Professional Documents

Culture Documents

Wps PQR Format

Wps PQR Format

Uploaded by

Daniel SalinasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps PQR Format

Wps PQR Format

Uploaded by

Daniel SalinasCopyright:

Available Formats

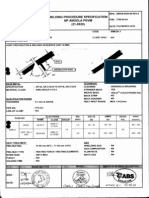

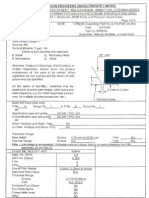

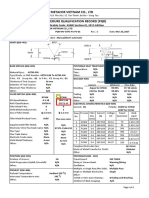

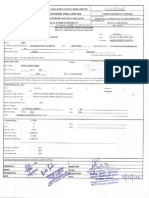

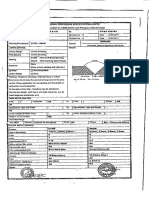

Welding Procedure Specification (WPS)

Prequalified : Yes Qualified by Testing : Yes / No / No Identification Revision Prepared : PQR- SMAW+SAW-GWPL/16 : 6 Date : 4-Jun-10 : Pradip Patil Authorized : Vikas Dighe

Company Name : Global Wind Power Limited Welding Process (es) : Root SMAW / Cover SAW Supporting PQR NO : PQR- SMAW+SAW-GWPL/16

JOINT DESIGN USED Refer Figure 3.3 Type : Butt Joint (double vee) Single / Double Backing : Yes / No Backing Material : Not Applicable Root Opening : 0 mm to 3 mm Root Face Dim. : 3.2 mm to 4 mm 0 0 65 C Groove Angle : 60 C to Back Gouging : Yes / No Grinding Method :

Type

: Manual Machine

/ Semi-automatic / Automatic

ELECTRICAL CHARACTORISTICS Transfer Mode : SAW Globular

Refer table 4.5 / Short Circuiting / Spray Yes / DCEP / Pulsed Not Applicable Not Applicable / Type Yes

Current

AC DCEN Other

BASE METAL Refer Table 4.9 Material Spec. : European Norm EN 10025 Type of grade : S355J2G3 Thickness : Groove 28 mm / Fillet all Diameter (Pipe) : to N/A Thickness Range Qualified : Refer table 4.2 16 mm to unlimited note d

Tungastan Electrode (GTAW) : Size

TECHNIQUE : Stringer bead : Multi Pass No of : Electrodes : Longitudinal : Leading Arc : Minimum : : / Weave bead / Single Pass

FILLER METALS AWS Specification Type of grade

Refer Annexure V : Root / Cover : Root / Cover

SHIELDING Flux Gas

Electrode Spacing Angle Contact tube to work distance Peening Inter pass cleaning

Lateral Trailing Arc Maximum

: : Compos Cup Size Electrode-Flux class :

Flow Rate POST WELD HEAT TREATMENT Loading temp : Heating rate : Holding temp. : Holding time : Cooling rate : Un-Loading temp Not Applicable Minimum Minimum Minimum Minimum Minimum / / / / Maximum Maximum Maximum Maximum Maximum

PREHEAT Preheat Temp Interpass Temp.

: Min. : Max.

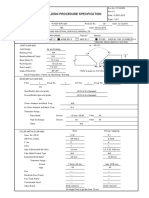

WELDING PROCEDURE (PARAMETERS)

Pass or weld Process layers (s) Class Root Run 1 SMAW Cover passes (root side) 1 SAW 2 SAW 3 SAW Cover passes (face side) 1 SAW 2 SAW 3 SAW 4 SAW 5 SAW : : Inside SFA 5.1 Inside SFA 5.17 SFA 5.17 SFA 5.17 Inside SFA 5.17 SFA 5.17 SFA 5.17 SFA 5.17 SFA 5.17 Filler Metal

Refer table 4.5

Current >10% Volts variation >7% Travel Speed >15% Interpass Temp. variatio variatio Max n n 0 mm/ min C Heat Input Joint Details (Sketch)

Dia (mm)

Type & Polarity Outside Outside DCEP DCEP DCEP Outside DCEP DCEP DCEP DCEP DCEP

Amps

table 4.6

3.15 mm 3.15 mm 3.15 mm 3.15 mm 487 to 594 487 to 594 487 to 594 27 to 31 27 to 31 27 to 31 438 to 592 438 to 592 438 to 592 2.5 max 2.5 max 2.5 max

3.15 mm 3.15 mm 3.15 mm 3.15 mm 3.15 mm

489 to 596 489 to 596 489 to 596 489 to 596 489 to 596

26 to 30 26 to 30 26 to 30 26 to 30 26 to 30

346 to 492 346 to 492 346 to 492 346 to 492 346 to 492

2.5 max 2.5 max 2.5 max 2.5 max 2.5 max

Notes

1 2 3 4

: : : :

You might also like

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Welder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkDocument1 pageWelder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkMahendra singhNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- WPS PQR WPQ PeiplDocument16 pagesWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Wps - PQR 401 TerbaruDocument12 pagesWps - PQR 401 TerbaruJeffri MalauNo ratings yet

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- WPS PQRDocument23 pagesWPS PQRHashim Khan88% (8)

