Professional Documents

Culture Documents

Monthly Blasting and Painting Inspection Report

Uploaded by

Tayyab Mayo0%(1)0% found this document useful (1 vote)

261 views1 pageCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

261 views1 pageMonthly Blasting and Painting Inspection Report

Uploaded by

Tayyab MayoCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

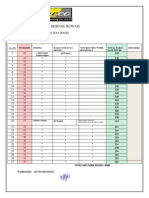

FAMECO GENRAL CONTRACTING LLC

PROJECT: B3P RUWAIS

Monthly Blasting & Painting Inspection

Subject

Project

Contract no

Monthly blasting/painting

inspection report

B3P-Ruwais

Report no

pp-12-7-7777

Date

Inspected by

4th August, 2012

M.TAYYAB (HSEO)

Mechanic:

Unit no:

satisfactory

1

2

Respirator

3

4

5

6

7

8

9

Compressor/ Hooper & accessories

10

1

2

3

4

5

6

7

8

9

General

2

3

4

Air filter for compressed air under maintenance schedule

(replacement for every 3 months)?

Regulator, air pressure gauge & pressure relief valve of in

good condition?

Air pressure of filter maintained as per the requirement of

respirator in use (80-90psi)?

Moister is drained from filter every four hours?

Respirator lenses clean and free from cuts, abrasion?

Air hose fitted with cool air tube/climate control tube?

Breathing hose in good condition, free from cuts,

abrasion?

Blasting & painting helmet available with chin strap,

suspension & cap?

The helmet, hose, air entry ports & fittings checked for

dust & debris?

User undergone respiratory protection training?

Compressor located away from exhaust of other

machines, toxic source and from any other source of

combustion?

No vehicle around compressor air intake

Air hose length kept as short as practicable and straight

line, sharp bends avoided, and free from soft spots, cuts

etc?

Remote control attached with blasting nozzle

Safety pins & safety cables installed at every coupling

connection to prevent accidental disengagement during

hose movement?

Gaskets of coupling checked for wear, distortion &

softness (no leakage from coupling)?

Air discharge pressure gauge, air discharge temperature

gauge is available in good working condition?

Grounding/ Earthing done for compressor/ hooper to

eliminate static electricity hazards?

Is there any oil spillage containment beneath the

compressor unit?

Affected zone of blasting & painting including equipment

barricaded suitably and warning signs posted to warn

unauthorized entry?

Is paints are mixed in spate shade, away from source of

ignition?

Are people other than operator & painter were given

suitable type of respirator? Are they trained?

Is eye wash available with the unit/ nearest location?

Prepared by: M.TAYYAB (HSEO)

Need

improvement

comments

Maintenance

Strongly

recommended

Eye wash station

required

You might also like

- SOP For Pneumatic Testing.Document2 pagesSOP For Pneumatic Testing.Ernst_SNo ratings yet

- Blasting Painting ProcedureDocument4 pagesBlasting Painting ProcedureRyanNo ratings yet

- Surface Preparation & Painting ReportDocument1 pageSurface Preparation & Painting ReportChethan100% (1)

- Painting ReportDocument1 pagePainting Reportbaidu1980No ratings yet

- 103-Paint Work Checklist (English)Document1 page103-Paint Work Checklist (English)asimnaqvi2008No ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- QCP-05 Penalty System For WelderDocument9 pagesQCP-05 Penalty System For Weldernaseema1No ratings yet

- MNT - QC - BP - 001 Blasting & Painting ReportDocument1 pageMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNo ratings yet

- Nitoproof 10Document2 pagesNitoproof 10Balasubramanian Ananth67% (3)

- Nitoproof 10Document2 pagesNitoproof 10Venkata RaoNo ratings yet

- Hydro Test ReportDocument2 pagesHydro Test ReportAnonymous a8oga83No ratings yet

- 3.painting InspectionDocument2 pages3.painting InspectionSRINIVASAN S M100% (1)

- Procedure - ShippingDocument2 pagesProcedure - Shippingشادي الاخرس100% (1)

- Painting Procedure TemplateDocument14 pagesPainting Procedure TemplateNnamdi Celestine NnamdiNo ratings yet

- Coating and Blasting Daily ReportDocument1 pageCoating and Blasting Daily ReportLawren IgnatiusNo ratings yet

- Best Practices For Waste Oil ManagementDocument3 pagesBest Practices For Waste Oil ManagementPedro Viegas100% (1)

- Sand Blast and Painting Work ProsedurDocument8 pagesSand Blast and Painting Work ProsedurRizki AgustiarNo ratings yet

- Painting and Blasting Sample Report.Document2 pagesPainting and Blasting Sample Report.Janardhan SuryaNo ratings yet

- Pre-Qualification Questionnaire: ConfidentialDocument4 pagesPre-Qualification Questionnaire: ConfidentialMazhar MahadzirNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Method Statements of Surface Treatment and Painting For Valves Nh3 ProjectDocument5 pagesMethod Statements of Surface Treatment and Painting For Valves Nh3 ProjectDuongthithuydung0% (1)

