Professional Documents

Culture Documents

G - Rolling Bearing Lubrication

Uploaded by

lightsonsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G - Rolling Bearing Lubrication

Uploaded by

lightsonsCopyright:

Available Formats

BEARING

LUBRICATION

FAG Bearings India Limited Slide 1

Why lubrication?

To prevent or reduce metal to

metal contact between rolling or

sliding surfaces

To reduce friction and

eliminate wear of bearing

surfaces and protect the

bearing against corrosion

To seal against dust,

dirt, and moisture (in

case of greases)

FAG Bearings India Limited Slide 2

SIX PURPOSE OF LUBRICATION

1. Reduce Friction – Reduces the energy required to perform work

2. Reduce Wear– Equipment life is extended

3. Cool Rubbing Surface– Maintain working tolerances, extend oil life and

avoid catastrophic wear

4. Prevent Corrosion– Corrosion causes premature failure of equipment

5. Seal out/flush away contamination – Keeps working surface clean

6. Dampen shock – Acts as a cushion against high loads imposed by shock

loading. Vibration and noise are also reduced.

FAG Bearings India Limited Slide 3

Different lubricating conditions

a] Full fluid film lubrication b] Mixed Lubrication c] Boundary Lubrication

The surfaces are Both the load carrying The lubricating effect

completely oil film and the mainly depends on the

separated by a load boundary layer plays a lubricating properties

carrying film. major role. of the boundary layer.

FAG Bearings India Limited Slide 4

What are the properties VISCOSIT

of a lubricant which Y AND V-T

influence the separating BEHAVIO

film? UR

Viscosity reduces with

increase in

Viscosity is the temperature

resistance of a fluid to

deformation and flow

Lower the

viscosity,

thinner is

the

lubricatin Water has low Honey has high

g film viscosity. It viscosity. It does

flows easily not flow easily

FAG Bearings India Limited Slide 5

How does the

lubricant The lubricant adhering to the

function? surface of the parts in rolling

contact forms a layer which

separates the bearing

components which are moving

relative to each other

Metal

Lubricant

film

FAG Bearings India Limited Slide 6

What should one consider

while selecting a lubricant?

SPEED MEAN BEARING DIAMETER LOAD

moisture heat

The lubricant must be

capable of providing a

dust

supporting film at

operating loads, speeds

TEMPERATURES ENVIRONMENTAL INFLUENCES

and temperatures

FAG Bearings India Limited Slide 7

What are the types of

lubricants used for

lubrication of bearings?

GREASE OIL

90% of all

rolling bearings

are lubricated SOLID

LUBRICANT

with grease

FAG Bearings India Limited Slide 8

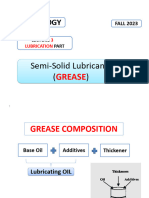

What is

grease? BASE

OIL THICKENER

GREASE IS A

DISPERSION

ADDITIVES INHIBITORS

ANTIOXIDANTS &

STABILISERS

FAG Bearings India Limited Slide 9

How does a grease Here’s how the

work? lubricant works!

The thickener functions

as a container for the base During the ‘running in’ of the

oil (similar to a sponge bearing, the grease works

holding water) itself into the cavities around

the bearing and remains there

throughout the service life of

the bearing. The base oil

It is the base oil in the bleeds from the thickener and

grease which does the supplies oil to the working

actual lubrication surfaces

FAG Bearings India Limited Slide 10

WHY

Why are greases used to

lubricate 90% of all GREASE

bearings?

Grease Grease is

Grease is

lubricated suitable for a

easily

arrangements wide range of

contained

are simple applications

Additionally Can be

No complicated Suitable for a

grease also has sealing transported

wide range of

a lubricating arrangements easily for

loads, speeds &

effect are required temperatures Relubrication

FAG Bearings India Limited Slide 11

Types of base oils

and thickeners?

LITHIUM

MINERAL

CALCIUM

SODIUM

THICKENERS

BASE OILS (SOAPS)

SYNTHETIC

SYNTHETIC

FAG Bearings India Limited Slide 12

Commonly seen in

a grease data

sheet? CONSISTENCY

CLASS The stiffness of a grease

which is assessed by

NLGI 1, 2, 3, 4

sinking a standard cone in

Depends on worked the grease and measuring

penetration the depth of penetration

NLGI 1: 310 - 340

The softer the grease, the

NLGI 2: 265 - 295

greater is the depth of

NLGI 3: 220 - 250 penetration

NLGI 4: 175 - 205

The lower limit defines the

temperature at which the

OPERATING grease can still flow

TEMPERATURE The upper limit defines

RANGE the temperature at which

the grease is thermally

stable

The temperature at which

DROP POINT

the grease begins to flow

FAG Bearings India Limited Slide 13

Will a grease give

optimum service life at the

upper temperature limit?

