Professional Documents

Culture Documents

Chapter 10 Predetermined Motion Time Systems

Chapter 10 Predetermined Motion Time Systems

Uploaded by

Shankaranarayanan GopalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 10 Predetermined Motion Time Systems

Chapter 10 Predetermined Motion Time Systems

Uploaded by

Shankaranarayanan GopalCopyright:

Available Formats

Predetermined Motion Time

Systems (PMTS)

CHAPTER 10

Predetermined Motion Time Systems

Predetermined motion time system (PMTS) is a work

measurement technique whereby times established for basic human

motions are used to build up the time for a job at a defined level of

performance.

PMTS also called predetermined time system (PTS), is a database

of basic motion elements and their associated normal time values,

together with a set of procedures for applying the data to analyze

manual tasks and establish standard times for the tasks.

The PMTS database is most readily conceptualized as a set of tables

listing time values that correspond to the basic motion elements, the

lowest level in our hierarchy of manual work activity

They include motions such as reach, grasp, move, and release.

The Predetermined Motion Time

Systems Concept

The concept is similar to constructing a building. A

building is composed of elements-Doors, walls, beams,

bricks, plumbing. The structure is the sum of the elements.

Likewise, a job is also considered to consist of elements, the

total of which is the sum of the elements.

In formal words, the assumption is that each job element is

independent and additive; that is, each element does not

affect what happens before or after it - independence and

additivity.

What are Predetermined Motion

Time Systems?

A collection of basic motion times.

Technique for obtaining a standard time by:

analyzing and subdividing a task into elemental

motions

assigning pre-set standard times for motions and

summing these to obtain a standard time for the

whole task.

Popular Predetermined Motion Time

Systems

Methods -Time Measurement

Work-Factor

Predetermined Time Standards Systems

Meyers

MOST

Methods Time Measurement

(MTM)

MTM is a procedure which analyzes any manual operation

or method into the basic motions required to perform it,

and assigns to each motion a predetermined time standard

which is determined by the nature of the motion and the

conditions under which it is made.

MTM gives values for the fundamental motions of:

reach, move, turn, grasp, position, disengage, and release.

Methods Time Measurement

(MTM)

Most predetermined motion time systems use time measurement

units (TMU) instead of seconds for measuring time. One TMU is

defined to be 0.00001 hours, or 0.036 seconds. These smaller units

allow for more accurate calculations without the use of decimals. 1 hr

= 100,000 TMU

MTM studies provided the following kinds of information

Developing effective work methods prior to production

Improving existing methods to increase production and decrease labor cost

per unit

Establishing time standards as basis for wages and incentive plans

Developing time formulas or standard data for future use

Guiding product design for most efficient manufacture

Developing effective tool designs for most efficient manufacture

Selecting effective equipment for most efficient manufacture

Advantages of PMTS systems

PMT systems offer a number of advantages over stop-watch time

study. With PMT systems one time is indicated for a given motion,

irrespective of where such a motion is performed.

A PMT system, which avoids both rating and direct observation,

can lead to more reliability in setting standard times.

PMT systems are not too difficult to apply and can be less time

consuming than other methods.

PMT systems are particularly useful for very short repetitive time

cycles such as assembly work in the electronics industry.

PMTS Levels and Generations

Chronologically, first-level PMT systems were the first to be

developed, and then second - and higher - level systems were

subsequently constructed based on the first-level systems.

Because of this chronological development of the systems, the

level of the system usually corresponds to the generation of the

system.

First-level PMT systems are called first generation systems, and

the subsequent systems are second and third generations.

For example, MTM-1 is first generation MTM-2 is second

generation and is based on MTM-1. MTM-3 is a third generation

MTM system.

Characteristics of PMT system levels

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

MTM-1

In our hierarchy of work activity, MTM-1 operates at the basic

motion element level, as illustrated in Figure 14.1.

Most of the MTM-1 basic motions involve hand and arm

movements, although elements are also provided for eye, leg,

foot, and body actions.

Time units in MTM are called TMUs (time measurement units).

MTM was developed by studying motion pictures of work activity,

and the time units for MTM were originally defined as the time

per frame of motion picture film, and defined as

1 TMU = 0.00001 hr = 0.0006 min = 0.036 sec

100,000 TMUs in 1 hour,

1667 TMUs in 1 min, and

27.8 TMUs in 1 sec.

Table 14.3 defines the MTM-1 motion elements, and Table 14.4

presents a tabulation of their time values.

