Professional Documents

Culture Documents

Topic - Manufacturing Process of Pump (Casing) by Casting

Uploaded by

2058SOMYAJIT RAY0 ratings0% found this document useful (0 votes)

48 views11 pagesg

Original Title

BMP PPT

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentg

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

48 views11 pagesTopic - Manufacturing Process of Pump (Casing) by Casting

Uploaded by

2058SOMYAJIT RAYg

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 11

BASIC MANUFACTURING

PROCESSES

TOPIC - MANUFACTURING PROCESS OF

PUMP (CASING) BY CASTING

GROUP MEMBERS

1.SOMU DE (2102057)

2.SOMYAJIT RAY (2102058)

3.TASKEEN AHMED (2102071)

4.JAYANTI BADARA (2102094)

What is Casting?

Casting is a manufacturing

process in which a liquid

material is usually poured

into a mold, which contains

a hollow cavity of the

desired shape, and then

allowed to solidify,the

solidified part is known as a

casting.

DIFFERENT COMPONENTS OF PUMP

Impeller

Shaft

Casing

Sealing

Bearings

Couplings

Suction Nozzle

Discharge Nozzle

CASING

The pump casing refers to the

outside shell of the pump. It

has to seal off the inside of

the unit to the outside with

respect to pressure and

fluids. The structure of the

casing differs depending on

the type of pump.

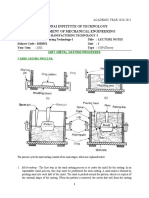

MANUFACTURING PROCESSES OF PUMP CASING

THROUGH CASTING

Pump casing manufacturing through casting is a popular

method in the industry due to its cost-effectiveness and

ability to produce complex shapes.The following are the

steps involved in pump casing manufacturing through

casting:

Pattern making: A pattern is a

replica of the final product. The

pattern is made by a skilled

worker, and it must be accurate

and of the same size as the final

product.

Mold making: The pattern is then

used to make a mold, a special

type of sand called casting sand is

prepared. This sand is mixed with

a binder and compacted around

the pattern to create the mold

cavity. The mold is made in two

halves, a cope and drag. The

cope is the top half of the mold,

and the drag is the bottom half.

Melting and pouring: The metal is melted

in a furnace and then poured into the mold.

The molten metal is poured from a ladle into

a sprue, which is a funnel-shaped channel

that leads to the mold cavity.

Cooling and solidification: The metal in

the mold cools and solidifies, taking on the

shape of the mold. This process is called

solidification, and it may take a few

minutes or several hours, depending on

the size of the casting.

Shakeout: After the casting

has cooled, the mold is broken

open, and the casting is

removed. This process is

called shakeout, and it may be

done by hand or by using a

mechanical vibrator.

Finishing: The casting is then cleaned up

by removing any excess material or rough

edges. This may be done by grinding,

sandblasting, polishing, or painting to

achieve the desired final shape and

appearance.

You might also like

- BMP - PPT 2Document12 pagesBMP - PPT 22058SOMYAJIT RAYNo ratings yet

- BMP - PPT 3Document13 pagesBMP - PPT 32058SOMYAJIT RAYNo ratings yet

- Casting LabDocument11 pagesCasting Labfawad naeemNo ratings yet

- BMP Report G6Document3 pagesBMP Report G6Damage SinghNo ratings yet

- Report On Pump Casing Manufacturing Through Sand CDocument2 pagesReport On Pump Casing Manufacturing Through Sand C2058SOMYAJIT RAYNo ratings yet

- Ae15301-Aircraft Materials and Manufacturing Technology PDFDocument115 pagesAe15301-Aircraft Materials and Manufacturing Technology PDFDurai Raj Kumar100% (1)

- 4castingprocesses 120526012606 Phpapp01Document28 pages4castingprocesses 120526012606 Phpapp01Chennai TuitionsNo ratings yet

- Training Material For Casting & ForgingsDocument8 pagesTraining Material For Casting & ForgingsNilesh GhodekarNo ratings yet