- PQRDocument2 pagesPQRHoangNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Thermax ION Exchange Resins SDS BrochureDocument8 pagesThermax ION Exchange Resins SDS Brochureparthibanemails5779No ratings yet

- English Grammar Workbook For Thai StudentsDocument60 pagesEnglish Grammar Workbook For Thai StudentsMieder van Loggerenberg100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Welding Procedure Specifica Tion (WPS) : I I I IDocument5 pagesWelding Procedure Specifica Tion (WPS) : I I I ITrinh DungNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- GMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsDocument2 pagesGMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsMohamedNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Lamas-Lopez Et Al. - Assessment of Integration Method for Displacement Determination Using Field Accelerometer and Geophone Data利用现场测试的加Document14 pagesLamas-Lopez Et Al. - Assessment of Integration Method for Displacement Determination Using Field Accelerometer and Geophone Data利用现场测试的加Paulo PereiraNo ratings yet

- LDS 6 CatalogDocument24 pagesLDS 6 CatalogStalin TambiNo ratings yet

- Longer Confession and Extant Fragments Final 10-27-2015Document17 pagesLonger Confession and Extant Fragments Final 10-27-2015André Galvão SoaresNo ratings yet

- Design and Develop An IGBT Inverter For AC Motor Drive ApplicationsDocument40 pagesDesign and Develop An IGBT Inverter For AC Motor Drive Applicationselectron1999100% (1)

- District Cooling Design GuideDocument31 pagesDistrict Cooling Design Guideatiqula100% (4)

- The RoleDocument7 pagesThe RolefaithokhaiefoNo ratings yet

- AOPA Membership Application GuidelinesDocument23 pagesAOPA Membership Application GuidelinesphenixousNo ratings yet

- Name: Rahul Bhardwaj Class: Ixb Roll No: 26 Prince Public SchoolDocument19 pagesName: Rahul Bhardwaj Class: Ixb Roll No: 26 Prince Public SchoolArti MaggoNo ratings yet

- Countdown To The End of TimeDocument56 pagesCountdown To The End of Timelelandmary7322314No ratings yet

- EXTREME PLUS QT SDS English Spot RemoverDocument5 pagesEXTREME PLUS QT SDS English Spot RemoverDonna PhillipsNo ratings yet

- BPM Technology TaxonomyDocument55 pagesBPM Technology TaxonomyKan FB100% (1)

- Cad Cam Full SubjectDocument359 pagesCad Cam Full Subjectjineesha p jNo ratings yet

- Indian Dairyman Nov 2021Document3 pagesIndian Dairyman Nov 2021Amritha JayanNo ratings yet

- Albumin (Human) 20%, USPPlasbumin®-20Document8 pagesAlbumin (Human) 20%, USPPlasbumin®-20Marfu'ah Mar'ahNo ratings yet

- Sciencedirect: Fabian Dillinger, Olivia Bernhard, Gunther Reinhart Fabian Dillinger, Olivia Bernhard, Gunther ReinhartDocument6 pagesSciencedirect: Fabian Dillinger, Olivia Bernhard, Gunther Reinhart Fabian Dillinger, Olivia Bernhard, Gunther ReinhartAnita SetyastutiNo ratings yet

- Cell 7Document6 pagesCell 7XI-A Vishal BishnoiNo ratings yet

- Sodhi's Attitude Scale (SAS) : AIM: To Assess The Attitude of The Subject Towards Different AreasDocument2 pagesSodhi's Attitude Scale (SAS) : AIM: To Assess The Attitude of The Subject Towards Different AreasShireen Suhail75% (4)

- Sung Hung KaiDocument17 pagesSung Hung KaiTay Kuan YoungNo ratings yet

- Moot CourtDocument2 pagesMoot CourtDeanne Mitzi SomolloNo ratings yet

- Bulldog Camera InstructionsDocument16 pagesBulldog Camera Instructionsonur77No ratings yet

- Phrasal Verbs and CollocationsDocument6 pagesPhrasal Verbs and CollocationsSandionio100% (1)

- CAST Optical Smoke Detector: Part NoDocument3 pagesCAST Optical Smoke Detector: Part NoAnis TantoushNo ratings yet

- Arc Chute Filter TechnologyDocument2 pagesArc Chute Filter TechnologyantigeniusNo ratings yet

- Case Studies On Organizational Behavior Relevant IssuesDocument28 pagesCase Studies On Organizational Behavior Relevant IssuesHasib HasanNo ratings yet

- Science (Reproductive System) Grade 6Document4 pagesScience (Reproductive System) Grade 6Nurwulan Yuni HapsariNo ratings yet

- Stefan Molyneux - The - Handbook - of - Human - Ownership PDFDocument25 pagesStefan Molyneux - The - Handbook - of - Human - Ownership PDFSamuelNo ratings yet

- ETU Conversion PDFDocument2 pagesETU Conversion PDFDamian Altaireotter100% (1)

- Artigo - Course of SN-curves Especcially in The High-Cycle Fatigue Regime With Regard To Component Design and Safety PDFDocument13 pagesArtigo - Course of SN-curves Especcially in The High-Cycle Fatigue Regime With Regard To Component Design and Safety PDFRenan SartoriNo ratings yet