Professional Documents

Culture Documents

Emission Control Sensors Guide

Uploaded by

Ankur Sachdeva0 ratings0% found this document useful (0 votes)

55 views42 pagesThe document discusses various sensors used in modern vehicle emission control systems. It describes the purpose and function of knock, lambda, camshaft position, crankshaft position, and exhaust gas temperature sensors. The knock sensor detects engine knocking and provides feedback to optimize ignition timing. The lambda sensor measures oxygen levels in the exhaust to maintain the optimal air-fuel ratio for clean emissions. The camshaft and crankshaft position sensors allow the engine control unit to synchronize fuel injection and ignition timing based on piston position. The exhaust gas temperature sensor monitors catalytic converter temperature during operation. Together these sensors help precisely control engine performance and reduce emissions.

Original Description:

Original Title

Emission Control Sensors.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses various sensors used in modern vehicle emission control systems. It describes the purpose and function of knock, lambda, camshaft position, crankshaft position, and exhaust gas temperature sensors. The knock sensor detects engine knocking and provides feedback to optimize ignition timing. The lambda sensor measures oxygen levels in the exhaust to maintain the optimal air-fuel ratio for clean emissions. The camshaft and crankshaft position sensors allow the engine control unit to synchronize fuel injection and ignition timing based on piston position. The exhaust gas temperature sensor monitors catalytic converter temperature during operation. Together these sensors help precisely control engine performance and reduce emissions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

55 views42 pagesEmission Control Sensors Guide

Uploaded by

Ankur SachdevaThe document discusses various sensors used in modern vehicle emission control systems. It describes the purpose and function of knock, lambda, camshaft position, crankshaft position, and exhaust gas temperature sensors. The knock sensor detects engine knocking and provides feedback to optimize ignition timing. The lambda sensor measures oxygen levels in the exhaust to maintain the optimal air-fuel ratio for clean emissions. The camshaft and crankshaft position sensors allow the engine control unit to synchronize fuel injection and ignition timing based on piston position. The exhaust gas temperature sensor monitors catalytic converter temperature during operation. Together these sensors help precisely control engine performance and reduce emissions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 42

UNIT-6:

Emission Control Sensors

Knock Sensor

Lambda Sensor

Camshaft position Sensor Crankshaft position Sensor

What Are Sensors

• A sensor is an electronic component, module,

or subsystem whose purpose is to detect

events or changes in its environment and send

the information to other electronics,

frequently a computer processor.

• A sensor is always used with other electronics,

whether as simple as a light or as complex as a

computer.

Need of Various Sensors

• Today's computerized engine control systems

rely on inputs from a variety of sensors to

regulate engine performance, emissions and

other important functions.

• The sensors must provide accurate

information otherwise driveability problems,

increased fuel consumption and emission

failures can result.

Sensors in Modern Vehicle

• Knock Sensor

• Oxygen Sensor

• Exhaust Gas Temperature Sensor

• Camshaft Position Sensor

• Crankshaft Position Sensor

• Water Sensor

Why Knock Sensor is required

Purpose of knock sensor

• The main purpose of a knock sensor is to

reduce the ignition system to inhibit any

damage to the engine.

• Knocks to an engine can be caused by a

number of reasons including overheating of

the engine and poor fuel quality.

• As mentioned previously, ignition timing is

manipulated by a knock sensor.

Knock Sensor

• The ignition system to a vehicle is controlled by a computer that

determines whether the engine timing is likely to cause a knock or

detonation.

• During combustion, if there is a knock, the computer connected to

ignition system will need to limit the spark advance to prevent

detonation from occurring. Every vehicle is fixed with a knock

sensor in order for the control unit to the ignition system to

anticipate a knock or detonation.

• Any knock to an engine manifests as a small vibration that is

detected by the knock sensor. This sensor works by changing the

vibration to an electrical signal, which is then transmitted to the

computer controlling the ignition system where the change in

vibration to this voltage signal alters the timing adjustments on the

ignition.

Construction & Working Principle

• The knock sensor is made up of a piezoelectric element. A

working principle to piezoelectric elements involves the

transmission of an electrical current in response to detecting

a change in pressure or vibration by these elements.

• The piezoelectric element inside the knock sensor is tuned to

detect the engine knock/detonation frequency.

• The knock sensor is made up of piezocrystals (piezoelectric

elements), a shunt resistor and a thread at one end of the

knock sensor which allows for the device to be threaded into

the block near the pistons.