A COMMON MISINTERPRETATION

The upper temperature limit of the operating

range should not be considered as the maximum

temperature at which the grease can

continuously operate.

The service life of grease reduces drastically at

temperatures close to the limiting values.

THUMB RULE:

Optimum Service Life of a grease is obtained when the

continuous operating temperature is approximately

Upper Temperature Limit - 60o C

FAG Bearings India Limited Slide 14

What are the

types of

greases?

MINERAL OIL GREASES

LITHIUM

CALCIUM SOAP SODIUM SOAP

SOAP

Water resistant Poor water Water resiistant

Moderate load resistance Moderate load

capacity Good load capacity capacity

Drop point: 80 - 100o Drop point: 150 - Drop point: 170

C 190o C - 200o C

Multipurpose grease

In case of higher operating temperatures complex soap suitable for continuous

based greases must be used operating temperatures

of 70 -80oC

FAG Bearings India Limited Slide 15

Are there any other

types of greases?

SYNTHETIC OIL GREASES SODIUM

METAL SOAPS CALCIUM

LITHIUM

SODIUM

COMPLEX METAL CALCIUM SYNTHETIC

SOAPS THICKENERS

ARE ALSO USED

LITHIUM

Metal Soap or Complex Metal Soaps in Synthetic Oil and Synthetic Greases are expensive

(2 - 1 50 times the cost of a multipurpose grease) and selected whenever operating

conditions absolutely demand their use

FAG Bearings India Limited Slide 16

What grease to

use where?

In the high load range, a grease

with EP additives must be used

ka.n.dm = speed index

ka = 1 for ball bearings

n = speed of rotation

dm = mean bearing diam.

P/C = Ratio of Equivalent

Dyn. Load to the Dyn.

In the normal range, Load Rating of the bearing

general multipurpose

greases can be used

In the high load, high speed

range, a thermally stable In the high speed range, a

grease must be used low friction grease must be

used

FAG Bearings India Limited Slide 17

Let us first look at the important effect of Lubricant Viscosity :

A well approved method is to compare Prevailing Viscosity to Required

Viscosity, also called Operating Viscosity to Reference Viscosity.This

viscosity ratio is called Kappa :

=

1

= Operating Viscosity (mm /s) or Prevailing Viscosity;affected by Rating

2

Viscosity (mm2/s) and Operating Temperature (°C)

1=Reference Viscosity (mm /s) or Required Viscosity;affected by

2

Bearing Pitch Diameter (mm) and Speed (rpm)

FAG Bearings India Limited Slide 18

Example

A bearing with Bearing bore d = 340mm, Bearing OD = 420 mm is required

to operate at a speed of N = 500 rpm. The operating temperature has been

determined by experience to be 70C.

Question:

What Viscosity is required to obtain satisfactory lubrication and what

viscosity does this represent at reference temperature 40 C

FAG Bearings India Limited Slide 19

Solution

dm = 0.5[D+D] = 380mm

Draw vertical line upto the

speed curve of 500 rpm.

Draw horizontal line from the

point of intersection to the Y

axis where the requisite

kinematic viscosity 1 is

obtained. In this case it is

13mm 2 / sec.

FAG Bearings India Limited Slide 20

Draw a vertical line from the

temperature of 70 degree

which intersect with the

horizontal line of the

requisite kinematic viscosity

13mm 2 / sec.

Then follow the slope of the

nearest diagonal until it

intersects the 40 degree

temperature line .

From this point project a

horizontal line to the Y axis

to find out the kinematic

viscosity of the oil. Thus the

kinematic viscosity of the oil

to be used must be at least

39mm 2 / sec.

FAG Bearings India Limited Slide 21

What does express ?

> 2 -- predominantly hydrodynamic lubrication

= 0.4 ... 2.0 -- predominantly mixed friction

< 0.4 -- predominantly metallic contact between rolling

elements and raceways

FAG Bearings India Limited Slide 22

How much

grease? Actually, very little

grease is required to

lubricate bearings

Then why are

large amounts of

grease provided?

Large empty spaces

For the sake of result in grease leaving

operational reliability. the vicinity of the

The grease reservoir bearing. The

must be as close to the lubricating effect is no

bearing as possible longer enhanced

FAG Bearings India Limited Slide 23

HOW MUCH

GREASE?

