Professional Documents

Culture Documents

Onepage Qcstory

Uploaded by

RS MANIKANDANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Onepage Qcstory

Uploaded by

RS MANIKANDANCopyright:

Available Formats

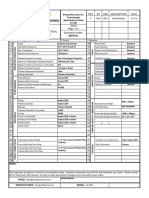

Organization Name : M/S JPPL- VI,Hosur

1.0 Problem 4.1 Development of solution:

Cut mark issue in Rear oil gallery - P0001199382 S No Root Cause Counter Measure

1 Tearing & Cutmark Modify the compound receipe

2 Airpocket Modify the compound receipe

Diaphragms 15.88 Modify the compound receipe & Blank weight arrived

3 Flow mark & Less weight

Induction part 14.49 besed on the volume of the mould

New product 13.17 4

` Deep wall 11.66

1.1 Theme and Target 4.2 Action Plan:

10

Reduce Rejection in induction parts S No What When Who How

9

From 4.8 to 2.50 New receipe to be designed to meet our rheo

1 Modify the compound recipe Wk 37 VJ/SR/VG

Hardness & Sp gravity and customer needs

8

Basic physical properties to be verified with

7 2 Compound validation Wk 38 SR/VG

Rejection in %

existing recipe

4.8

6 Rejection trend and component dimensions to

3 Process validation WK.39 VJ / SR

be verified with existing recipe

5

4 2.5

3

2

1

0

Actual Target

2.0 Observation

Vital few

(Pareto Analysis) 5.1 Check :

60 %

100

92.24 100

140

82.13

120 80

71.22

100 59.28

60

80

44.63

60 40

29.96

40 29.96

20

20 14.67 14.64 11.95 10.91 10.11 7.76

0 0

TUBE TUBE TUBE TUBE TUBE TUBE TUBE 5.2 Benefits :

OUT LET OUTLET ( INTAKE ( OUTLET - INLET INTAKE INTAKE

( N11) V) V) U121 ( CVT N52 (H2- N17 Productivity :

Quality :

Cost :

3.1 Causal Analysis Delivery :

MAN MACHINE Morale :

6.0 Standardization :

High rejection

High rejection in

Induction parts

Effect 60%

7.0 Conclusion :

Blank weight less

Recipe to be modified

METHOD MATERIAL

You might also like

- Polatrak ROV II - ManualDocument16 pagesPolatrak ROV II - ManualTamer Hesham AhmedNo ratings yet

- Capacitor Voltage TransformerDocument7 pagesCapacitor Voltage Transformerlkt_pestechNo ratings yet

- 11kV Dist Xfmr SpecDocument33 pages11kV Dist Xfmr SpecKarthikNo ratings yet

- EDC-DTS-LV003 - LV Distribution Board For Indoor SubstationDocument27 pagesEDC-DTS-LV003 - LV Distribution Board For Indoor SubstationJoe bilouteNo ratings yet

- EDC DTS MV009 Surge ArrestersDocument18 pagesEDC DTS MV009 Surge ArrestersJoe bilouteNo ratings yet

- Dokumen - Tips - bw211 212 213d 40 Service Manual e 00891163c08pdf PDFDocument1,040 pagesDokumen - Tips - bw211 212 213d 40 Service Manual e 00891163c08pdf PDFMahluk SosialNo ratings yet

- Datasheet Transistor C5476Document4 pagesDatasheet Transistor C5476fchavestaNo ratings yet

- BW219D-4 Tier3 Repair MuDocument906 pagesBW219D-4 Tier3 Repair Musuresh kNo ratings yet

- Installation and Operating Instructions: 0.1 Mbar VersionsDocument20 pagesInstallation and Operating Instructions: 0.1 Mbar Versionsinge VazquwzNo ratings yet

- Bw213-214enDocument1,108 pagesBw213-214enDanila1991100% (2)

