Professional Documents

Culture Documents

Rfid Based Attendance System

Uploaded by

mohan154Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rfid Based Attendance System

Uploaded by

mohan154Copyright:

Available Formats

RFID BASED ATTENDANCE SYSTEM

Background

In all aspects of our life, we encounter event recording applications very often. Recording of any entity

be it sound, pictures, events etc. is very useful as it enables us to manipulate data to our requirements.

One can exploit the full potential of the recorded information for specific user defined purposes. Keeping

in mind the significance of event recorders in todays world, we arrived at a common decision of

making ATTENDANCE RECORDING SYSTEM USING RFID as our project in fulfillment of our

degree course.

Function

An attendance recording systems basic function is to keep a record of the time at which the employees

of a particular firm report to work and leave from work. It is one of the most widely used event recording

application in the industry today. A track of employee attendance is a must for payroll generation. The

traditional method of maintaining an attendance register makes the job very tedious and prone to human

errors. The collection and processing of data of employee.

Attendance which may include leaves, half working days, overtime etc. and using it to generate the

payroll manually consumes important man hours, which in turn could be used to increase productivity

and in turn profitably of the firm. In case of an error, even more time will be used to detect and rectify it,

if the process is manual. The whole process will be simplified to great extent.

If a system is available by means of which attendance data be stored, accessed, sorted, and processed and

obtained in a form of a detailed report which may be used directly for payroll generation, hence saving a

lot of precious time. It functions as a network of microchip smart tags and receivers. Each smart tag

is embedded with a unique electronic product code (EPC) and a micro-antenna. Once assigned, the EPC

becomes a DNA-like marker for the item, identifying it from every other item in the world. When a

tagged item passes within range of a reader, the reader retrieves the EPC via radio waves, identifies the

item and its exact location, and relays this real-time information to a central computer. Taken together,

the series of transactions comprise a comprehensive record of the tagged items movement from point of

origin to point of sale.

Comparison

Manufacturers of time/attendance recorders (T/A recorders) in Taiwan offer mechanical/electronic and

computer-based units. Most manufacturers provide computer-based models and only a few offer

mechanical/electronic recorders. Most T/A recorders in Taiwan fall within the midrange to high-end

category. Computer-based models range in FOB price from Rs.10000 to Rs.15000, depending on the

product's networking and access control features. Well,our product will be made at a cost of Rs.6000

(approx) and will include an onboard programmer. The person concerned will then be able to program

the onboard microcontroller and will have access to the database.

User

The product can be used by many organizations like our college itself. Whereby the traditional system of

signing in the musters will now be replaced and replaced well by using tags allotted to the staff.

However the current user is a small California startup called InCom has developed a radio frequency

identification (RFID) system called InClass to automate attendance-taking in elementary and secondary

schools. The system uses ultra-high frequency (UHF) readers mounted in classroom doorways and

passive RFID tags attached to student ID card holders. A unique 15-digit ID number is written to

each tag and associated with the name of the student to whom it is issued. As the students pass through

the reader-generated interrogation field under a doorway, the reader sends the tags' unique ID numbers to

a central server. InCom has developed a software program, installed on the server, that collects the tag

data and uploads a list of present, absent and tardy (based on when they enter the classroom) students to

a PDA that is issued to the teacher.

Block Diagram

Block Diagram: RFID based Attendance System

Explaination:

Microcontroller:

It is the Heart of the circuit. We will be using ATMELs AT89S52 microcontroller. The controller that

we will be using is ATMELs AT 89s52, which is a 40 pin microcontroller with 32 I/O lines. The

controller communicates with the RFID reader & the PC using RS232 protocol for which MAX 232 IC

is required.

MAX232:

Microcontroller communicates with the PC using its inbuilt Serial Port. The voltage levels are 0 & 5

Volts, but for the controller to communicate with the PC we are using RS232 protocol so for converting

the CMOS (0-5) voltage levels into RS232 (12) voltage levels we will be using MAX 232.

Keypad:

The keypad is used to indicate if the person is entering or exiting the premise. So basically there will be

two switches one for enter & one for exit.

RTC:

Real Time Clock (RTC) is used to storing the real time. A battery is provided to the RTC so that even

when there is a power failure the time is intact. The controller communicates with the RTC using the I2C

protocol.

EEPROM:

EEPROM is used to store the LOGs of the person entering or exiting the premise. The EEPROM will

contain the persons ID, time of scan & if the person is entering or exiting. The controller communicates

with the EEPROM using the I2C Protocol.

LCD:

We will be using 2-Line, 16 characters LCD. This will be used to display the real time, scan successful

or not and other such details.