- A Conceptual Design of Pattern To Replace Investment CastingDocument19 pagesA Conceptual Design of Pattern To Replace Investment Casting113314No ratings yet

- MM Experiment ReportDocument10 pagesMM Experiment ReportAbdullah ArshadNo ratings yet

- Ceramic Materials Unit 5,6Document32 pagesCeramic Materials Unit 5,6Akhil BaaNo ratings yet

- Material HandlingDocument8 pagesMaterial HandlingSuman MukherjeeNo ratings yet

- Description of Machining Process: Figure 1 - Face Milling ProcessDocument7 pagesDescription of Machining Process: Figure 1 - Face Milling ProcessAmirul SyakirNo ratings yet

- Fundamentals of Manufacturing and Process Report (Group - 4)Document6 pagesFundamentals of Manufacturing and Process Report (Group - 4)Lovely VisakhaNo ratings yet

- Cassting 1Document10 pagesCassting 1steve ogagaNo ratings yet

- ME 2201 - Manufacturing Technology-IDocument147 pagesME 2201 - Manufacturing Technology-IMahendra Babu MekalaNo ratings yet

- Unit 1 Notes MTDocument25 pagesUnit 1 Notes MTRathesh Priyan KNo ratings yet

- Overviews: Estimators Parts Widgets Processes Materials Suppliers NewsDocument113 pagesOverviews: Estimators Parts Widgets Processes Materials Suppliers Newsrupesh89890% (1)

- Special CastingDocument24 pagesSpecial CastingManohara ErlaNo ratings yet

- BME UNIT2 ClasssDocument30 pagesBME UNIT2 ClasssUpendra NeravatiNo ratings yet

- Casting ProcessDocument40 pagesCasting Processharish3742No ratings yet

- Sequence of Manufacturing Process: Mold-MakingDocument3 pagesSequence of Manufacturing Process: Mold-MakingHammad SheikhNo ratings yet

- Types of CastingDocument14 pagesTypes of CastingRamoji Aditya Chary100% (1)

- Department of Industrial & Production Engineering BUET, Dhaka-1000Document25 pagesDepartment of Industrial & Production Engineering BUET, Dhaka-1000Anshul ShuklaNo ratings yet

- ME-208 Manufacturing Technology Innovative Work: Innovation and Recent Development in Casting TechniquesDocument20 pagesME-208 Manufacturing Technology Innovative Work: Innovation and Recent Development in Casting TechniquesSubhash SharmaNo ratings yet

- Chapter Four 4.special Casting Processes: Introduction Contents To Be IncludedDocument76 pagesChapter Four 4.special Casting Processes: Introduction Contents To Be IncludedberhaneNo ratings yet

- Casting:-: Terms Related To Casting ProcessDocument55 pagesCasting:-: Terms Related To Casting ProcessAjay RohillaNo ratings yet

- MOdule II 2 PageDocument2 pagesMOdule II 2 PageVyshakh SunilNo ratings yet

- Mp1 m1 Short NotesDocument43 pagesMp1 m1 Short NotesRadhika GandhiNo ratings yet

- Adama Science and Technology University: School of Mechanical, Chemical & Materials EngineeringDocument12 pagesAdama Science and Technology University: School of Mechanical, Chemical & Materials EngineeringAbel MeketaNo ratings yet

- Found AryDocument14 pagesFound Aryluv_leo007No ratings yet

- Mini Project Final ReportDocument37 pagesMini Project Final ReportSamanth Kumar Vasam86% (14)

- Ae15301 AMMTDocument98 pagesAe15301 AMMTDurai Raj KumarNo ratings yet

- Victa 2 Engine BlockDocument4 pagesVicta 2 Engine BlockJair Parreira50% (2)

- Manufacturing ProcessesDocument134 pagesManufacturing ProcessesB J ISAC ABRAHAM PAULNo ratings yet

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument40 pagesDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc LeNo ratings yet

- Steps Involved in Sand Casting Process: BY Aravindkumar BDocument39 pagesSteps Involved in Sand Casting Process: BY Aravindkumar BanilNo ratings yet