Figure 14.1 The position of MTM motion elements in our work

hierarchy.

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

Other MTM Systems

Other members of the MTM family satisfy various user needs.

MTM-2 Second-level PMTS in which basic motion elements

are combined into motion aggregates

GET combines Reach and Grasp

PUT combines Move and Position

MTM-3 Third-level PMTS which has four motion categories

1. Handle

2. Transport

3. Step and foot motions

4. Bend and arise

Table 14.5 lists many of these MTM systems with a brief

description of each.

Work Systems and the Methods, Measurement, and

Management of Work

by Mikell P. Groover, ISBN 0-13-140650-7.

2007 Pearson Education, Inc., Upper Saddle River, NJ. All

rights reserved.

Maynard Operation Sequence

Technique (MOST)

The Maynard Operation Sequence Technique

(MOST) is a high-level predetermined motion time

system (PMTS) that is based on MTM.

MOST is a work measurement technique that

concentrates on the movement of objects. It is used

to analyze work and to determine the normal time

that it would take to perform a particular process

/operation.

The basic version of MOST which is now referred to

as Basic MOST.

Maynard Operation Sequence Technique

(MOST)

More specifically, MOST is used to:

1. Break down the operation/process into smaller steps/units

2. Analyze the motions in each step/unit by using a standard

MOST method sequence

3. Assign indices to the parameters constituting the method

sequence for each task

4. Sum up the indices to arrive at a time value for each

step/unit

5. Sum up the time values for all the steps/units to arrive at

the normal time required to perform that

operation/process

MOST in the Work Pyramid

Figure 14.2 The position of the Basic MOST activity sequence model

in our work hierarchy

Basic MOST

The focus of Basic MOST is on work activity involve the movement

of objects. The majority of industrial manual work does involve

moving objects (e.g., parts, tools) from one location to another in

the workplace.

Basic MOST uses motion aggregates (collections of basic motion

elements) that are concerned with moving things. The motion

aggregates are called activity sequence models in Basic MOST.

There are three activity sequence models in Basic MOST, each of

which consists of a standard sequence of actions:

General move. This sequence model is used when an object is moved

freely through space from one location to the next (e.g., picking

something up from the floor and placing it on a table).

Controlled move. This sequence model is used when an object is moved

while it remains in contact with a surface (e.g., sliding the object along

the surface) or the object is attached to some other object during its

movement (e.g., moving a lever on a machine).

Tool use. This sequence model applies to the use of a hand tool (e.g., a

hammer or screwdriver).

The actions in an activity sequence model, called sequence model parameters

in Basic MOST, are similar to basic motion elements in MTM. Let us examine

the three sequence models and indicate the standard sequence of model

parameters for each.

General Move. The General Move sequence is applicable when an object is

moved through the air from one location to another. There are four parameters

(actions) in the General Move, symbolized by letters of the alphabet:

A Action distance, usually horizontal. This parameter is used to describe

movements of the fingers, hands, or feet (e.g., walking). The movement can be

per formed either loaded or unloaded.

B Body motion, usually vertical. This parameter defines vertical body

motions and actions (e.g., sitting, standing up).

G Gain control. This parameter is used for any manual actions involving the

fingers, hands, or feet to gain physical control of one or more objects. ft is

closely related to the grasp motion element in MTM (e.g., grasp the object).

P Placement. The placement parameter is used to describe the action

involved to lay aside, position, orient, or align an object after it has been moved

to the new location (e.g., position the object).

These parameters occur in the following standard sequence in the

General Move:

where the first three parameters (A B G) represent basic motions to get

an object, the next three parameters (A B P) represent motions to put

or move the object to a new location, and the final parameter (A)

applies to any motions at the end of the sequence, such as return to

original position.

To complete the activity sequence model, each parameter is assigned a

numerical value in the form of a subscript or index number that

represents the time to accomplish that action.

The value of the index number depends on the type of action, its

motion content, and the conditions under which it is performed. Table

14.6 lists the parameters and possible circumstances for the action,

together with the corresponding values of the index numbers.

When the index values have been entered for all parameters, the time

for the sequence model is determined by summing the index values

and multiplying by 10 to obtain the total TMUs. The procedure is

illustrated in the following example.

Example: General Move

Develop the activity sequence model and determine the normal time

for the following work activity: A worker walks 5 steps, picks up a small

part from the floor, returns to his original position, and places the part

on his worktable.

Solution: Referring to Table 14.6, the indexed activity sequence model for this

work activity would be the following:

A

10

B

6

G

1

A

10

B

0

P

1

A

0

where A

10

= walk 5 steps, B

6

= bend and arise, G

1

= control of small part, A

10

=

walk back to original position, B

0

= no body motion, P

1

= lay aside part on

table, and A

0

= no motion. The sum of the index values is 28. Multiplying by 10,

we have 280 TMUs (about 10 sec).

You might also like

- NYC Jazz Bass Checklist (Latest)Document11 pagesNYC Jazz Bass Checklist (Latest)David Esteban Cuervo FigueroaNo ratings yet

- Oral PathologyDocument9 pagesOral PathologyjanetNo ratings yet

- Time StudyDocument12 pagesTime Studyalexantsy27No ratings yet

- Maynard Operation Sequence Technique (MOST)Document8 pagesMaynard Operation Sequence Technique (MOST)VivekNo ratings yet

- Cleaning of Dairy EquipmentDocument20 pagesCleaning of Dairy Equipmentmilind_vetyNo ratings yet

- Lect - Problems - Jan 22 2021Document2 pagesLect - Problems - Jan 22 2021Dhairyashil Patil0% (1)

- Kinetics of Methanol Synthesis 2Document11 pagesKinetics of Methanol Synthesis 2Guhan ChendurnathanNo ratings yet

- Predetermined Time StudyDocument5 pagesPredetermined Time StudyJerome BayocbocNo ratings yet

- Work StudyDocument27 pagesWork Studyismael opondoNo ratings yet

- Chapter 1 Work StudyDocument50 pagesChapter 1 Work Studymanoj kumar singhNo ratings yet

- Productivity & Work Study BasicsDocument34 pagesProductivity & Work Study BasicsSangam Kadole75% (4)

- Chapter-5-Motion Study and Work DesignDocument34 pagesChapter-5-Motion Study and Work DesignPrincess AduanaNo ratings yet

- Factors Considered in The Method StudyDocument35 pagesFactors Considered in The Method StudyrajasekaranvgNo ratings yet

- Case Study On Operation ResearchDocument26 pagesCase Study On Operation Researchyvet1027100% (1)

- Method StudyDocument50 pagesMethod Studywintoday01100% (2)

- Function Analysis System Technique: Lesson 09Document11 pagesFunction Analysis System Technique: Lesson 09arun100% (1)

- Unit 2Document36 pagesUnit 2realguy556789No ratings yet

- Unit-Iii: Group TechnologyDocument23 pagesUnit-Iii: Group TechnologyRavi SekharNo ratings yet

- Idle Time Reduction in Machining Processes atDocument29 pagesIdle Time Reduction in Machining Processes atHarsheel PanchasaraNo ratings yet

- PMTS (Most)Document161 pagesPMTS (Most)Sundar Narayanan100% (1)

- Manufacturing and Operations ManagementDocument52 pagesManufacturing and Operations ManagementRohit Dhaware100% (1)

- Work Study Methods in Industrial EngineeringDocument20 pagesWork Study Methods in Industrial EngineeringSanat patilNo ratings yet

- Method StudyDocument69 pagesMethod StudySushayan Hunsasuk67% (3)

- Production Planning and ControlDocument22 pagesProduction Planning and ControlPravah Shukla100% (1)

- Product Design and Development 1516079078 20707Document24 pagesProduct Design and Development 1516079078 20707Er Dinesh ChauhanNo ratings yet

- Time and Motion StudyDocument68 pagesTime and Motion Studytushar100% (1)

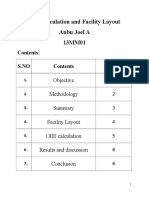

- Facility Layout and OEE CalculationDocument6 pagesFacility Layout and OEE CalculationAnbu Joel100% (1)

- Principles of Motion EconomyDocument63 pagesPrinciples of Motion EconomyAli ArsalanNo ratings yet