- Bw216d4-101583-Service ManualDocument974 pagesBw216d4-101583-Service ManualTeknik Makina100% (3)

- Type: Cocon 26 Dra-Lp/Mp: Und Erground Gas Regulation StationDocument25 pagesType: Cocon 26 Dra-Lp/Mp: Und Erground Gas Regulation StationAbraham Tellez FloresNo ratings yet

- ARM-DeN-0068 Coresight Base System Architecture 1.0Document29 pagesARM-DeN-0068 Coresight Base System Architecture 1.0Krishna Ram BudhathokiNo ratings yet

- Evaluating FCC Process Data to Improve Unit PerformanceDocument24 pagesEvaluating FCC Process Data to Improve Unit PerformanceOswaldo FigueraNo ratings yet

- Bechtel Corporation Engineering - Control Systems Engineering Design Guide Control Valves 3DG-J51-00001, Revision 002, 2002 August 5Document40 pagesBechtel Corporation Engineering - Control Systems Engineering Design Guide Control Valves 3DG-J51-00001, Revision 002, 2002 August 5Alvis JeffreyNo ratings yet

- Vdocument - in - Voiht Retarder VR 115Document94 pagesVdocument - in - Voiht Retarder VR 115IB EldinNo ratings yet

- Beta Manual MGZDocument28 pagesBeta Manual MGZvampiro_yiyoNo ratings yet

- b08 PDFDocument1,046 pagesb08 PDFАнатолийNo ratings yet

- C3987 SanyoSemiconDeviceDocument4 pagesC3987 SanyoSemiconDeviceucb51525354No ratings yet

- Smartsil 450 ResultsDocument1 pageSmartsil 450 ResultsAnkita Baban GavadeNo ratings yet

- 213D-4 Ra Eng 101583082400Document1,386 pages213D-4 Ra Eng 101583082400сергейNo ratings yet

- B40EA - Distillation Unit Operations A PDFDocument144 pagesB40EA - Distillation Unit Operations A PDFAnonymous vrKMTsa5qNo ratings yet

- Irc 112.2020Document256 pagesIrc 112.2020jcmohinishenoy100% (2)

- Din 22101Document51 pagesDin 22101abdelrahman EweesNo ratings yet

- Chemical Process ConceptionDocument66 pagesChemical Process ConceptionRapee Puaksungnoen100% (1)

- 80375-01 r0 Technical Data Sheet, AT-250Document1 page80375-01 r0 Technical Data Sheet, AT-250pablolz712No ratings yet

- VesselDocument113 pagesVesselAleem QureshiNo ratings yet

- CQR General MechanicDocument24 pagesCQR General MechanicdavidNo ratings yet

- QCP Is Prepared For Gurreh Jask Crude Oil Pump Stations ProjectDocument48 pagesQCP Is Prepared For Gurreh Jask Crude Oil Pump Stations ProjectAli TavakoliNo ratings yet

- Offshore Pipeline Installation ProcedureDocument31 pagesOffshore Pipeline Installation Procedurecbsd24100% (1)

- PRG PR Ves 0001 r03 e VesselsDocument113 pagesPRG PR Ves 0001 r03 e VesselsAleem QureshiNo ratings yet

- 02-736-Pt4 Iss2Document38 pages02-736-Pt4 Iss2br1ggsy100% (1)

- EDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersDocument33 pagesEDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersJoe bilouteNo ratings yet

- BW 219 (58290) SerDocument962 pagesBW 219 (58290) SerMichał BujaraNo ratings yet

- GBH Enterprises, LTD.: GBHE-PEG-MAS-608Document79 pagesGBH Enterprises, LTD.: GBHE-PEG-MAS-608arch0wnzNo ratings yet

- DEM20235FGH-PWDocument20 pagesDEM20235FGH-PWartur_nadolski9724No ratings yet

- EDC-DTS-MV006 - 35 KV and 22 KV Pole Mounted Auto ReclosersDocument27 pagesEDC-DTS-MV006 - 35 KV and 22 KV Pole Mounted Auto ReclosersJoe bilouteNo ratings yet

