical Engineering Calculations - Midterm ExamDocument12 pagesChemical Engineering Calculations - Midterm ExamJohnNo ratings yet

- Note: 1. Answer All Questions 2.any Missing Data May Be Suitably Assumed 3. Solve Problems AnalyticallyDocument2 pagesNote: 1. Answer All Questions 2.any Missing Data May Be Suitably Assumed 3. Solve Problems AnalyticallyNishanth ChandranNo ratings yet

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsFrom EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghNo ratings yet

- Lecture 1 Ideal Gases and Their MixtureDocument24 pagesLecture 1 Ideal Gases and Their MixtureMuez GhideyNo ratings yet

- Pyromet Examples Self StudyDocument2 pagesPyromet Examples Self StudyTessa BeeNo ratings yet

- Chemistry 2 K-12Document69 pagesChemistry 2 K-12Richtine VillasisNo ratings yet

- GENCHEM2 7thUEDocument5 pagesGENCHEM2 7thUEMea-Ann OscianasNo ratings yet

- Chapter 9 Problem StatementsDocument1 pageChapter 9 Problem StatementsRashef MahbubNo ratings yet

- 3.4.THERMODYNAMICS OF SOLUTIONS - SOME BASIC CONCEPTS - BusmeonDocument5 pages3.4.THERMODYNAMICS OF SOLUTIONS - SOME BASIC CONCEPTS - BusmeonAJ Kent Ray BusmeonNo ratings yet

- Volume FractionDocument2 pagesVolume FractionPavan TejNo ratings yet

- Desalination: Wafa Ali Suwaileh, Daniel James Johnson, Sarper Sarp, Nidal HilalDocument26 pagesDesalination: Wafa Ali Suwaileh, Daniel James Johnson, Sarper Sarp, Nidal HilalAnthony Mamani AtayauriNo ratings yet

- Dr. Nabeel Ahmad: Department of Chemical Engineering COMSATS University Islamabad, Lahore CampusDocument15 pagesDr. Nabeel Ahmad: Department of Chemical Engineering COMSATS University Islamabad, Lahore CampusFurqan AhmedNo ratings yet

- MM 439 - 2021 - Assignment-1 SolutionsDocument10 pagesMM 439 - 2021 - Assignment-1 SolutionsAryan MishraNo ratings yet

- Mole Fraction Volume FractionDocument9 pagesMole Fraction Volume FractionameyckulkarniNo ratings yet

- Bottomholemodaloil PCDocument6 pagesBottomholemodaloil PCKimiko ShopNo ratings yet

- CH Process-CalculationsDocument11 pagesCH Process-CalculationsHrutik NimbalkarNo ratings yet

- Chapter 16Document55 pagesChapter 16Khalil AlluhaybiNo ratings yet

- General Chemistry 2 (Reviewer)Document3 pagesGeneral Chemistry 2 (Reviewer)Jeremie R BacayNo ratings yet

- Lesson 2 ActivitiesDocument1 pageLesson 2 ActivitiesCrisanta GanadoNo ratings yet

- Unit 2 PABE11 Material Balance 1Document37 pagesUnit 2 PABE11 Material Balance 1Germa CandelaNo ratings yet

- 16.2 Concentrations of SolutionsDocument55 pages16.2 Concentrations of SolutionsAlejandro SuazoNo ratings yet

- Experiment 1 Thermodynamics of Mixtures The Determination of Partial Molar EnthalpyDocument4 pagesExperiment 1 Thermodynamics of Mixtures The Determination of Partial Molar EnthalpyJP DM ArcillaNo ratings yet

- HMT IMP Questions NewDocument3 pagesHMT IMP Questions NewRavi PatilNo ratings yet

- Chapter 5 PPTDocument42 pagesChapter 5 PPTSaikumar PNo ratings yet

- By MASSDocument33 pagesBy MASSRich AgustinNo ratings yet

- Group 1 MOLE FRACTIONDocument10 pagesGroup 1 MOLE FRACTIONjeromeespirituNo ratings yet

- Tutorial A1Document2 pagesTutorial A1xffngdgzNo ratings yet