Professional Documents

Culture Documents

เครื่องอัดอากาศ

เครื่องอัดอากาศ

Uploaded by

Artit BoonkoomCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

เครื่องอัดอากาศ

เครื่องอัดอากาศ

Uploaded by

Artit BoonkoomCopyright:

Available Formats

Technology

Production

>>>

2009

(air consumption)

25-50%

(compressed air)

1.

Air Compressor

1 ()

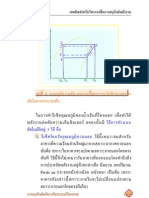

(air changes/hr) 10-15 (1)

= X Air Changes/ hr. ----------------------- (1)

LOUVERED

LOUVERED

EXHAUST FAN

WINDOW

WINDOW

AIR OUT

AIR IN

AIR IN

COMPRESSOR

UNIT

1

Technology Promotion Mag..

June-July 2009, Vol.36 No.205

023

Production

Technology

(installations)

I-Beam

2

2 I-Beam

(vibration

isolator)

150 %

2.

(air consumption)

25

50%

20% (

20%)

>>>

2009

024

June-July 2009, Vol.36 No.205

(reciprocating)

Positive Displacement

-

3

(rotary)

(rotor) 2

(centrifugal force)

(compression chamber)

(stage) 4

(centrifugal)

(impeller)

(oil free) 5

Technology Promotion Mag..

Technology Promotion Mag..

6 7

8

25%

Hydrostatics Test

4. (compressed air

system) (pneumatic distribution

system)

(losses)

10%

(main)

0.1-0.25 in/ft

Auto Drain

30 (

AUTO DRAIN 30 )

Technology

Production

PRINCIPAL FEATURES

High efficiency TEFC (IP55) 208-230/460V

electric

motor

Automatic starter switch with automatic

phase and

sequence failure detection

24V panel commands

Lubricated Compression unit and

oversized

air-end

Low oil carryover

Coolers are on top of the machine

facilitate

heat recovery at the customers

facilities

Thermostatic

valve for working

temperature control

Load/partial load unload control

Designed for use in harsh environments

Easy access for maintenance

Maximum ambient temperature 113 oF

Motor overload protection by thermal sensor

Synthetic oil

4

5

80

140 psi Lb/ft3 (5.5-9.65 )

(

(peak)

3. (compressed air receiver)

(SS400)

(pressure vessel)

6

(pressure gauge) (safety valve)

(air trap) 1 1

>>>

2009

June-July 2009, Vol.36 No.205

025

Production

Technology

>>>

2009

026

P Pleated Cellulose

(ring main) 8

.

8

(flexible coupling) 9

9

Flexible

After Cooler

10

(air dryer)

Air

Dryer (compressed air filter)

P (particulate filter media) C (coalesce

filter media)

Filter

C Micro-Glass

Coalesce 0.2 2

1-5

Differential Pressure Gauge

10

10 Differential Pressure Gauge

5. (installation of pipeline)

11

Main

air line

Air

Water

Slope

about 1 in./ft

Line to air-using

Devices (including FRLs)

Sludge

Water

11

(

1 ) L 12

1

ASTM-A-120 Grade A-53 Schedule 40 BS 1378

Medium Weight Galvanized Steel Pipe 13

June-July 2009, Vol.36 No.205

Technology Promotion Mag..

Technology

Technology Promotion Mag..

18

24 m/s (60 80 ft/s)

= KLQ2/ Rd5.3

K = 800

L = (equivalent length)

Q = dm3/s

R = Compression Ratio

d = mm

Production

12

13

(machine lines)

14

14

6. (determination of the

pipeline)

2

100 psig

10 psi /100 ft

6-9 m/s (20-30 ft/s)

>>>

2009

1

100 Psig

()

(free

air ) (cfm)

(psi /100 ft)

1/2

0 - 15

0 - 1.0

3/4

16 - 32

0.30 - 1.0

33 - 60

0.30 - 1.0

1

1

1/4

61 - 125

0.25 - 1.0

1 1/2

126 - 197

0.40 - 1.0

2

198 - 360

0.30 - 1.0

2 1/2

361 - 580

0.35 -1.0

3

581 - 1100

0.30 - 1.0

4

1101 - 2150

0.25 - 1.0

5

2151 - 3900

0.30 - 1.0

3901 - 6300

0.35 - 1.0

6

6301 - 13100

0.25 - 1.1

8

13101 - 24000

0.30 - 1.0

10

12

24001 - 35000

0.35 - 1.0

8.