FOR OPEN BEARINGS

WHICH ARE LOCATED IN

HOUSINGS

Pack the bearing with grease

Grease filling in high

speed bearings must be

about 20 to 30% of the

Pack the housing space

free space

partially with grease so that

there is adequate space in the

In low speed bearings housing to accommodate the

(n.dm < 50,000), the grease expelled from the

bearing and housing may bearing during the running in

be packed with grease period

Bearings which are pre-greased and sealed by

manufacturers carry a grease charge of 30 - 40% of

the free space in the bearing

FAG Bearings India Limited Slide 24

Factors to be considered for grease selection

Criteria for Grease Selection Properties of grease to be selected

Operating Condition

Speed index n.dm For high speed indices d.dm : consistency class 2-3

Load ratio P/C For High P/C load ratios : consistency class 1-2

Running Properties

Low friction, also during starting Grease of penetration class 1-2 with synthetic base oil of low viscosity

Low constant friction at steady state Grease of low penetration class 3-4, grease quantity =30% of the free

condition but higher starting friction bearing space or class 2 to 3, grease quantity<20% of the free bearing

admissible space

Low noise level Low noise grease [high degree of cleanliness]of penetration class 2

Mounting Conditions

Inclined/vertical position of bearing Grease with good adhesion properties of penetration class 3 to 4

axis

Outer ring rotating, inner ring Grease with large amount of thickener,penetration class 2 to 4, grease

stationary, or centrifugal force on the fill quantity depending on speed.

bearing

Maintenance

Frequent Relubrication Soft grease of penetration class 1 to 2

Infrequent Relubrication Grease retaining its penetration class 2 to 3 under stressing, upper

For life lubrication operating temperature limit higher than the operating temperature

FAG Bearings India Limited Slide 25

Factors to be considered for grease selection

Criteria for Grease Selection Properties of grease to be selected

Environmental Conditions

High temperature, for life lubrication Heat resistant grease with synthetic base oil and heat resistant[eg.

Synthetic ] Thickener

High temperature, Relubrication Grease which does not form any residues at high temperatures

Low temperature Grease with low-viscosity base oil and suitable thickener,penetration

class 1 to 2

Dust Environment Stiff grease of penetration class 3

Condensate Emulsifying grease e.g sodium or lithium soap base grease

Splash water Water repellent grease e.g. calcium soap base grease of penetration

class 3

Aggressive media[acids,bases etc.] Special grease to be used in consultation with FAG

Radiation Upto absorbed dose rate 2.104J/kg, rolling bearing grease to DIN 51 825

Up to absorbed dose rate2.107J/Kg – Consult FAG

EP lithium soap grease of consistency class 2, frequent Relubrication

Vibratory Stressing With Moderate vibratory stresses, barium complex grease of consistency

class2.

With solid lubricant additives or lithium soap base grease of consistency

class3

Up to 10-5 mbar, depending on temperature and base oil, rolling bearing

Vacuum greases according to DIN 51 825, consult FAG

FAG Bearings India Limited Slide 26

GREASE PROPERTIES

Suitability

Load

Thickener Temperature Drop Water For

Soap Base Oil Carrying Remarks

Type Range Point °C Resistance Rolling

Capacity

Bearings

Aluminium -20….70 120 ++ + + Swells with water

Good sealing action

Calcium -30….50 80….100 +++ + +

Mineral against water

Oil

Lithium -35….130 170….200 +++ + +++ Multipurpose grease

Normal

Sodium -30….100 150….190 - ++ ++ Emulsifies with water

For low and high

Lithium PAO -60….150 170….200 +++ ++ +++ temperatures, high

speeds

For low temperatures,

Lithium Ester -60….130 190 ++ + +++

high speeds

Aluminium -30….160 260 +++ + +++ Multipurpose grease

Multipurpose

Mineral

Complex Barium -30….140 220 ++ ++ +++ grease,resistant to

Oil

vapour

Multipurpose grease ,

Calcium -30….140 240 ++ ++ +++

may harden

+++ Very Good ++ Good + Moderate - Poor

FAG Bearings India Limited Slide 27

GREASE PROPERTIES

Load Suitability

Thickener Temperature Drop Water

Soap Base Oil Carrying For Rolling Remarks

Type Range Point °C Resistance

Capacity Bearings

Lithium -30….150 240 ++ ++ ++ Multipurpose grease

Mineral

Oil

Multipurpose grease for

Sodium -30….130 220 + + +++

high temperatures

For wide temperature

Aluminium -60….160 260 +++ ++ +

range, good supply

For low and high

Barium -60….160 220 +++ +++ +++ temperatures, high

PAO speeds

For low and high

Complex Calcium -60….160 240 +++ +++ +++ temperatures, high

speeds

For wide temperature

Lithium -40….180 240 ++ +++ +++

range

Barium -40….130 200 ++ ++ +++ For low temperature

and higher speeds at

Calcium Ester -40….130 200 +++ ++ +++ moderate loads

For wide temperature

Lithium -40….180 240 ++ + +++

range

For especially wide

Lithium Silicone -40….180 240 ++ + +++

temperature range.

