0% found this document useful (0 votes)

101 views6 pagesLine Breaking Procedure

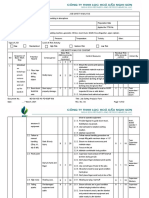

The Line Breaking Procedure at Axiall Corporation aims to protect employees from injuries due to the unexpected release of hazardous materials during the opening or disconnecting of process piping or equipment. It outlines the responsibilities of equipment owners, supervisors, and employees, including the need for visual verification, personal protective equipment (PPE) requirements, and specific safety measures to be taken during line breaking activities. Training requirements and administrative controls for PPE are also detailed to ensure safety compliance.

Uploaded by

Prophet Yves Oscar EliasCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

101 views6 pagesLine Breaking Procedure

The Line Breaking Procedure at Axiall Corporation aims to protect employees from injuries due to the unexpected release of hazardous materials during the opening or disconnecting of process piping or equipment. It outlines the responsibilities of equipment owners, supervisors, and employees, including the need for visual verification, personal protective equipment (PPE) requirements, and specific safety measures to be taken during line breaking activities. Training requirements and administrative controls for PPE are also detailed to ensure safety compliance.

Uploaded by

Prophet Yves Oscar EliasCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd