Professional Documents

Culture Documents

Waterproofing Wet Areas

Uploaded by

Muskan SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Waterproofing Wet Areas

Uploaded by

Muskan SinghCopyright:

Available Formats

WATERPROOFING

OF

WET AREAS

(Toilet and kitchen)

AR. AMITABH TYAGI

CAUSES OF DAMPNESS IN BUILDINGS

Absorption of moisture is one of the chief causes of dampness.

Thus, either on account of

- faulty design of structure

- bad workmanship

- by use of defective structures

- by use of defective materials

moisture may find its way on the interior of the building either through the wall, floor or

roof.

AR. AMITABH TYAGI

METHODS OF DAMP PROOFING

Following methods are generally adopted to prevent the defect of dampness in a

structure:

1. Membrane damp proofing

2. Integral damp proofing

3. Surface treatment

4. Cavity wall construction

5. Guniting

6. Pressure Grouting

AR. AMITABH TYAGI

1. MEMBRANE DAMP PROOFING

This consists in providing layers of membrane of water repellent material between

the source of dampness and the part of the structure adjacent to it.

Types of Materials for Damp Proof Course:

Flexible Materials: Materials like bitumen, bituminous felt, plastic sheet (polythene

sheets) etc.

Semi-rigid Materials: Materials like mastic asphalt, or combination of materials or

layers.

Rigid Materials: Materials like first class bricks, stones, slate, cement concrete etc.

AR. AMITABH TYAGI

a thin coating which

consists of usually a

primer coat and two coats

of top coats which are

applied by spray, roller, or

trowel.

Liquid Waterproofing Membrane

Cementitious Waterproofing

often used in the internal wet

areas such as toilets

AR. AMITABH TYAGI

Bituminous coating is also

called as asphalt coating.

It is not suitable for expose to

sunlight.

AR. AMITABH TYAGI

A popular method used for low-

sloped roofs.

Bituminous waterproofing

membrane have torch on

membrane and self-adhesive

membrane.

This method is used for the flat roof area and

exposed to weathering.

This waterproofing method is expensive.

Polyurethane Liquid Membrane Waterproofing

AR. AMITABH TYAGI

2. INTEGRAL DAMP PROOFING

This consists of adding certain water proofing compounds with the concrete mix

to increase its impermeability.

The compounds made from clay, sand or lime (chalk, fuller’s earth, etc) help to

fill the voids in concrete and make it water proof.

Compounds like alkaline silicates, aluminium sulphates, calcium chlorides, etc

react chemically when mixed with concrete to produce water proof concrete.

AR. AMITABH TYAGI

Commercially available compounds like LW+ (Dr. Fixit),

Krystol Internal Membrane (KIM) etc.

AR. AMITABH TYAGI

3. SURFACE TREATMENT

Surface treatment consists of application of layer of water repellent substances

or compounds on the surface through which moisture enters.

The use of water repellent metallic soaps such as calcium and aluminium oletes and

stearates are much effective against rain water protection.

AR. AMITABH TYAGI

4. CAVITY WALL CONSTRUCTION

This consists in shielding the main wall of the building by an outer skin wall leaving a

cavity in between the two. The cavity prevents the moisture from travelling from the

outer to the inner wall.

AR. AMITABH TYAGI

5. GUNITING

This consists of depositing an impervious layer of rich cement mortar over the

surface to be water proofed.

1. Surface to be treated is first thoroughly cleaned

and wetted properly.

2. A mixture of cement and sand (1:3 to 1:4) is shot

on the prepared surface under a pressure of 2 to 3 kg

per square cm by holding the nozzle of the cement

gun at the distance of 75 to 90 cm from the working

surface.

AR. AMITABH TYAGI

5. PRESSURE GROUTING / INJECTION GROUTING

Injection grouting is a process of filling the cracks, voids or honeycombs under

pressure in concrete or masonry structural members for repairing of cracks,

strengthening of damaged concrete or masonry structural members.

Steps Involved :

1. Drilling of holes 10 to 12 mm dia at the spacing of 1 mt., 10 mm (4) deep or as per site

conditions

2. Fixing of nipples with cement mortar and admixture.

3. Pressure cleaning of holes with water to remove undesirable materials from the holes ,if any.

4. Pressure grouting cement slurry and admixture with aid of 140 PSI grout pump into the

nipples until refusal.

5. Removal of nipples and blocking the holes with cement mortar and admixture.

AR. AMITABH TYAGI

R.C.C. WORK

BRICK WORK

AR. AMITABH TYAGI

DAMP PROOFING / WATER PROOFING

IN BUILDINGS

1. Foundation

2. Basement

3. Floors

4. Toilets/Kitchen

5. Terrace

AR. AMITABH TYAGI

WATER PROOFING IN TOILET

AR. AMITABH TYAGI

WATER PROOFING IN SUNKEN AREA

(TOILET/KITCHEN)

AR. AMITABH TYAGI

TAPECRETE P-151 SYSTEM

• Cleaning the concerned RCC surface by means of wire brush to expose the concrete

surface which should be free from all loose particles, dust, laitance, etc.

• Making 25 x 25mm size corner fillets with Polymer modified cementitious (PMC)

mortar (Tapecrete P-151: Cement: Silica Sand/ Fine sand = 1: 2: 4-6 by weight) at all

joints of horizontal and vertical surface and doing bore packing with PMC mortar.

Also the joints of pipes and concrete/masonry are to be sealed with epoxy putty CICO

Poxy LC or epoxy mortar CICO Poxy 2125 and the same is semi-rounded upto 5mm

above surface level all along the periphery of PVC pipes.

AR. AMITABH TYAGI

• Application of one coat of Tapecrete P-151– Acrylic Polymer Modified Cementitious slurry (

Tapecrete P-151: Cement = 1: 2 by weight) coating over the RCC slab surface and carried

upto 300 mm above finished floor level on vertical portion (walls). This coat is allowed to get

dry for 4-6 hours.

• Application of one coat of Tapecretebrush topping 1-1.5mm thick (Tapecrete P-151:

Cement: Silica Sand = 1: 2: 2 by weight) over the first coat.

• Moist curing of Tapecrete system for next two days.

• Laying 15 mm plaster in the ratio 1: 4 (Cement: Sand) admixed with CICO Super @ 100ml

per 50 kg cement on treated horizontal surface and carried upto treatment on vertical portion

(walls).

• Water curing of plaster as per good engineering practices.

AR. AMITABH TYAGI

TAPECRETE

WATERPROOFING

AR. AMITABH TYAGI

SURFACE PREPARATION APPLICATION

PIDILITE

AR. AMITABH TYAGI

PIDILITE

AR. AMITABH TYAGI

MATERIALS FOR SUNK FILLING

AAC BLOCK

CLC BLOCK

KHANGAR (FOAM CONC.)

AR. AMITABH TYAGI

PONDING TEST

Water ponding in bare concrete slab of bath room Water ponding after waterproofing in bath room

AR. AMITABH TYAGI

ASSIGNMENT

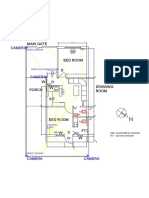

Select one existing toilet in your residence. You are required to draw –

a) Plan – Showing all fittings and fixtures, traps, WWP, SWP and tile work

b) Section (at least two – one each along the length and width) to clear all water

proofing details

c) Blowup of all important details

AR. AMITABH TYAGI

You might also like

- Pl100 Pl200 Pl300 Pl400 SparepartDocument9 pagesPl100 Pl200 Pl300 Pl400 Sparepartphantomboyz_aip100% (1)

- SAMIDocument14 pagesSAMIPURUSHOTTAM100% (3)

- BOQ For Waterproofing Works: Modern IT Solutions, NoidaDocument4 pagesBOQ For Waterproofing Works: Modern IT Solutions, NoidaAbhinav Saini100% (1)

- Key elevation of bow string girderDocument1 pageKey elevation of bow string girdergoutammand100% (2)

- Waterproofing RoofsDocument16 pagesWaterproofing RoofsIshita Sehgal100% (1)

- Waterproofing 140824131844 Phpapp02Document30 pagesWaterproofing 140824131844 Phpapp02Christelle Dela CruzNo ratings yet

- Waterproofing in ToiletDocument11 pagesWaterproofing in ToiletchaityaNo ratings yet

- Water Proofing of Building & StructuresDocument12 pagesWater Proofing of Building & StructuresAnshumali Baruah100% (1)

- BUILDING WATERPROOFING TECHNIQUESDocument30 pagesBUILDING WATERPROOFING TECHNIQUESPulkit SainiNo ratings yet