Service Unit FRL Filter,

Regulator Lubricator

Regulator Lubricator

300 ft 15

June-July 2009, Vol.36 No.205

027

Production

Technology

>>>

2009

Service Unit

10 Bar

60 C (

)

15 FRL (service unit)

9.

Belt

Tension Indicator 16

4,250 rpm

3

Belt Tension Indicator 17

16

17

2 Deflection Force Deflection

1. , 1.,

MOTOR

KW(H.P.)

NO. OF

Belts

Deflection

Force N (Lbs)

(per belt)

Deflection

In mm

(Inches)

30(40)

4

1.3 to 1.9 (6 to 8.5)

9.5 (3/8)

37(50)

4

1.5 to 2.2 (7 to 10)

9.5 (3/8)

1.3

24 .

028

June-July 2009, Vol.36 No.205

(quick reference)

Service Unit

, , 2543.

2. , , ,

, , 2542.

3. FRANK YEAPLE, FLUID POWER DESIGN HANDBOOK,

Marcel Dekker, Inc., New York and Basel, 1992.

4. (Mechanical Engineering

Quick Reference) (), ,

, 2544.

Technology Promotion Mag..

You might also like

- FoamDocument8 pagesFoamWichate Liambooppha (Capt.Moo)No ratings yet

- Thai Fire Requirement TR SD 20 1Document67 pagesThai Fire Requirement TR SD 20 1Grady Hopkins100% (1)

- 10 - Refrigeration and Air ConditioningDocument55 pages10 - Refrigeration and Air Conditioningpiya_engineer2786100% (1)

- Iso50001 PDFDocument78 pagesIso50001 PDFPitiporn HasuankwanNo ratings yet

- เครื่องกลึงDocument16 pagesเครื่องกลึงnarong112390% (10)

- บทที่ 3 เครื่องปรับอากาศDocument27 pagesบทที่ 3 เครื่องปรับอากาศSaksitBua-ngoenNo ratings yet

- พลังงานในระบบทำความเย็นDocument40 pagesพลังงานในระบบทำความเย็นWin MeeNo ratings yet

- Mid-01-อ่านเสริม psychrometric - CAL1 - OKDocument8 pagesMid-01-อ่านเสริม psychrometric - CAL1 - OKชนะภูมิ เทือกเถาว์No ratings yet

- DRSDFSDFDocument126 pagesDRSDFSDFJeffrey TooNo ratings yet

- VCKDocument59 pagesVCKEng Advance100% (3)

- EN 002 เครื่องดักจับฝุ่นด้วยไซโคลนและไฟฟ้าสถิตสำหรับโรงสีข้าวDocument4 pagesEN 002 เครื่องดักจับฝุ่นด้วยไซโคลนและไฟฟ้าสถิตสำหรับโรงสีข้าวตุ๊กตุ้ย ตัวกลมกลมNo ratings yet

- ระบบอัดอากาศDocument62 pagesระบบอัดอากาศAmpornchai PhupolNo ratings yet

- การคำนวณ Condensate load เพื่อใช้ในการเลือก Steam trapDocument17 pagesการคำนวณ Condensate load เพื่อใช้ในการเลือก Steam trapSAKDA MAPRADITKULNo ratings yet

- การติดตั้งท่อลมDocument11 pagesการติดตั้งท่อลมParinpa Ketar100% (2)

