Professional Documents

Culture Documents

01 - Fluid Flow

Uploaded by

Mgn SanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 - Fluid Flow

Uploaded by

Mgn SanCopyright:

Available Formats

Chapter 1: Fluid Flow

Rules of Thumb for Chemical Engineers, 5th Edition

by Stephen Hall

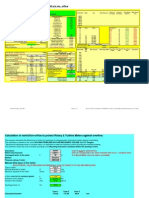

This Excel workbook includes Visual Basic for Application function subroutines.

Macros must be enabled for them to work.

The following Text Boxes contain the syntax for the functions.

Copy them to the worksheet where you want to use the functions for ready reference.

Function Subroutines in SI Units

ChemEng Software sells an Excel template called PIPESIZE.

www.chemengsoftware.com

Function NReSI(W, mu, d, Optional ro, Optional Tin, Optional Mw, Optional p)

' W = Flowrate in kg/h

' mu = Viscosity in mPa-s

' d = PipeID in mm

' ro = density in kg/m3 (required for liquid)

' Tin = temperature, deg C (required for gas) - default 20 deg C

' Mw = molecular weight (required for gas) - default 29

' p = pressure, kPa (required for gas) - default 1000 kPa

Function FrictionSI(epsilon, NRe, d)

' epsilon = Surface roughness is in units m

' d = PipeID is in units mm

Function PDSI(W, Pin, Pout, d, L, f, Optional Density, Optional Tin, Optional Mw, Optional Gamma, Optional

Isothermal)

' Pressure Drop due to friction in a round pipe (adiabatic for compressible flow)

' with the following arguments

' Specify two of the following three; function will compute the third

' W = mass flow rate, kg/h

' Pin = inlet, or upstream, pressure, kPa

' Pout = outlet, or downstream pressure, kPa

' Pipe properties

' d = pipe diameter, mm

' L = pipe length, m

' f = Darcy friction factor

' Fluid properties

' Density (optional) -- specify for liquids, kg/m3

' Tin (optional) -- specify for gas, inlet temperature, deg C (default to 20)

' Mw (optional) -- specify for gas, molecular weight (default to 29 for air)

' Gamma (optional) -- specify for gas, ratio of Cp/Cv (default to 1.4)

' Isothermal (optional) -- any value results in isothermal compressible calc, if missing then adiabatic calc

Function NReUS

' W = Flowrate in lb/h

' mu = Viscosity in cP

' d = PipeID in inches

' ro = density in lb/ft3 (required for liquid)

' Tin = temperature, deg F (required for gas)

' Mw = molecular weight (required for gas)

' p = pressure, psia (required for gas)

Function FrictionUS

' epsilon = Surface roughness is in units feet

' d = PipeID is in units inches

Function PDUS

' Pressure Drop due to friction in a round pipe (adiabatic or isothermal for compressible flow)

' with the following arguments

' Specify two of the following three; function will compute the third

' W = mass flow rate, lb/hr

' Pin = inlet, or upstream, pressure, psia

' Pout = outlet, or downstream pressure, psia

' Pipe properties

' d = pipe diameter, inches

' L = pipe length, feet

' f = Darcy friction factor

' Fluid properties

' Density (optional)

' Tin (optional)

' Mw (optional)

' Gamma (optional)

' Isothermal (optional)

PIPESIZE sizes pipes for gases and liquids. It includes a database of properties for piping materials, fluids,

roughness values, and recommended velocities. Order on-line or by telephone, 24-h/d; credit cards accepted.

Function Subroutines in US Units

Function NReUS(W, mu, d, Optional ro, Optional Tin, Optional Mw, Optional p)

' W = Flowrate in lb/h

' mu = Viscosity in cP

' d = PipeID in inches

' ro = density in lb/ft3 (required for liquid)

' Tin = temperature, deg F (required for gas) - default 60

' Mw = molecular weight (required for gas) - default 29

' p = pressure, psia (required for gas) - default 115

Function FrictionUS(epsilon, NRe, d)

' epsilon = Surface roughness is in units feet

' d = PipeID is in units inches

Function PDUS(W, Pin, Pout, d, L, f, Optional Density, Optional Tin, Optional Mw, Optional Gamma, Optional Isothermal)

' Pressure Drop due to friction in a round pipe (adiabatic or isothermal for compressible flow)

' with the following arguments

' Specify two of the following three; function will compute the third

' W = mass flow rate, lb/hr

' Pin = inlet, or upstream, pressure, psia

' Pout = outlet, or downstream pressure, psia

' Pipe properties

' d = pipe diameter, inches

' L = pipe length, feet

' f = Darcy friction factor

' Fluid properties

' Density (optional) -- specify for liquids, lb/ft3

' Tin (optional) -- specify for gas, inlet temperature, deg F (default to 60)

' Mw (optional) -- specify for gas, molecular weight (default to 29 for air)

' Gamma (optional) -- specify for gas, ratio of Cp/Cv (default to 1.4)

' Isothermal (optional) -- any value results in isothermal compressible calc, if missing then adiabatic calc

(W, Pin, Pout, d, L, f, Optional Density, Optional Tin, Optional Mw, Optional Gamma, Optional Isothermal)

SI Units US Units

Inputs

Flow Rate kg/h 10,000.0 lb/h 22,000.0

Viscosity mPa-s 1.2 cP 1.2

Pipe Diameter mm 38.1 in 1.5

Density kg/m3 961.5 lb/ft3 60.0

Output

Delta P Bar/100 m 1.83 psi/100 ft 8.09

Problem Statement:

Calculate pressure drop per 100 m or 100 ft using the

Inputs Liquid Gas

Parameter Units Example 1 Example 2

Mass Flow Rate kg/h 10,000.0 1,200.0

Viscosity mPa-s 1.2 0.011

Pipe Diameter mm 38.1 26.6

Density kg/m3 961.0

Temperature C 40.0

Molecular Weight kg/kgmol 16.04

Pressure kPa, absolute 2,200.0

Output

Reynolds Number dimensionless 77,357.3 1,450,489

Problem Statement:

Calculate Reynolds Number using VBA function call.

=NReSI(D8,D9,D10,D11) =NReSI(E8,E9,E10,,E12,E13,E14)

US Customary Units Liquid Gas

Units Example 1a Example 2a

lb/h 22,000.0 2,645.0

cP 1.2 0.011

in 1.5 1.047

lb/ft3 60.0

F 104.0

lb/lbmol 16.04

psia 319.0

77,197.9 1,450,580

=NReUS(I8,I9,I10,I11) =NReUS(J8,J9,J10,,J12,J13,J14)

Inputs Liquid

Parameter Units Example 3

Mass Flow Rate kg/h 290.0

Viscosity mPa-s 1.2

Pipe Diameter mm 38.1

Density kg/m3 961.0

Temperature C

Molecular Weight kg/kgmol

Pressure kPa, absolute

Pipe Roughness m 0.0000457

Output

Reynolds Number dimensionless 2,243

Darcy Friction Factor dimensionless 0.0302

Problem Statement:

Calculate Darcy Friction Factor using VBA function call.