+++ Very Good ++ Good + Moderate - Poor

FAG Bearings India Limited Slide 28

GREASE PROPERTIES

Suitability

Load

Thickener Temperature Drop Water For

Soap Base Oil Carrying Remarks

Type Range Point °C Resistance Rolling

Capacity

Bearings

Mineral For higher temperatures

-20….150 Without +++ + ++

Oil at low speeds

Bentonite

For wide temperature

PAO -50….180 Without +++ + ++

range

Mineral For higher temperatures

-25….160 250 +++ ++ +++

Oil at medium speeds

High temperature

PAO -30….200 250 +++ +++ +++ grease with good long

term effectiveness

Polyurea

Silicone For high and low

-40…200 250 +++ - ++

Oil temperatures, low loads

Fluoro For high and low

Silicone -40….200 250 +++ + +++ temperatures, moderate

Oil loads

Alkoxy- Both grease for very

fluoro -50….250 Without +++ ++ +++ high and low

oil temperatures

PTFE

Fluoro

Very good resistance to

Silicone -40….200 Without +++ ++ +++

chemicals and solvents

Oil

+++ Very Good ++ Good + Moderate - Poor

FAG Bearings India Limited Slide 29

GREASE RELUBRICATION QUANTITIES

Relubrication quantity m1 for weekly to yearly lubrication m 1 = D.B.x [g]

Relubrication x

Weekly 0.002

Monthly 0.003

Yearly 0.004

Relubrication Quantity m 2 for extremely short re lubrication intervals

m 2 = [0.5….20].V [Kg/h]

Relubrication Quantity m 3 prior to restarting after several years of standstill

m 3 = D.B .0.01[g] = D.B.0.01/28.35 [oz] D =bearing bore diameter [mm]

D =bearing outside diameter [mm]

V = free space in the bearing B =bearing width [mm]

G = bearing width [kg]

= /4.B.[D2 – d2].109 – G/7800 [ m3] G’= bearing weight [lb]

= /4.B.[D – d ].10 – G’.0.4536/7800 [ m ]

2 2 9 3

FAG Bearings India Limited Slide 30

OIL LUBRICATION :

Recommended when

• If adjacent machine component are supplied with oil.

• If heat must be dissipated by the lubricant.

The main advantages of Oil lubrication are:

– Churning of oil is avoided.

– Friction in the bearings is low.

– It provides for excellent cooling.

FAG Bearings India Limited Slide 31

Lubrication Systems

Lubrications systems can be classified according to

-- Kind of Lubricant Used

-- Kind of Lubrication System Employed.

FAG Bearings India Limited Slide 32

Kind of Lubricant Used

-- Dry Lubricant

-- Grease

-- Oil

FAG Bearings India Limited Slide 33

Kind of Lubrication System Employed

-- For Life Lubrication

-- Spray Lubrication

-- Oil Sump Lubrication

-- Circulating Oil Lubrication

-- Oil Jet Lubrication

-- Intermittent drip oil Lubrication/ Drip Feed Lubrication

-- Oil Mist Lubrication

-- Oil Air Lubrication

FAG Bearings India Limited Slide 34

Factors to be considered for Selection of Lubrication System

Operating Conditions for the Rolling bearings.

Requirements on running, noise, friction and temperature

behaviour.

Requirements on safety of operation i.e safety against

premature failure due to Wear, fatigue, corrosion and

against damage caused by foreign matter having penetrated

deep into the bearing.

Cost of Installation and maintenance of a lubricating system.

Detailed Information on the lubricating systems commonly used

is furnished in the forthcoming slides

FAG Bearings India Limited Slide 35

Selection of Lubrication System

Lubricant Lubrication Lubricating Design measures Index of

Suitable

systems equipment speed n . dm bearing types,

operational

behavior

Dry For life - - Mainly deep

lubricant lubrication 1500 groove ball

bearing

Relubrication - -

Grease For life - - 0,5 .106 All bearing

lubrication 1,8 .106 fortypes.

Relubrication Hand-operated Inlet holes suitable greases

Depending press, if necessary, grease on

rotational grease gun valve, collecting speed

and chamber for spend grease type

grease with the

Spray central Feed pipes or holes exception of

lubrication lubricating collecting chamber spherical roller

plant for spend grease thrust bearings.

FAG Bearings India Limited Slide 36

Selection of Lubrication System

Lubricant Lubrication Lubricating Design measures Index of

Suitable

systems equipment speed n . dm bearing types,

operational

il Oil sump Dipstick Housing space suffi- 0,5 .106 behavior

All bearing

arger lubrication tube, cient for certain oil type. Noise

olumes) oil level volume, overflow damping effect

indicator outlet holes, depending o

connection for oil viscosity;

monitoring higher energ

equipment losses due to

Circulating oil Oil supply holes Must be deter- increased

lubrication due housing space suffi- mined indivi- friction caused

to pumping cient for certain dually. by churning,

action of the oil volume conveying good cooling

bearings or elements adapter to effect, discharge

special conve- the oil viscosity and of wear particles

ying elements rotational speed. by circulating

oil.

