Professional Documents

Culture Documents

ALLOY CONSERVATION THROUGH PRECIPITATION STRENGTHENING

Uploaded by

amit gajbhiyeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALLOY CONSERVATION THROUGH PRECIPITATION STRENGTHENING

Uploaded by

amit gajbhiyeCopyright:

Available Formats

W –ABS-131

ALLOY CONSERVATION THROUGH PRECIPITATION

STRENGTHENING BY MICROALLOY ADDITION IN STEEL

FOR AUTOMOTIVE APPLICATION

Niranjan More, Sunil Nair & K R Srinivasan

Mukand Ltd, Mumbai

Abstract :

The effectiveness of enhancing metallurgical features through microalloying practice using Vanadium, Niobium or Titanium is by now established universally, with

Vanadium topping the list. It has been possible to obtain a good combination of strength, ductility and machinability characteristics through careful microalloying

percentages. The precipitation mechanism of Vanadium as a microalloying constituent for achieving the desired mechanical properties has been outlined in this paper.

With control on base microstructure through optimized chemistry and hot working temperature, it was established by industrial research trials that the Microalloy

technique could replace some of the conventional alloy steel grades, thus leading to alloy conservation. Typical properties obtained and their applications have been

outlined for two microalloyed grades, with Vanadium as the principal microalloying constituent. There is a huge potential for use of these grades in different

applications, replacing the conventional alloy grades.

1.0 INTRODUCTION 3.0 RESULTS 4.0 BENEFITS

The industrial experience gained in developing two microalloyed steel MICROSTRUCTURE OF HOT ROLLED BAR RELATED TO PROCESS STEP REDUCTION BY USE

grades, 38MnVS6 and 27MnSiVS6 for autocomponent application is COOLING OF MICROALLOYED STEEL

described in this presentation.

7 step

The strength of microalloyed steels is obtained through precipitation Coarse Fine

process; 4

heating & 3

Microstructure Microstructure

of microalloy constituents such as carbides and nitrides in the matrix shaping

microstructure of ferrite and pearlite.

Vanadium is preferable as a microalloy addition because of its

solubility at normal hot working temperatures.

Scope exists for using this steel for auto component applications such

as connecting rods, crankshafts, power steering rack bar and shaft

applications. 3 step

1000°C Still Air Cooled 1000°C Forced Air Cooled process; 1

heating &

2.0 STUDY CARRIED OUT MECHANICAL PROPERTIES RELATED TO HOT WORKING

TEMPERATURE AND COOLING CONDITION

2 shaping

Solubility limits of Vanadium & Nitrogen Effect of hot working temperature on Hardness Effect of hot working temperature on Hardness

& Tensile strength of 38MnVS6

at various austenitising temperatures 285 940

& Tensile strength of 27MnSiVS6

265 900

38MnVS6 280

920

Tensile strength (Mpa)

27MnSiVS6 255 860

APPLICATION BASED DEVELOPMENT OF

Hardness (BHN)

275

Tensile Strength (Mpa)

Hardness (BHN)

Microalloyed Steels 900

270 245 820 MICROALLOYED STEEL GRADES

880

265 TYPE STRENGTHENING GRADE APPLICATIONS

235 780

860 MECHANISM COMPOSITION

1200°C 260

225 740 Basic Precipitation of Medium C Connecting Rod

840

255 Vanadium micro alloyed Crank Shaft

1100°C Carbide steel

250 820 215 700 Wheel Hub

1000°C 1100°C 1200°C 1000°C 1100°C 1200°C Improved Intensify Microalloyed Front Axle

Temperature Temperature Toughness precipitation of steel with lower Steering

Normalising Forced Air Cooled Hardness Still Air Cooled Tensile strength Still Air Cooled Hardness Forced Air Cooled Hardness V compounds C, and small Knuckle

38MnVS6, 27MnSiVS6 Forced Air Cooled Tensile Strength Still Air cooled Hardness Still Air Cooled tensile strength Forced Air Cooled Tensile strength

Lower Carbon addition of Cr Rear hub

Still Air & Forced Air Cooled support

EXAMPLES OF REPLACEMENT OF CONVENTIONAL QUENCH Connecting Rod

AND TEMPERED ALLOY STEELS WITH MICROALLOY GRADES High Lower Carbon Low Carbon Knuckle Spindle

FOR AUTOCOMPONENT APPLICATION Toughness Forms Direct

High Martensite / quenching

Strength Banite

1000°C 1200°C

From the above curve it is possible to

determine the hot working temperature

1100°C

5.0 CONCLUSIONS 20µ

for a given concentration of Vanadium

and Nitrogen. In the heat manufactured 1. Microalloyed steels are finding greater

by us Vanadium level was kept at 0.15% Resulting properties studied: acceptance in the autocomponent

and Nitrogen at 0.015%. From the above Microstructure properties industry due to its cost effectiveness w.r.t

Hardenability

graph the hot rolling temperature was to processing and alloy composition.