- Unit.V: Finishings: 1. Damp ProofingDocument33 pagesUnit.V: Finishings: 1. Damp ProofingRajNo ratings yet

- Damp ProofingDocument30 pagesDamp Proofingमन्दिप नेपालNo ratings yet

- Waterproofing: Arch - Allen R. Buenaventura. MSCMDocument50 pagesWaterproofing: Arch - Allen R. Buenaventura. MSCMDenzel NgNo ratings yet

- Water Proofing BoqDocument4 pagesWater Proofing Boqravi1214No ratings yet

- Damp Proofing Methods & MaterialsDocument18 pagesDamp Proofing Methods & Materialschristelle do100% (2)

- Waterproofing, Damp Proofing, Insulation, Glass and Glazing: Building TechnologyDocument56 pagesWaterproofing, Damp Proofing, Insulation, Glass and Glazing: Building TechnologyArmie Jay dela CruzNo ratings yet

- Preventing Water Penetration in Below-Grade Concrete Masonry WallsDocument4 pagesPreventing Water Penetration in Below-Grade Concrete Masonry WallsDenver AbanoNo ratings yet

- Waterproofing, DPC, AntitermiteDocument30 pagesWaterproofing, DPC, AntitermiteDipti ShuklaNo ratings yet

- WaterproofingDocument23 pagesWaterproofingKenneth Ituralde BesmonteNo ratings yet

- SPW - II WaterproofingDocument9 pagesSPW - II WaterproofingAvanti ThorveNo ratings yet

- How to Prevent Dampness in BuildingsDocument64 pagesHow to Prevent Dampness in BuildingsPrasoon Prasenan PNo ratings yet

- Damp Preventation 2Document6 pagesDamp Preventation 2Alhilali ZiyadNo ratings yet

- Waterproofing and Weatherproofing MaterialsDocument37 pagesWaterproofing and Weatherproofing MaterialsSanjay Areyoukiddingme Somnath50% (2)

- Waterproofing and Damp ProofingDocument5 pagesWaterproofing and Damp ProofingAnand KunkulolNo ratings yet

- WaterproofingDocument7 pagesWaterproofingNeda Shakil100% (1)

- Waterproofing of ToiletsDocument10 pagesWaterproofing of ToiletsRi SovannaphumiNo ratings yet

- Essential waterproofing methods for flat roofsDocument39 pagesEssential waterproofing methods for flat roofsJaime A. NavarijoNo ratings yet

- Water Proofing MethodsDocument18 pagesWater Proofing MethodsreetNo ratings yet

- Traditional Method of WaterproofingDocument5 pagesTraditional Method of WaterproofingAnjali AnjuNo ratings yet

- WaterproofingDocument12 pagesWaterproofingJason GillespieNo ratings yet

- Water-Proofing SystemsDocument7 pagesWater-Proofing SystemsĐhíllońŘashìNo ratings yet

- Water Proofing WorksDocument8 pagesWater Proofing Worksukali_csNo ratings yet

- Recomendaciones GEODocument11 pagesRecomendaciones GEOSocrates GebremedhinNo ratings yet

- Installation of Ceramic Tile in Swimming PoolsDocument5 pagesInstallation of Ceramic Tile in Swimming PoolsTenaw AlamirewNo ratings yet

- Concrete Works at The Construction SiteDocument12 pagesConcrete Works at The Construction SiteakmldnielNo ratings yet

- WaterproofingDocument18 pagesWaterproofinglarnzNo ratings yet

- CHAPTER - 9-WaterproofingDocument18 pagesCHAPTER - 9-WaterproofingHelen RondinaNo ratings yet

- Damp Proofing and Water Proofing: Athira. P. R 101116007 Third Year B-ArchDocument9 pagesDamp Proofing and Water Proofing: Athira. P. R 101116007 Third Year B-ArchAshrutha HarshiniNo ratings yet

- Damp Proofing Sahil ChaudharyDocument30 pagesDamp Proofing Sahil ChaudharySahil ChaudharyNo ratings yet

- Construction Chemicals For WaterproofingDocument34 pagesConstruction Chemicals For WaterproofingsandyNo ratings yet

- B.C.M (Building Construction and Material)Document19 pagesB.C.M (Building Construction and Material)karanNo ratings yet

- Waterproofing structures guideDocument43 pagesWaterproofing structures guidearancyppNo ratings yet