Power Supply:

The complete circuit works on 5v this voltage is generated in the power supply section which basically

consists of a step down transformer, a rectifier & a voltage regulator.

The Advantages of RFID vs. barcode technology:

No line of sight requirement.

The tag can stand a harsh environment.

Long read range.

Portable database.

Multiple tag read/write.

Tracking people, items, and equipment in realtime.

Advantages

1. Store data on a tag

2. Can be hidden

3. Work in harsh environment

Disadvantges

1. Lack of standards!

2. Short range

3. Cost

Applications

1. Livestock Tagging

2. Wild Animal Tracking

3. Electronic Article Surveillance (EAS)

4. Automated Toll Collection

5. Animal Husbandry

You might also like

- Rfid Based Attendance SystemDocument4 pagesRfid Based Attendance SystemmveenavijayanmNo ratings yet

- 5.chapter 1Document4 pages5.chapter 1thethtet87No ratings yet

- Rfid Access Control SystemDocument16 pagesRfid Access Control SystemManjeet SinghNo ratings yet

- Synopsis For RFid Based Attendance System NewDocument3 pagesSynopsis For RFid Based Attendance System NewMandar DeshmukhNo ratings yet

- Chapppter Four & Five For JudeDocument14 pagesChapppter Four & Five For JudeoluwaseunNo ratings yet

- Examination Based On RfidDocument62 pagesExamination Based On Rfidsudhakar5472100% (2)

- Rfid Based Attendance System: Abstract - in Recent Past, A Rapid Growth in The Number ofDocument3 pagesRfid Based Attendance System: Abstract - in Recent Past, A Rapid Growth in The Number ofgandham vigneshNo ratings yet

- DSP PresentationDocument11 pagesDSP PresentationMuhammad Majid ZaheerNo ratings yet

- Tracking Police Man Using RF Proximity CardDocument6 pagesTracking Police Man Using RF Proximity CardSam JebaduraiNo ratings yet

- Atm Shoulder-Surfing Resistant Pin Entry by Using Base Pin and Base TextDocument3 pagesAtm Shoulder-Surfing Resistant Pin Entry by Using Base Pin and Base TextijaertNo ratings yet

- RfidDocument15 pagesRfidravikiran261No ratings yet

- Minor ReportFinalDocument34 pagesMinor ReportFinalPawan VishnoiNo ratings yet

- Electronic Toll Collection Sysem Based On RfidDocument84 pagesElectronic Toll Collection Sysem Based On Rfidspiromarurthi50% (4)

- Synopsis RfidDocument10 pagesSynopsis RfidneomayankNo ratings yet

- Rfid Project ReportDocument65 pagesRfid Project Reportgsrawat123No ratings yet

- Employee Log System Using Pc&RfidDocument3 pagesEmployee Log System Using Pc&RfidThanniru VenkateshNo ratings yet

- Review of Related Literature and Studies 2.1 Review of Related Literature 2.1.1 Servo MotorDocument6 pagesReview of Related Literature and Studies 2.1 Review of Related Literature 2.1.1 Servo MotorKarlyn CalimponNo ratings yet

- RFID Based Attendance Management SystemDocument10 pagesRFID Based Attendance Management SystemBarid NayakNo ratings yet

- Electronic Toll Collection Sysem Based On RfidDocument68 pagesElectronic Toll Collection Sysem Based On RfidUmar Rahamatullah ShareefNo ratings yet

- Voice Activated Traffic Management System Using Apr 9600 Based On Embedded SystemDocument7 pagesVoice Activated Traffic Management System Using Apr 9600 Based On Embedded SystemInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Ieee Paper On Image Processing Based On HUMAN MACHINE INTERFACEDocument6 pagesIeee Paper On Image Processing Based On HUMAN MACHINE INTERFACESuganya PeriasamyNo ratings yet

- RFID Based Attendance System Project Circuit and WorkingDocument5 pagesRFID Based Attendance System Project Circuit and WorkinglkjhNo ratings yet

- Automated Data Collection: Priya SharmaDocument17 pagesAutomated Data Collection: Priya SharmaSumanAgarwalNo ratings yet

- Research Paper Pic MicrocontrollerDocument6 pagesResearch Paper Pic Microcontrollerupvipbqlg100% (1)

- Literature Review of Rfid Based Attendance SystemDocument8 pagesLiterature Review of Rfid Based Attendance SystemmkcewzbndNo ratings yet

- Smart TrolleyDocument24 pagesSmart TrolleyAbdul Razzak100% (1)

- Smart TrolleyDocument24 pagesSmart TrolleyAbdul Razzak0% (1)

- Research Review of Related LiteratureDocument9 pagesResearch Review of Related LiteratureBless beljNo ratings yet

