Professional Documents

Culture Documents

Rohr2 - Pipe Stress Analysis PDF

Rohr2 - Pipe Stress Analysis PDF

Uploaded by

Nur Syahroni0 ratings0% found this document useful (0 votes)

13 views9 pagesOriginal Title

Rohr2 - Pipe Stress Analysis.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views9 pagesRohr2 - Pipe Stress Analysis PDF

Rohr2 - Pipe Stress Analysis PDF

Uploaded by

Nur SyahroniCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

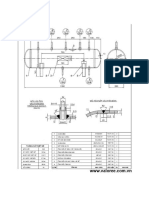

V d di y l 1 bi tnh minh ha Pipe Stress.

C 1 s vn s l vi mi

ngi.

Cc bc vui lng click vo hnh xem full size.

Mc ch bi tnh tp trung check stress theo B31.3 - Static Analysis, gi s cc support

c thit k chu c lc do ng ng tc dng vo. Ti tc ng bao gm:

1.Ti trng bn thn (weight + insulation + fluid), ti trng do valve : thuc nhm

Sustained Loads

2.Ti trng do gin n nhit (c 2 trng hp hot ng, xem chi tit cc hnh di) :

thuc nhm Secondary Loads

Bi tnh khng k n tc ng ca ti gi (Occasional Loads). Do , cc phng

trnh check stress gm 2 phng trnh chnh SL v SE. Tham kho ASME B31.3

bit thm chi tit.

Nhit lp t 20 C (Click vo hnh xem input data)

Nhit hot ng 1, valve m, tt c cc line u nng T= 316 C, P = 34.5 bar

Nhit hot ng 2, valve ng

Line mu : T = 316 C, P = 34.5 bar

Line mu xanh: T = 49 C, P = 0 bar

Kt qu SL cho thy node 20 (BEND) c stress ln nht l 50.4% so vi allowable

stress

Kt qu SE cho thy node 70 (TEE) c stress ln nht 97.6% so vi allowable

stress (xem phn tch kt qu hnh di)

Kt qu gi tr ng sut ln ti node 70 l do In-plane Moment (Mi) qu ln =

22.675kNm. Ni cch khc, Moment ny xoay quanh trc Y ngc kim ng h

(c th thy r qua hnh v chuyn v ti section 140-70, TEE b y ln trn).

Do , cn tnh ton thit k li gim ng sut ny xung h thng an ton

Cc gii php thit k li:

1. Nhn xt: Nguyn nhn gy ra Mi ln l do on thng ng 168-180 gin n

khi nhit tng.

2. Gii php 1: gn 1 khp ni mm (Expansion Joint, vit tt = EJ) hp th

gin n ca ng. Tuy nhin, do nhit cao 316 C, v vy khng c EJ no hot

ng c trong mi trng ny. Mt khc, gi tin ca 1 EJ kh cao.

3. Gi php 2: lm 1 loop ch U (xem hnh di). Kch thc loop trong bi ny

cho 1m

Kt qu sau khi tnh ton li cho thy ng sut ti node 70 l 63% so vi

allowable stress. Moment Mi gim xung cn 14.582kNm

--------------------------------------Bi tnh s dng phn mm ROHR2 - Pipe Stress Analysis Software

Email: infohbe@huynhbang.com

You might also like

- Chương 2. Máy Nén L NHDocument27 pagesChương 2. Máy Nén L NHPhùng Xuân QuangNo ratings yet

- Bai Tap PIDDocument27 pagesBai Tap PIDHiếu HoàngNo ratings yet

- Bơm Quạt Máy Nén - Chương 2 - Phương Trình Cơ Bản Của Máy Thủy Lực Cánh DẫnDocument51 pagesBơm Quạt Máy Nén - Chương 2 - Phương Trình Cơ Bản Của Máy Thủy Lực Cánh DẫnPham Ba ManhNo ratings yet

- Bơm Quạt Máy Nén - Chương 3 - Tính Toán Và Chọn Bơm Trong Thực TếDocument65 pagesBơm Quạt Máy Nén - Chương 3 - Tính Toán Và Chọn Bơm Trong Thực TếPham Ba ManhNo ratings yet

- Bơm Quạt Máy Nén - Chương 4 - Tính Toán Và Chọn Lựa Quạt Trong Thực TếDocument80 pagesBơm Quạt Máy Nén - Chương 4 - Tính Toán Và Chọn Lựa Quạt Trong Thực TếPham Ba ManhNo ratings yet

- Tutorial Su Dung PDMS Trong Piping WorkDocument10 pagesTutorial Su Dung PDMS Trong Piping WorkTrí NguyễnNo ratings yet

- (123doc) 01 Thuyet Minh He Thong Thu Bui Mt4500Document22 pages(123doc) 01 Thuyet Minh He Thong Thu Bui Mt4500Lê Việt TuấnNo ratings yet

- Thuyết Minh Tính ToánDocument16 pagesThuyết Minh Tính ToánNguyen Duc CuongNo ratings yet