- 8.Ms-Water Proofing WorkDocument17 pages8.Ms-Water Proofing WorkShenbagaraja PandianNo ratings yet

- Presentation 1 Water Proofing MaterialsDocument39 pagesPresentation 1 Water Proofing Materialsananya mukerjeeNo ratings yet

- SMARTPAVE Permeable Paving System by Littlehampton BrickDocument7 pagesSMARTPAVE Permeable Paving System by Littlehampton Brickmihai968No ratings yet

- Water ProofingDocument47 pagesWater ProofingJithesh DharmadasNo ratings yet

- Cemcoat Putty_TDS_13Document2 pagesCemcoat Putty_TDS_13Mohamed AtefNo ratings yet

- Building Materials and ConstructionDocument7 pagesBuilding Materials and ConstructionKavya 7No ratings yet

- WaterproofingDocument4 pagesWaterproofingChinmay KaranNo ratings yet

- WaterproofingDocument25 pagesWaterproofingDev ThakkarNo ratings yet

- Improving Waterproofing WorkmanshipDocument16 pagesImproving Waterproofing Workmanshipniran_udayangaNo ratings yet

- 599 PDFDocument2 pages599 PDFbizottsagNo ratings yet

- Seepage and Contraction Joints in Concrete Canal LiningDocument25 pagesSeepage and Contraction Joints in Concrete Canal LiningRohan ShivasundarNo ratings yet

- Water Proofing of BasementsDocument11 pagesWater Proofing of BasementsChidambar DudgikarNo ratings yet

- Method Statement of Waterproofing (Wet Area & Brick Bat Coba)Document4 pagesMethod Statement of Waterproofing (Wet Area & Brick Bat Coba)Salman Shah100% (1)

- Water Proofing MethodologyDocument6 pagesWater Proofing Methodologykartick adhikaryNo ratings yet

- Reinforced MasonaryDocument37 pagesReinforced MasonaryRAHULNo ratings yet

- Waterproofing Roofs PDFDocument40 pagesWaterproofing Roofs PDFyudhishthir singhNo ratings yet

- Parapet Waterproofing StagesDocument9 pagesParapet Waterproofing Stagespatel shivanginiNo ratings yet

- Asphaltic Concrete Membrane DamDocument7 pagesAsphaltic Concrete Membrane DamWeff JingNo ratings yet

- WaterproofingDocument2 pagesWaterproofinghoney4747No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Room Acoustics - 1: Ar. Smita RashmiDocument12 pagesRoom Acoustics - 1: Ar. Smita RashmiMuskan SinghNo ratings yet

- Cleaning Staff (F) Cleaning Staff (F) : Bathroom ToiletDocument1 pageCleaning Staff (F) Cleaning Staff (F) : Bathroom ToiletMuskan SinghNo ratings yet

- Qcentre 3Document1 pageQcentre 3Muskan SinghNo ratings yet

- Quarantine Centre: Muskan Singh 3Rd Year Gen 1 Submitted byDocument1 pageQuarantine Centre: Muskan Singh 3Rd Year Gen 1 Submitted byMuskan SinghNo ratings yet

- First Floor Plan: ToiletDocument1 pageFirst Floor Plan: ToiletMuskan SinghNo ratings yet

- Perimeter Protection System (MUSKAN SINGH) - ModelDocument1 pagePerimeter Protection System (MUSKAN SINGH) - ModelMuskan SinghNo ratings yet

- Researchccc PDFDocument2 pagesResearchccc PDFMuskan SinghNo ratings yet

- Disaster Management (BBB Assignment 2)Document12 pagesDisaster Management (BBB Assignment 2)Muskan SinghNo ratings yet

- 277Document11 pages277Emmanuel EmilianoNo ratings yet

- 00 GuptaDocument16 pages00 GuptaMuskan SinghNo ratings yet

- 10-09 GreenBldg PPTDocument72 pages10-09 GreenBldg PPTherokaboss1987No ratings yet

- BuddhismDocument14 pagesBuddhismMuskan SinghNo ratings yet

- Final IHCDocument7 pagesFinal IHCMuskan SinghNo ratings yet

- Engineered TIMBER PRODUCTSDocument9 pagesEngineered TIMBER PRODUCTSAr Ayoushika AbrolNo ratings yet