FAG Bearings India Limited Slide 37

Selection of Lubrication System

Lubricant Lubrication Lubricating Design measures Index of Suitable

system equipment speed n . dm bearing types,

operational

behavior

Oil Circulating Circulation Sufficiently large oil 1 . 106 All bearings

( larger oil lubrication plant inlet and outlet types. Noise

volume) holes damping effect

depending on

oil viscosity.

Oil jet Circulation Nozzles for direct

higher energy

lubrication plant oil injection, suffi-

losses due to

with nozzles ciently large oil Proved up to

increased

outlet holes 4 . 106

friction caused

by churning,

good cooling

effect, discharge

of wear particles

by circulating

oil.

FAG Bearings India Limited Slide 38

Selection of Lubrication System

Lubricant Lubrication Lubricating Design measures Index of Suitable

system equipment speed n . dm bearing type

operational

behavior

Oil Intermittent Central Outlet holes 1.5 . 106 All bearing

minimum drip oil lubri- lubricating depending ontypes. Noise

volumes ) cation plant, drip bearing type damping

drip feed lubri feed lubri- oil viscosity effect depen-

cation. cator, oil amount of oil ding on oil

spray design quantity and

equipment viscosity

Oil mist Oil mist Extraction equip-

lubrication lubricating ment if necessary

plant, if

necessary oil

separator

Oil air Central p/ Extraction equip-

lubrication “oil air” ment if necessary

FAG Bearings India Limited Slide 39

FAILURE ANALYSIS DUE TO INADEQUATE LUBRICATION

Damage Symptom Cause Remarks

Noise Starved Lubrication Local metal-to-metal contact,interrupted lubricating film

without load transmitting and damping effect

Unsuitable Lubricant Lubricating film too thin, due to too low a viscosity of the oil or

base oil of the grease. The structure of the grease thickener

can be unsuitable.

Contaminants Dirt particles disrupt the lubricating film and produce a noise

Cage Wear Starved Lubrication Local metal to metal contact, un-interrupted lubricating film

without load transmitting and damping effect.

Unsuitable Too low a viscosity of the oil or base oil, no boundary layer

lubrication formation

Wear on rolling Starved Lubrication Local metal to metal contact, interrupted lubricating film

elements, without load transmitting and damping effect

raceways, lip Tribocorossion due to oscillating relative motions, slip marks

surfaces

Unsuitable Lubricant Too low a viscosity of the oil or base oil.

Lubricants without antiwear or EP additives

Contaminants Solid hard particles or liquid, corrosive media

FAG Bearings India Limited Slide 40

You might also like

- ROTAIR Lubricants Leaflet PDFDocument16 pagesROTAIR Lubricants Leaflet PDFPhuc DcNo ratings yet

- Ferodo Datenblatt MontagepasteDocument9 pagesFerodo Datenblatt MontagepasteSpirosAlexopoulosNo ratings yet

- 2018.11.25 Grease Book FuchsDocument18 pages2018.11.25 Grease Book FuchsnghiaNo ratings yet

- The Element That Rolls The Bearing - eDocument64 pagesThe Element That Rolls The Bearing - esmc07No ratings yet

- LubricationDocument9 pagesLubricationHaseeb BokhariNo ratings yet

- Make Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsDocument24 pagesMake Bearings Live Longer.: Plain Bearing Lubrication: Product Selection and TipsMario MullerNo ratings yet

- Ease FundamentalsDocument32 pagesEase FundamentalsHazem Hasan100% (1)

- LEC5 Lubrication 2022Document37 pagesLEC5 Lubrication 2022mohamed hodiriNo ratings yet

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaNo ratings yet

- TI - LubricationDocument5 pagesTI - LubricationAlex LinsNo ratings yet

- FAG BearingDocument69 pagesFAG BearingBasemNo ratings yet

- Part 6 Bearing & Lubication 15Document15 pagesPart 6 Bearing & Lubication 15Aenur RofiiqNo ratings yet

- Gear Oil Basics: Additional DifferencesDocument5 pagesGear Oil Basics: Additional DifferencestarsotigerNo ratings yet

- Molykote M Gear Oil AdditiveDocument3 pagesMolykote M Gear Oil AdditiveJuan Pablo Fernandez ZuñigaNo ratings yet

- Applications For GreasesDocument23 pagesApplications For Greasesdanielr.hanna93No ratings yet