Tensile Properties

decided at 1220 deg C. This temperature Hardness, BHN

2. With proper hot working temperature

ensured that the austenite was Vanadium goes completely into solution

homogeneous prior to hot working. and precipitates uniformly as V(C,N) or

VN particles giving maximum strength in

the direct cooled post forged component.

CHEMICAL COMPOSITION: 3. Mechanical properties obtained in as

forged condition are equivalent to the

Grade Type %C %Si %Mn %P %S %Cr %Mo %V %Ti %Al

N2 conventional Quench & Tempered alloy

(ppm) Rack Bar 27MnSiVS6 steel grades made of costly alloying

Microalloyed elements like Mo and Cr. Therefore ,

38MnVS6 0.38 0.59 1.26 0.013 0.034 0.13 0.007 0.155 0.015 0.015 158

Steel 1200°C Fan Cooled considerable alloy conservation could be

38MnVS6

Conventional obtained with the use of Microalloy steel

42Cr4Mo2 0.42 0.22 0.75 0.025 0.023 1.05 0.22 - - 0.025

Alloy Steel

technology.

Microalloyed

27MnSiVS6 0.27 0.60 1.48 0.020 0.034 0.17 0.007 0.11 0.014 0.015 178

Steel 4. It is recommended that the hot rolling

Conventional temperature be maintained as per

41Cr4 0.43 0.22 0.85 0.020 0.020 1.15 - - - 0.022

Alloy Steel

solubility curves. It is preferable to have

forced air cooling to obtain relatively

MECHANICAL PROPERTIES: finer grain size and better mechanical

properties.

Designation 0.2% Proof UTS Elongation Post forging heat treatment

stress ( MPa ) ( MPa ) (%) Air Cooled Quench & Temper 5. 38MnVS6 achieved very good results in

42CrMo4 680 min 850 - 1000 13 Pulsation test as reported by our

customer.

38MnVS6 580 min 850 - 1000 12

(C38mod ) 6. Studies related to microstructure and

mechanical properties of higher

41Cr4 560 min 850 -1000 12 Axle shaft Vanadium and Nitrogen grades are being

27MnSiVS6 450 min 700 – 900 14 38MnVS6 44MnVS6

carried out.

You might also like

- NMD-ATM-2009 - Microalloy - FinalDocument1 pageNMD-ATM-2009 - Microalloy - Finalniranjan1483No ratings yet

- Top View: 300 1000 1000 150 300 0.25 0.5 1.0 1.0 2.5 1.5 Nominal Size 0.1 Fabrication MachiningDocument2 pagesTop View: 300 1000 1000 150 300 0.25 0.5 1.0 1.0 2.5 1.5 Nominal Size 0.1 Fabrication MachiningPunky IrlanditoNo ratings yet

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinNo ratings yet

- Elucidation of The Microstructure of Carboncarbon Composites by Raman MicrosDocument2 pagesElucidation of The Microstructure of Carboncarbon Composites by Raman MicrosMuhammad IkramullahNo ratings yet

- Chemical Engineering Buyers Guide 2018 - Liquid, Gas and Air HandlingDocument40 pagesChemical Engineering Buyers Guide 2018 - Liquid, Gas and Air HandlingLabnes100% (1)

- Datta 2018Document9 pagesDatta 2018Sullivam PrestesNo ratings yet

- Flir 617 DrawingsDocument11 pagesFlir 617 DrawingsfernandopfrancaNo ratings yet

- NGR Sizing 11kVDocument4 pagesNGR Sizing 11kVSantoshNo ratings yet

- MetmachthreadDocument3 pagesMetmachthreadPatrick - Assist. Técnica - CetemNo ratings yet

- LKM Steel Rainbow Chart 2014 UpmoldDocument1 pageLKM Steel Rainbow Chart 2014 UpmoldsrinivasaNo ratings yet

- Conveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationDocument27 pagesConveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationARAVINDRAJ V RNo ratings yet

- Yei%-P7: Bitumen-Mastic For Flooring - Specification (Third Revision)Document14 pagesYei%-P7: Bitumen-Mastic For Flooring - Specification (Third Revision)Amanulla KhanNo ratings yet

- Close Coupled Vertical In-Line Pumps: Series 4360 & 4380Document4 pagesClose Coupled Vertical In-Line Pumps: Series 4360 & 4380jrodNo ratings yet

- Optolink Fibre Optic ConnectorDocument2 pagesOptolink Fibre Optic ConnectorquanNo ratings yet

- Aerospace Material SpecificationDocument5 pagesAerospace Material SpecificationMohammad LavasaniNo ratings yet

- Xxvii No 26Document1 pageXxvii No 26Camilo Andrés Vargas JiménezNo ratings yet

- WP 7089 CH 28Document13 pagesWP 7089 CH 28Ramin ShojaNo ratings yet

- Section ProjectDocument2 pagesSection Projectapi-592003671No ratings yet

- Semco Fdc-EDocument2 pagesSemco Fdc-EmlambertucciNo ratings yet

- Screw Jacks O M ManualsDocument6 pagesScrew Jacks O M ManualsMohammed RawashdehNo ratings yet

- 8mm roof insulation with aluminum foil radiant barrierDocument1 page8mm roof insulation with aluminum foil radiant barrierglen raymundoNo ratings yet

- JAM003MQN400 pulley specificationsDocument1 pageJAM003MQN400 pulley specificationsSebastian Davila hernandezNo ratings yet

- Semco Fdc-EDocument2 pagesSemco Fdc-EJorge Ortiz OrdinolaNo ratings yet

- Production Engineering by SKMondal 12 PDFDocument201 pagesProduction Engineering by SKMondal 12 PDFJosh ManoharNo ratings yet

- Latest Technologies For Surge Arresters: 1 PrefaceDocument4 pagesLatest Technologies For Surge Arresters: 1 PrefaceLalNo ratings yet

- Fiber Optic CablesDocument24 pagesFiber Optic CablesARCC2030No ratings yet

- Material Product Data Sheet Nickel - Aluminum Materials: Quick FactsDocument6 pagesMaterial Product Data Sheet Nickel - Aluminum Materials: Quick FactsSerkan ÖzcanNo ratings yet

- Extruder Times 7Document12 pagesExtruder Times 7skimmer05No ratings yet

- Since 1975, Kyocera provides cutting-edge solar modulesDocument2 pagesSince 1975, Kyocera provides cutting-edge solar moduleswalter_lopezvNo ratings yet

- Metal Powder TechnologyDocument8 pagesMetal Powder TechnologyVenkateswaran Krishnamurthy100% (1)

- MMT Ed2 01 PC FX 0002 - 0Document1 pageMMT Ed2 01 PC FX 0002 - 0Thalles ResendeNo ratings yet

- Page 2Document1 pagePage 2Paul BasillaNo ratings yet

- MIT3 091SCF09 Lec2 PDFDocument32 pagesMIT3 091SCF09 Lec2 PDFJesús MartínezNo ratings yet

- LGMMA Acrylic Coating Resin Brochure 2017 EDocument2 pagesLGMMA Acrylic Coating Resin Brochure 2017 EFausa Okta Ananta LaksaNo ratings yet

- Reaffirmed 2004Document11 pagesReaffirmed 2004krixotNo ratings yet

- Recent Studies on Particulate Reinforced AZ91 Magnesium Composites Fabricated by Stir CastingDocument13 pagesRecent Studies on Particulate Reinforced AZ91 Magnesium Composites Fabricated by Stir CastingajskfdhasknNo ratings yet

- View Tender Drawings Volume-IVDocument22 pagesView Tender Drawings Volume-IVAnfal BarbhuiyaNo ratings yet

- Aa 326-EnDocument3 pagesAa 326-EnmorashidNo ratings yet

- Butadiene Unit 101 - ModelDocument5 pagesButadiene Unit 101 - ModelWaleed EL-sheshtawyNo ratings yet

- BS5400!5!1979-Code of Practice for Design of Composite BridgesDocument40 pagesBS5400!5!1979-Code of Practice for Design of Composite BridgesUKPENWU OLOCHENo ratings yet

