Professional Documents

Culture Documents

8D Response Report: Congrats To Team

Uploaded by

Sumeet SainiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8D Response Report: Congrats To Team

Uploaded by

Sumeet SainiCopyright:

Available Formats

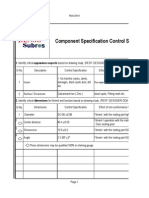

8D Response Report

WHO IS EFFECTED BY THE PROBLEM?

Date Open:

Company:

Gripwel Fasteners Pvt. Ltd.

Initial Response:

Address:

142A/30 T0 142A/51,NSEZ

Target Close Date:

Location:

NOIDA

Part No./Code

18SPL102

Product Name:

Axel Pin

Internal:

Revision Date(s):

Customer

Complaint

No.:

--

--

8D Initiator:

Sumeet Saini

8D Initiator's Spvr:

Ram Lakhan

External:

D1 TEAM MEMBER NAMES/TITLES:

Champion:

Mr. Gaurav Goyal

Team Leader:

Mr.Ramesh chand

Team Members:

Sumeet Saini, Ramsewak,Anil kumar

8D No.:

Actual Close Date:

D2 PROBLEM STATEMENT/DESCRIPTION (quantify) (one defect per 8D)

Variation the Outer diameter of pin.

The rejection rate of pins is 14.9%.Which has creat the problem at customer end.

D3 CHOOSE AND VERIFY INTERIM CONTAINMENT ACTION(S) (ICA):

%

Effective:

Target

Date:

Actual

Date:

GFPL Invontry has checked and found 1735 parts.All parts varified for outer diameter and 800 Pcs. Are found with

runout error.

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE ICA?

100% Inspection

D4 DEFINE AND VERIFY ROOT CAUSE(S):

1. Grinding process variation.Centerless grinder is not suitable for this Grinding (Dia. Is large at milling).

2. Micrometer is used for checking outer dia.

3. The defect was not detected during final inspection and part was cleared.

HOW DID YOU VERIFY THE ROOT CAUSE(S)?

1. Gauge R&R study.

2. Every part outer diameter checked at 4 different points.

D5 CHOOSE AND VERIFY PERMANENT CORRECTIVE ACTION(S) (PCA):

1. Air ring gauges are interduced.

2. All parts are checked with air ring gauges.

3. Using cyliderical grinder for outer dia. Grinding.

% Contribution:

% Effective:

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE PCA?:

Process monitoring

D6 IMPLEMENT AND VALIDATE PERMANENT CORRECTIVE ACTION(S) (PCA):

Target

Date:

Actual

Date:

Target

Date:

Actual

Date:

1. Air ring gauges are available for inspection of outer dia.

2. New vender developed.

HOW WILL YOU VALIDATE THE PCA?

100% Inspection

D7 SYSTEM PREVENTION ACTIONS TO PREVENT RECURRENCE:

Mistake Proofing: How are you going to ensure it can't happen again?

1. 100% inspection with Air ring gauges.

HAS CORRECTIVE ACTION/IMPLEMENTATION BEEN REVIEWED AGAINST DOCUMENTS?:

FMEA

Proc./Work Instr.

Flowchart

Control Plan

Check boxes that apply:

D8 TEAM AND INDIVIDUAL RECOGNITION: Recognize the collective efforts of the team.

congrats to team

Add to Internal Audit

You might also like

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- 8DDocument9 pages8DJeanUndangNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- 8 D Report FormatDocument9 pages8 D Report FormatAlok MehtaNo ratings yet

- 8D Problem Solving A3 Sheets and Description1Document3 pages8D Problem Solving A3 Sheets and Description1et_store1561No ratings yet

- Industrial Statistics: Practical Methods and Guidance for Improved PerformanceFrom EverandIndustrial Statistics: Practical Methods and Guidance for Improved PerformanceNo ratings yet

- Customer Information: BRKT Assy Center HingeDocument1 pageCustomer Information: BRKT Assy Center HingepodraoNo ratings yet

- 8D Form InstrucDocument9 pages8D Form InstrucPedro Pi100% (2)

- 8D Form InstructionDocument9 pages8D Form InstructionLokesh NarasimhaiahNo ratings yet

- 8D Report Solves Seat Cushion VoidsDocument9 pages8D Report Solves Seat Cushion VoidsPedro Pi100% (3)

- Fine Carbide Tools PTE.LTD. Potential Failure Mode and Effects AnalysisDocument2 pagesFine Carbide Tools PTE.LTD. Potential Failure Mode and Effects AnalysisHeidi Dedication Pader NicolasNo ratings yet

- 8D Report FormatDocument2 pages8D Report Formatwilliamnuevo100% (3)

- CORRECTIVE ACTION REPORT SUMMARYDocument12 pagesCORRECTIVE ACTION REPORT SUMMARYWilmer EnarioNo ratings yet

- Ppap Spacer TubeDocument37 pagesPpap Spacer TubeSeenivasagam SeenuNo ratings yet