Piezoelectric Knock Sensor

Working of Knock Sensor

• During combustion, a knock in the combustion chamber

sends a vibration to the silicone rings attached to the

piezoelectric crystals in the knock sensor (in the form of

mechanical stress), accelerating the silicon ring, forcing this

sensor to generate an electrical voltage and a pressure wave

through the cylinder block. Voltage output from the knock

sensor will be high during a knock to the ignition system.

• A typical voltage signal generated by the knock sensor can

range between 300 millivolts to approximately 500

millivolts; however, this will depend purely on the intensity

of the knock during combustion.

Acoustic Type Knock Sensor

• The device is a small microphone positioned

against a cylinder block and detects vibrations

during the running of an engine.

• Detection of vibrations from a microphone is

followed by an electrical signal to an engine

control unit (ECU) to prepare the unit for a

knock during combustion

Magnetostriction Type Knock Sensor

Oxygen Sensor

Types of EGO Sensors

ZrO2 EGO Sensor

ZrO2 EGO Sensor

EGO Sensor

EGO Sensors

Operation Mode of EGO

Heated EGO Sensors

What is EGTS ?

• The exhaust gas temperature

sensor (EGTS), which is located

in front of the Diesel Oxidation

Catalyst (DOC) and/or in front

of the Diesel Particulate Filter

(DPF), detects exhaust gas

temperature and converts it

into a voltage and feeds back

to the engine ECU with the

voltage signal in order to

control engine conditions to

effectively reduce emission.

Characteristics of EGTS

Working of EGTS

• The sensing part, which is

inserted into the exhaust

pipe with the thermistor, has

a single tube structure rather

than a double tube structure

of conventional exhaust gas

temperature sensors.

• This achieves a more than 90

percent size reduction in

volume compared to

conventional exhaust gas

temperature sensors.

Working of EGTS

• With the improved temperature

detection performance of EGTS,

post injection control and

particulate matter loaded

amount estimation is enabled in

DPF regeneration control,

resulting in cleaner emissions, as

well as increased fuel efficiency

due to less fuel required in the

DPF regeneration process.

• In addition, catalyst deterioration

and over heat protection is

ensured in catalyst control.

Crankshaft Position Sensor

Crankshaft Position Sensor

Crankshaft Position Sensor

Crankshaft Position Sensor

Hall Effect Position Sensor

Hall Effect

Hall Effect

Camshaft Position Sensor

Functions of

Camshaft Position Sensor

• To determine which cylinder is in its power stroke, while the

car's computer (for example) monitors the rotating position of

the camshaft which is relative to the crankshaft position using a

camshaft position (CMP) sensor. It will use this information to

adjust the spark timing and the operation of the fuel injectors.

• The CAM sensor or camshaft position sensor's role is to signal

the ECM the camshaft position. The crank and cam sensor

operates in sync with each other. The CAM sensor is frequently

used in determining which injector to fire in a sequential

system and for the COP or coil on-plug ignition systems coil

firing event.

Camshaft Position Sensor

Camshaft Position Sensor

• The task of the camshaft sensor is to work with the

crankshaft sensor to define the exact position of the

crankshaft drive. Through the combination of both

sensor signals, the engine control unit knows when

the first cylinder is in the top dead point.

• This information is needed for three purposes:

– For the start of injection during sequential injection.

– For the actuation signal of the solenoid valve for the

pump-nozzle injection system.

– For cylinder-selective knocking control.

Camshaft Position Sensor

• The camshaft sensor works according to the

Hall principle.

• It scans a ring gear on the camshaft.

• The rotation of the ring gear changes the Hall

voltage of the Hall IC in the sensor head.

• This change in voltage is transmitted to the

control unit and evaluated there in order to

establish the required data.

Types of Camshaft Sensors

• In accordance to its production design there

are three different types of sensors:

• Inductive

• Hall Effect

• AC output

Inductive Type Camshaft Ensor

• The induction phase sensor may be located

inside the distributor or on the camshaft.

• Therefore near the camshaft a device with

permanent magnet is mounted.

• Every time the magnet passes through the

sensor, its magnetic field is changed and the

resulting pulse is sent to the onboard controller

for processing.

Hall Effect Type Camshaft sensor

• Hall Effect sensor may be located inside the distributor or

on the camshaft.

