Professional Documents

Culture Documents

Trakindo-Andi Mauraga

Uploaded by

Mahmudur RahmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trakindo-Andi Mauraga

Uploaded by

Mahmudur RahmanCopyright:

Available Formats

Voice of

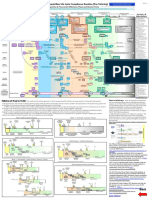

PROJECT CHARTER

Business Case Opportunity - Batuhijau Branch

This project is inline with our CSF for MARC. Currently the cost of Unscheduled Maintenance for

Customer/Biz

793 PM’s form a large part of MARC agreement, Engine, Brake, and Suspension is US$ 1 M p.a

which requires robust processes to ensure profitability

is maintenance. The other opportunity come from the machine hours

that we can sell.

Our opportunity is estimated US$ 904K p.a 300

Goal Statement Project Scope

In Scope :

1. Scheduling of the PM (PM Accuracy) 250 Current Performance

Hour/Month/Truck

Y=f(X

2. Supply of Facilities and Labour

Y= Reduce downtime hours between scheduled 3. Performance of Defect Jobs

maintenance events due to Engine, Brake, Out Scope: 200

and Suspension 1. Performing the PM including Condition Monitoring &

X= High quality of scheduled maintenance events Inspections

150

Focus 100

Mean

ID Task N ame

Aug 1 Aug 12 Aug 23 Sep 3 Sep 14 Sep 25 Oct 6

50

8/10 8/12 8/14 8/16 8/18 8/20 8/22 8/24 8/26 8/28 8/30 9/1 9/3 9/5 9/7 9/9 9/11 9/13 9/15 9/17 9/ 19 9/21 9/23 9/25 9/27 9/29 10/1 10/3 10/5 10/7

GAP!

1 Dedicated Supervisor for PM

2 Dedicated TA for PM

3 Day and Night Foreman

4 Review Level and Ratio for PM Crew

Desired Level

5

0

6 PM Crew Train ing

7 Meeting about scope

8 Send feedback all information to TC

9 TC, find out tailored training for PM

10 Appr oval from GOM/PO

1 19 37 55 73 91 109 127 145 163 181 199 217 235 253 271

•Reduce Unscheduled

11 Preparing Instruct or

12 Kick of training

13

14 PM Trolley

15

16

17

R edesign due to additional requirement

Send layout to BAC Aussie/BAC will review

Get quotation from BAC

Sep 01 - Feb 02

Downtime to 29.31 hr/month

18 Appr oval from GOM/PO

19 Built Trolley and send to BHJ

20 Preparation tool/parts/procedure to trolley

21 H ow to us e - to m ech

22 Kick off

23

24 PM Ch ecksheet - review

25 PM Chec ksheet- finalize

26 Team preparation

27 Training

•Increase Availability of

28 Kick Off Piloting- Pm - str uctured

29

30 Maint enance Strategy

31 Installing air filter for Wastegate line

32 Find out candidate truck

33 Open job

34 Ordering part s

35 Perform replacement

Process? machine to 92 %

Process : Preventive Maintenance

SOLUTION ! Process : Preventive Maintenance service

Sub Process

Sub-processes

Receive Inspect Perform Testing Adjusting Delivery

Receiving Inspect Performing Testing Adjusting Delivery

Clean Machine Conditioning Monitoring PM Testing Adjusting Clean up machine

Pre Inspection Inspect Frame Contamination Control Calibration Clean cabin Clean machine Conditioning monitoring Perform PM Perform Test as per PM's required Clean up

Backlog Performance Test Post inspection

Stratifi

General Inspection

Inspect Frame

Backlog/Defect

Contamination control

Perform Test as per appropriate repair Clean cabin

General Inspection

Environment Machine People

lack of skill

cation

improper training

dusty

Improve

mechanic

weather

watering road

lack of supervision

habit/awareness

Improve 793C Downtime Hour per Major Component

Road mtc

10% engine problem, come from

air filter restriction

100

clean interval/process

793C Breakdown by Engine Comp Cd

20000

Focus only

Maintenance Strategy

# interval to replace for Engine, 80

Stratification

Material Methode

700 100 Brake

Percent

60

system &

Count

600

80

Analyze 10000

500

Suspension 40

Percent

60

Count

400

300 40 20

200

20

100 0 0

0 0

Defect

Defect

Count 64 54 51 48 36 31 28 27 25 24 24 23 264

Count 4925.873689.85

2 687.652663.322015.44

1 101.16 983.51 389.53 378.17 318.53295.93 729.26

Percent 9 8 7 7 5 4 4 4 4 3 3 3 38 Percent 24.4 18.3 13.3 13.2 10.0 5.5 4.9 1.9 1.9 1.6 1.5 3.6

