Professional Documents

Culture Documents

Pump Theory

Uploaded by

Mukund KashyapCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Theory

Uploaded by

Mukund KashyapCopyright:

Available Formats

Pump types and theory

Types of pumps

There are three main types that will

be covered;

Rotary gear

Rotary vane

Centrifucal

Centrifucal pumps are the most

common type of pump found today,

we will go into its use in depth

Rotary Gear Pumps

Rotary pumps

work by using tight

tolerance gears to

push water

Tolerances are so

tight that this

pump will pump air

Rotary Vane Pumps

These pumps work

like the rotary gear

pumps, but have

vanes that can

extend and retract

This pump resists

the effects of wear

much better

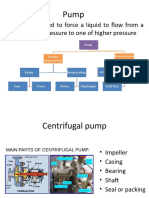

Parts of the centrifical pump

Throttle controls

the rotation speed

of the impellor.

More throttle =

more pressure

How the centrifical pump works

How the centrifical pump

works

How a centrifical pump works

Water supply for the pump

Booster

tank

Intake

from

steamers

and 2

Tank to pump

Tank fill

Water being supplied to steamer intake

into pump, flowing discharges and filling

tank at the same time

Two stage pumps

two stage pump in volume

Two stage pump in pressure

Discharge Manifold

The water being

discharged from

the pump is forced

into a manifold; the

junction for all

discharge lines

The manifold has

all of the discharge

valves that are

controled from the

pump panel

Using the relief valve

Relief Valves are

Used to sharp

increases in

pressure from

going all the way

through the

attack lines and

harming the

nozzle crew

Excess

pressure is

dumped into

the intake

side of the

pump

Using the relief valve

Using the relief valve

Centrifucal Pump Problems

There are several conditions that can

reduce the life or destroy the pump;

Running the pump with nothing flowing

or circulating

Cavitating the pump

Running the pump dry

Pump Running, but not

Discharging

Water that is held in

closed lines and in the

pump will be warmed by

the friction of the

running pump

If let go long enough, the

water can boil and

cavitate the pump

Check to see if your

hoselines are warm or

hot

Pump Cavitation

This occurs when

there is too much air

in the pump, or there

is more water being

discharged than is

coming into the pump

Sounds like gravel

rolling around on the

inside of the pump

casing

Running the Pump Without

Water

Pumps need the

water for cooling,

lubrication, and to

swell the packing

Without water in

the pump, the heat

from friction will

quickly destroy a

pump

Conclusion

You might also like

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Pump TheoryDocument23 pagesPump TheoryFatur RachmanNo ratings yet

- Pump TheoryDocument23 pagesPump TheoryYeahkevinrocksNo ratings yet

- Pump TheoryDocument23 pagesPump TheoryAbdul Wali KhanNo ratings yet

- Pump Tech 3 Pump TypesDocument149 pagesPump Tech 3 Pump TypesGAMUCHIRAI MUGADZANo ratings yet

- Basic Pump ConstructionDocument90 pagesBasic Pump ConstructionMariaEzzaSyUyNo ratings yet

- Centrifugal PumpDocument12 pagesCentrifugal PumpSanjibani100% (2)

- Pumps and TurbinesDocument20 pagesPumps and TurbinesEICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- 01 - Transfer Pumps & TexsteamDocument26 pages01 - Transfer Pumps & TexsteamMarsyaNo ratings yet

- Lecture 20 Hydraulic PumpsDocument31 pagesLecture 20 Hydraulic PumpsCao Mạnh CườngNo ratings yet

- CHC303 Report (Pumps) - 20CH8067 - Sabyasachi PradhanDocument19 pagesCHC303 Report (Pumps) - 20CH8067 - Sabyasachi PradhanSabyasachi PradhanNo ratings yet

- Pump Types and Pump SelectionDocument37 pagesPump Types and Pump SelectionShaik Nizam UddinNo ratings yet