• Screen with a slot and magnet is mounted on the shaft.

When the screen goes between the magnet and the hall

sensor, sensor is turned on and off.

• While a slot is in front of the sensor, a voltage returns to

the amplifier through a third signal cable.

• As long as in front of the sensor is a solid sector of the

screen, the feedback voltage is interrupted, because the

magnetic field is deviated.

AC Output Type Camshaft Sensor

• AC output sensor is different from the others in that

the output is an AC voltage signal.

• The onboard controller generates very high frequency

(between 150 and 2500 cycles per second) to the

exciter coil, which is located near the rotating disc.

• This disc is mounted at the end of the camshaft and

there is a slot in it.

• When the slot passes the coil, it is excited by the

mutual inductance and a signal indicating the position

of the first cylinder is sent to the onboard controller..

Water Sensor

You might also like

- Don't Be an Arc Welder - Always Disconnect Battery Ground Before Working on StarterDocument63 pagesDon't Be an Arc Welder - Always Disconnect Battery Ground Before Working on Starterwreathbearer100% (1)

- Automatic Transmission ComponentsDocument12 pagesAutomatic Transmission ComponentsRizqy Fadry LazimNo ratings yet

- Automobile BasicsDocument156 pagesAutomobile Basicsrembrandt mostolesNo ratings yet

- I C EngineDocument73 pagesI C EngineHarshit AgarwalNo ratings yet

- Fuel Trim and Misfire Analysis Y: A "No Excuse" Approach PPDocument243 pagesFuel Trim and Misfire Analysis Y: A "No Excuse" Approach PPSalah Edeen Al-Ardah100% (1)

- Automotive Ignition SystemDocument8 pagesAutomotive Ignition SystemA A.DevanandhNo ratings yet

- Electronic Control of Automobiles: K.Niharika V.SindhuDocument61 pagesElectronic Control of Automobiles: K.Niharika V.SindhuNiharika KolliNo ratings yet

- 8.0 Brake by Wire Ja505Document16 pages8.0 Brake by Wire Ja505Nareesh RajNo ratings yet

- Ch-10-Steering and Front AxleDocument45 pagesCh-10-Steering and Front Axlekeval patel100% (2)

- Engine TerminologyDocument13 pagesEngine Terminologyhotbuddy723No ratings yet

- Starting and Charging SystemDocument21 pagesStarting and Charging SystemAllen Castor100% (1)

- Automotive Transmission: Be Skilled Be SmartDocument55 pagesAutomotive Transmission: Be Skilled Be SmartgvnagamaniNo ratings yet

- Electronic Control System: Systems OperationDocument12 pagesElectronic Control System: Systems OperationEshop ManualNo ratings yet

- What Is Forced Induction?Document15 pagesWhat Is Forced Induction?Fugaru Paul - AlexandruNo ratings yet

- Requirements and Types of Starting SystemsDocument34 pagesRequirements and Types of Starting SystemsChandan135100% (1)

- Sensors in Engine Management SystemsDocument19 pagesSensors in Engine Management SystemsRohit RajNo ratings yet

- Fuel Injection SystemDocument49 pagesFuel Injection SystemRavi Teja KarumuriNo ratings yet

- Unit 4-AEEDocument92 pagesUnit 4-AEEMrs G Hemalatha PSG-PTCNo ratings yet

- Sfi SystemDocument96 pagesSfi SystemWawan SatiawanNo ratings yet

- Fuel Injection SystemDocument9 pagesFuel Injection SystemJM PraveenNo ratings yet

- A Comparison of in Memory DatabasesDocument6 pagesA Comparison of in Memory DatabasesPiyush MandalNo ratings yet

- Starting Sys PDFDocument42 pagesStarting Sys PDFAnonymous 8GJQCGaeNo ratings yet

- Automatic Transmission SystemDocument34 pagesAutomatic Transmission SystemGurpreet Singh AnttalNo ratings yet

- Week 1 M-Motronic Systems LectureDocument16 pagesWeek 1 M-Motronic Systems LectureAhmed El-helwNo ratings yet

- GTU Seminar on Warning and Alarm InstrumentsDocument28 pagesGTU Seminar on Warning and Alarm InstrumentsVivekDhameliyaNo ratings yet

- 04 Ignition SystemDocument26 pages04 Ignition SystemRalph JaramilloNo ratings yet