Cum % 9 17 24 31 36 41 45 48 52 56 59 62 100 Cum % 24.4 42.7 56.0 69.2 79.2 84.7 89.5 91.5 93.3 94.9 96.4 100.0

You might also like

- Payroll (HR) RCM 2022-2023Document1 pagePayroll (HR) RCM 2022-2023Aman ParchaniNo ratings yet

- Chassid Ipc ConnectionDocument4 pagesChassid Ipc ConnectionPayal PriyaNo ratings yet

- Marketing Plan FinalDocument11 pagesMarketing Plan FinalNguyễn QuangNo ratings yet

- Cmmi-Svc v13 Poster v30 ObDocument1 pageCmmi-Svc v13 Poster v30 ObH DsrNo ratings yet

- PATENT DUCTUS ARTERIOSUS Concept MapDocument2 pagesPATENT DUCTUS ARTERIOSUS Concept MapErika CadawanNo ratings yet

- Sample Project DASHBOARD REPORT - 03th October 2022 Construction WEEK No. 26Document1 pageSample Project DASHBOARD REPORT - 03th October 2022 Construction WEEK No. 26moes83No ratings yet

- Defense Acquisition Life Cycle Wall Chart v1.3Document2 pagesDefense Acquisition Life Cycle Wall Chart v1.3joe TNo ratings yet

- AssessDocument5 pagesAssessAshoka NarayananNo ratings yet

- 11 - Dashboard (MentWay)Document4 pages11 - Dashboard (MentWay)Mahmoud GhanemNo ratings yet

- FORM D-Manpower (Final With Histogram) - Form D1Document2 pagesFORM D-Manpower (Final With Histogram) - Form D1manoranjan dasNo ratings yet

- Defense Acquisition Life Cycle Compliance Baseline (Pre-Tailoring)Document2 pagesDefense Acquisition Life Cycle Compliance Baseline (Pre-Tailoring)Chit Win MaungNo ratings yet

- SelectDocument12 pagesSelectAshoka NarayananNo ratings yet

- CF OPI ONLINE LIST - June 2019Document1 pageCF OPI ONLINE LIST - June 2019Tony CefaiNo ratings yet

- Project Dashboard: Expected Time at Completion (Days) #REF! Expected Cost at Completion (EGP) #REF!Document4 pagesProject Dashboard: Expected Time at Completion (Days) #REF! Expected Cost at Completion (EGP) #REF!Conception & Fabrication MécaniqueNo ratings yet

- Project Concept / Business Proposal / Business Case Fund Authorization Letter Project Definition and PlanningDocument1 pageProject Concept / Business Proposal / Business Case Fund Authorization Letter Project Definition and Planningvivekcp87No ratings yet

- With Machine Room - GAD-02Document1 pageWith Machine Room - GAD-02Nagarajan SNo ratings yet

- LIFE CYCLE INSTITUTE-Criticality AnalysisDocument1 pageLIFE CYCLE INSTITUTE-Criticality AnalysisJonathan Ferney CastroNo ratings yet

- Dmaic 12873122766122 Phpapp01Document1 pageDmaic 12873122766122 Phpapp01quycoctuNo ratings yet

- List of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)Document63 pagesList of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)rohitNo ratings yet

- Dmaic 12873122766122 Phpapp01Document1 pageDmaic 12873122766122 Phpapp01quycoctuNo ratings yet

- CCS CC1026 6Document21 pagesCCS CC1026 6gregNo ratings yet

- ExecutionDocument4 pagesExecutionnieves lias correaNo ratings yet

- Chapter 5 Design of Goods and Services OpmDocument1 pageChapter 5 Design of Goods and Services Opmnurfarhana6789No ratings yet

- 1 20RiskRegisterexampleDocument3 pages1 20RiskRegisterexampleChristian Alfred SorianoNo ratings yet

- Base Enterprise Value Map PDFDocument1 pageBase Enterprise Value Map PDFjvr001100% (1)

- (Soluciones Minería) PC05IPTT01BDocument2 pages(Soluciones Minería) PC05IPTT01BSheryl Calderón CoroseoNo ratings yet