- 013-บทที่13 เครื่องกำเนิดไฟฟ้าสำรอง N 30Document112 pages013-บทที่13 เครื่องกำเนิดไฟฟ้าสำรอง N 30Wasawat TANAPIROMNo ratings yet

- Calcuedlations of Ventilation Rate According To ASHRAE Standard 62 1Document21 pagesCalcuedlations of Ventilation Rate According To ASHRAE Standard 62 1Anonymous 4vOfBaNo ratings yet

- 19มาตรฐานมอเตอร์เครื่องสูบน้ำดับเพลิงDocument19 pages19มาตรฐานมอเตอร์เครื่องสูบน้ำดับเพลิงsunny_2502No ratings yet

- ระบบปรับอากาศ (P10-29) 1Document36 pagesระบบปรับอากาศ (P10-29) 1mao100% (1)

- การประเมินศักยภาพการอนุรักษ์พลังงานDocument337 pagesการประเมินศักยภาพการอนุรักษ์พลังงานVora somNo ratings yet

- EconomizerDocument6 pagesEconomizerpaween saetaeNo ratings yet

- ความรู้พื้นธานระบบปรับอากาศDocument24 pagesความรู้พื้นธานระบบปรับอากาศPeppy Kung100% (2)

- หนังสือ ความดันDocument216 pagesหนังสือ ความดันPoom PhongphawitNo ratings yet

- การคำนวณDetunedDocument3 pagesการคำนวณDetunedยศนัยฆ่ามดคันไฟด้วยมือเปล่าNo ratings yet

- สารหล่อลื่นDocument47 pagesสารหล่อลื่นSAKDA MAPRADITKULNo ratings yet

- 7.energy Saving Manual Vol.7Document104 pages7.energy Saving Manual Vol.7akeNo ratings yet

- สารทำความเย็นDocument87 pagesสารทำความเย็นmighe100% (6)

- เลือกมิเตอร์ให้เหมาะกับบ้าน PDFDocument2 pagesเลือกมิเตอร์ให้เหมาะกับบ้าน PDFJikky JikkaNo ratings yet

- M&V Guideline 2558Document122 pagesM&V Guideline 2558Energy4YouNo ratings yet

- Ie Network 2017 01Document6 pagesIe Network 2017 01TonmokNo ratings yet

- Oil CompositionDocument20 pagesOil CompositionS Tunkla EcharojNo ratings yet

- Pulsator Clarifier Vacuum TypeDocument20 pagesPulsator Clarifier Vacuum TypeMambo_Junus_5783No ratings yet

- การอบแห้งพลังงานแสงอาทิตย์Document9 pagesการอบแห้งพลังงานแสงอาทิตย์Saransiri WongsiriNo ratings yet

- การทำกังหันลมผลิตไฟฟ้าด้วยตัวเองDocument241 pagesการทำกังหันลมผลิตไฟฟ้าด้วยตัวเองkik ph100% (1)

- วิธีการติดตั้ง - Catia Network License PDFDocument19 pagesวิธีการติดตั้ง - Catia Network License PDFNamelezz ShadowwNo ratings yet

- คำนวนการเคลื่อนที่ของลิฟท์Document3 pagesคำนวนการเคลื่อนที่ของลิฟท์Win MeeNo ratings yet

- การศึกษาต้นแบบโรงไฟฟ้าชีวมวลขนาดเล็กDocument12 pagesการศึกษาต้นแบบโรงไฟฟ้าชีวมวลขนาดเล็กsaravoot_jNo ratings yet

- 4 การอนุรักษ์พลังงานในระบบอากาศอัดDocument66 pages4 การอนุรักษ์พลังงานในระบบอากาศอัดYuwarath Suktrakoon100% (1)

- เฉลยงานเครื่องมือกลช่างยนต์Document73 pagesเฉลยงานเครื่องมือกลช่างยนต์บุญเหลือ ยืนยงNo ratings yet