- Hướng dẫn tạo file LISP đơn giản! - Quản lý chi phí xây dựng, Quản lý thi công xây dựng, Quản lý dự án xây dựngDocument9 pagesHướng dẫn tạo file LISP đơn giản! - Quản lý chi phí xây dựng, Quản lý thi công xây dựng, Quản lý dự án xây dựngtranduc88No ratings yet

- Đồ Án Tính Toán Thiết Kế Bồn Chứa XăngDocument13 pagesĐồ Án Tính Toán Thiết Kế Bồn Chứa XăngTieu Ngoc LyNo ratings yet

- Bơm Quạt Máy Nén - Chương 5 - Máy Nén Và Hệ Thống Khí NénDocument37 pagesBơm Quạt Máy Nén - Chương 5 - Máy Nén Và Hệ Thống Khí NénPham Ba ManhNo ratings yet

- Đại Cương Về Kỹ Thuật Xử LýDocument302 pagesĐại Cương Về Kỹ Thuật Xử LýHuy Le100% (1)

- Thuyet Minh Bien Phap Thi Cong PCCCDocument13 pagesThuyet Minh Bien Phap Thi Cong PCCCĐặng TrungNo ratings yet

- Welding Inspector Book (Phuoc)Document145 pagesWelding Inspector Book (Phuoc)Phuoc JA100% (1)

- Auto LispDocument62 pagesAuto Lispvoanhtu2009No ratings yet

- Ngung Tiep Nhan TS Von Ngoai NS 052022Document1 pageNgung Tiep Nhan TS Von Ngoai NS 052022An Bui100% (2)

- VI Du Ket Cau ThepDocument10 pagesVI Du Ket Cau ThepMai Thế NamNo ratings yet

- THIẾT LẬP CÔNG THỨC BÁN THỰC NGHIỆM TÍNH HỆ SỐ MA SÁT CỦA DÒNG CHẢY RỐI TRONG ĐƯỜNG ỐNG TRÒN. TS. Lê Văn Dực, Bộ môn Cơ Lưu Chất, Khoa Kỹ Thuật Xây Dựng, Đại Học Bách Khoa - ĐHQG TP. HCM,Document6 pagesTHIẾT LẬP CÔNG THỨC BÁN THỰC NGHIỆM TÍNH HỆ SỐ MA SÁT CỦA DÒNG CHẢY RỐI TRONG ĐƯỜNG ỐNG TRÒN. TS. Lê Văn Dực, Bộ môn Cơ Lưu Chất, Khoa Kỹ Thuật Xây Dựng, Đại Học Bách Khoa - ĐHQG TP. HCM,lvdntx100% (1)

- Cặp Nhiệt Điện (TC)Document13 pagesCặp Nhiệt Điện (TC)Thien BinhNo ratings yet

- Caesar IiDocument56 pagesCaesar IiĐạt Cold100% (1)

- 8 - TÍNH TOÁN THIẾT KẾ BỘ TRUYỀN TRỤC VÍTDocument7 pages8 - TÍNH TOÁN THIẾT KẾ BỘ TRUYỀN TRỤC VÍTChương Đoàn HồngNo ratings yet

- Auto LispDocument59 pagesAuto LisphoacvxdNo ratings yet

- 6.TongHop BaiGiang LapTrinhNETDocument134 pages6.TongHop BaiGiang LapTrinhNETĐại NguyễnNo ratings yet

- Dien Tich Tiet Dien Thuc Cua BulongDocument2 pagesDien Tich Tiet Dien Thuc Cua BulongmameniqNo ratings yet

- BÀI TẬP LỚN KẾT CẤU THÉP 1 THIẾT KẾ HỆ SÀN DẦM BẰNG THÉPDocument25 pagesBÀI TẬP LỚN KẾT CẤU THÉP 1 THIẾT KẾ HỆ SÀN DẦM BẰNG THÉPMinh Nghĩa100% (2)

- Giáo Trình Đào tạo quy trình Thi công Lắp đặt Piping SystemDocument34 pagesGiáo Trình Đào tạo quy trình Thi công Lắp đặt Piping SystemThànhh PhonggNo ratings yet

- Bai3 Thanh Chiu Keo (Nen) Dung Tam 02072021Document52 pagesBai3 Thanh Chiu Keo (Nen) Dung Tam 02072021tran huyNo ratings yet

- Lap Rap Chan VitDocument4 pagesLap Rap Chan VitCong Nguyen ChiNo ratings yet

- Bang Tra Cong ThucDocument26 pagesBang Tra Cong ThucMộcNo ratings yet

- TCVN 8366 - Binh Chiu Ap Luc PDFDocument381 pagesTCVN 8366 - Binh Chiu Ap Luc PDFductaiutc100% (6)