=FrictionSI(D16,D19,D10)

US Customary Units Liquid

Units Example 3a

lb/h 22,000.0

cP 1.2

in 1.5

lb/ft3 60.0

F

lb/lbmol

psia

ft 0.00015

77,198

0.0236

=FrictionUS(I16,I19,I10)

Inputs Liquid Gas

Parameter Units Example 4 Example 5

Mass Flow Rate kg/h 10,000.0 1,200.0

Pressure in (upsteam) kPa, absolute 700.0 2,200.0

Viscosity mPa-s 1.2 0.011

Pipe Diameter mm 38.1 26.6

Equivalent Length of Pipe m 40.0 60.0

Density kg/m3 961.0

Temperature C 40.0

Molecular Weight kg/kgmol 16.04

Cp/Cv 1.35

Pipe Roughness m 0.0000457 0.0000457

Output

Reynolds Number dimensionless 77,357 1,450,489

Darcy Friction Factor dimensionless 0.0236 0.0227

Pressure Out, given Mass Flow and Pressure in 623.6 1,246.3

Problem Statement:

Calculate Pressure Drop due to Friction

=PDSI(D8,D9,,D12,D13,D24,D14)

=PDSI(E8,E9,,E12,E13,E24,,E15,E16,E17)

US Customary Units Liquid Gas

Units Example 4a Example 5a

lb/h 22,000.0 3,080.0

psia 101.5 319.0

cP 1.2 0.011

in 1.5 1.047

ft 131.0 197.0

lb/ft3 60.0

F 104.0

lb/lbmol 16.04

1.35

ft 0.00015 0.00015

77,197.9 1,689,145

0.0236 0.0227

90.5 171.3

=PDUS(I8,I9,,I12,I13,I24,I14)

=PDUS(J8,J9,,J12,J13,J24,,J15,J16,J17)

Inputs Gas

Parameter Units Example 5

GUESS Mass Flow Rate kg/h 1200

Pressure in (upsteam) kPa, absolute 2200

Pressure out (downstream) 1340

Viscosity mPa-s 0.011

Pipe Diameter mm 26.6

Equivalent Length of Pipe m 60

Temperature C 40

Molecular Weight kg/kgmol 16.04

Cp/Cv 1.35

Pipe Roughness m 0.0000457

Output

Reynolds Number dimensionless 1,450,489

Darcy Friction Factor dimensionless 0.0227

Mass Flow, given Pressure in and out 1,152.5

Difference between GUESS and calculated rate, E8-E26 47.5

Problem Statement:

Calculate Flow Rate given upstream and downstream pressures

=PDSI( ,E9,E10,E12,E13,E24,E14,E15,E16,E17)

Use Goal Seek to find a value for

the Guessed flow rate (Cell E8)

that equals the calculated flow rate

(Cell E26). Notice that Reynolds

Number is calculated using the

Guess.

US Customary Units Gas

Units Example 5a

lb/h 3,080.4

psia 319.0

psia 116

cP 0.011

in 1.047

ft 197.0

F 104.0

lb/lbmol 16.04

1.35

ft 0.00015

1,689,382

0.0227

3,015.6

64.8

Use Goal Seek to find a value for

the Guessed flow rate (Cell E8)

that equals the calculated flow rate

(Cell E26). Notice that Reynolds

Number is calculated using the

Guess.

=PDUS( ,L9,L10,L12,L13,L24,,L15,L16,L17)

Inputs Liquid Gas

Parameter Units Example 4 Example 5

Mass Flow Rate kg/h 10,000.0 1,200.0

Pressure in (upsteam) kPa, absolute 700.0 2,200.0

Viscosity mPa-s 12.0 0.011

Pipe Diameter mm 50.0 26.6

Length of Pipe m 38.1 60.0

Density kg/m3 961.0 13.6

Temperature C 40.0

Molecular Weight kg/kgmol 16.04

Cp/Cv 1.35

Pipe Roughness m 0.0000457 0.0000457

Fittings Quantity

90 deg, welded r/D = 1 6

TEE, through branch (as elbow) 2

Plug valve, straight 2

Swing check, Vmin = 35 ro^0.5 1

Output

Reynolds Number dimensionless 5,895 1,450,489

Darcy Friction Factor dimensionless 0.0373 0.0227

Pressure Drop, given Mass Flow and Pressure in 29.6 953.7

Equivalent length of fittings m 14.80 7.87

Pressure Drop, equiv length method 41.08 1,018.93

Mass flux kg/m2-s 1,414.71 599.83

Velocity m/s 1.47 44.25

Fitting pressure loss kg/m2 937.50 59,320.48

kPa 9.19 581.34

Pressure Drop, 3-K method 38.77 1,535.02

Pressure Drop, Crane method 35.51 1,029.16

Problem Statement:

Compare pressure drop calculations using equivalent length and K-value methods for fittings.

Eq L 3-K Method

total Kf

Ex 4 Ex 5

(L/D)eq Km Ki Kd Total L/D

20 800 0.091 4 120 3.14 24.00

20 800 0.28 4 40 2.66 8.00

18 300 0.084 3.9 36 0.80 7.80

100 1500 0.46 4 100 2.22 4.00

296 8.82 43.80

Pressure Drop, Pa

Flow Regime Equiv L Crane K 3-K

50 Laminar 0.060 0.043 0.051

100 Laminar 0.120 0.087 0.102

500 Laminar 0.598 0.446 0.525

1000 Laminar 1.196 0.921 1.089

2000 Laminar 2.392 1.960 2.331

10000 Turbulent 41.079 35.508 38.774

30000 Turbulent 284.129 257.934 278.315

50000 Turbulent 716.261 663.917 715.526

70000 Turbulent 1,328.928 1,247.301 1,344.249

US Customary UnitsLiquid

Units Example 4a

lb/h 63,000.0

psia 101.5

cP 10.0

in 3.1 3 nominal size

ft 31.5

lb/ft3 112.5

F 127.0

lb/lbmol

Crane

ft Crane K ft 0.00015

0.019213 2.31

0.019213 0.77 12,970.0

0.019213 0.69

0.019213 1.92 0.03003

5.69

Delta P, pipe 0.413

Velocity 3.03

f, full turbulence 0.01731498

Leq Crane K 3-K

90 Ell 2 10.23 0.692599 0.828956

Branch tee 1 5.11 0.3463 1.147211

Swing check 1 25.57 1.731498 1.899022

Plug valve 1 4.60 0.31167 0.342748

3 x 1 reducer 1 822.68 57.92 57.92

868.19 61.00 62.14

Delta P, comparison 11.78 7.22 7.34

0.61 (0.02) 1

Inputs Liquid

Parameter Units Example 6

Mass Flow Rate kg/h 10,000.0

P0 Pressure in (upsteam) kPa, absolute 700.0

Viscosity mPa-s 1.2

Pipe Diameter mm 38.1

Equivalent Length of Pipe m 60.0

Density kg/m3 961.0

Temperature C

Molecular Weight kg/kgmol

Cp/Cv

Pipe Roughness m 0.0000457

Orifice Diameter mm 19.1

Output

Reynolds Number dimensionless 77,357

Darcy Friction Factor dimensionless 0.0236

P1 Pressure out (downstream) kPa, absolute 585.4

V1 Velocity through orifice m/s 10.1

Sonic velocity m/s

Orifice diameter ratio dimensionless 0.5

C Orifice Coefficient of Discharge dimensionless 0.61

r

Y Expansion factor dimensionless 1.0

P2 Orifice discharge pressure kPa, absolute 452.6

P3 Permanent Loss kPa, absolute 485.8

DeltaP P1-P3 kPa 99.61

K flow coefficient dimensionless 29.46

Equivalent Length m 56.12

Compare equivalent length ratio to pressure drop ratio

Pipe L / Orifice L 1.07

Pipe Pressure Drop / Orifice Pressure Drop 1.15

Problem Statement:

Calculate Permanent Pressure Drop Through Orifice

Pipe Header at 700

kPa absolute

60 m, 38.1 mm ID

P0

Result

Close enough, although not perfect

60 m, 38.1 mm ID

RO

P1

P2

P3

Close enough, although not perfect

Inputs Steam-Water at Saturated Conditions Water

Total Mass Flux kg/m2-s 1,356.0

Quality Mass Fraction Vapor 0.5

Inlet Pressure Bar 1.01

Pipe Diameter mm 5.0

Equivalent Length of Pipe m 1.0

Pipe Roughness m 0.0000015 (Smooth Tube = 0.0000015 m)

Calculations / Property Lookup

Parameter Units Total as Liq Vapor Props Mixture

Cross-sectional area m2 1.9635E-05

Total Mass Flow Rate kg/h 95.8

Inlet Pressure kPa 101.0

Temperature C 97.4

Viscosity mPa-s 0.28 0.012 0.023

Molecular Weight kg/kgmol 18.0

Density kg/m3 998.7 0.6 1.2

Cp/Cv 1.31

Output

Reynolds Number dimensionless 24,014 294,943

Darcy Friction Factor dimensionless 0.0255 0.0171

Pressure Drop, given Mass Flow and Pressure in 4.69 2,664.10

Liquid PD Multiplier phi 23.83

phi^2 567.65

Pressure Drop, 2-Phase Flow kPA 2,664.10

0.2

0.3

0.6

0.8

Problem Statement:

Calculate Pressure Drop due to Friction for Water-Steam Mixture

1000

10000

1.01 Bar

1

Quality

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1

10

100

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

1.01 Bar

6.89 Bar

34.4 Bar

68.9 Bar

103 Bar

138 Bar

172 Bar

207 Bar

221.2 Bar

100

150

200

250

G=339

G=1356

G=5424

Quality

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0

50

100

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

5

10

15

20

25

Awad

Janssen

Property Correlations for all correlations, t = deg C

Vapor Pressure: log(mm Hg) = A - B / (t+C) Liquid Viscosity: ln(cP) = A + B / (C+t)

A B C

R12 6.99 918.17 253.38

R22 7.04 850.10 245.18

Water 8.31 1,986.50 268.74

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Reference: IPC2004-721

Comparison Case

R12

2,000.0

0.9

6.00

50.0

1.0

(Smooth Tube = 0.0000015 m) 0.0000015 (Smooth Tube = 0.0000015 m)

Total as Liq Vapor Props Mixture

0.001963495

14,137.2

600.0

22.0

0.20 0.013 0.015

120.9

1,325.3 29.6 32.8

1.17

488,377 6,864,651

0.0136 0.0103

0.41

5.55

30.75

12.63

Phi^2

Quality 1.01

0 1

0.03 46.41645292

0.05 73.3322877

0.08 111.1844284

0.11 147.185195

0.15 193.407243

0.2 249.3652528

0.3 357.7600186

0.6 670.8147204

0.8 875.2441564

User inputs are in RED

Temperature, viscosity, and density are determined from

correlation parameters in lookup table (down at the bottom of the

worksheet). These are affected by the inlet pressure variable. It

is assumed that the temperature is the saturation temperature at

the pressure.

Calculations for Re, f, and pressure drop are performed in VBA

subroutines --

subroutines are correct.

Clicking on the "Re

macro that runs the calculation on various combinations of

inputs, based on the charts in IPC2004

It seems like the only way to get a straight line (per the

reference) for Figure 7 (Row 123) is to do the friction factor

calculations once, then recalculate phi for a range of qualities (0

to 1) without recomputing the mixture viscosity and density for

each quality.

1 1078.089605

Phi^2

Quality 339

0 1

0.1 21.65342509

0.2 38.38506949

0.3 53.69737283

0.4 68.23836666

0.5 82.28544802

0.6 95.98612791

0.7 109.4292805

0.8 122.6730181

0.9 135.7576073

1 148.7121853

Phi^2

Quality 2278

0 1

0.1 3.225019566

0.2 5.336625128

0.3 7.386603283

0.4 9.398360896

0.5 11.38436636

0.6 13.35199619

0.7 15.30594741

0.8 17.24937895

0.9 19.1845074

1 21.11294176

Liquid Viscosity: ln(cP) = A + B / (C+t) Vapor Viscosity: ln(cP) = A + B / (C+t) Density: kg/m3 = m t + b

A B C

(8.77) 5,134.3 693.01 (9.00) (4,611.86) (1,008.87)

20.79 46,143.5 (2,064.89) (3.47) (278.74) 286.66

4.34 6,927.32 (1,332.33) (4.92) (200.49) (502.57)

6.89 34.4 68.9 103 138 172 207 221.2

1 1 1 1 1 1 1 1

8.224628681 2.48118952 1.724209 1.471297363 1.341214662 1.26543664 1.21338118 1.196944

12.64834922 3.42330677 2.1931 1.779418297 1.565753054 1.44090455 1.35493938 1.327755

18.93805921 4.78780781 2.879825 2.233848908 1.898624121 1.70203456 1.56627859 1.52327

24.95216539 6.10832883 3.550296 2.68027314 2.22725028 1.96085338 1.77647153 1.717971

32.68889358 7.81877575 4.424186 3.265040944 2.659601824 2.302653 2.05503895 1.976355

42.05776424 9.89799524 5.491334 3.982109516 3.191936121 2.72512011 2.40069759 2.297472

60.18602161 13.9265317 7.565445 5.380827356 4.23461845 3.55633082 3.08428571 2.933941

112.3770188 25.4933944 13.52198 9.405154978 7.245188894 5.96923649 5.08469657 4.804169

146.3711257 32.9985878 17.37767 12.00665506 9.191022614 7.53131397 6.38577582 6.024389

User inputs are in RED

Temperature, viscosity, and density are determined from

correlation parameters in lookup table (down at the bottom of the

worksheet). These are affected by the inlet pressure variable. It

is assumed that the temperature is the saturation temperature at

the pressure.

Calculations for Re, f, and pressure drop are performed in VBA

subroutines -- other worksheets in this workbook verify that those

subroutines are correct.