- Building ConstructionDocument20 pagesBuilding ConstructionMuskan SinghNo ratings yet

- Final IHCDocument7 pagesFinal IHCMuskan SinghNo ratings yet

- Education ProgrammesDocument1 pageEducation ProgrammesMuskan SinghNo ratings yet

- Etabs ChecklistDocument2 pagesEtabs ChecklistNaresh JirelNo ratings yet

- Tass Data SheetDocument2 pagesTass Data SheetruwanpuraNo ratings yet

- AA1060 - Aluminum Alloy SheetDocument1 pageAA1060 - Aluminum Alloy SheettljytzNo ratings yet

- WIS 4-08-02 Specification Bedding Sidefill Material Buried PipelinesDocument6 pagesWIS 4-08-02 Specification Bedding Sidefill Material Buried PipelinespursuitpNo ratings yet

- BC Chapter 1Document37 pagesBC Chapter 1umarguyo38No ratings yet

- Pushover Analysis of Asymmetric Ordinary Moment R.C Frames Designed According To The Iranian CodesDocument10 pagesPushover Analysis of Asymmetric Ordinary Moment R.C Frames Designed According To The Iranian CodesGelbert SilotNo ratings yet

- Is SP 34 1987Document19 pagesIs SP 34 1987ankitNo ratings yet

- Technical Standard: (Signed Original On File) Sheet OFDocument7 pagesTechnical Standard: (Signed Original On File) Sheet OFd r hardyNo ratings yet

- New Port Project - Mr. Nabeel AL Buenain For MEED FINAL PDFDocument24 pagesNew Port Project - Mr. Nabeel AL Buenain For MEED FINAL PDFeng.tash5526No ratings yet

- Boedeker Plastics Polyurethane - Technical GuideDocument26 pagesBoedeker Plastics Polyurethane - Technical GuideJagdish PatelNo ratings yet

- Fire Dampers PL 10 19 20 Acc. en 1366 2Document28 pagesFire Dampers PL 10 19 20 Acc. en 1366 2candra trisilawatiNo ratings yet

- How To INSTALL Anchors in Accordance With BS 8539Document4 pagesHow To INSTALL Anchors in Accordance With BS 8539hanyaNo ratings yet

- Ce0061 Professional Course 4 - (Specialized 2) Ste Track: Prestressed Concrete DesignDocument38 pagesCe0061 Professional Course 4 - (Specialized 2) Ste Track: Prestressed Concrete DesignjerichoNo ratings yet

- F-EQC-09 Cladding Inspection ReportDocument1 pageF-EQC-09 Cladding Inspection Reportsamir ranjan dhalNo ratings yet

- Albodur 1055 en FormulationDocument10 pagesAlbodur 1055 en FormulationВиктор ИсакNo ratings yet

- Delayed PWHTDocument4 pagesDelayed PWHThasan_676489616No ratings yet

- Roof Beam and Concrete Gutter DesignDocument1 pageRoof Beam and Concrete Gutter DesignEric James L. PinaraNo ratings yet

- Revised Company ProfileDocument30 pagesRevised Company ProfileCharmaine CabreraNo ratings yet

- CR002 Project TimelineDocument1 pageCR002 Project Timelinephuckha2012No ratings yet

- Craftsman Compressor User ManualDocument60 pagesCraftsman Compressor User ManualMichael ShafferNo ratings yet

- MODocument10 pagesMOMark Libo-onNo ratings yet

- Electrical Work ActivitiesDocument2 pagesElectrical Work ActivitiesAlvin BadzNo ratings yet

- Horizon Linen Chutes Installation RequirementsDocument4 pagesHorizon Linen Chutes Installation Requirementshunkydee100% (1)

- Project: My Project Results For Design Section 0: Design Section 0Document86 pagesProject: My Project Results For Design Section 0: Design Section 0Santan KelapaNo ratings yet

- SPARK STAR-41 Failure of Metering UnitDocument1 pageSPARK STAR-41 Failure of Metering UnitChanna BasavarajNo ratings yet

- Handbook5 PDFDocument257 pagesHandbook5 PDFZAKROUNNo ratings yet

- Appendix D Geotechnical MemorandumDocument44 pagesAppendix D Geotechnical Memorandumdaniel bergerNo ratings yet

- 9A 01403 Structural Analysis - IDocument8 pages9A 01403 Structural Analysis - Isivabharathamurthy100% (1)