- bài tập lonwsDocument11 pagesbài tập lonwsPham Van Tin B1909842No ratings yet

- Tính Toán Thiết Kế Thiết Bị Cung Cấp Hơi Nước Sử Dụng Năng Lượng Mặt Trời (Kèm Bản Vẽ)Document30 pagesTính Toán Thiết Kế Thiết Bị Cung Cấp Hơi Nước Sử Dụng Năng Lượng Mặt Trời (Kèm Bản Vẽ)Tieu Ngoc LyNo ratings yet

- 4. Đề Thi & Đáp Án Môn Thủy Lực 4.1. Đề thi môn Thủy lựcDocument10 pages4. Đề Thi & Đáp Án Môn Thủy Lực 4.1. Đề thi môn Thủy lựcTất Bình ĐàoNo ratings yet

- Tong Hop Lap Trinh Net Lap Trinh Net HufiDocument138 pagesTong Hop Lap Trinh Net Lap Trinh Net HufiVinh TriNo ratings yet

- Giáo Trình Mô Phỏng Tập 1Document115 pagesGiáo Trình Mô Phỏng Tập 1NgoVietCuong100% (1)

- tính toán phụ tảiDocument5 pagestính toán phụ tảiQuân Nguyễn VănNo ratings yet

- 1doanmauctm PDFDocument53 pages1doanmauctm PDFHuy Danh100% (1)

- Bai Giang f2 PDFDocument65 pagesBai Giang f2 PDFNguyễn Đầy100% (1)

- Dung Sai Do LuongDocument13 pagesDung Sai Do LuongvngaconNo ratings yet

- TÍNH BẢN ĐẾDocument6 pagesTÍNH BẢN ĐẾKhắc ĐăngNo ratings yet

- Tính Ứng Suất Bền Cho Bình Theo Tcvn 8366Document3 pagesTính Ứng Suất Bền Cho Bình Theo Tcvn 8366Cuu LongNo ratings yet

- Cách Tính Bền Bình Áp LựcDocument5 pagesCách Tính Bền Bình Áp LựcNguyen Anh HungNo ratings yet

- Bài 2Document9 pagesBài 2trongtuan251003No ratings yet

- Thiet Ke Tuapin GioDocument65 pagesThiet Ke Tuapin Giod_ndmNo ratings yet

- tài liệu CLC-c123-HK193Document37 pagestài liệu CLC-c123-HK193Thành Đàm Lê0% (1)

- Chieu Dai Bulong NeoDocument5 pagesChieu Dai Bulong NeoKhac Hoang PhamNo ratings yet

- 17-Tính Toán Và Kiểm Tra Tiết Diện CộtDocument36 pages17-Tính Toán Và Kiểm Tra Tiết Diện CộtTrương Phước ĐứcNo ratings yet

- NHỮNG KIẾN THỨC CƠ BẢN KHI HÀN TỰ ĐỘNG DƯỚI LỚP THUỐC BẢO VỆ HÀN SAWDocument17 pagesNHỮNG KIẾN THỨC CƠ BẢN KHI HÀN TỰ ĐỘNG DƯỚI LỚP THUỐC BẢO VỆ HÀN SAWlâmNo ratings yet

- Thuyet Minh PCCCDocument18 pagesThuyet Minh PCCCNguyen VinhNo ratings yet

- (Revit) Lấy Tọa Độ Cho File Revit LinkDocument6 pages(Revit) Lấy Tọa Độ Cho File Revit LinkNguyễn Hoàng AnhNo ratings yet

- Đ Án Thép 2Document61 pagesĐ Án Thép 2le6e tuan kietNo ratings yet

- Chương 3 Thiết kế hệ thống đường ống PDFDocument59 pagesChương 3 Thiết kế hệ thống đường ống PDFMinh Nguyen Van100% (12)

- (123doc) - Thiet-Ke-Be-Chua-Cac-San-Pham-Dau-Theo-Tieu-Chuan-Api-650Document26 pages(123doc) - Thiet-Ke-Be-Chua-Cac-San-Pham-Dau-Theo-Tieu-Chuan-Api-650Trường Tùng LýNo ratings yet

- Modbus CommunicationDocument81 pagesModbus CommunicationCảnh Trần100% (1)

- BÀI TẬP PHẦN LIÊN KẾT HÀNDocument6 pagesBÀI TẬP PHẦN LIÊN KẾT HÀNViệt LêNo ratings yet

- Báo Cáo Nhóm 4Document20 pagesBáo Cáo Nhóm 4hoanhhh654No ratings yet

- BÀI 6: Hệ Thống Điều Khiển Nhiệt Độ: 6.1 Mục đíchDocument9 pagesBÀI 6: Hệ Thống Điều Khiển Nhiệt Độ: 6.1 Mục đíchPhat Nguyen ThanhNo ratings yet

- Bai 3-Chu Trinh Ly Tuong Cua DCDTDocument8 pagesBai 3-Chu Trinh Ly Tuong Cua DCDThuu trieuNo ratings yet

- Đo Không Điện Thi Giữ KìDocument10 pagesĐo Không Điện Thi Giữ KìViệt Anh Nguyễn HuyNo ratings yet