- Your Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller NameDocument20 pagesYour Company Name 1680995-101 1680995-101 Bushing, Guide Slot E 2/1/2003 N/A 12/23/2005 0 John Smith Amy Millimen Jane Doe Bob Miller Namekaran11deshmukhNo ratings yet

- 8D Training For SuppliersDocument25 pages8D Training For SuppliersiqbalmuarNo ratings yet

- 8D TemplateDocument1 page8D Templateaapl_josephNo ratings yet

- CAPA FormDocument1 pageCAPA Formprabhat suma100% (1)

- Ingress Protection-IP66-IEC60529Document12 pagesIngress Protection-IP66-IEC60529tushar2.khandelwalNo ratings yet

- Ultrasonic Examination Report: Discharge DamperDocument1 pageUltrasonic Examination Report: Discharge DamperSaurav RoyNo ratings yet

- QSB UjDocument162 pagesQSB Ujpatima_sv4875No ratings yet

- Process & Product Audit Check SheetDocument6 pagesProcess & Product Audit Check SheetPrakashRai100% (7)

- Run at Rate AuditDocument12 pagesRun at Rate AuditPurushothama Nanje GowdaNo ratings yet

- G8D Report: Speedlip Loose in Front BumperDocument4 pagesG8D Report: Speedlip Loose in Front BumperLakshmanan VenkatesanNo ratings yet

- 3 3bb0aDocument7 pages3 3bb0aEleandro JoaquimNo ratings yet

- Gage R&R Study - Data Entry: Part #/name: Gage #/name: Feature Name: Completed By: Feature Tolerance: Study DateDocument3 pagesGage R&R Study - Data Entry: Part #/name: Gage #/name: Feature Name: Completed By: Feature Tolerance: Study DateFrancisco HernandezNo ratings yet

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- APQP2 ADocument78 pagesAPQP2 AMukesh PathakNo ratings yet

- 8D FormatDocument2 pages8D FormatMani VannanNo ratings yet

- Cntlplan1 Week 9 Johnson AndersonDocument7 pagesCntlplan1 Week 9 Johnson AndersonLuis Angel RoudriguezNo ratings yet

- Pressure Vessel High Pressure Stripper R0 Final Report R1Document5 pagesPressure Vessel High Pressure Stripper R0 Final Report R1AJ NugrohoNo ratings yet

- 14 - 200 DPG Catalogue NewDocument4 pages14 - 200 DPG Catalogue NewMOHANNo ratings yet

- Cooper Industries PPAP Forms KitDocument25 pagesCooper Industries PPAP Forms KitAshutosh SinghNo ratings yet

- WELD SUMMARY TRACKINGDocument30 pagesWELD SUMMARY TRACKINGThamaraikani Mani100% (1)

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Document1 pageIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNo ratings yet

- Appendix 11F: Operational ChecklistsDocument15 pagesAppendix 11F: Operational Checklists许爱文No ratings yet

- Scuba Modern Pfra MethodDocument8 pagesScuba Modern Pfra Methodapi-265295002No ratings yet

- 8DDocument14 pages8DMark Anthony Sabio LuceroNo ratings yet

- SQ Mark & 100ppm ChecklistDocument14 pagesSQ Mark & 100ppm Checklistkarpags100% (2)

- Intro To DMAICDocument40 pagesIntro To DMAICjvanandhNo ratings yet

- CSCS Rods & BracketsDocument66 pagesCSCS Rods & BracketsshuklahouseNo ratings yet

- Work Instruction Sheet Tata Motors IndiaDocument1 pageWork Instruction Sheet Tata Motors IndiaPranjal Tiwari100% (1)

- Functional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVDocument18 pagesFunctional Specifications FOR Test Separation Module: Onshore Engg Services, N Delhi Document No.: OESG/ARP/TSP/M002 REVAnonymous O0lyGOShYGNo ratings yet

- QRQCDocument1 pageQRQCVirginia GrandoNo ratings yet

- 8D For Big ID DepthDocument18 pages8D For Big ID DepthKuldeep SinghNo ratings yet

- 8D Report For Eye Bolt Internal DiaDocument1 page8D Report For Eye Bolt Internal DiaKapil HarchekarNo ratings yet

- Apqp FormsDocument25 pagesApqp FormsgkspNo ratings yet

- GM 1927-16a PWT Gear Commodity AuditDocument5 pagesGM 1927-16a PWT Gear Commodity AuditSergio BoillosNo ratings yet

- 215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDocument4 pages215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDeepak ChaudharyNo ratings yet

- Attribute Gage R&R: Easurement SystemsDocument6 pagesAttribute Gage R&R: Easurement Systemsadialexela1447No ratings yet

- IPQC General FormatDocument17 pagesIPQC General FormatMohd Isa HarunNo ratings yet

- Sakthi Automotive Corrective Action Form GM Knuckle Tool IssueDocument5 pagesSakthi Automotive Corrective Action Form GM Knuckle Tool IssueVenkatesh RegunathanNo ratings yet