Clicking on the "Re-Run All Inputs" button at cell L35 runs a

macro that runs the calculation on various combinations of

inputs, based on the charts in IPC2004-721.

It seems like the only way to get a straight line (per the

reference) for Figure 7 (Row 123) is to do the friction factor

calculations once, then recalculate phi for a range of qualities (0

to 1) without recomputing the mixture viscosity and density for

each quality.

180.0619704 40.4208391 21.18376 14.57066284 11.10631356 9.06799534 7.66705922 7.227597

Sonic Velocity

489.498723 m/s

Pipe flow area 1.9635E-05 m2

Velocity, m/s

1356 5424 Mass Flux Density 339 1356 5424 kg/m2-s

1 1 998.66 0.34 1.36 5.43

22.97164511 24.5221439 5.87 57.75 231.02 924.06 YELLOW = > Mach 0.3

42.05776424 46.4192905 2.94 115.17 460.67 1,842.69 RED > Mach 1

60.18602161 67.8640232 1.96 172.58 690.33 2,761.33

77.83538138 89.1071994 1.47 230.00 919.99 3,679.96

95.19986265 110.239906 1.18 287.41 1,149.65 4,598.59

112.3770188 131.304262 0.98 344.83 1,379.30 5,517.22

129.4225584 152.322783 0.84 402.24 1,608.96 6,435.85

146.3711257 173.308745 0.74 459.66 1,838.62 7,354.48

163.2456352 194.270555 0.66 517.07 2,068.28 8,273.11

180.0619704 215.213833 0.59 574.48 2,297.94 9,191.74

M

T R Z

U

max

Mass Flux

1

3

5.5

7

8

9.5

11.5

Density: kg/m3 = m t + b Density: lb/ft3 = m t + b Molecular Cp/Cv

m b m b Weight

(3.09) 1,393.40 (0.19) 86.99 120.91 1.170

(3.20) 1,279.33 (0.20) 79.87 86.48 1.250

(1.56) 1,150.42 (0.06) 64.24 18.00 1.310

YELLOW = > Mach 0.3

RED > Mach 1

Inputs Steam-Water at Saturated Conditions R12

Total Mass Flux kg/m2-s 100.0

Quality Mass Fraction Vapor 0.5

Inlet Pressure Bar 9.40

Pipe Diameter mm 10.0

Equivalent Length of Pipe m 1.0

Pipe Roughness m 0.0000015 (Smooth Tube = 0.0000015 m)

Calculations / Property Lookup

Parameter Units Liquid Vapor

Cross-sectional area m2 7.85398E-05

Total Mass Flow Rate kg/h 14.1 14.1

Inlet Pressure kPa 940.0 940.0

Temperature C 39.2 39.16

Viscosity mPa-s 0.17 0.014

Molecular Weight kg/kgmol 120.9 120.9

Density kg/m3 1,272.5 43.8

Cp/Cv 1.17

Velocity (assuming avg density) m/s 1.18

Critical Velocity m/s 158.70

Output

Reynolds Number dimensionless 2,888 34,868

Darcy Friction Factor dimensionless 0.0424 0.0231

Pressure Drop, given Mass Flow and Pressure in 0.004 0.07

Lower Bound 0.13

Upper Bound 0.34

Average kPa 0.23

= Pa 231.83

Problem Statement:

Calculate Pressure Drop due to Friction for R12 at Saturation

100

1,000

10,000

100,000

f

r

i

c

t

i

o

n

a

l

p

r

e

s

s

u

r

e

g

r

a

d

i

e

n

t

(

P

a

/

m

)

1

10

10 100 1000

f

r

i

c

t

i

o

n

a

l

p

r

e

s

s

u

r

e

g

r

a

d

i

e

n

t

(

P

a

/

m

)

mass flux (kg/m2-s)

Reference: IMECE2005-81493

Comparison Case

R12

2,000.0

0.9

6.00

50.0

1.0

(Smooth Tube = 0.0000015 m) 0.0000015 (Smooth Tube = 0.0000015 m)

Liquid Vapor

0.001963495

1,413.7 12,723.5

600.0 600.0

22.0 22.05

0.20 0.013

120.9 120.9

1,325.3 29.6

1.31

61.05

163.26

48,838 6,815,813

0.0210 0.0103

0.006 15.49

7.67

12.94

10.30

Quality 0.5

Mass Flux Lower

20 8

80 86

200 425

400 1,431

600 2,909

1000 7,112

Sonic 158.7016

Average Upper Density Velocity, m/s

14 20 84.6277 0.236329

157 228 0.945317

780 1,134 2.363292

2,623 3,815 4.726585

5,333 7,756 7.089877

13,037 18,962 11.81646

Inputs Steam-Water at Saturated Conditions R12

Total Mass Flux kg/m2-s 100.0

Quality Mass Fraction Vapor 0.5

Inlet Pressure Bar 9.40

Pipe Diameter mm 10.0

Equivalent Length of Pipe m 1.0

Pipe Roughness m 0.0000015 (Smooth Tube = 0.0000015 m)

Calculations / Property Lookup

Parameter Units Liquid Vapor

Cross-sectional area m2 7.85398E-05

Total Mass Flow Rate kg/h 14.1 14.1

Inlet Pressure kPa 940.0 940.0

Temperature C 39.2 39.16

Viscosity mPa-s 0.17 0.014

Molecular Weight kg/kgmol 120.9 120.9

Density kg/m3 1,272.5 43.8

Cp/Cv 1.17

Output

Reynolds Number dimensionless 2,888 34,868

Darcy Friction Factor dimensionless 0.0424 0.0231

Pressure Drop, given Mass Flow and Pressure in 0.00416 0.0710

dp/dz Pa/m 4.16273 65.8781

Fitting parameter p 0.8

Total pressure drop kPa/m 75.038706

Problem Statement:

Calculate Pressure Drop due to Friction for R12 at Saturation

Reference: IMECE2004-61410

water

Comparison Case Reference article, Figure 1

R12 Water-Air

2,000.0 591.0

0.9 0.035

6.00 1.30

50.0 27.0

1.0 1.0

(Smooth Tube = 0.0000015 m) 0.0000015 (Smooth Tube = 0.0000015 m) 0.0000015 (Smooth Tube = 0.0000015 m)

Liquid Vapor Liquid Vapor

0.001963495 0.00057256

1,413.7 12,723.5 1,197.6 20.6

600.0 600.0 130.0 130.0

22.0 22.05 20.0 20.00

0.20 0.013 0.39 0.020

120.9 120.9 18.0 29.0

1,325.3 29.6 1,119.3 1.55

1.31 1.40

48,838 ######## 39,913 13,500

0.0210 0.0103 0.0221 0.0287

0.006 15.49 0.123 0.04

kPa/m 0.00634 11.3444 0.11882 0.1460

0.3 This method depends on fitting parameter, p 0.25 This method depends on fitting parameter, p

15.86 2.11

2,110.16

Reference article, Figure 1

(Smooth Tube = 0.0000015 m)