- Value-Map TM DeloitteDocument1 pageValue-Map TM DeloitteHugo SalazarNo ratings yet

- Seeking Accreditation Across The Americas: COPC Performance Management SystemDocument3 pagesSeeking Accreditation Across The Americas: COPC Performance Management Systemcitjagan15180% (2)

- Bridge No Bearing Capacity Calculation As Per IS: 6403 and 8009 Bore Hole No P3BH-4 Chaninage: Section-Budhwal-Sitapur 104Document3 pagesBridge No Bearing Capacity Calculation As Per IS: 6403 and 8009 Bore Hole No P3BH-4 Chaninage: Section-Budhwal-Sitapur 104Dileep singhNo ratings yet

- Monthly Report Commissary April 2023Document2 pagesMonthly Report Commissary April 2023JosephAsuncionNo ratings yet

- Work Program - 230 PpeDocument6 pagesWork Program - 230 PpeHarris DarpingNo ratings yet

- Jumbo MDocument5 pagesJumbo MholkeirNo ratings yet

- UN Contractor Crew Competency Review Form G - 2011Document5 pagesUN Contractor Crew Competency Review Form G - 2011AKOGU J. AKPOCHI J.No ratings yet

- Q 1 PropertyDocument1 pageQ 1 PropertyMichael CorpusNo ratings yet

- OE - ODR - Cat 994 Presentation - 041111Document45 pagesOE - ODR - Cat 994 Presentation - 041111Antony Armando Huaylla Quispe100% (1)

- DRP and BCP PDFDocument1 pageDRP and BCP PDFHan JeeNo ratings yet

- USAID SMEA Project: Guidance On Grant Application Budget FormDocument6 pagesUSAID SMEA Project: Guidance On Grant Application Budget FormCh. Muhammad AnwarNo ratings yet

- A. Process MapDocument2 pagesA. Process MaprmdarisaNo ratings yet

- MGRP-OTD-R-01 Training Request Form - Doc 2011Document2 pagesMGRP-OTD-R-01 Training Request Form - Doc 2011vinothNo ratings yet

- Standard Kaizen / Pdca (Chronical Problems) : Plan DO PlanDocument14 pagesStandard Kaizen / Pdca (Chronical Problems) : Plan DO Plansuraj rawatNo ratings yet

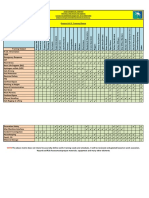

- Training MatrixDocument2 pagesTraining MatrixAmeerHamzaWarraichNo ratings yet

- Free Breeze PS500-500kW EnglishDocument6 pagesFree Breeze PS500-500kW EnglishRey Martial RodriguezNo ratings yet

- 20.COBIT5 For Assurance LaminateDocument2 pages20.COBIT5 For Assurance LaminateLuqman HakimNo ratings yet

- WCI Needs For 5 Rigs-UPDATEDocument3 pagesWCI Needs For 5 Rigs-UPDATEArdian NNo ratings yet

- Gap Analysis Action Plan Permit To Work System (Updated 28.03.2020)Document4 pagesGap Analysis Action Plan Permit To Work System (Updated 28.03.2020)Alaa El-shafeiNo ratings yet

- Mindmap European Operations FootprintDocument1 pageMindmap European Operations FootprintJoão Pedro Correia BorgaNo ratings yet

- Performance Dialogue Between Production, Operator and Maintenance SupervisorDocument1 pagePerformance Dialogue Between Production, Operator and Maintenance Supervisorabhishek rathoreNo ratings yet

- ElectronicDoc Cyc MatrixDocument1 pageElectronicDoc Cyc MatrixIceman_81No ratings yet

- Topo Survey at Ch. 77+000 To 98+000 PDFDocument8 pagesTopo Survey at Ch. 77+000 To 98+000 PDFAshraf KhanNo ratings yet

- Risk RegisterDocument1 pageRisk RegistermanchiqsNo ratings yet

- Portfolio PosterDocument4 pagesPortfolio PosterTHATO GUNDUNo ratings yet

- Procurement & Supply Chain InnovationDocument7 pagesProcurement & Supply Chain InnovationPaula Lande CoralNo ratings yet

- PIR Workshop TemplatesDocument5 pagesPIR Workshop TemplatesnurNo ratings yet

- 3.1 Gestion de Proyectos - Ingles - EntregadoDocument1 page3.1 Gestion de Proyectos - Ingles - EntregadoDavid SanchezNo ratings yet