- Components of Fuel Injection System-1Document25 pagesComponents of Fuel Injection System-1yoyotoyo100% (3)

- Tractor Training PresentationDocument55 pagesTractor Training PresentationSantosh LokhandeNo ratings yet

- Gasoline Direct InjectionDocument21 pagesGasoline Direct InjectionhoangNo ratings yet

- Ignition System - 1Document5 pagesIgnition System - 1Sudhakar Uppalapati100% (1)

- 2.sensors & ActuatorsDocument30 pages2.sensors & Actuatorszakariyae el mourabit100% (1)

- Lesson Plan 7 Electrical Installation and Maintenance I. ObjectivesDocument7 pagesLesson Plan 7 Electrical Installation and Maintenance I. Objectivescecille mañacapNo ratings yet

- M73loc - View V12 BMWDocument110 pagesM73loc - View V12 BMWYgor AbreuNo ratings yet

- Introduction To Vehicle Electronic Systems and Fault DiagnosisDocument20 pagesIntroduction To Vehicle Electronic Systems and Fault Diagnosisyogita patil100% (1)

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesFrom EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNo ratings yet

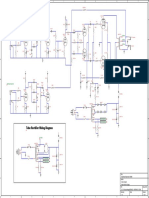

- Tube amplifier circuit diagramDocument1 pageTube amplifier circuit diagramrobertlangdon99100% (1)

- Anti Sleep Alarm For StudentsDocument25 pagesAnti Sleep Alarm For Studentspradeeptanwar1180% (15)

- Gasoline electronic Direct Injection SystemDocument34 pagesGasoline electronic Direct Injection Systemloganathanpalani100% (1)

- Basic Emission Control SystemsDocument5 pagesBasic Emission Control SystemsNadhirah JohaNo ratings yet

- 2 Conventional Efi DieselDocument16 pages2 Conventional Efi DieselSharan SuryaNo ratings yet

- Engine Managment SystemDocument13 pagesEngine Managment SystemF Man Temu100% (1)

- MPFI Vs Carburetor Technology For Multi Cylinder EnginesDocument14 pagesMPFI Vs Carburetor Technology For Multi Cylinder EnginesDipak Kumar100% (1)

- Anti-Lock Braking System (ABS) & Electronic Brake-Force Distribution (EBD or EBFD) SystemDocument15 pagesAnti-Lock Braking System (ABS) & Electronic Brake-Force Distribution (EBD or EBFD) SystemAkshit GoyalNo ratings yet

- Engine ControlDocument4 pagesEngine ControlJoné Jaquay100% (1)

- Ignition SystemsDocument10 pagesIgnition Systemselvergonzalez1No ratings yet

- Mild Hybrid Electric Vehicle (MHEV) - IntroductionDocument6 pagesMild Hybrid Electric Vehicle (MHEV) - IntroductionRui MendesNo ratings yet

- Air Brake System: Presented By: T Pravalika 19D45A0307 Presented By: T Pravalika 19D45A0307Document24 pagesAir Brake System: Presented By: T Pravalika 19D45A0307 Presented By: T Pravalika 19D45A0307priyanka priya100% (1)

- Fuel System of Conventional EFI-dieselDocument27 pagesFuel System of Conventional EFI-dieselnahomNo ratings yet

- Fuel Pump PDF FINALDocument5 pagesFuel Pump PDF FINALravidra markapudiNo ratings yet

- Anti-Lock Braking SystemDocument11 pagesAnti-Lock Braking SystemArjunAgharaNo ratings yet

- 2 Wheel and Four Wheel DriveDocument14 pages2 Wheel and Four Wheel DriveSIDHANT JAINNo ratings yet

- KAYO EFI Instructions: 1 Operating PrincipleDocument16 pagesKAYO EFI Instructions: 1 Operating Principlekenny nieuwenwegNo ratings yet

- Get Charged Up For Electrical Change: The Three Charging StrategiesDocument1 pageGet Charged Up For Electrical Change: The Three Charging StrategiesRohit YadavNo ratings yet

- Engine System ComponentsDocument33 pagesEngine System Componentsgatul denaenNo ratings yet

- Turbo ChargerDocument19 pagesTurbo ChargerHamimi AkmalNo ratings yet

- Charging SystemDocument15 pagesCharging SystemvigneshwaranNo ratings yet

- Fuel Injection Systems of CI EnginesDocument24 pagesFuel Injection Systems of CI EnginesShiv Kumar Singh100% (4)