- Assignment Pump and Its PartsDocument19 pagesAssignment Pump and Its PartsSabyasachi PradhanNo ratings yet

- 16 PumpsDocument3 pages16 Pumpsmostafa aliNo ratings yet

- Unit 5 FMDocument74 pagesUnit 5 FMRupan MurugesanNo ratings yet

- PumpsDocument124 pagesPumpsantonyale90% (10)

- 614 Pumps, Valves, and FansaDocument49 pages614 Pumps, Valves, and Fansam_alodat6144No ratings yet

- Reciprocating PumpDocument6 pagesReciprocating PumpSandip MannaNo ratings yet

- Hydraulic ActuatorDocument55 pagesHydraulic ActuatorMASOUD75% (4)

- Presentation - Pumps and ValvesDocument31 pagesPresentation - Pumps and ValvesisharaNo ratings yet

- A Presentation On PumpsDocument34 pagesA Presentation On PumpsSajjad Rasool ChaudhryNo ratings yet

- Gfos InstallHotWater OriginalDocument12 pagesGfos InstallHotWater OriginalPete PompesNo ratings yet

- Positive Displacement PumpsDocument81 pagesPositive Displacement PumpsSyafiq Muhammad AbdillahNo ratings yet

- Pumps: Types of ValvesDocument7 pagesPumps: Types of Valvesaldz5No ratings yet

- Presentation - Valves, PumpsDocument17 pagesPresentation - Valves, PumpsAndsNo ratings yet

- Types of PumpsDocument13 pagesTypes of Pumpsm3d1c09No ratings yet

- General Overview of Types of Pumps On ShipDocument21 pagesGeneral Overview of Types of Pumps On ShipOm Prakash RajNo ratings yet

- Air Cpmpressor Pump Boiler Steam Engine IEC Gas TurbineDocument75 pagesAir Cpmpressor Pump Boiler Steam Engine IEC Gas TurbineMd Shariful HasanNo ratings yet

- Chapter 4Document42 pagesChapter 4zelalemniguseNo ratings yet

- Design of Hydraulic CircuitsDocument77 pagesDesign of Hydraulic CircuitsSrinivasan V PNo ratings yet

- Basic Civil and Mechanical EngineeringDocument17 pagesBasic Civil and Mechanical EngineeringskctdhansNo ratings yet

- Fluid MachinesDocument42 pagesFluid Machinesabo yossefNo ratings yet

- Pumps Centrifugal and ReciprocatingDocument24 pagesPumps Centrifugal and ReciprocatingumarNo ratings yet

- Pumps: Created By-Suneth Bombuwela Student Number - 6622313Document32 pagesPumps: Created By-Suneth Bombuwela Student Number - 6622313Suneth Dilusha BombuwelaNo ratings yet

- MICRO-PROGECT - Hydraulics (22401)Document18 pagesMICRO-PROGECT - Hydraulics (22401)hemant sakhareNo ratings yet

- Pumps, Valves, FansDocument34 pagesPumps, Valves, Fansm_alodat6144No ratings yet

- How Does Ram Pump WorksDocument3 pagesHow Does Ram Pump Worksidzmir fahmyNo ratings yet

- Topic 6 Pump, Valve CompressorDocument68 pagesTopic 6 Pump, Valve CompressorThevanraj The King MakerNo ratings yet

- Topic 6 Pump, Valve CompressorDocument68 pagesTopic 6 Pump, Valve CompressorThevanraj The King MakerNo ratings yet

- Centrifugal PumpsDocument14 pagesCentrifugal PumpsMAYURESH PATILNo ratings yet

- Reciprocating PumpDocument21 pagesReciprocating PumpPUTRI IMA M100% (1)

- Module 7Document63 pagesModule 7Agilan ChellaramNo ratings yet

- Hydraulic Pump: Made By: Arsheen and Shweta DEPARTMENT: F.P.TECH (2019-23) Submitted To: Ms. RuchitaDocument11 pagesHydraulic Pump: Made By: Arsheen and Shweta DEPARTMENT: F.P.TECH (2019-23) Submitted To: Ms. RuchitaDis ShwetaNo ratings yet

