Professional Documents

Culture Documents

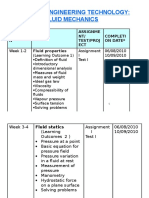

Flywheel & Clutch

Uploaded by

YashrajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flywheel & Clutch

Uploaded by

YashrajCopyright:

Available Formats

2 πNTmean

Flywheel-1:- Step1)To det. T mean, P= ; T mean=__Nm ; Step2) To det. W.d./cycle,

60

W=T mean*θ=_Nm --- θ=4π ; Step3) Max W.D., W max =1.3*W ; Step4) To det. T max,

π

W max =area under T-θ diag. =∫ T max∗sin θ T max= ❑ =__Nm

;

0

❑

Eqn of Power Stroke,T=T max*sin θ ;Step5) To det. θ B & θ D, ; at B & D, T=T mean=__

θD

θ B=_rad & θ D=_rad ; Step6) To det. ΔE(area under curve bcd) ; ΔE=∫ (T −¿ T mean ) dθ ¿

θB

2 πN

ΔE=__Nm ; Step1)To det I(psg7.120), ΔE=I* K s *ω 2 ; ω= = _. Therefore, I=_

60

Step2) To det. Mean dia D, ; V= πDN V=3000to4000M/min(psg) ;Let us select V=3500m/min; D=_.

D² I

Step3) To det. Mass, I=mk² ; k²= =_ ; m= =_ ; weight, w=mg=__.N ; w=(πDbh)r …(psg7.120)

4 k²

r= sp wt = __N/cm³ (psg1.1) =__N/m³ ; b/h=0.65 to 2, say b/h = 2 ; b=2h ; w=(πD2h*h)r ; h=_m

r∗v ² πDN

h=_mm ; b=2h=_mm ; Checking ind stress,σ t = ; V= = _m/s. σ t=_N/m²=N/mm²

g 60

π ² v ² Dr 3 1

Bend. Stress, σ b= ; Assuming no of arms, n=6 ; σ b=¿_ ; , σ total= σ t + σ b = _N/mm²

n ² gh 4 4

, σ total=___<200N/mm². so safe ; allowble total stress, σ tot=200 to 300

Check , σ t=__ <28N/mm². so safe

M t ( D−d)

Step1)To det , z yy , [σ ¿¿ bt ]¿= --eq.1 ; assuming,σ t = 100 to 150 N/mm²

n∗z yy∗D

16 M t

M t =__Nm=_*10³Nmm ; D=_m=_mm, d=dia of hub= 2d s ; d s =dia of shaft= 3

Assuming allowable [τ]=40 ; d s =_mm to take care of ben & other stress

√ π (τ )

64∗z yy

d=2*d s =_mm; z yy = __mm³. ; major axis of elliptical arm, a= 3

√ π

=_mm

minor axis, c=a/2 = _mm ; d 0 =D+h = __mm ; Draw diag. with dimension,; Note: if mtrl not

Mention, assume C.I. & V=1500m/min.

Flywheel-2

Fs τ∗u∗πdx

Step1:to det energy req to punch 1 hole, ; E1=[ *x] = [ ]*x = __Nm.

2 2

Step2:to det fluctuation of energy, ; ΔE= E1 [1 – 1/5] = __Nm

H

To det or select electrical motor, ; Theo. Power, Motor power= E1* =_W =_KW

60

Theo Power

The actual power of motor, P= =_KW ; Selecting steel motor ---(psg5.124)

η

Selecting motor with power=_KW – from psg ; Selection of speed of electrical motor,

Speed of Flywheel, N=i*H = __rpm ; Thereforre speed of elec. Motor=1000rpm

Sel. min speed ; Let us select 3ф induc.Motor of _KW from psg

2 πN ΔE

Step3:to det I, ΔE= I* K s *ω 2 from psg 7.120 ; ω= = _. Therefore, I= = __kg-m²

60 K s∗ω2

D² I

I=mk², k²= =_ ; m= =_Kg. ; Weight of the flywheel = __mg

4 k²

DESIGN DATA---PSG TECH 7.115

πDN

To det. b & h, selec. of mtrl., V= = _m/s. ; V=_*60 = __rpm < 1500rpm

60

C.I. Flywheel can be used. ---(psg7.120) ; Now, w=(πDbh)r ; b=2h; w=(πD2h*h)r ;

r∗v ²

h=_m; h=_mm ; b=2h=_mm ; Checking ind stress,σ t =

g

π ² v ² Dr 3 1

Bend. Stress, σ b= ; σ total= σ t + σ b = _N/mm²

n ² gh 4 4

M t ( D−d)