- Car Cooling SystemDocument42 pagesCar Cooling Systemymessaoud100% (1)

- Delphi Heavy Duty Emissions Brochure 2011 2012Document100 pagesDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamNo ratings yet

- SI Engine Combustion StagesDocument4 pagesSI Engine Combustion Stagesmailsk123No ratings yet

- InternshipDocument45 pagesInternshipPrakashRaiNo ratings yet

- AE - Unit-2-Sensorsand ActuatorsDocument125 pagesAE - Unit-2-Sensorsand ActuatorsShitalPatilNo ratings yet

- Engine Management & Data Acquisition Systems: Formula SAE Seminar May 2004 DetroitDocument103 pagesEngine Management & Data Acquisition Systems: Formula SAE Seminar May 2004 DetroitAvinashRaiNo ratings yet

- Unit 1 NotesDocument57 pagesUnit 1 NotesAnkur SachdevaNo ratings yet

- Numerical Problems On HXs (LMTD Method)Document13 pagesNumerical Problems On HXs (LMTD Method)Ankur SachdevaNo ratings yet

- MRD 101 Previous Year Question Papers by IgnouassignmentguruDocument88 pagesMRD 101 Previous Year Question Papers by IgnouassignmentguruAnkur SachdevaNo ratings yet

- Theory of Jet Propulsion PDFDocument10 pagesTheory of Jet Propulsion PDFAnkur SachdevaNo ratings yet

- Unit 5 NotesDocument45 pagesUnit 5 NotesAnkur SachdevaNo ratings yet

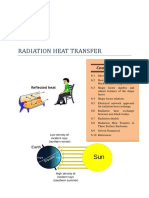

- RADIATION HEAT TRANSFER COURSEDocument30 pagesRADIATION HEAT TRANSFER COURSEAnkur SachdevaNo ratings yet

- 2010 11Document2 pages2010 11Ankur SachdevaNo ratings yet

- 2012 13Document4 pages2012 13Ankur SachdevaNo ratings yet

- Compact Heat Exchangers and Heat PipesDocument11 pagesCompact Heat Exchangers and Heat PipesAnkur SachdevaNo ratings yet

- Unit 3 NotesDocument17 pagesUnit 3 NotesAnkur SachdevaNo ratings yet

- 2013 14Document3 pages2013 14Ankur SachdevaNo ratings yet

- Unit 2 NotesDocument37 pagesUnit 2 NotesAnkur SachdevaNo ratings yet

- KIET Group Mechanical Engineering Airflow TutorialDocument1 pageKIET Group Mechanical Engineering Airflow TutorialAnkur SachdevaNo ratings yet

- 2011 12Document2 pages2011 12Ankur SachdevaNo ratings yet

- RAC Tutorial Sheet 5Document2 pagesRAC Tutorial Sheet 5Ankur SachdevaNo ratings yet

- RAC Tutorial Sheet 4Document3 pagesRAC Tutorial Sheet 4Ankur SachdevaNo ratings yet

- Emission Standards and Test ProceduresDocument77 pagesEmission Standards and Test ProceduresAnkur SachdevaNo ratings yet

- RAC Assignment No. 1Document3 pagesRAC Assignment No. 1Ankur SachdevaNo ratings yet

- RAC Tutorial Sheet 3Document2 pagesRAC Tutorial Sheet 3Ankur SachdevaNo ratings yet

- RAC Tutorial Sheet 2Document3 pagesRAC Tutorial Sheet 2Ankur Sachdeva0% (1)

- Fuels Combustion Calorific Values Tutorial SheetDocument1 pageFuels Combustion Calorific Values Tutorial SheetAnkur SachdevaNo ratings yet

- ENGINE EMISSIONS & OPERATING PARAMETERSDocument50 pagesENGINE EMISSIONS & OPERATING PARAMETERSAnkur SachdevaNo ratings yet

- KIET Group Mechanical Engineering Airflow TutorialDocument1 pageKIET Group Mechanical Engineering Airflow TutorialAnkur SachdevaNo ratings yet

- ENGINE EMISSIONS & OPERATING PARAMETERSDocument50 pagesENGINE EMISSIONS & OPERATING PARAMETERSAnkur SachdevaNo ratings yet

- ORV Equipment GuideDocument51 pagesORV Equipment GuideAnkur SachdevaNo ratings yet