- Bi-Axial Toggle DrivenDocument4 pagesBi-Axial Toggle Drivensanthosh ponnusamyNo ratings yet

- Chapter 2 Casting: Manufacturing ProcessesDocument52 pagesChapter 2 Casting: Manufacturing ProcessesnunuNo ratings yet

- CastingDocument74 pagesCastingParth Maldhure100% (1)

- Unit - I-Manu Tech-IDocument38 pagesUnit - I-Manu Tech-IMareeswaran Maruthamuthu MNo ratings yet

- Notes MT Module I - KTUDocument47 pagesNotes MT Module I - KTURagesh Dudu100% (1)

- Foundry TechnologyDocument16 pagesFoundry Technologynikhil110705No ratings yet

- Man Tech Assignment 1Document6 pagesMan Tech Assignment 1trishNo ratings yet

- MGF Notes - 1Document79 pagesMGF Notes - 1A ABHISHEK MARSHALLNo ratings yet

- ME 203 Manufacturing Technology: V. ThulasikanthDocument77 pagesME 203 Manufacturing Technology: V. ThulasikanthRaghav satijaNo ratings yet

- 4 Various Types of Expendable Mold and Permanent Mold CastingDocument45 pages4 Various Types of Expendable Mold and Permanent Mold CastingLiaquat AliNo ratings yet

- Unit-1 (1) MPDocument189 pagesUnit-1 (1) MPVishvas SinghhNo ratings yet

- Foundry Process Updated 1Document52 pagesFoundry Process Updated 1krishnamoorthiNo ratings yet

- Castingitstypes 140222031231 Phpapp02Document85 pagesCastingitstypes 140222031231 Phpapp02Harmain Ahmed CMNo ratings yet

- Unit 6 w10 Djj3213 (Metal Processing Casting)Document44 pagesUnit 6 w10 Djj3213 (Metal Processing Casting)Syfull musicNo ratings yet

- Casting Definition Types Steps Involved in Casting Advantages Disadvantages Importance PDFDocument7 pagesCasting Definition Types Steps Involved in Casting Advantages Disadvantages Importance PDFMausamNo ratings yet

- DFM ch-2Document114 pagesDFM ch-2Trâp A NâtïøñNo ratings yet

- Casting ProcessesDocument20 pagesCasting ProcessesVv4HNo ratings yet

- Class5 - Types of CastingDocument94 pagesClass5 - Types of CastingSriharsha SarmaNo ratings yet

- Lab Report 2Document21 pagesLab Report 2Cherif ChokeirNo ratings yet

- Unit 3Document42 pagesUnit 3Anup M UpadhyayaNo ratings yet

- Manufacturing Technology - I Course ID: ME 222 (3-0-0-6)Document33 pagesManufacturing Technology - I Course ID: ME 222 (3-0-0-6)captain indiaNo ratings yet

- Original FoundryDocument15 pagesOriginal FoundryMarvelous EkpenyongNo ratings yet

- BMP - CastingDocument217 pagesBMP - Castingmantra2010No ratings yet

- BMP - Powder MetallurgyDocument71 pagesBMP - Powder Metallurgymantra2010No ratings yet

- Course Handout (BMP)Document4 pagesCourse Handout (BMP)058-Somyajit RayNo ratings yet

- MP Sessional (Welding)Document14 pagesMP Sessional (Welding)2058SOMYAJIT RAYNo ratings yet

- Writeup and Critical ThinkingDocument4 pagesWriteup and Critical Thinking058-Somyajit RayNo ratings yet

- MKD - Lab (1) BholaDocument3 pagesMKD - Lab (1) Bhola2058SOMYAJIT RAYNo ratings yet

- Mid-Term Test SolutionDocument7 pagesMid-Term Test Solutionsui sui mangNo ratings yet

- Bursting Disc Devices in Series 3070 Chap9 1Document6 pagesBursting Disc Devices in Series 3070 Chap9 1Alberto LazzarettiNo ratings yet

