2D DRAWING EXPECTATIONS

GENERAL

1. The filename of each 2D DRW shall be the same as the 3D model name and shall be

stored in the same folder as the 3D model file.

2. All Assy’s are expected to be on A3 sheets and all Detail DRWs shall be on either A3

or A4 sheets.

3. Only the Sheet Format you altered in class is to be used in all 2D DRWs. Remember

that there are two different versions, one each for Assy DRWs and one for Detail

DRWs.

SHEET FORMAT

1. This Sheet Format fills itself in from the file properties. The following file properties

are used:

Author

Title

Subject

Creation Date

Appr Date

Appr By

Material

Coating

2. This Sheet Format has the correct CPUT drawing number on it. The index number

part is a drawing number get bigger with each new 2D DRW that you do, and should

be somewhere greater than 10 by now.

ASSY 2D DRAWINGS

1. All Assy DRWs have a DRW No with a “A” before the index number at the end.

2. Assy DRWs may have orthogonal and / or isometric views. Assy’s with internal part

shall have a section view.

3. All Assy DRWs shall have a BoM. Each cell of the BoM shall be filled in.

4. The BoM used must be the Excel version with the correct columns.

5. All Assy DRWs shall have balloons one for each item on the BoM. These must

always be in a straight line.

6. All Assy DRWs shall have three and only three overall dimensions. Remember to

use Shift to click dims on the edges of circles and arcs.

7. All Assy DRWs shall have a note on some assembly instructions e.g. “USE

LOCKTITE 272” and “TIGHTEN ALL BOLTS & NUTS AS PER TORQUE TABLE”.

8. All Assy DRWs do not have UOS tolerance tables.

9. All Assy DRWs shall have a Torque Table.

10. 2 Sheets are required, i.e. COLLAPSED and EXPLODED.

�DETAIL 2D DRAWINGS

1. All Detail DRWs have a DRW No with a “D” before the index number at the end.

2. There are 2 or 3 orthogonal views. Orthogonal views show lines only no shading. All

cylindrical (lathe) parts always only have 2 orthogonal views.

3. There is always a shaded isometric view which may be at a smaller scale it fit it on.

4. All Detail DRWs shall have an UOS tolerance table.

5. All Detail DRWs shall have at least one extra tolerance on a specific dimension which

overrides and tightens the UOS tolerance.

6. All holes which get shafts or bushes in them shall have a Reamer Tolerance i.e. H7.

7. All Detail DRWs shall have a note on some manufacturing instruction e.g. “Deburr All

Sharp Edges”.

8. All Detail DRWs shall have the material & coating specified in the title block

eg. “Material: M/S Round Bar Φ30 x 200 Long” and “Coating: Electro Galvanizing”.

The material specification shall include the shape and size of that material. If a

number of different pieces of material are to be used then a cutting list in the form of

a table must be given.

9. If a part has any machining on it then machining symbols must be given, this is not

optional. A lathe part will have at least one overall machining symbol on it.

10. All welded frames are considered single parts and NOT ASSEMBLIES. These

welded parts shall be populated liberally with welding symbols.

11. Each Detail DRW shall specify the manufacturing process to be used to make the

part. This is also not optional. Suggestion: Use machining symbols with the process

name on then for all machined parts.

12. Expect to see at least one Geometric Tolerance.

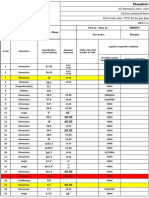

UOS TOLERANCE TABLE

SIZE <1 1 - 100 100 – 1000 > 1000

TOLERANCE ±0.05 ±0.5 ±1 ±2