- 1.4 ข้อกำหนดมาตรฐานห้องเย็นDocument15 pages1.4 ข้อกำหนดมาตรฐานห้องเย็นwk13thNo ratings yet

- การป้องกันและระงับอัคคีภัยในโรงงาน ปี ๒๕๕๒Document100 pagesการป้องกันและระงับอัคคีภัยในโรงงาน ปี ๒๕๕๒[^UffuhNo ratings yet

- บัญชีรายชื่อเครื่องจักรและอุปกรณ์: Equipment and Machine ListDocument3 pagesบัญชีรายชื่อเครื่องจักรและอุปกรณ์: Equipment and Machine Listpornnarong tosomNo ratings yet

- พื้นฐานปั๊มและระบบท่อ 211225Document169 pagesพื้นฐานปั๊มและระบบท่อ 211225nickelback.mx19100% (1)

- Heat Transfer in BoilerDocument12 pagesHeat Transfer in BoilermanatchaiNo ratings yet

- การวิเคราะห์คุณภาพน้ำมันDocument4 pagesการวิเคราะห์คุณภาพน้ำมันSanoa100% (1)

- การคำนวณค่าความร้อนกากอ้อยที่ความชื้นต่างกันDocument2 pagesการคำนวณค่าความร้อนกากอ้อยที่ความชื้นต่างกันวิทวัส นิเทียนNo ratings yet

- บทที5 ระบบทำความเย็นDocument19 pagesบทที5 ระบบทำความเย็นSitthichai JaitawongNo ratings yet

- ระบบปรับอากาศ บำราศนรดูร PDFDocument102 pagesระบบปรับอากาศ บำราศนรดูร PDFยินดี ที่ได้ รู้จัก100% (1)

- 2.4.balancing ValveDocument16 pages2.4.balancing Valvechok0% (1)

- 1.7 การจัดการหม้อไอนำ okDocument36 pages1.7 การจัดการหม้อไอนำ okภูมิรพี ศรีโวทานัยNo ratings yet

- 11 วิธีบำรุงรักษาระบบไฟฟ้าDocument13 pages11 วิธีบำรุงรักษาระบบไฟฟ้าวิจิตร แก้วน้ําNo ratings yet

- คู่มือการปรับปรุงประสิทธิภาพการใช้พลังง PDFDocument297 pagesคู่มือการปรับปรุงประสิทธิภาพการใช้พลังง PDFMECHANICAL ENGINEERINGNo ratings yet

- CHILLER Design Report (Condensing Size) Thai LanguageDocument74 pagesCHILLER Design Report (Condensing Size) Thai Languagemeneking75% (4)

- Thai PDP2018Rev1Document68 pagesThai PDP2018Rev1kittithat_pNo ratings yet

- CH4Document152 pagesCH4Adib Sa-idi100% (1)

- ทำ Return Air Chamber ให้ดีได้อย่างไรDocument6 pagesทำ Return Air Chamber ให้ดีได้อย่างไรTeraNo ratings yet

- 3บทที่ 1Document4 pages3บทที่ 1PORAMET SORNNARAINo ratings yet

- บทที่ 4 การเตรียมระบบอากาศอัดในอุตสาหกรรมDocument38 pagesบทที่ 4 การเตรียมระบบอากาศอัดในอุตสาหกรรมMe SitthichaiNo ratings yet

- รายงานอุปกรณ์ต่างๆในระบบนิวเมติกส์ ก้องเกียรติ 020Document21 pagesรายงานอุปกรณ์ต่างๆในระบบนิวเมติกส์ ก้องเกียรติ 020supakorn khlangNo ratings yet

- การบำรุงรักษาอินเวอร์เตอร์ (Basic VFD Maintenance) - e-Industrial Technology CenterDocument4 pagesการบำรุงรักษาอินเวอร์เตอร์ (Basic VFD Maintenance) - e-Industrial Technology Centerkiatisak07102537No ratings yet

- 39G ManualDocument29 pages39G ManualtachetNo ratings yet