- Chapter 2Document1 pageChapter 2Minhh KhanggNo ratings yet

- Day3 Function FMEADocument56 pagesDay3 Function FMEAPaul StarkNo ratings yet

- Dashboard TemplateDocument7 pagesDashboard Templateavdesh7777No ratings yet

- Rag Tss Folder Engl 160215Document5 pagesRag Tss Folder Engl 160215Alexander Aristizábal PeñalozaNo ratings yet

- Cicpa - C&mcig1w922Document782 pagesCicpa - C&mcig1w922mahmoudNo ratings yet

- Transformation To An Agile and Virtualized World: Operations Center of The FutureDocument1 pageTransformation To An Agile and Virtualized World: Operations Center of The FuturepinardoNo ratings yet

- Estimation Risk Register - Commercial ProjectsDocument1 pageEstimation Risk Register - Commercial ProjectsYogender Singh RawatNo ratings yet

- 11675089_03Document90 pages11675089_03Mahmudur RahmanNo ratings yet

- Notification of Award (NOA) : View All NotificationsDocument3 pagesNotification of Award (NOA) : View All NotificationsMahmudur RahmanNo ratings yet

- Pi - Ea1060Document1 pagePi - Ea1060Mahmudur RahmanNo ratings yet

- PG-2101 CPA ProjectDocument8 pagesPG-2101 CPA ProjectMahmudur RahmanNo ratings yet

- Training On Enercon Generator Control PanelDocument2 pagesTraining On Enercon Generator Control PanelMahmudur RahmanNo ratings yet

- PG-2101 CPA Project (Rev3) - 07 April 2022 - Model - 8 April 2022Document8 pagesPG-2101 CPA Project (Rev3) - 07 April 2022 - Model - 8 April 2022Mahmudur RahmanNo ratings yet

- Data Sheet - PDUDocument4 pagesData Sheet - PDUMahmudur RahmanNo ratings yet

- Dominion LX: Affordable, High-Quality, Kvm-Over-Ip For The Evolving Small or Midsize BusinessDocument2 pagesDominion LX: Affordable, High-Quality, Kvm-Over-Ip For The Evolving Small or Midsize BusinessMahmudur RahmanNo ratings yet

- PG-2101 CPA Project (Rev1)Document8 pagesPG-2101 CPA Project (Rev1)Mahmudur RahmanNo ratings yet

- Rhino Catalog 2014Document28 pagesRhino Catalog 2014Mahmudur RahmanNo ratings yet

- Rackmount LCD Consoles: 17'' AND 19'' LED-BACKLIT LCD DrawersDocument2 pagesRackmount LCD Consoles: 17'' AND 19'' LED-BACKLIT LCD DrawersMahmudur RahmanNo ratings yet

- Data Sheet - Aisle Containmnet SystemDocument3 pagesData Sheet - Aisle Containmnet SystemMahmudur RahmanNo ratings yet

- PT-P900W / P950NW: Introducing The Label Printers That Make Business A PleasureDocument4 pagesPT-P900W / P950NW: Introducing The Label Printers That Make Business A PleasureMahmudur RahmanNo ratings yet

- CPA Project 8MW Rev1Document8 pagesCPA Project 8MW Rev1Mahmudur RahmanNo ratings yet

- Data Sheet - SSA Series CabinetDocument4 pagesData Sheet - SSA Series CabinetMahmudur RahmanNo ratings yet

- Section 5. Bill of Quantity (Boq) : Group - "A" Raise Floor With AccessoriesDocument6 pagesSection 5. Bill of Quantity (Boq) : Group - "A" Raise Floor With AccessoriesMahmudur RahmanNo ratings yet

- BBSCL TC 2018Document153 pagesBBSCL TC 2018Mahmudur RahmanNo ratings yet

- Getco 6sigmaDocument13 pagesGetco 6sigmaMahmudur RahmanNo ratings yet

- Betelco - SPL-315 kVA SS-1.1Document8 pagesBetelco - SPL-315 kVA SS-1.1Mahmudur Rahman100% (1)

- Authorized Distributor - Saif PowerTec - 31 Mar 2021 - SignedDocument1 pageAuthorized Distributor - Saif PowerTec - 31 Mar 2021 - SignedMahmudur RahmanNo ratings yet

- Capability Analysis Data Measurement Plan Business Risk Management Control Chart Total Defects Per PlanDocument1 pageCapability Analysis Data Measurement Plan Business Risk Management Control Chart Total Defects Per PlanMahmudur RahmanNo ratings yet