- Book 02 1Document51 pagesBook 02 1mohammadnur89No ratings yet

- College AutomationDocument47 pagesCollege AutomationGauri Priya RohithNo ratings yet

- RFID Based Security SystemDocument30 pagesRFID Based Security Systemletter2lalNo ratings yet

- On Rfid Based Attendance System: Internet of Things Project ReportDocument36 pagesOn Rfid Based Attendance System: Internet of Things Project ReportNaveen KumarNo ratings yet

- Smart Billing For Trolley Using RFIDDocument5 pagesSmart Billing For Trolley Using RFIDPrathyush P SNo ratings yet

- Anytime Anyplace-Remote Monitoring of Students Attendance Based On Rfid and GSM NetworkDocument4 pagesAnytime Anyplace-Remote Monitoring of Students Attendance Based On Rfid and GSM NetworkAllyson WattsNo ratings yet

- Smart Shopping Cart IEEE PDFDocument4 pagesSmart Shopping Cart IEEE PDFradz248100% (3)

- CodeedDocument72 pagesCodeedAbhilashNo ratings yet

- Arduino and RFID Based Security SystemDocument8 pagesArduino and RFID Based Security SystemharrysinghNo ratings yet

- Keywords - Barcode, SMS, Attendance, Enquiry, Student, LCD, GUIDocument10 pagesKeywords - Barcode, SMS, Attendance, Enquiry, Student, LCD, GUImahesh chandewarNo ratings yet

- Barcode System MCTDocument27 pagesBarcode System MCTYogi BhimaniNo ratings yet

- HMS RfidDocument23 pagesHMS RfidMahesh KumarNo ratings yet

- Design and Implementation of Low Cost Automatic Toll Collection System Using RFIDDocument6 pagesDesign and Implementation of Low Cost Automatic Toll Collection System Using RFIDGRD JournalsNo ratings yet

- A Real Time Embedded Finger Vein Recognition System For Authentication On Mobile DevicesDocument4 pagesA Real Time Embedded Finger Vein Recognition System For Authentication On Mobile DevicesRaghul RamasamyNo ratings yet

- Department of Electronics & Communication Engineering 1.modern Home (AC/DC) Automation Using GSM ModuleDocument4 pagesDepartment of Electronics & Communication Engineering 1.modern Home (AC/DC) Automation Using GSM ModuleSuresh ChintalaNo ratings yet

- Rfid Based Vehicle Monitoring and Toll Collection SystemDocument38 pagesRfid Based Vehicle Monitoring and Toll Collection SystemAbdul Razzak0% (1)

- Chapter Iv Progress 1Document22 pagesChapter Iv Progress 1Daine GoNo ratings yet

- Rfid Access Control System and Security WebcamDocument6 pagesRfid Access Control System and Security WebcamAjay BhaleraoNo ratings yet

- The Design of PLC Entrance Guard System Based On RFID TechnologyDocument4 pagesThe Design of PLC Entrance Guard System Based On RFID TechnologyMIRCEA MIHAINo ratings yet

- RFID Based Museum Guide For TouristsDocument47 pagesRFID Based Museum Guide For Touristspraveen_kodgirwarNo ratings yet

- EXP1Document6 pagesEXP1Ronny Fae FabonNo ratings yet

- Iot Based Biometric Attendance SystemDocument18 pagesIot Based Biometric Attendance SystemPrajoth 171A224No ratings yet

- Microcontroller Based Automated Attendance System For Employees Using Zigbee ModuleDocument5 pagesMicrocontroller Based Automated Attendance System For Employees Using Zigbee ModuleInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- IoT Mining Tracking &worker Safety Emergency AlertDocument4 pagesIoT Mining Tracking &worker Safety Emergency AlertIJMTST-Online JournalNo ratings yet

- RF Id Rationcard-OkDocument24 pagesRF Id Rationcard-OkRamalingam ShanmugamNo ratings yet

- Automatic Barcode Scanner With Billing System Using Arduino: Dhamodharan.T, Prakash.S, Vasantha Kumar.RDocument4 pagesAutomatic Barcode Scanner With Billing System Using Arduino: Dhamodharan.T, Prakash.S, Vasantha Kumar.Rhamza shahNo ratings yet

- GPS Based Voice Alert SystemDocument13 pagesGPS Based Voice Alert SystemRavi RajNo ratings yet

- Ambulance Controlled Traffic System Using Rfid Technology With Labview SimulationDocument5 pagesAmbulance Controlled Traffic System Using Rfid Technology With Labview SimulationSimona NicoletaNo ratings yet

- 1.0 Background of StudyDocument8 pages1.0 Background of StudyLawal Abimbola100% (1)