Check , σ t=__ <35N/mm². so safe ; Step1)To det , z yy , [σ ¿¿ bt ]¿=

n∗z yy∗D

D∗60 3 16 M t

M t=

2 πN

= _Nmm ; d s =

√π (τ )

, Asume allwable[τ]=40 ; d s =_mm, d=2*d s =_mm

64 z yy

a=_mm; c=a/2=_mm; d 0 =D+h = _mm ;

√

Assume σ bt=150 ; z yy = __mm³. ; Major axis of ellipticalar, a= 3

π

DESIGN DATA---PSG TECH 7.115

Multi-plate clutch:psg7.89,

[ M ¿¿ t] P∗60

i min= ¿ --eqn-1 ; a.Torque, M t = *106

2 π Pa b∗r∗r m ² 2 πN

r max +r min

Step2) Design Torque,[ M ¿¿ t ]¿= K w ∗M t=_. ; b=r max -r min =__; r m= =__

2

sub in eqn-1, i min=__ ; select i min net highest even no.

i i

psg7.90 ; m 1=no of driver plates(steel) ; m1= = __ m 2= +1= __

2 2

Total no. of plates=m 1+m 2=__ ; Step1)To det dia of i/p shaft,

P∗60

i> M t= *106 =_(rated torque) ; ii>To det K w =service factor (7.90)

2 πN

K w = K 1+ K 2+ K 3+ K 4 (psg7.89) ; K 1=driver dynamic characteristics

factor=0.5 ; K 2=driven shaft dy ch fac=1.25

K 3=wear factor=0.32 ; K 4 =frequency of operation fact=0.75

Therefore, K w = ___ ; iii>Design Torque, [ M ¿¿ t ]¿= K w ∗M t=_.

iv>selection of mtrl & stress, ; let us assume c-45 steel as mtrl.

Then from psg1.9, σ y=__ ; Let us assume FOS=4

σy [M ¿¿ t ] =_

Design shear stress, [τ]=

2∗FOS

D

√

=_. ; v>dia of the shaft, d s = 3 16

πτ

¿

Design of friction plates, ; r max = -thickness of housing(t)-radial clearance

2

r r

Assume t=5mm & c =1mm ; max =__mm ; Note:if space restriction is not given,

First find r min =2d (psg7.90) ; d=dia of shaft, r=__ ; r max =1.25 to 1.8 r min (psg7.90)

r max =1.5r min ; r min =__ ; Step3> Thickness of plate(c)=1 to 3mm

Let us take c=3mm ; Specifications:- r max =__ ; r min =__;c=_

[ M ¿¿ t]

ii>to det no of plates; i min= ¿ ; eqn-1; psg7.89 ; pa=k* pb

2 π Pa b∗r∗r m ²

pb=2.5 to 3kg/cm = 0.25 to 0.3N/mm ; r max =__ ;Therfore d max =__

π∗d max∗n r max +r min

Vel at max rad, v= = __m/s ; pa =_ ; b=r max -r min =__; r m = =__

60000 2

Μ=0.2 to 0.3 for dry[new unground] =0.0 to 0.07 for wet[ground plate]

Method-II to find r, r=0.2 [for dry plates] ; i min=__ ; from psg7.90

i i

m 1= = __ m 2= +1= __(driven plates)

2 2

Total no of plates = 1+m 2=__ (psg5.30) ; For dia 35mm, std spline, 8*36*40 can be selec.

m

d s=36=inner dia ; 40= outer dia ; Step4>design of spring: Actual press betwn plate(7.90)

[M ¿¿ t ]

σ= ¿ =__; ; Axial force,Q=π*σ*(r max ²-r min ²) = __N.

2 πi∗b∗r∗r m ²

Let us assume no of springs=6 ; Approx axial force per spring = 300N.

Q

The total force on each spring = = __N

no of spring

4

Gd

Force req during engagement, Pmin= __N ; Stiffness of spring, q = G d = (psg-7.100)

8 D³n 8C³n

DESIGN DATA---PSG TECH 7.115

Let us assume C=6 ; G=__; Let d=__mm ; N= no of active coil = _ ; q=_N/mm

Pmax = Pmin+qy. Let us assume axial motion of ; Plate=3mm [2to 5mm] ;y=3mm [comp of sprng]

Max force, Pmax = __N ; checking for induced stress, ;

no of ×used shift no of day

To det no of cycle= * * ; *no of years =__. Psg7.102 as 104 <N<1*16

shift day year

4 c−1 0.615

7.105psg d=_ gr34mat ; σ u =__ ; [τ]=0.344*σ u ; Psg7.100 ; K s = + =1.2525.

