100% found this document useful (1 vote)

277 views2 pagesPerkins LP5 Pump Test Plan

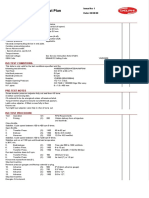

The document provides test procedures and requirements for a Perkins Darwin LP5 fuel pump. It details 23 test operations to check specifications such as priming, stabilization, fuel delivery amounts, back leakage, transfer pressure and governor function across various engine speeds and conditions.

Uploaded by

MilanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

277 views2 pagesPerkins LP5 Pump Test Plan

The document provides test procedures and requirements for a Perkins Darwin LP5 fuel pump. It details 23 test operations to check specifications such as priming, stabilization, fuel delivery amounts, back leakage, transfer pressure and governor function across various engine speeds and conditions.

Uploaded by

MilanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd