Professional Documents

Culture Documents

Module 04 Hydraulics 7 16 2015

Module 04 Hydraulics 7 16 2015

Uploaded by

Sammy PolancoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 04 Hydraulics 7 16 2015

Module 04 Hydraulics 7 16 2015

Uploaded by

Sammy PolancoCopyright:

Available Formats

Hydraulics

Module 04

1 | Hydraulic Module 04|

Module Objectives

• Match Hydraulic Schematic Symbols with correct definition

• Describe how the components of the hydraulic system work,

where they are located, and their function

• Discuss possible adjustments to the hydraulic system and way

to maintain peak performance.

• Define maintenance required to keep the hydraulic system

operating at peek performance

• Utilize each functional system circuit to know how they affect

the system for future diagnostic approach

2 | Hydraulic Module 04|

Schematic Symbols

WORKBOOK

ACTIVITY

3 | Hydraulic Module 04|

Schematic Symbols

Variable Displacement - Unidirectional Cylinder, Single Acting Hydraulic Motor - Fixed Displacement - Unidirectional

Direction of Hydraulic Flow Hydraulic Motor - Variable Displacement - Unidirectional

Variable Displacement Pump - Bidirectional

Check Valve

Two Position, Three Connection Valve

Accumulator, Gas Charged Filter, Strainer

Flow Control, Adjustable Non-Compensated Orifice On-Off (Manual Shut-Off) Line to Reservoir - Below Fluid Level

Two Position, Two Connection Valve

Three Position, Four Connection Valve

Cylinder, Double Acting, Single End Rod Reservoir - Vented

Line, Flexible

Hydraulic Motor - Variable Displacement - Bidirectional Pressure Relief Valve

4 | Hydraulic Module 04|

Hydraulic Flow “Refresher”

Direction of oil flow

High pressure oil

Direction of pressure against a mechanical object

Medium pressure oil

Direction of mechanical movement

Low pressure oil

Direction of Rotation

Return oil Level of standing oil

“Cutoff” on shafts or lines

Trapped oil

Load or weight

5 | Hydraulic Module 04|

Hydraulic Circuit “Refresher”

Closed Center Circuit

Open Center Circuit

6 | Hydraulic Module 04|

Hydraulic System Updates (CH570)

New Cooling Fan

Changes and Improvements Hydraulic Motor AXT10832

• Topper cutting disk and collector drums on

separate circuits to balance horsepower

• New more efficient topper valve

New Cylinder Functions

• New piston type motor used for topper system that Pressure Compensated Pump

replaces gear type for higher torque and efficiency

• Modulating cooling fan with temperature controlled

variable speed for hydraulic oil cooling

• New pressure compensated pump on the cylinder

circuit replaces gear pump and provides better New Topper Valve

system response and delivers oil only when needed

• New pump for cooling fan and primary extractor

fan, that allows extractor fan speed to be

maintained better under different conditions and

engine rpm and variable cooling fan speed for the

cooling package to be more efficient based on New Pump for Cooling System

temperature and Primary Extractor

7 | Hydraulic Module 04|

Topper Hydraulic System Updates

Topper circuit - new valve design (For Side Knife Machines Only)

•Balance of horsepower for topper center disk, and side knives.

•New topper valve design for decreased parasitic losses and improved plumbing

Topper Center Disk

Left Side Knife

Right Side Knife

8 | Hydraulic Module 04|

Variable Cooling Circuit

•Hydraulically reversible and variable cooling fan

circuit optimized for increased cooling

requirements of Tier 4 engine for improved circuit

efficiency but used on all Tier engines.

•Hydraulic components and control logic similar to

CH330 vehicle New Fan

Fan Tip Speed

New variable fan will have slower tip speeds

except for during high load conditions in high

ambient temps.

9 | Hydraulic Module 04|

Improved Hydraulic Oil Temperature Control

• Thermal Bypass Valves

• Variable Speed Fan

10 | Hydraulic Module 04|

Hydraulic Oil Tank/Reservoir

11 | Hydraulic Module 04|

Hydraulic Oil Tank/Reservoir

Modular type

Oil level sight gauge

Filler quick disconnect coupler

Pressurized system with 4 PSI.

Note:

Always fill up the harvester hydraulic

system. Do it by using the quick release filler

cap to prevent oil contamination.

12 | Hydraulic Module 04|

Hydraulic Oil Tank/Reservoir

Tank capacity: 397 liters/ 105 gallons

System total capacity: approximately 600

liters/158 gallons

The hydraulic system is filled up with:

RYCON 68

or

10W30

The oil filter system is comprised of 3 return

filters.

Submit an oil sample every 1500 hours and

change it as required.

13 | Hydraulic Module 04|

Technical Features

The breather valve (1) of 4 psi keeps the tank

pressurized at all times.

It is located inside the cooling package.

14 | Hydraulic Module 04|

Pump Locations

15 | Hydraulic Module 04|

Hydraulic Pump Identification (High HP system)

Chopper Drive

Left Ground Pump

Drive Pump

Fan Pump (Cooling

and Primary

Right Ground Extractor)

Drive Pump

Scrolls and

Basecutter Topper Pump

Pump

Cylinder

Functions

Elevator Drive Pump

Pump

Front Feed and

Topper Collectors

Rear Feed

Drive Pump

Drive Pump

16 | Hydraulic Module 04|

Hydraulic Pump Identification (Low HP system)

Basecutter

&Chopper

Left Ground Drive Pump

Drive Pump

Fan Pump (Cooling

and Primary

Right Ground Extractor)

Drive Pump

Scrolls and

Topper Pump

Elevator Drive Cylinder

Pump Functions

Pump

Rear Feed

Drive Pump Front Feed and

Topper Collectors

Drive Pump

17 | Hydraulic Module 04|

Valve Locations

Elevator Speed Control Valve

Rear Feed Valve

Front Feed Valve

Lower Cylinder Valve

Basecutter/Crop Divider Cylinder Valve

Topper Valve

Pilot Valve

Cylinder (Tilt) Function Valve

Scroll Valve

Elevator Valve

18 | Hydraulic Module 04|

Pilot Valve

CHG

HFF

T

LTOP RTOP HFR SKPL SKPR

IN

CIN COUT

OUT

Back

19 | Hydraulic Module 04|

Cylinder (Tilt) Function Valve Back

RCD2 RSK2

LCD2 LSK2

LKD2 UKD2

PUMP

RCD1 RSK1

LSK1

LCD1 TANK

UKD1

LKD1

20 | Hydraulic Module 04|

Basecutter/Crop Divider Valve

P1

BC

LCDU RCDU

RCDT

T1 LCDT

T2

LBCD RBCD

RCDD

LCDD RCDA

LCDA

Back

21 | Hydraulic Module 04|

Lower Cylinder Valve

T

PHL TU

TU

ESR ESR PHL

TD

TD

ESL PHR

ESL

PHR

PCU

Back

22 | Hydraulic Module 04|

Elevator Speed Control Valve

Motor

Tank

Pump Back

23 | Hydraulic Module 04|

Topper Valve, Scroll Valve, Front Feed Valve, and Rear Feed

Valve

Work Ports

Pump Inlet

Back Tank

24 | Hydraulic Module 04|

25 | Hydraulic Module 04|

You might also like

- Manual MuellerDocument36 pagesManual MuellerFabianoNo ratings yet

- Astm c110 - CalDocument23 pagesAstm c110 - CalDouglas Ribeiro100% (3)

- (Walter Podolny, JR., John B. Scalzi) Construction PDFDocument354 pages(Walter Podolny, JR., John B. Scalzi) Construction PDFJuan Carlos CastroNo ratings yet

- H1 045-053 Tandem Pumps - Service Manual - 520L0928 - Rev AD - May 2008Document48 pagesH1 045-053 Tandem Pumps - Service Manual - 520L0928 - Rev AD - May 2008Jose Manuel Barroso PantojaNo ratings yet

- Vane Cat 2005Document62 pagesVane Cat 2005omni_partsNo ratings yet

- Hydraulic OverviewDocument32 pagesHydraulic OverviewMACHINERY101GEAR100% (2)

- Aksa Startup ChecklistDocument2 pagesAksa Startup ChecklistUmar RajputNo ratings yet

- J-Gear Pumps CatalogueDocument21 pagesJ-Gear Pumps CatalogueturandotNo ratings yet

- PLL 1397 PDFDocument63 pagesPLL 1397 PDFpamururamuNo ratings yet

- Hidraulico CaterpillarDocument4 pagesHidraulico CaterpillarJoseCorreaNo ratings yet

- VMQ PDFDocument78 pagesVMQ PDFoleg-spbNo ratings yet

- M90 Service Manual PDFDocument72 pagesM90 Service Manual PDFluis eduardo corzo enriquez100% (1)

- Uenr0213uenr0213-01 Sis PDFDocument2 pagesUenr0213uenr0213-01 Sis PDFRaphael Ruiz Ramos100% (2)

- Catálogo Geral Motores Clar-Lyn PDFDocument322 pagesCatálogo Geral Motores Clar-Lyn PDFRafael Antonio Rosa RomeroNo ratings yet

- Vicker Pumps Specsx708Document91 pagesVicker Pumps Specsx708omni_partsNo ratings yet

- Trans Diagram Ml260Document2 pagesTrans Diagram Ml260ferneyNo ratings yet

- Sauer Series 90 ManualDocument72 pagesSauer Series 90 ManualJCNo ratings yet

- Series 45 Frame F Open Circuit Axial Piston Pumps: Repair InstructionsDocument28 pagesSeries 45 Frame F Open Circuit Axial Piston Pumps: Repair InstructionsJose Manuel Barroso PantojaNo ratings yet

- SF 6721 PDFDocument10 pagesSF 6721 PDFSamuel Frank VejarNo ratings yet

- Filter Overview With Service Intervals and CapacitiesDocument2 pagesFilter Overview With Service Intervals and CapacitiesMohammad DahabNo ratings yet

- Regulation Pompe Sauer Danfos Series 90Document2 pagesRegulation Pompe Sauer Danfos Series 90ezeazeazeaeNo ratings yet

- Variable Priority Flow DividersDocument8 pagesVariable Priority Flow DividersMichael DavenportNo ratings yet

- Session - 16 - Eliminator - Oil - Filter (Compatibility Mode)Document42 pagesSession - 16 - Eliminator - Oil - Filter (Compatibility Mode)agvass100% (1)

- Service Manual 300050007500 PermconDocument19 pagesService Manual 300050007500 PermconMiguel Angel Santos PintadoNo ratings yet

- Ford Series Service Parts List n2999c Home PageDocument46 pagesFord Series Service Parts List n2999c Home PageJuan TapiaNo ratings yet

- Case IH A8000 & A8800 - Fluids SpecificationDocument1 pageCase IH A8000 & A8800 - Fluids SpecificationKristomiDerMarine-IngenieurNo ratings yet

- Catálogo Caterpillar - Motores e GeradoresDocument106 pagesCatálogo Caterpillar - Motores e GeradoresFranciele GomesNo ratings yet

- H1 New Hydrostatics: of - The GenerationDocument69 pagesH1 New Hydrostatics: of - The GenerationJose Manuel Barroso PantojaNo ratings yet

- Heavy Duty Mechanical - COCODocument59 pagesHeavy Duty Mechanical - COCOJose Jimenez SilvaNo ratings yet

- 6 - Powershuttle TransmissionDocument21 pages6 - Powershuttle TransmissionOscar VazquesNo ratings yet

- 3002 Slid Electr in Put Out PutDocument36 pages3002 Slid Electr in Put Out Putyecner salvadorNo ratings yet

- cqm13392 7jDocument8 pagescqm13392 7jsunilbholNo ratings yet

- Wa0005Document202 pagesWa0005Murat KoçakNo ratings yet

- PC600 (LC) 8 UEN00128 01 TroubleshootingDocument368 pagesPC600 (LC) 8 UEN00128 01 TroubleshootingdatphuongNo ratings yet

- Denison Cam-Cartridge PDFDocument12 pagesDenison Cam-Cartridge PDFmiguel04891100% (1)