4 c−4 c

K ∗8∗P c

τ= s = __< [τ] check ; Heat balance---if asked in as in problem

π∗d ²

Step1>heat generated per cycle, ;Heat generated/cycle=[ M t ¿ avg∗θ =[

[ M t ] + D ]θ = [ M t ] * wt J/cycle

2 2

2 πN

ω= = _. [Note:if t is not given t=o.1 sec] ; H g =__ ; heat generated/hour=Hg/cycle cycle/hr=_

60

Step2>Heat dissipated, overall dimensions of housing c shell ;

π∗D∗n

B=(m 1+m 2)C +20= __. {Housing} Area=πD*B=_ ; Peripheral vel of housings, π= =__

60000

H d =6.14*A v 0.78*Δt= __ ---9.15psg ; H d = H g ; Δt=__ ; ΔT=T h*T atm

T h=housing surface ; T h= __ºc ; T h>75 increase r max or provide external looks

DESIGN DATA---PSG TECH 7.115

Cone Clutch:

P∗60

Step1: to det dia of splinrd shaft ; Transmitted torque, M t = *106 = _Nmm

2 πN

Step2) Design Torque,[ M ¿¿ t ]¿= K w ∗M t=_.(7.89) ; (7.90) K 1=0.5, K 2=1.2, K 3=0.285, K 4 =0.75

K w = K 1+ K 2+ K 3+ K 4 (psg7.89) ; Selection of mtrl for shaft & design stress

σy

Let select C-30 as mtrl of shaft ; σ y=30kgf/mm², fos=4 ;Allowable Ten. Stress, σ y= =_

fos

[σ ¿¿ t ] 16 M t

Allowable Shear stress[τ]=

2 √

¿= _ ; To det dia of shaft, d s = 3

π (τ )

= _ (psg5.30)

Sel of std spline, 8*46*50 can be selec. ; d s=46=inner dia; 8=no of spline ; 50= outer dia

To design cone, design assumption, total cone ; Angle, 2α=23º . therefore, α = 12.5º

Coeff of friction, μ=0.2, normal axial pre, Pa =0.25 ; Mean dia,d m =368=8*d s ; Step1> to det face width,

dm r max −r min

[ M t ]=μ* Pa(πd m *b) r m ; b=_. Check =4.5to8 ; Step2>to det r max & r min ; = sin α --eqn1

b b

r max +r min d m

; = --eqn-2 ; Solv. r max =_ ; r min =_ ; Actual α from the diagram as per pythagoras rule

2 2

Design of cup, generates t=10 – 15, say t=10mm ; t’=t+5=_. Thickness of friction lining, D0= D 1+2t=_

len of cone, L’=bcos α =_. Len of cup,L=t’+gap+L’ ; Note:1>if pres is 1to1.25 given pres is normal

Press. & get Pa = Pnsinα. 2>if given pres is around ; 0.25 it is axial press even though it is mentioned

Normal press intensity. ; Design of spring: Stepi> to det max force on spring,

Pmax =(πd m*b). Pa(sinα+rcosα) = _N. ; Step2> min force on spring, Pmin=(πd m*b). Pa*sinα=_

P max

Step3>deciding no of springs, let us 4 springs, =_ ; force on each spring [note there are two approach for

n

design of spring] 1>static load method, 2>static approach to variable loading. Use 1st method when

no of operations per hour(or per shaft)and/or life reqd ; method-I: use second method when given, ; psg1.17

[σ ¿¿ y /2]

spring steel SS 5:2 m90 ; (1.15psg) σ y=150kgf/mm² ; fos=2 ; hence allowable shear stress[τ]= ¿= _

fos

D 4 c−1 0.615

spring index=C= =_. ; then wohls factor(psg7.100) ; K s = + =1.2525. ; (psg7.100) τ =

d 4 c−4 c

K s∗8∗P c

, d=_

π∗d ²

8 PC ³ n

Mean coil dia=D=C*d=_. ; Let us assume compr of spring, y=6mm ; y= =_

Gd

8 PC ³ n

No of active coil,n=_ ; actual compr, ; y= =_ ; Assuming square & ground end, n’=n+2=_

Gd

Free length of spring, Lf =n’d+1.5y ; Spring specifications: 1>wire dia, d=11mm

2>coil mean dia,D=66; 3> free len, Lf =75mm ; 3>no of coil,n’=6 ; no of springs = 4

Lf −1 P

Pitch,P= ' =_ ; helix angle,α= tan = _<10º ; Method-II: note spring force should be less than2000

n −1 πD

P max no of ×used shift no of day

Let take 5 spring,P= =_. To det no of cycles ; To det no of cycle= * *

5 shift day year

4 6

*no of years =__.; frm psg7.102 as 10 <N<1*1 ; 7.105psg. ; trial d=6mm & gr 3mtrl therf, u =_. σ