This method depends on fitting parameter, p

Inputs Steam-Water at Saturated Conditions water

Total Mass Flux kg/m2-s 110.6

Quality Mass Fraction Vapor 0.1

Inlet Pressure Bar 14.83

Pipe Diameter mm 38.1

Equivalent Length of Pipe m 30.5

Pipe Roughness m 0.0000457

Calculations / Property Lookup

Parameter Units Liquid Vapor

Cross-sectional area m2 0.001140092

Total Mass Flow Rate kg/h 392.7 61.3

Inlet Pressure kPa 1,482.8 1,482.8

Temperature C 197.7 197.70

Viscosity mPa-s 0.17 0.014

Molecular Weight kg/kgmol 18.0 18.0

Density kg/m3 842.4 6.8

Cp/Cv 1.40

Output

Reynolds Number dimensionless 21,198 40,346

Darcy Friction Factor dimensionless 0.0282 0.0255

Pressure Drop, given Mass Flow and Pressure in 0.123 0.33

Lockhart and Martinelli Method

X dimensionless 0.61

Phi-liquid dimensionless 29.38

Total Pressure Drop, 2-phase kPa 3.61

psi/100 ft 0.52 Branan: 0.49 psi/100 ft

Rukan: 0.28 psi/100 ft

100

100

100

100

Problem Statement:

Calculate Pressure Drop due to Friction for Water-Steam Mixture

0.08

0.09

0.10

Comparison of Two-Phase Models

R12, 6 Bar pressure, 100 kg/m2-s in 50 mm smooth pipe

100

100

10

50

100

200

300

400

500

600

700

800

1000

1000

1000

1000

1000

1000

1000

1000

1000

1000

1000

1000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

2000

5000

5000

5000

5000

5000

5000

5000

5000

5000

5000

5000

-

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

P

r

e

s

s

u

r

e

D

r

o

p

,

k

P

a

p

e

r

m

Quality

-

20

40

60

80

100

120

140

160

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

P

r

e

s

s

u

r

e

D

r

o

p

,

k

P

a

p

e

r

m

Quality

Comparison of Two-Phase Models

R12, 6 Bar pressure, 5000 kg/m2-s in 50 mm smooth pipe

Reference: Branan, Rules of Thumb, 4th Edition

Comparison Case Wallis

R12

2,000.0

0.9

6.00

50.0

1.0

0.0000015

Liquid Vapor

0.001963495

1,413.7 12,723.5

600.0 600.0

22.0 22.05

0.20 0.013

120.9 120.9

1,325.3 29.6

1.31

48,838 6,815,813

0.0210 0.0103

0.006 11.34

0.02 Phi^2, lo 20.893051

3,771.04 Phi, lo 4.5708917

23.91 0.13

Mass Flux Quality Velocity Homog Split

100 0 0.075 0.00 0.00

100 0.1 0.406 0.01 0.01

100 0.2 0.737 0.01 0.02

100 0.3 1.068 0.02 0.03

100 0.4 1.399 0.02 0.03

100 0.5 1.729 0.03 0.04

100 0.6 2.060 0.03 0.05

100 0.7 2.391 0.04 0.05

100 0.8 2.722 0.04 0.05

100 0.9 3.052 0.04 0.05

100 1 3.383 0.05

10 0.5 0.159 0.003 0.005

50 0.5 0.795 0.051 0.084

100 0.5 1.590 0.176 0.284

200 0.5 3.179 0.613 0.954

300 0.5 4.769 1.285 1.940

400 0.5 6.359 2.184 3.209

500 0.5 7.948 3.304 4.742

600 0.5 9.538 4.641 6.524

700 0.5 11.128 6.194 8.545

800 0.5 12.717 7.961 10.794

1000 0.5 15.897 12.133 15.951

1000 0 0.755 0 0

1000 0.1 4.062 1 1

1000 0.2 7.370 1 1

1000 0.3 10.678 1 2

1000 0.4 13.986 2 2

1000 0.5 17.294 2 2

1000 0.6 20.601 2 3

1000 0.7 23.909 3 3

1000 0.8 27.217 3 3

1000 0.9 30.525 3 3

1000 1 33.833 4

2000 0 1.509 0 0

2000 0.1 8.125 2 2

2000 0.2 14.740 3 4

2000 0.3 21.356 5 5

2000 0.4 27.972 6 6

2000 0.5 34.587 7 8

2000 0.6 41.203 9 9

2000 0.7 47.818 10 10

2000 0.8 54.434 11 10

2000 0.9 61.050 13 10

2000 1 67.665 14

5000 0 3.773 2 2

5000 0.1 20.312 11 11

5000 0.2 36.851 19 18

5000 0.3 53.390 28 25

5000 0.4 69.929 36 32

5000 0.5 86.468 44 38

5000 0.6 103.007 52 43

5000 0.7 119.546 60 48

5000 0.8 136.085 68 51

5000 0.9 152.624 76 51

5000 1 169.163

0.9 1

Homogeneous

Split

Asymptotic

Lockhart

0.9 1

Homogeneous

Split

Asymptotic

Lockhart

Asymp Lockhart Fluid Inlet Pressure Pipe Diameter Equivalent Length of Pipe Pipe Roughness