- FSS 971 40SS 0001 - 1Document34 pagesFSS 971 40SS 0001 - 1Victor Eduardo Gonzalez RojasNo ratings yet

- I-PF-21 Bonding Procedure SpecificationDocument10 pagesI-PF-21 Bonding Procedure SpecificationCamilo SierraNo ratings yet

- Es321 Pole Mounted Distribution Transformers Issue 10Document29 pagesEs321 Pole Mounted Distribution Transformers Issue 10Anley NigissieNo ratings yet

- Uky21041 DC12Document9 pagesUky21041 DC12Mehdi berenjiNo ratings yet

- Norsok.650.edn.4 2Document30 pagesNorsok.650.edn.4 2ABHISHEK DOLLENo ratings yet

- Crane SWF 5 Ton Manual Book PDFDocument28 pagesCrane SWF 5 Ton Manual Book PDFAnggit0% (1)

- PRV Sizing - XLSMDocument11 pagesPRV Sizing - XLSMDesiree MolinaNo ratings yet

- Stablelines: Safeguarding Life, Property and The EnvironmentDocument35 pagesStablelines: Safeguarding Life, Property and The Environmentaem dcNo ratings yet

- Data Sheet HFE-7500Document8 pagesData Sheet HFE-7500sshaffer_9No ratings yet

- Celule Sarcina 7.6-02-09Document21 pagesCelule Sarcina 7.6-02-09Peter MateNo ratings yet

- RPV311 TM en 11.2aDocument302 pagesRPV311 TM en 11.2aThiago PradoNo ratings yet

- 8401 enDocument32 pages8401 enSLAMET PAMBUDINo ratings yet

- A/Litigation Hycjrodynamic: ResistanceDocument3 pagesA/Litigation Hycjrodynamic: ResistanceMuhamad Nazren Mohamed ZaidiNo ratings yet

- Roller - BW211D-40 PDFDocument972 pagesRoller - BW211D-40 PDFarjun cNo ratings yet

- L.A. Abrasion Specific Gravity Absorption Soundness Loss Soundness Loss On Screenings Unit Weight - ABCDocument5 pagesL.A. Abrasion Specific Gravity Absorption Soundness Loss Soundness Loss On Screenings Unit Weight - ABCmsohaibazizNo ratings yet

- Manuale Glup Ht-htlp v2.1 0315 EnDocument92 pagesManuale Glup Ht-htlp v2.1 0315 EngabrieleshlNo ratings yet

- Manual: Installation and Operating InstructionsDocument132 pagesManual: Installation and Operating Instructionsmishu35No ratings yet

- Part Inspection Report: 458519100 Cover Plate 4/12/2021 NILDocument3 pagesPart Inspection Report: 458519100 Cover Plate 4/12/2021 NILRohit QualityNo ratings yet

- Service - Manual: BW 211 D-4 / PD-4 BW 213 D-4 / PD-4 BW 214 D-4Document6 pagesService - Manual: BW 211 D-4 / PD-4 BW 213 D-4 / PD-4 BW 214 D-4Khalid MajorNo ratings yet

- Mpact PlusDocument135 pagesMpact PlusJack SparrowNo ratings yet

- Load Tests Tcm109-257651Document2 pagesLoad Tests Tcm109-257651joNo ratings yet

- PFMEA-KVTDocument3 pagesPFMEA-KVTRS MANIKANDANNo ratings yet

- Illumination Level Checksheet - QualityDocument4 pagesIllumination Level Checksheet - QualityRS MANIKANDANNo ratings yet

- Luxlevel Monitering SheetDocument1 pageLuxlevel Monitering SheetRS MANIKANDANNo ratings yet