- Microcontroller Based Digital Code LockDocument2 pagesMicrocontroller Based Digital Code LockHcv Prasad KacharlaNo ratings yet

- Ijret - Design of Intelligent Transport Related Issue System Based On Arm7Document5 pagesIjret - Design of Intelligent Transport Related Issue System Based On Arm7International Journal of Research in Engineering and TechnologyNo ratings yet

- Manual Fischertechnik DesignerDocument42 pagesManual Fischertechnik Designerlauraelena_diazlopez01No ratings yet

- SA253MA DetailDocument16 pagesSA253MA Detailksquare2001100% (1)

- Features: InputDocument2 pagesFeatures: InputFaisaludinNo ratings yet

- Aircraft Radio Navigation Communication SystemsDocument192 pagesAircraft Radio Navigation Communication Systemspontoo100% (16)

- MRP List: Think Innovation. Think RishabhDocument69 pagesMRP List: Think Innovation. Think RishabhSukhirthan SenthilkumarNo ratings yet

- E - Theory/Operation - Efi: 1991 Mitsubishi MonteroDocument7 pagesE - Theory/Operation - Efi: 1991 Mitsubishi MonteroAnimemanuel MuñozNo ratings yet

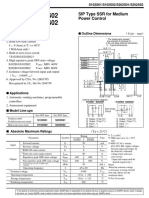

- S102S01/S102S02 S202S01/S202S02: SIP Type SSR For Medium Power ControlDocument4 pagesS102S01/S102S02 S202S01/S202S02: SIP Type SSR For Medium Power ControlРоман АлександровичNo ratings yet

- Where Use Dong-A Cable CleatsDocument5 pagesWhere Use Dong-A Cable CleatsA.K.A. HajiNo ratings yet

- Marking Code RG 73Document5 pagesMarking Code RG 73José AdelinoNo ratings yet

- EPOCH 600 - Basic Operation (En)Document60 pagesEPOCH 600 - Basic Operation (En)Jacques SauNo ratings yet

- AM61 Gu A Del Usuario (AM61,05, ES)Document154 pagesAM61 Gu A Del Usuario (AM61,05, ES)PRUEBANo ratings yet

- Balluff BUS003C Instruction - SheetDocument3 pagesBalluff BUS003C Instruction - SheetLuchito BuenoNo ratings yet

- Unit 1Document52 pagesUnit 1seetha lakshmiNo ratings yet

- Distributed Databases: Not Just A Client/server SystemDocument43 pagesDistributed Databases: Not Just A Client/server Systemwidya yuniariNo ratings yet

- Pneumatic SwitchDocument3 pagesPneumatic SwitchMuddassar SultanNo ratings yet

- Live Recording Guide Av3rd Asio Streamer enDocument15 pagesLive Recording Guide Av3rd Asio Streamer enmihaimiitNo ratings yet

- Control ProductsDocument174 pagesControl Productswilfred pastranaNo ratings yet

- Advantages and Disadvantages of Finfets - AlyaaDocument12 pagesAdvantages and Disadvantages of Finfets - AlyaaAlyaa Nadzirah Binti ShbiniNo ratings yet

- Fill in The Correct Options: Pre Test PaperDocument4 pagesFill in The Correct Options: Pre Test PaperVikas MishraNo ratings yet

- Mini Project ReportDocument19 pagesMini Project Reportrinkumaurya91No ratings yet

- FGXR System SpecificationsDocument11 pagesFGXR System SpecificationsAknouch AbdelmoujibNo ratings yet

- Specific Industrial TrainingDocument23 pagesSpecific Industrial TrainingSangary PeriyasamyNo ratings yet

- Exploring The Potential of VLSI ComputingDocument28 pagesExploring The Potential of VLSI ComputingGeetanjali DeviNo ratings yet

- Laporan Shift Malam 05 Maret 2019Document1 pageLaporan Shift Malam 05 Maret 2019Veeko RinaldoNo ratings yet

- Aegis: - Vacuum Circuit Breaker Ring Main UnitDocument6 pagesAegis: - Vacuum Circuit Breaker Ring Main Unitdrsh81No ratings yet

- 505-505E Digital Control For Steam Turbines PDFDocument4 pages505-505E Digital Control For Steam Turbines PDFJoão Marcos MagalhãesNo ratings yet

- Chapter 3Document25 pagesChapter 3ermaNo ratings yet

- Operating SystemsDocument2 pagesOperating SystemslovebanglaNo ratings yet

- Filter Map Technical Reference ManualDocument51 pagesFilter Map Technical Reference ManualOscar CastroNo ratings yet

- PE304 - Buck ConverterDocument4 pagesPE304 - Buck ConverterBenjamin SebastianNo ratings yet