R12 6.00 50.0 1.0 0.0000015

0.01 0.02 R12 6.00 50.0 1.0 0.0000015

0.02 0.03 R12 6.00 50.0 1.0 0.0000015

0.03 0.04 R12 6.00 50.0 1.0 0.0000015

0.03 0.05 R12 6.00 50.0 1.0 0.0000015

0.04 0.06 R12 6.00 50.0 1.0 0.0000015

0.05 0.07 R12 6.00 50.0 1.0 0.0000015

0.05 0.08 R12 6.00 50.0 1.0 0.0000015

0.06 0.09 R12 6.00 50.0 1.0 0.0000015

0.06 0.08 R12 6.00 50.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

0.007 0.011 R22 9.10 10.0 1.0 0.0000015

0.076 0.124 R22 9.10 10.0 1.0 0.0000015

0.272 0.443 R22 9.10 10.0 1.0 0.0000015

0.940 1.527 R22 9.10 10.0 1.0 0.0000015

1.945 3.157 R22 9.10 10.0 1.0 0.0000015

3.273 5.311 R22 9.10 10.0 1.0 0.0000015

4.913 7.969 R22 9.10 10.0 1.0 0.0000015

6.859 11.123 R22 9.10 10.0 1.0 0.0000015

9.105 14.762 R22 9.10 10.0 1.0 0.0000015

11.648 18.882 R22 9.10 10.0 1.0 0.0000015

17.613 28.542 R22 9.10 10.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

1 1 R12 6.00 50.0 1.0 0.0000015

1 2 R12 6.00 50.0 1.0 0.0000015

2 3 R12 6.00 50.0 1.0 0.0000015

2 4 R12 6.00 50.0 1.0 0.0000015

3 4 R12 6.00 50.0 1.0 0.0000015

3 5 R12 6.00 50.0 1.0 0.0000015

4 6 R12 6.00 50.0 1.0 0.0000015

4 6 R12 6.00 50.0 1.0 0.0000015

4 6 R12 6.00 50.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

2 4 R12 6.00 50.0 1.0 0.0000015

4 7 R12 6.00 50.0 1.0 0.0000015

6 10 R12 6.00 50.0 1.0 0.0000015

8 13 R12 6.00 50.0 1.0 0.0000015

10 16 R12 6.00 50.0 1.0 0.0000015

12 19 R12 6.00 50.0 1.0 0.0000015

14 22 R12 6.00 50.0 1.0 0.0000015

15 24 R12 6.00 50.0 1.0 0.0000015

16 24 R12 6.00 50.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

14 25 R12 6.00 50.0 1.0 0.0000015

24 41 R12 6.00 50.0 1.0 0.0000015

35 58 R12 6.00 50.0 1.0 0.0000015

46 76 R12 6.00 50.0 1.0 0.0000015

58 93 R12 6.00 50.0 1.0 0.0000015

69 111 R12 6.00 50.0 1.0 0.0000015

79 126 R12 6.00 50.0 1.0 0.0000015

88 138 R12 6.00 50.0 1.0 0.0000015

94 141 R12 6.00 50.0 1.0 0.0000015

R12 6.00 50.0 1.0 0.0000015

Pipe Roughness

Hashizume's Data

90 0.1

120 0.23

185 0.4

250 1

4

5

6

7

F

r

i

c

t

i

o

n

a

l

P

r

e

s

s

u

r

e

D

r

o

p

,

k

P

a

p

e

r

m

Comparison of Two

R12, 6 Bar pressure, 1000 kg/m2

-

1

2

3

0 0.1 0.2 0.3

F

r

i

c

t

i

o

n

a

l

P

r

e

s

s

u

r

e

D

r

o

p

,

k

P

a

p

e

r

m

1.000

10.000

100.000

P

r

e

s

s

u

r

e

D

r

o

p

,

k

P

a

p

e

r

m

Comparison of Two

R22, 9.1 Bar pressure, 0.5 Quality in 10 mm smooth tube

0.001

0.010

0.100

1.000

10

P

r

e

s

s

u

r

e

D

r

o

p

,

k

P

a

p

e

r

m

Comparison of Two-Phase Models

R12, 6 Bar pressure, 1000 kg/m2-s in 50 mm smooth pipe

0.4 0.5 0.6 0.7 0.8 0.9

Quality

Comparison of Two-Phase Models

R22, 9.1 Bar pressure, 0.5 Quality in 10 mm smooth tube

100

Mass Flux, kg/m2-s

Lockhart

Asymptotic

Split

0.9 1

Split

Homogeneous

Lockhart

1000

Lockhart

Asymptotic

Split

Homogenous

Hashizume's Data

Inputs Steam-Water at Saturated Conditions Water

Total Mass Flux kg/m2-s 1,356.0

Quality Mass Fraction Vapor 0.1

Inlet Pressure Bar 6.00

Pipe Diameter mm 50.0

Equivalent Length of Pipe m 1.0

Pipe Roughness m 0.0000015 (Smooth Tube = 0.0000015 m)

Calculations / Property Lookup

Parameter Units Total as Liq Vapor Props Mixture

Cross-sectional area m2 0.001963495

Total Mass Flow Rate kg/h 9,585.0

Inlet Pressure kPa 600.0

Temperature C 158.3

Viscosity mPa-s 0.21 0.013 0.084

Molecular Weight kg/kgmol 18.0

Density kg/m3 903.7 3.0 29.2

Cp/Cv

Output

Reynolds Number dimensionless 321,257 807,573

Darcy Friction Factor dimensionless 0.0146 0.0127

Pressure Drop, given Mass Flow and Pressure in 0.30

Liquid PD Multiplier phi 1.86

phi^2 3.47

Pressure Drop, 2-Phase Flow kPA 0.55

Sonic Velocity

475.6

Pipe flow area 0.001963495

Velocity, m/s

Quality Density 5424 kg/m2-s

0 903.75 6.00

0.01 226.40 23.96 YELLOW = > Mach 0.3

0.02 129.41 41.91 RED > Mach 1

0.03 90.60 59.87

Problem Statement:

Calculate Pressure Drop Through an Elbow for Different Steam Qualities

M

T R Z

U

max

0.04 69.69 77.83

0.05 56.63 95.78

0.06 47.69 113.74

0.07 41.19 131.69

0.08 36.24 149.65

0.09 32.36 167.61

0.1 29.23 185.56

0.11 26.65 203.52

0.12 24.49 221.47

0.13 22.65 239.43

0.14 21.07 257.39

0.15 19.70 275.34

0.16 18.49 293.30

0.17 17.43 311.25

0.18 16.48 329.21

0.19 15.62 347.17

0.2 14.86 365.12

0.21 14.16 383.08

0.22 13.53 401.03

0.23 12.95 418.99

0.24 12.41 436.95

0.25 11.92 454.90

0.26 11.47 472.86

0.27 11.05 490.81

0.28 10.66 508.77

0.29 10.30 526.73

0.3 9.96 544.68

0.31 9.64 562.64

0.32 9.34 580.59

0.33 9.06 598.55

Property Correlations for all correlations, t = deg C

Vapor Pressure: log(mm Hg) = A - B / (t+C) Liquid Viscosity: ln(cP) = A + B / (C+t)

A B C

R12 6.99 918.17 253.38

R22 7.04 850.10 245.18

Water 8.31 1,986.50 268.74

(Smooth Tube = 0.0000015 m)

Km Ki Kd

m/s 800 0.091 4

m2 K 0.39 elbow

6.33 kPa

25.28

44.23

63.19

700.00

Pressure Drop Through a DN Elbow

82.14

101.09

120.04

138.99

157.94

176.89

195.84

214.79

233.74

252.69

271.64

290.59

309.54

328.49

347.44

366.39

385.34

404.29

423.24

442.19

461.14

480.09

499.04

517.99

536.94

555.89

574.84

593.79

612.75

631.70

-

100.00

200.00

300.00

400.00

500.00

600.00

700.00

0 0.05 0.1 0.15

Liquid Viscosity: ln(cP) = A + B / (C+t) Vapor Viscosity: ln(cP) = A + B / (C+t) Density: kg/m3 = m t + b

A B C

(8.77) 5,134.3 693.01 (9.00) (4,611.86) (1,008.87)

20.79 46,143.5 (2,064.89) (3.47) (278.74) 286.66

4.34 6,927.32 (1,332.33) (4.92) (200.49) (502.57)