- Modes of Heat Transfer: O Q (Gate, Ies, Ias)Document7 pagesModes of Heat Transfer: O Q (Gate, Ies, Ias)ankitNo ratings yet

- CPT - Lecture - 22 and 23 - Sulphuric Acid ProcessDocument29 pagesCPT - Lecture - 22 and 23 - Sulphuric Acid ProcesssaisounyaNo ratings yet

- K01 Group 5Document42 pagesK01 Group 5Miss MichelleNo ratings yet

- It Lecture 1Document42 pagesIt Lecture 1Georges Abou HaydarNo ratings yet

- Troubleshooting A C3 Splitter Tower Part 1 EvaluationDocument6 pagesTroubleshooting A C3 Splitter Tower Part 1 EvaluationZangNo ratings yet

- Name Course & Year: ApparatusDocument9 pagesName Course & Year: ApparatusJE SalmaNo ratings yet

- Assignment 4.4Document2 pagesAssignment 4.4Rohan YadavNo ratings yet

- CHEMCAD Models 2Document33 pagesCHEMCAD Models 2Sheraz FiazNo ratings yet

- Air Bersih, IPA, Rapid Sand Filter, Design CalculationDocument15 pagesAir Bersih, IPA, Rapid Sand Filter, Design CalculationAndrizal KotoNo ratings yet

- General Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)Document20 pagesGeneral Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)TuTuy AnNo ratings yet

- Effects of Sealing Strips On Shell Side Flow and HDocument12 pagesEffects of Sealing Strips On Shell Side Flow and Hshakil ahmadNo ratings yet

- Faisal - Internship Report'12Document88 pagesFaisal - Internship Report'12Inaam Ur RehmanNo ratings yet

- 5 Final CoagulationDocument19 pages5 Final CoagulationGroup-4 CommonNo ratings yet

- Heat Transfer 2nd Ed. by Cengel-647Document1 pageHeat Transfer 2nd Ed. by Cengel-647Gifted MouhcineNo ratings yet

- Batch: General InformationDocument5 pagesBatch: General InformationSteve WanNo ratings yet

- Lecture Note - Che 332-2Document56 pagesLecture Note - Che 332-2NestorNo ratings yet

- PoolSpaN USPHDocument47 pagesPoolSpaN USPHpetar.petrov.111964No ratings yet

- Case 1 REPORTDocument13 pagesCase 1 REPORTnorman1968No ratings yet

- Gas Injection Technology.Document49 pagesGas Injection Technology.Irfan AliNo ratings yet

- CH3510 Momentum Transfer and MO Lab: 7.flow Through VenturimeterDocument8 pagesCH3510 Momentum Transfer and MO Lab: 7.flow Through VenturimeterAwik DharNo ratings yet

- Schematic: 320C Excavator VA Boom Hydraulic System (Attachment)Document2 pagesSchematic: 320C Excavator VA Boom Hydraulic System (Attachment)mirbek mairykovNo ratings yet

- Ejercicios 4Document2 pagesEjercicios 4Raul ZepedaNo ratings yet

- Evaluation of Gas Mass Transfer in Reactor For Syngas FermentationDocument8 pagesEvaluation of Gas Mass Transfer in Reactor For Syngas FermentationKeryanti KeryNo ratings yet

- Differentiate Between The Terms Stable EquilibriumDocument4 pagesDifferentiate Between The Terms Stable EquilibriumLucas KesiNo ratings yet

- MODES OF HEAT TRANSFER - Docx FinDocument6 pagesMODES OF HEAT TRANSFER - Docx FinJerome MosadaNo ratings yet

- Basics of Shell and Tube Heat Exchangers With PDFDocument12 pagesBasics of Shell and Tube Heat Exchangers With PDFSachin KumarNo ratings yet

- To StudentsDocument1 pageTo StudentsSuper FreakNo ratings yet

- Pressure Relief Valves Transcritical Co2Document2 pagesPressure Relief Valves Transcritical Co2Edita SzuketiováNo ratings yet