- PA02 Spec MIT Spot & Soda Blasting (IFC)Document7 pagesPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriNo ratings yet

- Painting Report FormatDocument1 pagePainting Report FormatZulHafiz100% (1)

- Falcon Zinc Metal Industries L.L.CDocument7 pagesFalcon Zinc Metal Industries L.L.Ccyril nbhhNo ratings yet

- Standard Specification FOR Pipeline Internal CoatingDocument2 pagesStandard Specification FOR Pipeline Internal CoatingRanjan KumarNo ratings yet

- Itp Internal CoatingDocument4 pagesItp Internal CoatingkamlNo ratings yet

- Work Method StatementDocument9 pagesWork Method StatementdjvhNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- PP WP28Document15 pagesPP WP28mohd as shahiddin jafriNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- Surface Preparation and PaintingDocument4 pagesSurface Preparation and PaintingSimbu ArasanNo ratings yet

- Procedure For Fab, Erec & Testing of Undergroud PipingDocument12 pagesProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86No ratings yet

- BlastpaintDocument12 pagesBlastpaintdeje1726No ratings yet

- Machinery Inspection Checklist - Wah FungDocument4 pagesMachinery Inspection Checklist - Wah FungMKhairulMDNo ratings yet

- Objective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresDocument11 pagesObjective 2. Reference Documents 3. Procedure 4. Painting System 5. Inspection 6. Repairs 7. Safety AnnexuresChethanNo ratings yet

- Graco King Sprayers Operators ManualDocument44 pagesGraco King Sprayers Operators Manualpotheek pantho100% (1)

- Painting Procedure Template PDFDocument14 pagesPainting Procedure Template PDFjohn100% (1)

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-Gblara_rajkumar667No ratings yet

- Pressure VesselsDocument9 pagesPressure VesselsSajal KulshresthaNo ratings yet

- Painting Procedure NG SystemsDocument6 pagesPainting Procedure NG SystemsTanveer Rajput EngrNo ratings yet

- DPI Test ReportDocument1 pageDPI Test Reportengsam777No ratings yet

- Tender Response Open Procedure: Antibiotics Resistance Macro Game SCM1155MDocument17 pagesTender Response Open Procedure: Antibiotics Resistance Macro Game SCM1155MJames prickly100% (1)

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- 1798-305-RC-0-B Packing ProcedureDocument28 pages1798-305-RC-0-B Packing ProcedureBrain AliveNo ratings yet

- CS Colours2011-1 PDFDocument3 pagesCS Colours2011-1 PDFmanbkk100% (1)

- 07 Packing, Marking & Shipping Instructions - DomesticDocument2 pages07 Packing, Marking & Shipping Instructions - DomesticLuisNo ratings yet

- Decklite Access SolutionsDocument22 pagesDecklite Access Solutionshash117No ratings yet

- Invitation Letter PQT AEC & CWCDocument3 pagesInvitation Letter PQT AEC & CWCIqbal Nurrasa BaktiNo ratings yet

- RespiratoryprotectionDocument10 pagesRespiratoryprotectionismailayarNo ratings yet

- Air SystemDocument76 pagesAir SystemRobin Attalla100% (1)

- Mps SDM 2014 Tp042Document37 pagesMps SDM 2014 Tp042Janardhan Surya100% (1)

- 57 - Abbrasive Blasting Check ListDocument3 pages57 - Abbrasive Blasting Check ListZeeshan AbbasiNo ratings yet

- Filter HALTON Clean Room PDFDocument71 pagesFilter HALTON Clean Room PDFNiedha Mulya NurshandyNo ratings yet

- B A SetDocument13 pagesB A Setsruhil100% (1)

- Air Comp ChecklistDocument1 pageAir Comp Checklistshabeermalik13No ratings yet

- Maintenance of HVACDocument47 pagesMaintenance of HVACab_s5036No ratings yet

- Sop AirDocument28 pagesSop Airvarun awasthiNo ratings yet

- Almig Pistons 'A' Range Operating ManualDocument22 pagesAlmig Pistons 'A' Range Operating ManualAndy MitchellNo ratings yet

- Nearmiss Trending AnalysisDocument40 pagesNearmiss Trending AnalysisTayyab MayoNo ratings yet

- Monthly Blasting and Painting Inspection ReportDocument1 pageMonthly Blasting and Painting Inspection ReportTayyab Mayo0% (1)

- Ill Health ReportDocument1 pageIll Health ReportTayyab MayoNo ratings yet

- Monthly Safety Statisics ReportDocument1 pageMonthly Safety Statisics ReportTayyab Mayo100% (1)

- Monthly PPE Inspection ReportDocument1 pageMonthly PPE Inspection ReportTayyab MayoNo ratings yet

- Slings Etc Inspection ReportDocument1 pageSlings Etc Inspection ReportTayyab MayoNo ratings yet

- Total Safe Man Hours (July 2012)Document1 pageTotal Safe Man Hours (July 2012)Tayyab MayoNo ratings yet

- Monthly Safety Statisics ReportDocument1 pageMonthly Safety Statisics ReportTayyab Mayo100% (1)