- Qip Ice 11 CarburetorDocument40 pagesQip Ice 11 CarburetorAbdulMathinNo ratings yet

- RAC Tutorial Sheet 1Document1 pageRAC Tutorial Sheet 1Ankur SachdevaNo ratings yet

- Ripuranjan Singh Asst. Professor: Department of Mechanical Engg. S.R.I.M.T, LucknowDocument40 pagesRipuranjan Singh Asst. Professor: Department of Mechanical Engg. S.R.I.M.T, LucknowAnkur SachdevaNo ratings yet

- Excavators PDFDocument41 pagesExcavators PDFAnkur SachdevaNo ratings yet

- Raspberry Pi DHT11 Humidity and Temperature Sensor InterfaceDocument15 pagesRaspberry Pi DHT11 Humidity and Temperature Sensor InterfaceTwinkle RatnaNo ratings yet

- On The Origin of The Free Radical Property of MelaninsDocument2 pagesOn The Origin of The Free Radical Property of MelaninsitbwngNo ratings yet

- Mechanical Era (Dark Age)Document3 pagesMechanical Era (Dark Age)Fatima AhmedNo ratings yet

- KSZ8041RNL Hardware Design Checklist 00002702ADocument14 pagesKSZ8041RNL Hardware Design Checklist 00002702ArajasekaranNo ratings yet

- Als BrochureDocument7 pagesAls BrochureJyoti SinghNo ratings yet

- Coex C1000-1F Marine Camera Station: Data SheetDocument2 pagesCoex C1000-1F Marine Camera Station: Data Sheetrahmanu wiyonoNo ratings yet

- MTK5659 (FHD Models) AM Service Manual Ver1.0 2018-5-31Document57 pagesMTK5659 (FHD Models) AM Service Manual Ver1.0 2018-5-31MarcosRomano100% (2)

- EES Data LTD Free To Use Estimating Labour Guide: ElectricalDocument63 pagesEES Data LTD Free To Use Estimating Labour Guide: ElectricalShahin Shajahan100% (1)

- The Following Table Lists The 8051 Instructions by HEX CodeDocument5 pagesThe Following Table Lists The 8051 Instructions by HEX CodeBruce_Jass_3739No ratings yet

- IRPSM NotingDocument4 pagesIRPSM NotingNagi Reddy ChintakuntaNo ratings yet

- Load Flow AnalysisDocument5 pagesLoad Flow AnalysisReza AhmadiNo ratings yet

- Samsung Microwave TrainingDocument23 pagesSamsung Microwave Trainingbody2030No ratings yet

- Generator Automatic Voltage Regulator Operation ManualDocument4 pagesGenerator Automatic Voltage Regulator Operation ManualmusafirNo ratings yet

- MDPN471 Omar MohsenDocument11 pagesMDPN471 Omar MohsenOmaroMohsenNo ratings yet

- Intro to OS FunctionsDocument7 pagesIntro to OS FunctionsAnum Abdul SalamNo ratings yet

- Ao3413 PDFDocument5 pagesAo3413 PDFMohamed Ibrahim AhamedRasmiNo ratings yet

- Analysis of Electric Vehicles' Impact To The Electric GridDocument5 pagesAnalysis of Electric Vehicles' Impact To The Electric GridwwzzNo ratings yet

- Chapter 3: The PIC MicrocontrollersDocument16 pagesChapter 3: The PIC MicrocontrollersBernard Maacaron100% (1)

- 2 Mva Bushing Neutral EarthingDocument1 page2 Mva Bushing Neutral Earthingindrajit mondalNo ratings yet

- SamsungDocument46 pagesSamsungRainhardfrostNo ratings yet

- Technical-Note Failure-Process Global en V202108Document9 pagesTechnical-Note Failure-Process Global en V202108rxmymNo ratings yet

- Pressure MeasurementDocument19 pagesPressure Measurementdevarshikumar vaidya100% (1)

- Distribution Business Unit Cummins Field Service Report Srinivasa Sales & Service Private Limited, OdishaDocument1 pageDistribution Business Unit Cummins Field Service Report Srinivasa Sales & Service Private Limited, OdishaSantosh Kumar MahantyNo ratings yet

- Recharge! Ha-302 Hearing Aid: User ManualDocument14 pagesRecharge! Ha-302 Hearing Aid: User ManualMac CheeseNo ratings yet