- Direct Chill Aluminum Casting Without Homogenization Using HT-EMS TechnologyDocument4 pagesDirect Chill Aluminum Casting Without Homogenization Using HT-EMS TechnologyRaj Kumar GiriNo ratings yet

- Corrosion prevention through hot dip galvanizingDocument1 pageCorrosion prevention through hot dip galvanizingEng-Ahmed AllamNo ratings yet

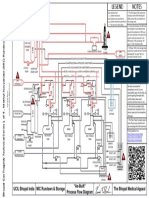

- MIC Rundown & Storage "As-Built" Process Flow Diagram The Bhopal Medical Appeal UCIL Bhopal IndiaDocument1 pageMIC Rundown & Storage "As-Built" Process Flow Diagram The Bhopal Medical Appeal UCIL Bhopal IndiapstindiaNo ratings yet

- Roll Breakage DetectionDocument7 pagesRoll Breakage DetectionZubair AhmadNo ratings yet

- Stabilization of retained austenite in AISI D2 tool steelDocument1 pageStabilization of retained austenite in AISI D2 tool steelEdward Giovanni Rodriguez AriasNo ratings yet

- Polycrystalline Solar Modules: KK-SERIES: KK270P-3CD8CGDocument2 pagesPolycrystalline Solar Modules: KK-SERIES: KK270P-3CD8CGTiago MottaNo ratings yet

- Minera ODT OilType CommercialBrochure EN PDFDocument2 pagesMinera ODT OilType CommercialBrochure EN PDFVladimir ĐorđevićNo ratings yet

- Analysis of Pulsar 150cc Piston by Material Optimization: Aakash Dorga, Prakhar Singh, Mayank Kumar AgrawalDocument6 pagesAnalysis of Pulsar 150cc Piston by Material Optimization: Aakash Dorga, Prakhar Singh, Mayank Kumar AgrawalAakash DograNo ratings yet

- Repair of A Steam Turbine in Thailand Using Pulsed Laser Beam WeldingDocument3 pagesRepair of A Steam Turbine in Thailand Using Pulsed Laser Beam WeldingfendynovapamelaNo ratings yet

- Boron FiberDocument2 pagesBoron FiberVikranth DeepakNo ratings yet

- Study of Salt Spray Corrosion On Powdermetallurgymade Aluminummetal Matrix CompositesDocument3 pagesStudy of Salt Spray Corrosion On Powdermetallurgymade Aluminummetal Matrix Compositesmechanical mahathammaNo ratings yet

- WH2 GaDocument5 pagesWH2 GaRaveendra Babu CherukuriNo ratings yet

- $RR87KV7Document1 page$RR87KV7SalauddinAnsariNo ratings yet

- Aluminium Foam Investigation for Automotive ApplicationsDocument58 pagesAluminium Foam Investigation for Automotive ApplicationsAnish HariharanNo ratings yet

- Ficha Tecnica Cobre Pure CopperDocument4 pagesFicha Tecnica Cobre Pure CopperANDRES DOMINGUEZNo ratings yet

- Fiber reinforcement technical specificationsDocument6 pagesFiber reinforcement technical specificationsTheLady InblackNo ratings yet

- Msa 2022060115090222Document16 pagesMsa 2022060115090222Hany KhalifaNo ratings yet

- Molecular Beam Epitaxy: Materials and Applications for Electronics and OptoelectronicsFrom EverandMolecular Beam Epitaxy: Materials and Applications for Electronics and OptoelectronicsHajime AsahiNo ratings yet

- Metal Powders: A Global Survey of Production, Applications and MarketsFrom EverandMetal Powders: A Global Survey of Production, Applications and MarketsNo ratings yet

- AC7102 - Rev - K - For - Use - On - Audits - On - or - After - 15-Aug-2021 (Main Induction Furnace) AUDIT SHEET 42CRMO4Document111 pagesAC7102 - Rev - K - For - Use - On - Audits - On - or - After - 15-Aug-2021 (Main Induction Furnace) AUDIT SHEET 42CRMO4amit gajbhiyeNo ratings yet

- WI For Macro Streak Flaw Test - TkapDocument8 pagesWI For Macro Streak Flaw Test - Tkapamit gajbhiyeNo ratings yet

- WI For Inclusion Rating - TkapDocument10 pagesWI For Inclusion Rating - Tkapamit gajbhiyeNo ratings yet