- Pumps, Valves, & Fans: Moving FluidsDocument33 pagesPumps, Valves, & Fans: Moving Fluidskamal_muralikumarNo ratings yet

- Presentation Pump 1Document27 pagesPresentation Pump 1Mohammed.abudi1996No ratings yet

- Full Pump InductionDocument94 pagesFull Pump InductionPrathmesh LoharNo ratings yet

- Pumps SBDocument55 pagesPumps SBMirza Salman BaigNo ratings yet

- FD, Lect-Pumps-IVDocument33 pagesFD, Lect-Pumps-IVNomanNo ratings yet

- Chapter 11 Types of PumpsDocument45 pagesChapter 11 Types of Pumpssuraj7266No ratings yet

- Chapter 3 - PumpsDocument66 pagesChapter 3 - Pumpsmohd irfanNo ratings yet

- Centrifugal PumpDocument22 pagesCentrifugal PumpSona ChiyyarathNo ratings yet

- Chapter 1 PumpsDocument38 pagesChapter 1 Pumpsفيصل القاسمNo ratings yet

- Auxiliary Machinery SystemDocument86 pagesAuxiliary Machinery SystemChristian Cañon GenterolaNo ratings yet

- Pumps & TurbinesDocument27 pagesPumps & TurbinesAbhilash S SNo ratings yet

- PumpsDocument35 pagesPumpsMuhammad Ahmed Saleem100% (2)

- Piston PumpDocument16 pagesPiston Pumpacostaflorencemay13No ratings yet

- Reciprocating Pump PratishthaDocument13 pagesReciprocating Pump Pratishthamike rosaNo ratings yet

- Design of PumpsDocument29 pagesDesign of PumpsRenz Alfred AdremesinNo ratings yet

- BSI PP ST Guide PDFDocument78 pagesBSI PP ST Guide PDFMukund KashyapNo ratings yet

- ASTI - Boiler Tube Failure Investigation & Prevention - NACE - ForDocument9 pagesASTI - Boiler Tube Failure Investigation & Prevention - NACE - ForVinoth RajendraNo ratings yet

- Boiler Maintenance and Safety Study GuideDocument10 pagesBoiler Maintenance and Safety Study GuideKapila2zNo ratings yet

- Astm A90Document4 pagesAstm A90Mukund KashyapNo ratings yet

- Welding SafetyDocument58 pagesWelding SafetyMukund KashyapNo ratings yet

- Format of Typical Security Plan For Industrial Radiography PDFDocument4 pagesFormat of Typical Security Plan For Industrial Radiography PDFBalachandar ArumugamNo ratings yet

- UNF Threads ANSI B1.1: Major Major Tapping Diameter Diameter Nut Drill Size Inch MM MM TPI Diameter Pitch MMDocument1 pageUNF Threads ANSI B1.1: Major Major Tapping Diameter Diameter Nut Drill Size Inch MM MM TPI Diameter Pitch MMMukund KashyapNo ratings yet

- Wind Load ExampleDocument4 pagesWind Load Examplemerlin1112255100% (1)

- Wooden Package/dunnage Material Requirements, Uppdated March/2011Document4 pagesWooden Package/dunnage Material Requirements, Uppdated March/2011Mukund KashyapNo ratings yet

- Preiss Core Standards in The Pressure Equipment Area 4668Document42 pagesPreiss Core Standards in The Pressure Equipment Area 4668Mukund KashyapNo ratings yet

- Unfire Pressure VesselDocument146 pagesUnfire Pressure Vesselsungkang83% (6)

- Na 131121Document50 pagesNa 131121Mukund KashyapNo ratings yet

- PSRAO Welding DefectsDocument34 pagesPSRAO Welding DefectsRohit Soni100% (3)