Pressure Drop Through a DN Elbow

0.2 0.25 0.3

Velocity

Density: kg/m3 = m t + b Density: lb/ft3 = m t + b Molecular Cp/Cv

m b m b Weight

(3.09) 1,393.40 (0.19) 86.99 120.91 1.170

(3.20) 1,279.33 (0.20) 79.87 86.48 1.250

(1.56) 1,150.42 (0.06) 64.24 18.00

Inputs SI Units Value US Units Value

Gas molecular weight 17.4 17.4

Temperature C 37.8 F 100

Pipe diameter mm 102 in 4.026

Pipe length km 32.2 miles 20

Inlet pressure kPa abs 13,700 psia 2,000

Outlet pressure kPa abs 10,300 psia 1,500

Elevation difference m 30.5 ft 100

Efficiency 1 1

Average compressibility factor 1 1

Constants

Base temperature C - F 60

Base pressure kPa abs 100 psia 14.7

Pipe roughness m 0.0000457 ft 0.00015

Calculations

Isothermal Gas Calculation

Reynolds Number 200,000 200,000

Friction factor 0.0187 0.0187

Flow Rate kg/h 8,982 lb/h 20,126

Standard volumetric rate MM m3/day 278 MM ft3/day 10,521

Intermediate Calcs

Gas specific gravity 0.60 0.60

Average temperature K 311 R 560

Average pressure kPa abs 12,080 psia 1,762

Head correction kPa 49 psi 7

Weymouth

Standard volumetric rate MM m3/day MM ft3/day 10,151

Panhandle A

Standard volumetric rate MM m3/day 402 MM ft3/day 15,110

Panhandle B

Standard volumetric rate MM m3/day 428 MM ft3/day 16,034

Problem Statement:

Compare the Panhandle and Weymouth formulas with the Isothermal gas calculation

You might also like

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- 01 - Fluid FlowDocument80 pages01 - Fluid FlowEmir KarNo ratings yet

- Flujo de FluidosDocument72 pagesFlujo de Fluidosmolimoli1981No ratings yet

- 01 - Fluid FlowDocument8 pages01 - Fluid FlowalyshahNo ratings yet

- Gas Volume CalculationDocument123 pagesGas Volume CalculationZulfitrizulkarnain ZulkarnainNo ratings yet

- Line SizingDocument20 pagesLine SizingAhmed HassanNo ratings yet

- Meter Selection Rev 031Document5 pagesMeter Selection Rev 031andrew_c_potocki902No ratings yet

- Pipe Size CalcDocument19 pagesPipe Size Calcnitin_bir100% (1)

- Line Size of Pipe Based On Economic VelocityDocument19 pagesLine Size of Pipe Based On Economic Velocitymabrouk2013No ratings yet

- Ductulator May 2010Document8 pagesDuctulator May 2010haroub_nasNo ratings yet

- Line SizingDocument18 pagesLine SizingNathaniel Thomas100% (1)

- Orifice CalculationsDocument23 pagesOrifice CalculationsYatish Kumar Jain0% (1)

- ISO 23210 2009 Calculation Program EDocument9 pagesISO 23210 2009 Calculation Program ETri SulyonoNo ratings yet

- Theoretical DeliverabilityDocument197 pagesTheoretical Deliverabilitymath62210No ratings yet

- 62577A Calculation of Orifice Coefficient Si UnitsDocument18 pages62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioNo ratings yet

- Pump Sizing CalculationDocument11 pagesPump Sizing CalculationvkumaranNo ratings yet

- Perforated Pipe Distributor Sizing CalcuDocument6 pagesPerforated Pipe Distributor Sizing CalcuInggit Prillasari100% (1)

- Lecture Set No. 1Document41 pagesLecture Set No. 1baseball604No ratings yet

- 16 - Blending and AgitationDocument20 pages16 - Blending and AgitationRafael ReyesNo ratings yet

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesNo ratings yet

- Block 2 Engineering Principles & Heat TransfersDocument188 pagesBlock 2 Engineering Principles & Heat TransfersBabu AravindNo ratings yet

- Lec 1 Introduction To Engineering CalculationsDocument80 pagesLec 1 Introduction To Engineering Calculationsjan gastiloNo ratings yet

- Assignment - 1 - finaFPP L - Fluid - & - Particle - FinalDocument24 pagesAssignment - 1 - finaFPP L - Fluid - & - Particle - FinalKharkhodaNo ratings yet

- CALIB053 - Mathcad 15 EquationsDocument8 pagesCALIB053 - Mathcad 15 Equationsilie_vlassaNo ratings yet

- Gas Pipeline Hydraulic Analysis CalculationDocument10 pagesGas Pipeline Hydraulic Analysis Calculationbalakrishna100% (3)

- Cement Process Engineering Vade-Mecum: 8. Fluid FlowDocument10 pagesCement Process Engineering Vade-Mecum: 8. Fluid FlowHasnaoui SamirNo ratings yet

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- Ductulator May 2010Document10 pagesDuctulator May 2010Arshavin Watashi WaNo ratings yet

- Student Name ID: Aysha Housani 200503484 Maha Al Shehhi 200509462 Hessa Al Shehhi 200509582 Mona Thabet 200521150Document78 pagesStudent Name ID: Aysha Housani 200503484 Maha Al Shehhi 200509462 Hessa Al Shehhi 200509582 Mona Thabet 200521150minumcincauNo ratings yet

- Solution To Chemical Engineering Question - Extruder Given:: H 200 N-S/M H 400 N-S/MDocument3 pagesSolution To Chemical Engineering Question - Extruder Given:: H 200 N-S/M H 400 N-S/MjamesdigolNo ratings yet

- Unit ConversionsDocument2 pagesUnit Conversionsangry_granNo ratings yet

- Theoretical DeliverabilityDocument201 pagesTheoretical DeliverabilityJorge Cespedes De UgarteNo ratings yet

- Design of Shell & Tube HXDocument40 pagesDesign of Shell & Tube HXprateek_bhoirNo ratings yet

- CalculationDocument8 pagesCalculationmahaveenNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationDavid Lambert67% (3)

- Basic Calculations For Line Pressure DropDocument28 pagesBasic Calculations For Line Pressure DropAhmed HassanNo ratings yet

- Extraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)Document17 pagesExtraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)weeseongNo ratings yet

- Pitot Selection RefDocument2 pagesPitot Selection RefVinay ChhatrolaNo ratings yet

- Vortex FlowmeterDocument16 pagesVortex FlowmeterBiswajit DebnathNo ratings yet

- Mine Ventilation: Specific Gravity of GasesDocument18 pagesMine Ventilation: Specific Gravity of GasesJevendiran RamadasuNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Recommended Reference Materials for Realization of Physicochemical Properties: Pressure–Volume–Temperature RelationshipsFrom EverandRecommended Reference Materials for Realization of Physicochemical Properties: Pressure–Volume–Temperature RelationshipsE. F. G. HeringtonNo ratings yet

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Traverse ComputationsDocument42 pagesTraverse Computationsjaffna100% (3)

- Sewage Treatment PlantDocument11 pagesSewage Treatment Plantjaffna86% (7)

- Basic Civil and Mechanical Engineering Unit 1Document60 pagesBasic Civil and Mechanical Engineering Unit 1A.R. Pradeep Kumar91% (11)

- Pre-Cast Girder ConstructionDocument19 pagesPre-Cast Girder ConstructionjaffnaNo ratings yet