- 695SR 26061062GBDocument16 pages695SR 26061062GBwalk111No ratings yet

- Salient Features:: Pipe LayerDocument4 pagesSalient Features:: Pipe LayerJackson Phinni100% (1)

- 4 TransmissionDocument163 pages4 TransmissionBaciu NicolaeNo ratings yet

- 0.02.1 Motor (87735214)Document4 pages0.02.1 Motor (87735214)Nikole SanchezNo ratings yet

- Forwarder 564 PDFDocument70 pagesForwarder 564 PDFLeclerc Keven100% (1)

- Delta Gear Flow DividerDocument12 pagesDelta Gear Flow Dividerrodruren01100% (1)

- JD Transmision HidrostaticoDocument4 pagesJD Transmision Hidrostaticorolex21No ratings yet

- 320c Excavadora Cat Desarmado y Armado Bombas HidraulicasDocument20 pages320c Excavadora Cat Desarmado y Armado Bombas HidraulicasJuan camilo Cárdenas garciaNo ratings yet

- 01 Doosan TIER 4I Engine (120425)Document6 pages01 Doosan TIER 4I Engine (120425)Jose Rafael Ramos ChiquilloNo ratings yet

- Circuit RecommendationsDocument37 pagesCircuit RecommendationsTatiana Mancera100% (1)

- Series 45 Frame F 74-90 Parts ManualDocument160 pagesSeries 45 Frame F 74-90 Parts ManualArko RoosNo ratings yet

- Orbit RolDocument12 pagesOrbit RolFabio MartinsNo ratings yet

- John Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)Document17 pagesJohn Deere PowerTech 10.5L Diesel Engines Level 6 Electronic Fuel Systems With Lucas EUIs Service Repair Manual (CTM188)laopaodunNo ratings yet

- Hy30-8200 UkDocument80 pagesHy30-8200 UklewisprotecNo ratings yet

- Hydraulics Part 3Document24 pagesHydraulics Part 3MACHINERY101GEAR100% (4)

- Esquematico Camion 777 FDocument4 pagesEsquematico Camion 777 Fjmoralescamarena100% (1)

- B1840 Hyd Manual UKDocument21 pagesB1840 Hyd Manual UKMANUEL CASTILLONo ratings yet

- Indo Farm Company Profile PDFDocument28 pagesIndo Farm Company Profile PDFƎɯox SatíshNo ratings yet

- Adb3e001 eDocument6 pagesAdb3e001 eAnthony Flores ValeraNo ratings yet

- Gidronasosy Serii PMV10Document48 pagesGidronasosy Serii PMV10alsief1951No ratings yet

- Transmission - Valve, Regulator and Oil PumpDocument2 pagesTransmission - Valve, Regulator and Oil PumpSilvio Roman100% (1)

- 892ELC Excavator IntroductionDocument6 pages892ELC Excavator IntroductionVictor Hugo Rodriguez Ramirez100% (1)

- Hydraulic of DozerDocument83 pagesHydraulic of DozerLinzaw OoNo ratings yet

- Basic Component OF Hydraulic SystemDocument64 pagesBasic Component OF Hydraulic SystemWalid Houran100% (2)

- Hydraulic Circuits: Introduction ToDocument161 pagesHydraulic Circuits: Introduction ToahmedNo ratings yet

- Hydraulic BasicDocument64 pagesHydraulic BasicAvinash KulkarniNo ratings yet

- Basic Hydraulics A IlyasDocument64 pagesBasic Hydraulics A IlyasshafiqNo ratings yet

- Hydraulics: - Hydraulic Module 04 - 1Document25 pagesHydraulics: - Hydraulic Module 04 - 1Sammy Polanco100% (1)

- A New Adaptive and Self Organizing Fuzzy Policy ToDocument13 pagesA New Adaptive and Self Organizing Fuzzy Policy ToSammy PolancoNo ratings yet

- Total Energy Supply, Disposition, and Price SummaryDocument10 pagesTotal Energy Supply, Disposition, and Price SummarySammy PolancoNo ratings yet

- 2 - 3 Práctica 6Document1 page2 - 3 Práctica 6Sammy PolancoNo ratings yet

- Mecánica de FluidosDocument2 pagesMecánica de FluidosSammy PolancoNo ratings yet