- Certificate of Relief Valve Capacity (PROCA) 7 PDFDocument1 pageCertificate of Relief Valve Capacity (PROCA) 7 PDFAdeoye OkunoyeNo ratings yet

- 8D Report For VDC Wrong - NNLDocument10 pages8D Report For VDC Wrong - NNLAbhinav SinghNo ratings yet

- 8D Report SummaryDocument9 pages8D Report SummaryLukas LukasNo ratings yet

- Capacity VerificationDocument5 pagesCapacity VerificationHarsha MP100% (2)

- 8D TemplateDocument9 pages8D TemplateCarlos Oliver MontejanoNo ratings yet

- Rust and Paint Peel Off Issue 8D ReportDocument1 pageRust and Paint Peel Off Issue 8D ReportLorenzo CarmeniNo ratings yet

- 05 - Practicals - DGA - Electric Line - 4-5-6Document12 pages05 - Practicals - DGA - Electric Line - 4-5-6Saïd Ben AbdallahNo ratings yet

- Indian Novelists and Their ContributionsDocument6 pagesIndian Novelists and Their ContributionsSumeet SainiNo ratings yet

- Defect Reduction in Robo WeldingDocument14 pagesDefect Reduction in Robo WeldingSumeet SainiNo ratings yet

- Design ResponsibilityDocument1 pageDesign ResponsibilitySumeet SainiNo ratings yet

- Covid 19 RajkotDocument4 pagesCovid 19 RajkotSumeet SainiNo ratings yet

- Call Letter For InterviewDocument1 pageCall Letter For InterviewSumeet SainiNo ratings yet

- Indian Novelists and Their ContributionsDocument6 pagesIndian Novelists and Their ContributionsSumeet SainiNo ratings yet

- Defect Analysis Report for Manufacturing ProcessDocument3 pagesDefect Analysis Report for Manufacturing ProcessSumeet SainiNo ratings yet

- (Ebook) Catia Tutorial PDFDocument38 pages(Ebook) Catia Tutorial PDFmahesh89% (57)

- (Ebook) Catia Tutorial PDFDocument38 pages(Ebook) Catia Tutorial PDFmahesh89% (57)

- 022 PDFDocument3 pages022 PDFSumeet SainiNo ratings yet

- V5R16 Detail DraftingDocument230 pagesV5R16 Detail DraftingRuben RedondoNo ratings yet

- 22BCO418 (2) .CATDrawingDocument1 page22BCO418 (2) .CATDrawingSumeet SainiNo ratings yet

- Slides Sep2014 AbhiDocument19 pagesSlides Sep2014 AbhiSumeet SainiNo ratings yet

- Sae j419 1983 Methods of Measuring Decarburization PDFDocument8 pagesSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiNo ratings yet

- Formulas for Calculating Surface Areas and VolumesDocument12 pagesFormulas for Calculating Surface Areas and VolumesMuhammad SajidNo ratings yet

- 2.5third Angle ProjectionDocument6 pages2.5third Angle ProjectionSumeet Saini0% (1)

- 10-25 Dimensioning Review PDFDocument26 pages10-25 Dimensioning Review PDFSumeet SainiNo ratings yet

- CH 5 Casting FundamentalsDocument14 pagesCH 5 Casting FundamentalsSumeet SainiNo ratings yet

- Standards for Dimensioning DrawingsDocument6 pagesStandards for Dimensioning Drawingsjuan_o_620No ratings yet

- Design ResponsibilityDocument1 pageDesign ResponsibilitySumeet SainiNo ratings yet

- Rules and Concepts of GD&TDocument31 pagesRules and Concepts of GD&TSumeet Saini75% (4)

- 2.5third Angle Projection PDFDocument6 pages2.5third Angle Projection PDFSumeet SainiNo ratings yet

- Unipartsgroup 04 06 15 02 33 53Document1 pageUnipartsgroup 04 06 15 02 33 53Sumeet SainiNo ratings yet

- WWW - Irctc.co - in Eticketing Printticket - JSF PNR 2757028603 B 30-Nov-2015 0Document2 pagesWWW - Irctc.co - in Eticketing Printticket - JSF PNR 2757028603 B 30-Nov-2015 0Sumeet SainiNo ratings yet

- Study of Microstructure of Thick Wall Ductile Iron Castings: S.K. Swain and S. SenDocument5 pagesStudy of Microstructure of Thick Wall Ductile Iron Castings: S.K. Swain and S. SenSumeet SainiNo ratings yet

- IJC1158Document11 pagesIJC1158Sumeet SainiNo ratings yet

- Tolerance Stackup AnalysisDocument1 pageTolerance Stackup AnalysisSumeet Saini100% (1)

- SCH 2Document38 pagesSCH 2Sumeet SainiNo ratings yet

- 381617.41 77276 FinalDocument5 pages381617.41 77276 FinalSumeet SainiNo ratings yet

- Din en 1563Document2 pagesDin en 1563Tayfun Tezanlar78% (9)