- Notes in Method StudyDocument3 pagesNotes in Method StudyKathrine Kate CadiangNo ratings yet

- Method StudyDocument80 pagesMethod StudyladdooparmarNo ratings yet

- CHAP (35) 35 Engr Metrology & InstrumentationDocument4 pagesCHAP (35) 35 Engr Metrology & InstrumentationfarizanNo ratings yet

- Inventory Management-A Case StudyDocument9 pagesInventory Management-A Case StudyAnagha BhatkarNo ratings yet

- Productivity Concept, Measurement and Improvement 09Document72 pagesProductivity Concept, Measurement and Improvement 09Sameer Sawant100% (1)

- GE6 SigmaDocument44 pagesGE6 SigmaFisher1987No ratings yet

- FAST (Functional Analysis System Technique)Document11 pagesFAST (Functional Analysis System Technique)abilash_nivas100% (1)

- Method Study: by Kunal PatelDocument28 pagesMethod Study: by Kunal PatelPatel KunalNo ratings yet

- Quality Function DeploymentDocument15 pagesQuality Function DeploymentKarandeep SinghNo ratings yet

- Unit Ii: Process PlanningDocument17 pagesUnit Ii: Process PlanningVijaya Prabhu KumarasamyNo ratings yet

- ProductivityDocument14 pagesProductivityPeter CalvoNo ratings yet

- Design For ManufacturingDocument20 pagesDesign For ManufacturingNadiaRahmaNoorSalsabilaNo ratings yet

- Industrial Engineering Is A Branch ofDocument10 pagesIndustrial Engineering Is A Branch ofashokkumarNo ratings yet

- History of Lean ManufacturingDocument14 pagesHistory of Lean ManufacturingVan Michael100% (2)

- Control Charts NotesDocument39 pagesControl Charts NotesFred Muthoka100% (1)

- Of Work To Be Done by An Operator in A Given Time Under Specified Conditions at The Defined Level of Performance. Requirement. Each WorkerDocument13 pagesOf Work To Be Done by An Operator in A Given Time Under Specified Conditions at The Defined Level of Performance. Requirement. Each WorkerDeepu lumarNo ratings yet

- The Taguchi Method:: The Service Manager S Primer To Quality by Ruth Robertson, Boise State University ©2002Document26 pagesThe Taguchi Method:: The Service Manager S Primer To Quality by Ruth Robertson, Boise State University ©2002Prateek Khanna100% (2)

- Introduction To Work StudyDocument36 pagesIntroduction To Work StudyVinesh86% (7)

- SQC - X Bar & R ChartDocument12 pagesSQC - X Bar & R ChartHery SasoriNo ratings yet

- Week 14 (Rapid Prototyping)Document50 pagesWeek 14 (Rapid Prototyping)Umair MalikNo ratings yet

- Time Study Revised 2018Document21 pagesTime Study Revised 2018Shishir Kumar100% (1)

- Unit 1 Introduction To Work Study and Work MeasurementDocument10 pagesUnit 1 Introduction To Work Study and Work Measurementleonard dela cruzNo ratings yet

- Work SamplingDocument36 pagesWork SamplingAakashMehtaNo ratings yet

- Statistical Process ControlDocument24 pagesStatistical Process ControlAnoopa Narayan100% (1)

- Lean ManufacturingDocument17 pagesLean ManufacturingAmbarish100% (6)

- Systematic Layout PlanningDocument7 pagesSystematic Layout PlanningsthalNo ratings yet

- TQMDocument46 pagesTQMjillmehta14No ratings yet

- ForecastingDocument50 pagesForecastingjoiematerumNo ratings yet

- Sample Lecture 1Document168 pagesSample Lecture 1Maryjoy DimaandalNo ratings yet

- Design For Manufac Ture and Assembly (Dfma)Document13 pagesDesign For Manufac Ture and Assembly (Dfma)Harshal KhotNo ratings yet

- Esua3 Ep3 Ind05a ModaptsDocument19 pagesEsua3 Ep3 Ind05a ModaptsJocelyn SolisNo ratings yet

- PMTSDocument124 pagesPMTSMANASNo ratings yet

- PPT8 - 11 - Work Design - PMTS - Work Sampling - Worker-Machine RelationshipDocument33 pagesPPT8 - 11 - Work Design - PMTS - Work Sampling - Worker-Machine RelationshipHASEL CONENo ratings yet