- A Sugar Substitute Is A Food Additive That Duplicates The Effect of Sugar in TasteDocument4 pagesA Sugar Substitute Is A Food Additive That Duplicates The Effect of Sugar in TasteMahmudur RahmanNo ratings yet

- NGO - TANIA - 18 April 2020Document53 pagesNGO - TANIA - 18 April 2020Mahmudur RahmanNo ratings yet

- Carbohydrate Chemistry: Dr. Herat D. Soni Assistant Professor Rural Medical College LoniDocument117 pagesCarbohydrate Chemistry: Dr. Herat D. Soni Assistant Professor Rural Medical College LoniMahmudur RahmanNo ratings yet

- Carbohydrate: Nursing PathDocument25 pagesCarbohydrate: Nursing PathMahmudur RahmanNo ratings yet

- Ass1 Merged MergedDocument15 pagesAss1 Merged MergedAkash SahuNo ratings yet

- FlowerDocument43 pagesFlowermark dave luangcoNo ratings yet

- Eve Berlin PDFDocument2 pagesEve Berlin PDFJeffNo ratings yet

- Print ChallanDocument1 pagePrint Challanmubarakuet225No ratings yet

- CREII-Module-I - Lecture 4 PDFDocument34 pagesCREII-Module-I - Lecture 4 PDFshubhamNo ratings yet

- IGCSE Edexcel CircuitsDocument87 pagesIGCSE Edexcel CircuitsКіра Струлєва ОлексіївнаNo ratings yet

- Platinum Gazette 21 MayDocument16 pagesPlatinum Gazette 21 MayAnonymous w8NEyXNo ratings yet

- CANbedded CANopen Availability enDocument4 pagesCANbedded CANopen Availability enAndres RiveraNo ratings yet

- 378-011 Engine Oil SamplingDocument3 pages378-011 Engine Oil SamplingMike PerryNo ratings yet

- Re-Education On CannabisDocument11 pagesRe-Education On CannabisAmritGomesToppoNo ratings yet

- Temperature Transmitter Ex I: Series 9182Document40 pagesTemperature Transmitter Ex I: Series 9182Saša KrbavacNo ratings yet

- FootprintingDocument14 pagesFootprintingAdlina AnwarNo ratings yet

- Gass BillDocument1 pageGass BillRana Sunny KhokharNo ratings yet

- I Fxyda I Fxydxdy: Doing Physics With Matlab Mathematical RoutinesDocument12 pagesI Fxyda I Fxydxdy: Doing Physics With Matlab Mathematical Routinessintya rachmaNo ratings yet

- UEC612Document1 pageUEC612goyaldeepanshugoyal9000No ratings yet

- Protolon (ST)Document8 pagesProtolon (ST)Emmanuel Entzana HdzNo ratings yet

- Powerware 9: FeaturesDocument2 pagesPowerware 9: Featuresandy175No ratings yet

- 08m50e00 - FARO Laser Tracker Accessories - February 2007Document108 pages08m50e00 - FARO Laser Tracker Accessories - February 2007f1f2f3f4f5cruzNo ratings yet

- Waves in Continuous Media PDFDocument149 pagesWaves in Continuous Media PDFvicher2020No ratings yet

- Greek ArchitectureDocument11 pagesGreek ArchitectureRon SalungaNo ratings yet

- MR Bean Is in The Staff Room at School. He Is Making A Cup of Coffee. Miss Smith Comes in ..Document12 pagesMR Bean Is in The Staff Room at School. He Is Making A Cup of Coffee. Miss Smith Comes in ..Sandhya RafiansyahNo ratings yet

- Drilling Presentation May 2017Document71 pagesDrilling Presentation May 2017IgorCencičNo ratings yet

- Mollier Hs Diagram 500 A3 FreeDocument1 pageMollier Hs Diagram 500 A3 FreeLabib WaniNo ratings yet

- Surface Vehicle Recommended PracticeDocument3 pagesSurface Vehicle Recommended PracticeVIGNESH KUMARNo ratings yet

- Indicador NT 200aDocument53 pagesIndicador NT 200alisita23_182No ratings yet

- Roteiro - SinaisDocument98 pagesRoteiro - SinaisJuliano FerreiraNo ratings yet

- Electrical Engineering Internship CertificateDocument6 pagesElectrical Engineering Internship Certificatexosim12242No ratings yet