- 01EN Rev E DELTA Family Quick Start InternationalDocument26 pages01EN Rev E DELTA Family Quick Start Internationalamit gajbhiyeNo ratings yet

- Sep 1314-1990Document1 pageSep 1314-1990amit gajbhiyeNo ratings yet

- Geoff B Associates: Technical Note - Foaming Slag PracticeDocument1 pageGeoff B Associates: Technical Note - Foaming Slag Practiceamit gajbhiyeNo ratings yet

- Billet Defects: Off-Corner Formation, Prevention and EvolutionDocument15 pagesBillet Defects: Off-Corner Formation, Prevention and Evolutionamit gajbhiyeNo ratings yet

- Daido KogyoDocument11 pagesDaido Kogyoamit gajbhiyeNo ratings yet

- Customer Complaint Handling Procedure Flow DiagramDocument1 pageCustomer Complaint Handling Procedure Flow Diagramamit gajbhiyeNo ratings yet

- Astm A255Document26 pagesAstm A255amit gajbhiye100% (1)

- Sunflag Iron's Guide to Continuous Casting DefectsDocument30 pagesSunflag Iron's Guide to Continuous Casting Defectsamit gajbhiye100% (1)

- Computerized Properties Prediction in Heat Treatment of Low Alloy Steels B.Radhakrishnan, Bharat Forge LimitedDocument17 pagesComputerized Properties Prediction in Heat Treatment of Low Alloy Steels B.Radhakrishnan, Bharat Forge Limitedamit gajbhiyeNo ratings yet

- ROLLED PRODUCT DEFECTS AND REMEDIESDocument32 pagesROLLED PRODUCT DEFECTS AND REMEDIESamit gajbhiye100% (2)

- Congratulations On The Bonus Accrued!: Gajbhiye AmitkumarDocument2 pagesCongratulations On The Bonus Accrued!: Gajbhiye Amitkumaramit gajbhiyeNo ratings yet

- HDFC Life bonus update for policy no. 15906510Document2 pagesHDFC Life bonus update for policy no. 15906510amit gajbhiyeNo ratings yet

- Continuous Casting Defects Causes and SolutionsDocument32 pagesContinuous Casting Defects Causes and Solutionsamit gajbhiyeNo ratings yet

- Astm - E83Document14 pagesAstm - E83amit gajbhiyeNo ratings yet

- Development of High Strength SteelDocument26 pagesDevelopment of High Strength Steelamit gajbhiyeNo ratings yet

- Sheet Metal Forming: Formability & Forming LimitsDocument53 pagesSheet Metal Forming: Formability & Forming Limitsamit gajbhiyeNo ratings yet

- MSrinivas - STEELS FOR CRITICAL APPLICATIONSDocument46 pagesMSrinivas - STEELS FOR CRITICAL APPLICATIONSamit gajbhiye100% (1)

- Din Data 405 PDFDocument644 pagesDin Data 405 PDFamit gajbhiyeNo ratings yet

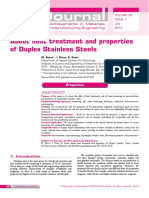

- Copyrighted Material Licensed for Limited UseDocument13 pagesCopyrighted Material Licensed for Limited UseSarvesh Mishra50% (2)

- Recent Developments in P Electric Steel Making: ET Academy of Excellence For EmpowermentDocument36 pagesRecent Developments in P Electric Steel Making: ET Academy of Excellence For Empowermentamit gajbhiyeNo ratings yet

- Electro Slag Refining: N.B. BallalDocument34 pagesElectro Slag Refining: N.B. Ballalamit gajbhiyeNo ratings yet

- Din Data 405 PDFDocument644 pagesDin Data 405 PDFamit gajbhiyeNo ratings yet

- Din Data 405 PDFDocument644 pagesDin Data 405 PDFamit gajbhiyeNo ratings yet

- Din Data 401 PDFDocument524 pagesDin Data 401 PDFamit gajbhiye100% (2)

- Duplex SteelDocument11 pagesDuplex SteelCinitha ANo ratings yet

- Din Data 401 PDFDocument524 pagesDin Data 401 PDFamit gajbhiye100% (2)

- Effects of Heat Control On The Stress Build Up During High-Strength Steel Welding Under Defined Restraint ConditionsDocument8 pagesEffects of Heat Control On The Stress Build Up During High-Strength Steel Welding Under Defined Restraint ConditionsBHARANINo ratings yet