- Lubrication PDFDocument123 pagesLubrication PDFFran JimenezNo ratings yet

- Tribology InternationalDocument9 pagesTribology InternationalBragasNo ratings yet

- 02 Additive Components Southern Asia 2019Document42 pages02 Additive Components Southern Asia 2019Jahmia Coralie100% (1)

- Lecture 3Document52 pagesLecture 3saxadi4814No ratings yet

- Grease 2Document4 pagesGrease 2arunNo ratings yet

- Analisis de Grasa en CampoDocument10 pagesAnalisis de Grasa en CampoAlfonso VásquezNo ratings yet

- Types of Lubricants and How To Use ThemDocument14 pagesTypes of Lubricants and How To Use ThemJohn Robert FumeraNo ratings yet

- Technical Trainer Pack - SARALDocument121 pagesTechnical Trainer Pack - SARALPratheesh100% (1)

- LubricationDocument49 pagesLubricationAdel KlkNo ratings yet

- Multifak EP - Data SheetDocument2 pagesMultifak EP - Data SheetJeremias UtreraNo ratings yet

- 6000 en 00 07 LubricationDocument28 pages6000 en 00 07 LubricationM Ferry AnwarNo ratings yet

- 4 Additive Components NaDocument26 pages4 Additive Components NaJahmia Coralie100% (2)

- LB Series Asphalt Mixing Plant Repair and Maintenance ManualDocument38 pagesLB Series Asphalt Mixing Plant Repair and Maintenance ManualLai_Wei_Wah_7018No ratings yet

- SKF Bearings With Solid OilDocument8 pagesSKF Bearings With Solid OilLuisSilvaNo ratings yet

- 4 Article TLT Grease AdditivesDocument11 pages4 Article TLT Grease AdditivesYasir ShaikhNo ratings yet

- Shell Gadus S4 OG Clear Oil 20000Document2 pagesShell Gadus S4 OG Clear Oil 20000Muhammad SaputraNo ratings yet

- Grease BasicsDocument6 pagesGrease BasicsnagbabuiNo ratings yet

- MCE321 - Lubrication and LubricantsDocument9 pagesMCE321 - Lubrication and LubricantsVanina VaniniNo ratings yet

- Automatic and Manual GreasingDocument10 pagesAutomatic and Manual GreasingAhmed SalahNo ratings yet

- DID YOU Know?: Chassis Part MaintenanceDocument1 pageDID YOU Know?: Chassis Part MaintenanceJulio SanjuanNo ratings yet

- TT Components and Characteristics of GreaseDocument2 pagesTT Components and Characteristics of GreaseAnonymous alQXB11EgQNo ratings yet

- Additive ComponentsDocument32 pagesAdditive ComponentsmaiatostiNo ratings yet

- "Lubed For Life" Bearings - Fact or FrictionDocument7 pages"Lubed For Life" Bearings - Fact or Frictionmechmaster4uNo ratings yet

- Components: Hitec® 5777Document2 pagesComponents: Hitec® 5777mgamal1080No ratings yet

- Lubrication Training - Basics of LubricationDocument35 pagesLubrication Training - Basics of LubricationFran JimenezNo ratings yet

- 05 - Lubrifiere PDFDocument14 pages05 - Lubrifiere PDFRadu BurloiuNo ratings yet

- TIY383 - Milwaukee Grease ManualDocument7 pagesTIY383 - Milwaukee Grease ManualCarlos SalcedoNo ratings yet

- Understanding Lubrication From The BearingDocument22 pagesUnderstanding Lubrication From The BearingengrsurifNo ratings yet

- Tle Automotive 9 - Week 7-8Document5 pagesTle Automotive 9 - Week 7-8Gretchen Sarmiento Cabarles AlbaoNo ratings yet

- 1.2. BTR - Lubrication NotesDocument17 pages1.2. BTR - Lubrication Notesvishnu vishnu G.T.No ratings yet

- Vikas Yadav For Successfully Completing The Elearning Program On BearingsDocument30 pagesVikas Yadav For Successfully Completing The Elearning Program On BearingsAvinash SinghNo ratings yet

- Fundamentals of LubricantDocument25 pagesFundamentals of Lubricantfadzfirdaus100% (1)

- EGT001 Roller Bearings Lubrication TrainingDocument10 pagesEGT001 Roller Bearings Lubrication TrainingJom BonhayagNo ratings yet

- Grease AppearanceDocument2 pagesGrease AppearanceMohamed HassanNo ratings yet

- Grasa Hyperion Red HD EP 2Document4 pagesGrasa Hyperion Red HD EP 2johnNo ratings yet

- Shell Gadus S3 High Speed Coupling GreaseDocument2 pagesShell Gadus S3 High Speed Coupling GreaseMUHAMMAD LUTHFINo ratings yet