- Introduction To Surveying: Basics of TraversingDocument33 pagesIntroduction To Surveying: Basics of Traversingjaffna100% (1)

- Levelling ProceduresDocument58 pagesLevelling Proceduresjaffna100% (1)

- Management AccountingDocument21 pagesManagement AccountingbelladoNo ratings yet

- Earthing HandoutDocument18 pagesEarthing Handoutjaffna100% (1)

- Multiview SketchesDocument28 pagesMultiview SketchesjaffnaNo ratings yet

- Leveling MethodsDocument33 pagesLeveling Methodsjaffna100% (2)

- Introduction To Bridge EngineeringDocument125 pagesIntroduction To Bridge Engineeringjaffna100% (1)

- Hot Mix Plant Calibration, Laying & TestingDocument55 pagesHot Mix Plant Calibration, Laying & Testingjaffna88% (17)

- Ingredients of Bituminous Mixes & Introduction To ModifiersDocument69 pagesIngredients of Bituminous Mixes & Introduction To ModifiersjaffnaNo ratings yet

- Fusion WeldingDocument31 pagesFusion WeldingjaffnaNo ratings yet

- Grillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarDocument59 pagesGrillage Method of Superstructure Analysis: Dr. Shahzad Rahman NWFP University of Engg & Technology, PeshawarpotharajudvnagaNo ratings yet

- Engineering Product SpecificationDocument39 pagesEngineering Product SpecificationjaffnaNo ratings yet

- Expansion JointsDocument35 pagesExpansion Jointsjaffna100% (2)

- Chain SurveyDocument21 pagesChain SurveyjaffnaNo ratings yet

- Bituminous Mix Design & Superpave MixesDocument53 pagesBituminous Mix Design & Superpave Mixesjaffna100% (9)

- Concrete Making MaterialsDocument55 pagesConcrete Making Materialsjaffna100% (1)

- Managing Groups & TeamsDocument23 pagesManaging Groups & TeamsjaffnaNo ratings yet

- Partially Full Pipe Flow CalculationsDocument17 pagesPartially Full Pipe Flow Calculationsjaffna0% (1)

- Lecture 8 BearingsDocument53 pagesLecture 8 BearingsReemALMousawiNo ratings yet

- Building Management System - BMS 2Document44 pagesBuilding Management System - BMS 2jaffna100% (3)

- Building Management System - BMS 1Document31 pagesBuilding Management System - BMS 1jaffna100% (1)

- Natural Open Channel FlowDocument4 pagesNatural Open Channel FlowjaffnaNo ratings yet

- Motivating EmployeesDocument21 pagesMotivating EmployeesjaffnaNo ratings yet

- Organizational StructureDocument26 pagesOrganizational Structurejaffna100% (2)

- The Evolution of Management TheoryDocument25 pagesThe Evolution of Management TheoryjaffnaNo ratings yet

- Pipeline DesignDocument12 pagesPipeline Designjaffna0% (1)

- Breakout For Gas-Lift DesignDocument12 pagesBreakout For Gas-Lift DesignpmrNo ratings yet

- Control Flow PhilosophyDocument21 pagesControl Flow PhilosophyMoulyaniNo ratings yet

- Thermodynamics ProblemsDocument2 pagesThermodynamics ProblemsAlexander Salado IbrahimNo ratings yet

- Fluid FlowDocument15 pagesFluid Flowdekra abdoNo ratings yet

- Practical-5 (System Design - Dryers)Document9 pagesPractical-5 (System Design - Dryers)Hassan Iftekhar AhmedNo ratings yet

- Cosr Brochure - AspenDocument1 pageCosr Brochure - AspenSamuel OnyewuenyiNo ratings yet

- Salinity of Ocean WaterDocument7 pagesSalinity of Ocean WateryzavelitaNo ratings yet

- Hydrostatics WorksheetDocument10 pagesHydrostatics Worksheettuvvac0% (1)

- General Chemistry 2: Quarter 3 - WEEK 1Document22 pagesGeneral Chemistry 2: Quarter 3 - WEEK 1RODEL AZARESNo ratings yet

- Oxy Miser 1Document4 pagesOxy Miser 1serlioNo ratings yet

- Chanitex (Shanghai) Pure Water Equipment Co.,LTD RO Elements Technical ManualDocument116 pagesChanitex (Shanghai) Pure Water Equipment Co.,LTD RO Elements Technical ManualbharatMMMNo ratings yet

- Ikon Science SGreen Hydrodynamics AAPG2014Document10 pagesIkon Science SGreen Hydrodynamics AAPG2014Jhonatan_Valdi_8987No ratings yet

- Voorbeeld: Internatio N Al Standard 2186Document10 pagesVoorbeeld: Internatio N Al Standard 2186Pansawut WanitwanakornNo ratings yet

- Numéro de Repère: Date: 06/05/2016 87 PSV-23: Relief Device Calculation SheetDocument1 pageNuméro de Repère: Date: 06/05/2016 87 PSV-23: Relief Device Calculation SheetDiby AlainNo ratings yet

- Science-10 Q4 Module-2 Week-2Document5 pagesScience-10 Q4 Module-2 Week-2Marl Rina EsperanzaNo ratings yet

- Department of Irrigation and Water ManagementDocument40 pagesDepartment of Irrigation and Water Managementahsanul haqueNo ratings yet

- Dokumen - Tips Chapter 7 Compressible FlowDocument74 pagesDokumen - Tips Chapter 7 Compressible Flowinam vfNo ratings yet

- Hydrology AssignmentDocument21 pagesHydrology AssignmentchrisleepeiingNo ratings yet

- Problem 1Document3 pagesProblem 1Alfredo Gonzalez SoteloNo ratings yet

- Recarga de Acuiferos en La Zona UrbanaDocument5 pagesRecarga de Acuiferos en La Zona UrbanaMireya FernandaNo ratings yet

- Steam TableDocument5 pagesSteam TableAyush BhadauriaNo ratings yet

- CO2 Removal Using Cryogenic SeparationDocument8 pagesCO2 Removal Using Cryogenic SeparationKokil JainNo ratings yet

- Module 1Document3 pagesModule 1Yang RhiaNo ratings yet

- Water Treatment PlantDocument100 pagesWater Treatment PlantDr. Akepati Sivarami Reddy96% (23)

- En PPT Evs SWP RainwaterDocument32 pagesEn PPT Evs SWP Rainwaternaveengargns100% (1)

- 22.3 Failure of Canal Lining: G Level BackingDocument7 pages22.3 Failure of Canal Lining: G Level Backingועדת איכות הסביבה חייםNo ratings yet

- AMCA - 200 - Air SystemsDocument62 pagesAMCA - 200 - Air SystemsDiogo RomeroNo ratings yet

- Research and Special Programs Admin., DOT 180.209Document5 pagesResearch and Special Programs Admin., DOT 180.209parmindersinNo ratings yet

- Hidraulics Chapter 1Document13 pagesHidraulics Chapter 1tekalign yerangoNo ratings yet