- Customer Visit Plan Vs Actual_Apr-24Document3 pagesCustomer Visit Plan Vs Actual_Apr-24RS MANIKANDANNo ratings yet

- 2.PFD & PQCS-18293-KVT-9000Document3 pages2.PFD & PQCS-18293-KVT-9000RS MANIKANDANNo ratings yet

- Mold Drop Check SheetDocument1 pageMold Drop Check SheetRS MANIKANDANNo ratings yet

- routcar3Document2 pagesroutcar3RS MANIKANDANNo ratings yet

- 10.CHECKING AIDSDocument1 page10.CHECKING AIDSRS MANIKANDANNo ratings yet

- trial details march 2024Document48 pagestrial details march 2024RS MANIKANDANNo ratings yet

- Cavity Dummy ChartDocument7 pagesCavity Dummy ChartRS MANIKANDANNo ratings yet

- Touch Base TrackerDocument4 pagesTouch Base TrackerRS MANIKANDANNo ratings yet

- Compound & Chemical Change Trial ReportDocument2 pagesCompound & Chemical Change Trial ReportRS MANIKANDANNo ratings yet

- trial details april 2024Document45 pagestrial details april 2024RS MANIKANDANNo ratings yet

- Customer complaints tracker 2023-2024Document3 pagesCustomer complaints tracker 2023-2024RS MANIKANDANNo ratings yet

- 42.SPC FormatDocument1 page42.SPC FormatRS MANIKANDANNo ratings yet

- BackupDocument8 pagesBackupRS MANIKANDANNo ratings yet

- Problem BatchesDocument12 pagesProblem BatchesRS MANIKANDANNo ratings yet

- Taxonomy With Ids - en USDocument124 pagesTaxonomy With Ids - en USSuman KumarNo ratings yet

- 5EHG1U24C0101Document2 pages5EHG1U24C0101RS MANIKANDANNo ratings yet

- Q DashboardDocument17 pagesQ DashboardRS MANIKANDANNo ratings yet

- Production - Needs and ExpectationsDocument1 pageProduction - Needs and ExpectationsRS MANIKANDANNo ratings yet

- 17 Mould Pick Up Check SheetDocument2 pages17 Mould Pick Up Check SheetRS MANIKANDANNo ratings yet

- Project 1 - TypoholicDocument2 pagesProject 1 - TypoholicRS MANIKANDANNo ratings yet

- Q DashboardDocument17 pagesQ DashboardRS MANIKANDANNo ratings yet

- 18 4M Change Request Cum Approval FormDocument1 page18 4M Change Request Cum Approval FormRS MANIKANDANNo ratings yet

- Life Cycle AnalysisDocument1 pageLife Cycle AnalysisRS MANIKANDANNo ratings yet

- Compound & Chemical Change Trial ReportDocument2 pagesCompound & Chemical Change Trial ReportRS MANIKANDANNo ratings yet

- Compound Return NoteDocument1 pageCompound Return NoteRS MANIKANDANNo ratings yet

- Mould Parameter ChangeDocument3 pagesMould Parameter ChangeRS MANIKANDANNo ratings yet

- Material Inward RegisterDocument2 pagesMaterial Inward RegisterRS MANIKANDANNo ratings yet

- Key Responsibilities On Skill.: Curriculum Vitae PersonalDocument3 pagesKey Responsibilities On Skill.: Curriculum Vitae PersonalLAM NYAWALNo ratings yet

- Frame Fit Specifications 2019 MTB Components Rev CDocument167 pagesFrame Fit Specifications 2019 MTB Components Rev Cpicko 86No ratings yet

- Tpe Reflection AssignmentDocument5 pagesTpe Reflection Assignmentapi-351869082No ratings yet

- The Man Who Married A Hen, Stories of A Zambian SchoolboyDocument78 pagesThe Man Who Married A Hen, Stories of A Zambian SchoolboyGerard StoutNo ratings yet