- Gmax LTG-couplings PDFDocument4 pagesGmax LTG-couplings PDFannica reclosadoNo ratings yet

- SKF Bearings With Solid Oil: Relubrication-Free Solutions For Wet EnvironmentsDocument12 pagesSKF Bearings With Solid Oil: Relubrication-Free Solutions For Wet EnvironmentsPhương ThảoNo ratings yet

- General Lubricant Training - Livre - Blanc - v5 - en-GBDocument44 pagesGeneral Lubricant Training - Livre - Blanc - v5 - en-GBYos BirNo ratings yet

- 0901d196802aada0 PDF Preview MediumDocument2 pages0901d196802aada0 PDF Preview MediumAbraham Jimenez CordobaNo ratings yet

- Chapter Four Lubrication and CorrosionDocument32 pagesChapter Four Lubrication and CorrosionTemesgen GetaNo ratings yet

- 06 WDD012 Tribology (2020)Document31 pages06 WDD012 Tribology (2020)Varun Mahulikar100% (1)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- CBDD Quality Control Check PlanDocument3 pagesCBDD Quality Control Check PlanlightsonsNo ratings yet

- CBDD Standard Paint Spec (With SW Data)Document5 pagesCBDD Standard Paint Spec (With SW Data)lightsonsNo ratings yet

- Piping Design ConsiderationDocument46 pagesPiping Design ConsiderationlightsonsNo ratings yet

- Presentation Preheater Fan SelectionDocument22 pagesPresentation Preheater Fan SelectionlightsonsNo ratings yet

- Selection PresentationDocument15 pagesSelection PresentationlightsonsNo ratings yet

- XXXXX - PCM - 001with BWE Contact DetailsDocument8 pagesXXXXX - PCM - 001with BWE Contact DetailslightsonsNo ratings yet

- CBDD QAQC Manual (Rev G-2010Document18 pagesCBDD QAQC Manual (Rev G-2010lightsonsNo ratings yet

- Deliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00Document13 pagesDeliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00lightsonsNo ratings yet

- Piping Engineering NotesDocument46 pagesPiping Engineering Noteslightsons100% (1)

- Pipe BranchingsDocument12 pagesPipe BranchingslightsonsNo ratings yet

- 2097-1-G-G0-028 Air & Gas System - Rev 00Document15 pages2097-1-G-G0-028 Air & Gas System - Rev 00lightsonsNo ratings yet

- 2097-1-G-G0-034 COAL PREPARATION & FIRING SYSTEM - Rev 00Document15 pages2097-1-G-G0-034 COAL PREPARATION & FIRING SYSTEM - Rev 00lightsonsNo ratings yet

- Role of Erection EngDocument15 pagesRole of Erection Englightsons100% (1)

- Boiler High Pressure Chemical Dosing System Functional Description 2097-1-G-G0-031Document7 pagesBoiler High Pressure Chemical Dosing System Functional Description 2097-1-G-G0-031lightsonsNo ratings yet

- 2097-1-G-G0-027 LDO and HFO System - Rev 00Document12 pages2097-1-G-G0-027 LDO and HFO System - Rev 00lightsonsNo ratings yet

- 2097-1-G-G0-030 - AH Wash.&fire Figh.Document9 pages2097-1-G-G0-030 - AH Wash.&fire Figh.lightsonsNo ratings yet

- I - Fits and ToleranceDocument17 pagesI - Fits and TolerancelightsonsNo ratings yet

- F - Rolling Bearing Storage and HandlingDocument13 pagesF - Rolling Bearing Storage and HandlinglightsonsNo ratings yet

- E - Rolling Bearing CagesDocument20 pagesE - Rolling Bearing CageslightsonsNo ratings yet

- 2097-1-G-G0-033 - Aux. Steam SystemDocument6 pages2097-1-G-G0-033 - Aux. Steam SystemlightsonsNo ratings yet

- Valve SpecificationDocument7 pagesValve SpecificationlightsonsNo ratings yet

- Fuzzy LogicDocument29 pagesFuzzy LogiclightsonsNo ratings yet

- Parametric Design of A Waste To Energy PDocument3 pagesParametric Design of A Waste To Energy PlightsonsNo ratings yet

- Boiler Alkali BoiloutDocument5 pagesBoiler Alkali BoiloutlightsonsNo ratings yet

- 2 X 30 MW Boiler For DPL (Unit 1 & 2) PpilDocument2 pages2 X 30 MW Boiler For DPL (Unit 1 & 2) PpillightsonsNo ratings yet

- PDS - E - Igolflex R 2011-10 - 1 PDFDocument3 pagesPDS - E - Igolflex R 2011-10 - 1 PDFSiEn PhaNithNo ratings yet