- GasCalc Module enDocument2 pagesGasCalc Module ensppramNo ratings yet

- Liquid Pipeline HydraulicsDocument74 pagesLiquid Pipeline HydraulicsSimon Kapoma100% (1)

- Self-Supported Steel Chimney Analysis As Per Indian StandardDocument6 pagesSelf-Supported Steel Chimney Analysis As Per Indian StandardndrarlyNo ratings yet

- Fluid KinematicsDocument49 pagesFluid KinematicsJM Jusay CarabLeNo ratings yet

- Syllabus 671Document1 pageSyllabus 671ilexmollyNo ratings yet

- Bolt FEADocument18 pagesBolt FEADattaNo ratings yet

- Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesCopper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsGreg YeeNo ratings yet

- Aao 2 Clinical OpticDocument4 pagesAao 2 Clinical Opticria mutiaraNo ratings yet

- Roof design and reinforcement detailingDocument30 pagesRoof design and reinforcement detailingJohn Paul Hilary EspejoNo ratings yet

- Stress AnalysisDocument60 pagesStress AnalysisTejas DesaiNo ratings yet

- Stainless Steel Spring Wire: Standard Specification ForDocument7 pagesStainless Steel Spring Wire: Standard Specification FormanojNo ratings yet

- 6 - Pressuremeter PDFDocument71 pages6 - Pressuremeter PDFjenvarmatNo ratings yet

- 300+ TOP STRENGTH of Materials Multiple Choice Questions and AnswersDocument36 pages300+ TOP STRENGTH of Materials Multiple Choice Questions and AnswersM/S Sew Infrastructure Ltd100% (1)

- Van Deemter EquationDocument19 pagesVan Deemter EquationAsif AliNo ratings yet

- Rapid Detection of Milk Constituents Using Chromatography, Spectroscopy, Dielectric Properties and SensorsDocument12 pagesRapid Detection of Milk Constituents Using Chromatography, Spectroscopy, Dielectric Properties and SensorsNihal AhmadNo ratings yet

- Physics II Dec 2002Document2 pagesPhysics II Dec 2002api-3782519No ratings yet

- Improved Aluminium Alloy Properties from Boron Grain RefinementDocument4 pagesImproved Aluminium Alloy Properties from Boron Grain RefinementAsdrubal Antonio Gonzalez DiazNo ratings yet

- Bonded Repair of Aircraft Composite Sandwich StructuresDocument121 pagesBonded Repair of Aircraft Composite Sandwich StructuresDKARAG100% (3)

- Inflow & Outflow Performance Archives - Production TechnologyDocument7 pagesInflow & Outflow Performance Archives - Production Technologywinarnob100% (2)

- Jurnal Nano3 PDFDocument5 pagesJurnal Nano3 PDFamaliaNo ratings yet

- Cladding Metals 2 - Non-Ferrous Metals: AluminiumDocument7 pagesCladding Metals 2 - Non-Ferrous Metals: Aluminiumpaulo_linanNo ratings yet

- June 2013 QP - Unit 2 Edexcel PhysicsDocument26 pagesJune 2013 QP - Unit 2 Edexcel PhysicsnaamashirNo ratings yet

- DocxDocument9 pagesDocxjamsheed sajidNo ratings yet

- The Earth's InteriorDocument46 pagesThe Earth's InteriorThumbNo ratings yet

- Electron Beam LithographyDocument15 pagesElectron Beam LithographyRizwan YusoffNo ratings yet

- DSE Section 1 Planet Earth (Eng)Document25 pagesDSE Section 1 Planet Earth (Eng)(4C27) Wong Ching Tung, Zoey 20181D043spss.hkNo ratings yet

- NCERT Class 12 Chemistry Surface Chemistry QuestionsDocument14 pagesNCERT Class 12 Chemistry Surface Chemistry QuestionsKapoor SaabNo ratings yet

- 3 - The Role of Oxygen-Permeable Ionomer For Polymer Electrolyte Fuel CellsDocument9 pages3 - The Role of Oxygen-Permeable Ionomer For Polymer Electrolyte Fuel CellsFaseeh KKNo ratings yet

- Metrology Unit 3 PPT 3Document34 pagesMetrology Unit 3 PPT 3Punith RajNo ratings yet