- Project Number: A3179 Composite Text Video Display: Theory of OperationDocument5 pagesProject Number: A3179 Composite Text Video Display: Theory of OperationNilav ChokshiNo ratings yet

- Power Electronics in Wind and Solar System-Sample-Question-Paper (Msbte-Study-Resources) PDFDocument4 pagesPower Electronics in Wind and Solar System-Sample-Question-Paper (Msbte-Study-Resources) PDFRevati KalalNo ratings yet

- Asme Standards Committee Gas Technology InstituteDocument30 pagesAsme Standards Committee Gas Technology InstituteWalid MohammedNo ratings yet

- Manual Qs Rc5Document1 pageManual Qs Rc5Director Tecnico AdministrativoNo ratings yet

- Sylvania Incandescent Lighting Guide Book 1957Document24 pagesSylvania Incandescent Lighting Guide Book 1957Alan MastersNo ratings yet

- The Schrödinger Equation. A Particle in A One-Dimensional BoxDocument11 pagesThe Schrödinger Equation. A Particle in A One-Dimensional BoxPrateek GhaiNo ratings yet

- Cargo Plant GuidelinesDocument93 pagesCargo Plant GuidelinesPhani PrahladNo ratings yet

- Silicones PhophazenesDocument35 pagesSilicones PhophazenesGaurav 016No ratings yet

- Til 1937-R1Document12 pagesTil 1937-R1BouazzaNo ratings yet

- Formula Sheet Aircraft TutorialsDocument2 pagesFormula Sheet Aircraft TutorialsPythonraptorNo ratings yet

- Construction Specification For Excavating and Backfilling-StructuresDocument10 pagesConstruction Specification For Excavating and Backfilling-StructuressenhuNo ratings yet

- Hot Blast CupolaDocument18 pagesHot Blast CupolaAtadiars Rizki PratamaNo ratings yet

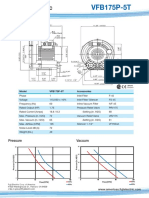

- VFB175P 5TDocument1 pageVFB175P 5TEduardo Santa MaríaNo ratings yet

- Linux/Unix/Aix Discovery in IserveDocument5 pagesLinux/Unix/Aix Discovery in IserveppparmarNo ratings yet

- FMHM BitsDocument5 pagesFMHM BitsallakagopichandNo ratings yet

- ZXMSG 9000 Series NGN PDFDocument3 pagesZXMSG 9000 Series NGN PDFAze Aze100% (1)

- Tos 3Document24 pagesTos 3Dave VargasNo ratings yet

- Carboguard 193: Selection & Specification DataDocument4 pagesCarboguard 193: Selection & Specification DataGraciele SantosNo ratings yet

- Laporan Praktikum Line CodingDocument36 pagesLaporan Praktikum Line CodingAlna Destra ShafiraNo ratings yet

- 3 Traffic Light Controller With 8085Document6 pages3 Traffic Light Controller With 8085adeivaseelanNo ratings yet

- On-Board Diagnostics - Wikipedia, The Free EncyclopediaDocument12 pagesOn-Board Diagnostics - Wikipedia, The Free EncyclopediaBOUMARAFNo ratings yet

- Astm A 29 (1030)Document10 pagesAstm A 29 (1030)Rizki FebriyantoNo ratings yet

- Hazard Communication ProgramDocument9 pagesHazard Communication Programelvis1979No ratings yet

- Dangerous Cargo GuidelinesDocument3 pagesDangerous Cargo GuidelinesJavier PenanoNo ratings yet

- Center Line PDFDocument1 pageCenter Line PDFZayaf AbabNo ratings yet

- Simple Machines: Principle of MomentsDocument3 pagesSimple Machines: Principle of Momentsearl pannilaNo ratings yet

- Atmos Wood Boiler ManualDocument29 pagesAtmos Wood Boiler ManualglynisNo ratings yet

- PNOZ s3 Operat Man 21395-En-10Document17 pagesPNOZ s3 Operat Man 21395-En-10Rudi WidjajaNo ratings yet