- EagleBurgmann RoTechBooster For-Alliance EN 0120Document3 pagesEagleBurgmann RoTechBooster For-Alliance EN 0120edavidNo ratings yet

- Phase Diagrams:: The Iron-Iron Carbide (Fe-Fe3C) Diagram or Iron-Carbon (Fe-C) Equilibrium DiagramDocument46 pagesPhase Diagrams:: The Iron-Iron Carbide (Fe-Fe3C) Diagram or Iron-Carbon (Fe-C) Equilibrium DiagramUsman FarooqNo ratings yet

- WHO HSE WSH 10.01 10 Rev1 EngDocument19 pagesWHO HSE WSH 10.01 10 Rev1 EngAman YadavNo ratings yet

- Francis 2002Document12 pagesFrancis 2002Puku KunNo ratings yet

- Chapter 11Document109 pagesChapter 11Tysir Sarhan100% (1)

- Sterlization of Water Using Bleaching PowderDocument18 pagesSterlization of Water Using Bleaching PowdersachinNo ratings yet

- Spinodal DecompositionDocument13 pagesSpinodal DecompositionRudrang ChauhanNo ratings yet

- Food Processing Preservation - 2021 - Rezzadori - Bioavailability of Bioactive Compounds of Guava Leaves Psidium GuajavaDocument11 pagesFood Processing Preservation - 2021 - Rezzadori - Bioavailability of Bioactive Compounds of Guava Leaves Psidium GuajavaSergio SánchezNo ratings yet

- Chapter 1 Introduction To Biopharmaceutics and Pharmacokinetics 1Document92 pagesChapter 1 Introduction To Biopharmaceutics and Pharmacokinetics 1Marc Alamo100% (2)

- Effects of Preparation Parameters On Paraffin Wax MicroemulsionDocument5 pagesEffects of Preparation Parameters On Paraffin Wax MicroemulsionCarlotta C.No ratings yet

- 01 03 01 Coolant TR0199 99 2091 enDocument18 pages01 03 01 Coolant TR0199 99 2091 enNelliNo ratings yet

- Water and Its Treatment: Unit 1Document72 pagesWater and Its Treatment: Unit 1Amal RasheedNo ratings yet

- Final Exam Me 500 and Me 442 (Vincoy)Document18 pagesFinal Exam Me 500 and Me 442 (Vincoy)Vincoy JohnlloydNo ratings yet

- Global Hydrogen Compressors Market - Growth, Trends and Forecasts 2018 - 2023Document144 pagesGlobal Hydrogen Compressors Market - Growth, Trends and Forecasts 2018 - 2023vikasaggarwal01No ratings yet

- Tissue RespirationDocument28 pagesTissue RespirationSheldon MillerNo ratings yet

- ACTIVITY 8 Blood and Blood StainsDocument5 pagesACTIVITY 8 Blood and Blood StainsLouella Kaye C. LopezNo ratings yet

- Calculation of Shafts in Marine Applications: Classification NotesDocument28 pagesCalculation of Shafts in Marine Applications: Classification NotesMorteza ShakerienNo ratings yet

- Stress-Strain Model of Unconfined and Confined Concrete and Stress-Block ParametersDocument112 pagesStress-Strain Model of Unconfined and Confined Concrete and Stress-Block ParametersGabrielaSanMartínNo ratings yet

- CH 5 - ProblemsDocument8 pagesCH 5 - ProblemsKhris Griffis89% (18)

- q3 cGBPariantDocument4 pagesq3 cGBPariantGhasem BashiriNo ratings yet

- S-MDT PB RB e Eu A4Document6 pagesS-MDT PB RB e Eu A4lesmosNo ratings yet

- Harmonized Microbial Limits Testing Val... Strategies - IVT - GMP - MicrobiologyDocument9 pagesHarmonized Microbial Limits Testing Val... Strategies - IVT - GMP - MicrobiologyRouag AbdelkarimNo ratings yet

- CDocument17 pagesCaischosNo ratings yet

- Nuclear Energy Is A Boon or Bane 2Document10 pagesNuclear Energy Is A Boon or Bane 2saket100% (1)

- DFL E-28 MixtureDocument13 pagesDFL E-28 MixtureFersan AngelesNo ratings yet

- Evoke Ch-1 MCQsDocument7 pagesEvoke Ch-1 MCQsHimanshu SattiNo ratings yet

- Klubersynth UH1 6Document6 pagesKlubersynth UH1 6Antonio Rivera VillavicencioNo ratings yet

- KalrezDocument8 pagesKalreza100acomNo ratings yet

- Exp 4 Osborne Reynolds DemonstrationDocument9 pagesExp 4 Osborne Reynolds DemonstrationJivashiniBalasupurManiamNo ratings yet