- Business PlanDocument8 pagesBusiness PlanyounggirldavidNo ratings yet

- Visulas Yag III User ManualDocument126 pagesVisulas Yag III User ManualTomNo ratings yet

- Final Research Dossier - Joey KassenoffDocument11 pagesFinal Research Dossier - Joey Kassenoffapi-438481986No ratings yet

- 279 Glenridge Avenue, St. Catharines ON, LST 3K3: "Agriculture and Irrigation Solutions". Contech Engineered SolutionsDocument52 pages279 Glenridge Avenue, St. Catharines ON, LST 3K3: "Agriculture and Irrigation Solutions". Contech Engineered Solutionsapi-251312018No ratings yet

- Internal Control QuestionnaireDocument19 pagesInternal Control QuestionnaireIchsanNo ratings yet

- ECN 202 Final AssignmentDocument10 pagesECN 202 Final AssignmentFarhan Eshraq JeshanNo ratings yet

- Azzi, R., Fix, D. S. R., Keller, F. S., & Rocha e Silva, M. I. (1964) - Exteroceptive Control of Response Under Delayed Reinforcement. Journal of The Experimental Analysis of Behavior, 7, 159-162.Document4 pagesAzzi, R., Fix, D. S. R., Keller, F. S., & Rocha e Silva, M. I. (1964) - Exteroceptive Control of Response Under Delayed Reinforcement. Journal of The Experimental Analysis of Behavior, 7, 159-162.Isaac CaballeroNo ratings yet

- Understanding Customer Loyaltyfor Retail StoreandtheinfluencingfactorsDocument15 pagesUnderstanding Customer Loyaltyfor Retail StoreandtheinfluencingfactorsTanmay PaulNo ratings yet

- Sales Manager or Regional Manager or Senior Sales ExecutiveDocument3 pagesSales Manager or Regional Manager or Senior Sales Executiveapi-77473806No ratings yet

- Myntra Sku Template New ShootDocument204 pagesMyntra Sku Template New ShootPriyal SaxenaNo ratings yet

- Cost ReductionDocument8 pagesCost Reductionmlganesh666100% (3)

- 1814 d01 PDFDocument20 pages1814 d01 PDFteletrabbiesNo ratings yet

- Internal and external factors affecting pricing decisionsDocument6 pagesInternal and external factors affecting pricing decisionsNguyễn YếnNo ratings yet

- 0000 0000 0335Document40 pages0000 0000 0335Hari SetiawanNo ratings yet

- Edu Mphil SyllabusDocument27 pagesEdu Mphil Syllabussollu786_889163149No ratings yet

- Class Will and TestamentDocument4 pagesClass Will and TestamentAllan Tomas33% (3)

- Buwis ButilDocument2 pagesBuwis ButilHelbert Agluba PaatNo ratings yet

- The dangers of electrostatic phenomenaDocument14 pagesThe dangers of electrostatic phenomenaYaminNo ratings yet

- Cooper Tire Warranty InformationDocument28 pagesCooper Tire Warranty InformationAbdulAziz AlGhamdiNo ratings yet

- Sample Action Research in MathDocument12 pagesSample Action Research in MathKresta BenignoNo ratings yet

- English AssignmentDocument79 pagesEnglish AssignmentAnime TubeNo ratings yet

- Sri Bhavishya Educational AcademyDocument4 pagesSri Bhavishya Educational AcademyAnonymous A6Jnef04No ratings yet

- En Eco-Drive Panel ConnectionDocument4 pagesEn Eco-Drive Panel ConnectionElectroventica ElectroventicaNo ratings yet

- Ej18 DetailsDocument6 pagesEj18 Detailsdaniel FerreiraNo ratings yet

- FINANCE Company SlidersDocument10 pagesFINANCE Company SlidersKartik PanwarNo ratings yet

- Kawai MP7 Owner's ManualDocument148 pagesKawai MP7 Owner's ManualMiloNo ratings yet