Professional Documents

Culture Documents

Scd. a Project Brief Part 2A

Scd. a Project Brief Part 2A

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageScd. a Project Brief Part 2A

Scd. a Project Brief Part 2A

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

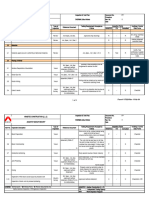

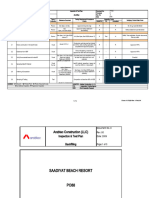

STATE OF QATAR ‘SCHEDULE A: PROJECT BRIEF

ASHGHAL _ PART 2A: SURFACE WATER PROJECT SPECIFIC COMPLIANCES AND

OTHER REQUIREMENTS

e. Drop shaft pipes shall be designed so that a minimum air core of 25% of

the area of the drop shaft pipe is maintained under the peak design flow.

{The Froude number in the approach conduit to the vortex generator shall

be less than 0.6 at the peak design flow.

g. The distance between the vortex generator and any steps, bends,

transitions or other hydraulic obstructions in the approach conduit shall

be greater than 3xB, where B is the width of the approach conduit.

hh. Drop shaft pipes shall be vertical and shall not have any discontinuities.

2. The design of energy dissipation chambers at the base of vortex drop shaft

pipes and backdrop structures shall be in accordance with the following criteria:

a. The height of the end of the drop shaft pipe shail be the greater of 1)

1.5*Dp above the invert of the dissipation chamber, where Dp is the

diameter of the drop shaft pipe, or 2) the soffit level of the tunnel at the

particular shaft location.

b, The drop shaft pipe shall protrude a minimum of 150mm below the roof

of the dissipation chamber at the base of the shaft.

c. The edge of the drop shaft pipe shall be a minimum distance of 0.5xD,

from any wall and shall be positioned to the side of the dissipation

chamber to maximise the dissipation area,

d. An overflow weir of minimum height of 0.3*D; from the dissipation

chamber floor shall be provided to discharge vortex flow, where Di is the

intemal diameter of the outgoing. This weir wall shall have a drainage

opening at its base with benching formed within the dissi

direct drainage of the chamber towards the opening.

€. Provision shall be made to protect the dissipation chamber against

abrasive forces due to the water falling down the drop shaft pipe and

turbulent flow within the chamber.

life for the all access structures, hydraulic structures, pipework and all

civil works shail be eighty (80) years.

B, The minimum design life for orifice plates (minimum 3161) shall be twenty (20) years.

C. Design life is defined as the life for which the structure maintains adequate structural

‘capacity and integrity with sufficient serviceability provided for proper operation of the

system throughout the term.

D. _Allelements of the structures shall be designed to achieve the durability requirements

by:

1. appropriate selection of materials;

2. consideration of the long-term deterioration of materials in their service

‘environment; and

3. due care in design and detailing so as to facilitate ease of construction.

E. Particular consideration shall be given to the durability of elements that cannot be

accessed for inspection, maintenance or repair during normal operations, including

microtunnels, piping, shafts, hydraulic structures, ducting, and all other sub-surface

works, The design solulon for such elements ‘shal use prover technology and

incorporate:

‘PROJEGT ID PA 20106030 FPS Schedule A Pat 2A: Surface Wale Projet Speatic

18 Contract for FRP 2A. AIThumama

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DN001-P02-HYD-HBK-LET-A11567Document6 pagesDN001-P02-HYD-HBK-LET-A11567soorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11724Document4 pagesDN001-P02-HYD-HBK-LET-A11724soorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A12145 Wrapping tape, primerDocument2 pagesDN001-P02-HYD-HBK-LET-A12145 Wrapping tape, primersoorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11550 Duker pipeDocument3 pagesDN001-P02-HYD-HBK-LET-A11550 Duker pipesoorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013-REPLYDocument5 pagesC851-3A-MAT-MAT-CIV-013-REPLYsoorajNo ratings yet

- 1) Geoscience Testing Laboratory ReportsDocument83 pages1) Geoscience Testing Laboratory ReportssoorajNo ratings yet

- MAT-CIV-024 - Grout Material Submittal - fullDocument129 pagesMAT-CIV-024 - Grout Material Submittal - fullsoorajNo ratings yet

- 4) CERAM UK Physical Testing ReportsDocument40 pages4) CERAM UK Physical Testing ReportssoorajNo ratings yet

- 3) Abu Dhabi Municipality Central Laboratory ReportsDocument9 pages3) Abu Dhabi Municipality Central Laboratory ReportssoorajNo ratings yet

- 2) Dubai Central Laboratory ReportsDocument14 pages2) Dubai Central Laboratory ReportssoorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11528 warnuing tapeDocument7 pagesDN001-P02-HYD-HBK-LET-A11528 warnuing tapesoorajNo ratings yet

- Geotechnical Interpretative ReportDocument1,353 pagesGeotechnical Interpretative ReportsoorajNo ratings yet

- BRE Digest 326Document8 pagesBRE Digest 326soorajNo ratings yet

- IJS 2400-3000-HDPE-SSC - 2Document1 pageIJS 2400-3000-HDPE-SSC - 2soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013Document463 pagesC851-3A-MAT-MAT-CIV-013soorajNo ratings yet

- IJS 2400-2888-HDPE-SSC Model (1)Document1 pageIJS 2400-2888-HDPE-SSC Model (1)soorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- IJS 2000-2400-HDPE-SSC Model (1)Document1 pageIJS 2000-2400-HDPE-SSC Model (1)soorajNo ratings yet

- C851 3A MAT MAT CIV 013 Material SubmittalDocument464 pagesC851 3A MAT MAT CIV 013 Material SubmittalsoorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- MAT-CIV-024 - Grout Mix design & Raw material test reportsDocument18 pagesMAT-CIV-024 - Grout Mix design & Raw material test reportssoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142407Document7 pagesItsupport@apbava - Com 20100208 142407soorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142829Document22 pagesItsupport@apbava - Com 20100208 142829soorajNo ratings yet