- Unit-4: V.Kamala Asst Professor Department of Industrial Engineering Anna University, ChennaiDocument43 pagesUnit-4: V.Kamala Asst Professor Department of Industrial Engineering Anna University, ChennaiArun R UNo ratings yet

- Work Measurement PDFDocument6 pagesWork Measurement PDFarunkadveNo ratings yet

- Theorical Famework Estudio Del TrabajoDocument33 pagesTheorical Famework Estudio Del TrabajoJocelyn SolisNo ratings yet

- Rolliflex Cables: Field-Bus CablesDocument2 pagesRolliflex Cables: Field-Bus CablesnikhilbhorNo ratings yet

- English Skills BookDocument49 pagesEnglish Skills BookAngela SpadeNo ratings yet

- Class 10 Science Perodic Classification Chapter 5 NotesDocument13 pagesClass 10 Science Perodic Classification Chapter 5 NotescxsdvNo ratings yet

- Answer Key To Hess' Law ProblemsDocument3 pagesAnswer Key To Hess' Law ProblemsTabitha HowardNo ratings yet

- CBSE Class 3 English Question Paper SA 2 2012Document7 pagesCBSE Class 3 English Question Paper SA 2 2012Anonymous 9WyPyismNo ratings yet

- M7025cat Milpower Ysmetronics M7025-10aDocument5 pagesM7025cat Milpower Ysmetronics M7025-10abhutaniseNo ratings yet

- Aurinio L50 L30 Brochure en TXM WEBDocument9 pagesAurinio L50 L30 Brochure en TXM WEBfikNo ratings yet

- End of Year Tercero Eso BilDocument4 pagesEnd of Year Tercero Eso BilCLEMENTE GARCIA RAFAEL DARIONo ratings yet

- Chapter-8 (Lag Lead Compensation)Document16 pagesChapter-8 (Lag Lead Compensation)Nischal MaharjanNo ratings yet

- Research Proposal - IKEADocument3 pagesResearch Proposal - IKEABhanuka GamageNo ratings yet

- Costa DataDocument85 pagesCosta DatasamftaylorNo ratings yet

- Ketamine ZhaoPDocument12 pagesKetamine ZhaoPSutanMudaNo ratings yet

- Ash LeshaDocument2 pagesAsh Leshaf_factorNo ratings yet

- Perfecting The Jet EngineDocument3 pagesPerfecting The Jet EnginesenthilNo ratings yet

- CH 084 Oral ThrushDocument7 pagesCH 084 Oral ThrushSavir GuptaNo ratings yet

- Twelve: Power Flow StudyDocument15 pagesTwelve: Power Flow StudyRasheed ShahNo ratings yet

- MMC Lecture7Document18 pagesMMC Lecture7Redo RamadhanNo ratings yet

- DOWSIL™ 795 Structural Glazing Sealant Technical Data SheetDocument5 pagesDOWSIL™ 795 Structural Glazing Sealant Technical Data SheetTrung Nguyễn NgọcNo ratings yet

- AGM Minutes 2019Document5 pagesAGM Minutes 2019nomadNo ratings yet

- Boy in DarknessDocument47 pagesBoy in DarknessAdam GreenNo ratings yet

- Padhle 11th - Gravitation NotesDocument48 pagesPadhle 11th - Gravitation Notesamritatak1No ratings yet

- Ehnv1 Est1: EQP-, EP-and Two-Phase Titration Function FunctionsDocument2 pagesEhnv1 Est1: EQP-, EP-and Two-Phase Titration Function FunctionsFernando Chacmana LinaresNo ratings yet

- (Cambridge School Classics Project) Cambridge Latin Course Book 1 (B-Ok - CC)Document189 pages(Cambridge School Classics Project) Cambridge Latin Course Book 1 (B-Ok - CC)bob ha92% (13)

- Los Rios Community College District - Job Safety Analysis: Job Category: Carpenter (For Specifics See Below )Document5 pagesLos Rios Community College District - Job Safety Analysis: Job Category: Carpenter (For Specifics See Below )Tiffany NNo ratings yet

- (Muscle Tissue) SHREYASI PDFDocument5 pages(Muscle Tissue) SHREYASI PDFShreyasi DongreNo ratings yet