DESIGN DATA---PSG TECH 7.115

Τ=_. ; psg7.100, τ= K s *

8 PC

= _check for stress ; Step1)Heat generated/cycle=[ M t ¿ avg∗θ =[

[ M t ] + D ]θ

πd ² 2

[ M t] 2 πN

= * wt J/cycle ; ω= = _. [Note:if t is not given t=o.1 sec]

2 60

H g =__ ; heat generated/hour=Hg*(no of cycle/hr)=_ ; Det heat generated when MI of rotating part is

[ Mt]

known,, I=mk² ; [ M t ¿=Iα ; α= ; find slip time,t’, v=u+at ; t=w/α

I

heat generated=avg torque * wt ; heat generated/hour=Hg*(no of cycle/hr)=_

DESIGN DATA---PSG TECH 7.115

You might also like

- Min Max: Design Data - PSG TechDocument4 pagesMin Max: Design Data - PSG TechYashrajNo ratings yet

- Flat BeltDocument2 pagesFlat BeltYashrajNo ratings yet

- Chain DriveDocument2 pagesChain DriveYashrajNo ratings yet

- Beton Treci Programski ZadatakDocument24 pagesBeton Treci Programski ZadatakMesanović EmirNo ratings yet

- Fluid Mechanics Assignment: Course No. Ce2130Document16 pagesFluid Mechanics Assignment: Course No. Ce2130Bikash Gaurav BhuyanNo ratings yet

- H H L L Q V Q A V η Q Q η Q A d: s d s d actDocument4 pagesH H L L Q V Q A V η Q Q η Q A d: s d s d actYashrajNo ratings yet

- Rezanje FORMULEDocument13 pagesRezanje FORMULEАлександар ВујаковићNo ratings yet

- Fluid mechanics assignment viscosity calculationDocument17 pagesFluid mechanics assignment viscosity calculationBikash Gaurav BhuyanNo ratings yet

- Pengolahan Data Pf-4 (Presesi'S Power) : 1. Meaasuring Fallent Time (T)Document5 pagesPengolahan Data Pf-4 (Presesi'S Power) : 1. Meaasuring Fallent Time (T)Shinta RazakNo ratings yet

- Sums of FlangesDocument19 pagesSums of FlangesRADHE GRAPHICS100% (1)

- Experiment No. 2: A. Aim: B. Software To Be Used: C. Equation To Be UsedDocument3 pagesExperiment No. 2: A. Aim: B. Software To Be Used: C. Equation To Be UsedAditya TiwariNo ratings yet

- Design of a mechanical bottle jack with bevel gearsDocument9 pagesDesign of a mechanical bottle jack with bevel gearsdagem100% (1)

- Solved Problems of Theory of Structures PolimiDocument47 pagesSolved Problems of Theory of Structures PolimiDario GiuaNo ratings yet

- Phys303K Dicus Exam4Solutions Spring08Document16 pagesPhys303K Dicus Exam4Solutions Spring08Kayla WorachekNo ratings yet

- Escuela Superior Politécnica De Chimborazo: D= P P U sin (θ) dθ d ∅ PDocument7 pagesEscuela Superior Politécnica De Chimborazo: D= P P U sin (θ) dθ d ∅ PJorge SaNo ratings yet

- Trabajo N°2 Concreto IiDocument12 pagesTrabajo N°2 Concreto IiJ Carlos MejíaNo ratings yet

- Post Task Final ActivityDocument19 pagesPost Task Final ActivityCristian VillegasNo ratings yet

- Calculation of Screw JackDocument20 pagesCalculation of Screw JackVenu Gopal RaoNo ratings yet

- Exercises Belt Drives 3Document14 pagesExercises Belt Drives 3ZIZIPHO MNTUMNINo ratings yet

- Stability of Gravity Dams and Minimum Slope for Guaranteed StabilityDocument32 pagesStability of Gravity Dams and Minimum Slope for Guaranteed StabilityManu RodrigoNo ratings yet

- Ujian Tengah Semester: R R R 4,407 MM 0,4407 CMDocument4 pagesUjian Tengah Semester: R R R 4,407 MM 0,4407 CMmegaNo ratings yet

- Governor Spring NumericalDocument3 pagesGovernor Spring NumericalHarsh RajNo ratings yet

- Homework 7Document4 pagesHomework 7Trung Kỹ PhạmNo ratings yet

- CLUTCHDocument6 pagesCLUTCHAboud MNo ratings yet

- Assignment 5 21122002Document7 pagesAssignment 5 21122002Aarav 127No ratings yet

- 1.) Reakcije U Osloncima Za Horizontalnu (X-Z) Osu: B Ax 1x 1z 4x 4z Ax 1x 1z 4x 4zDocument6 pages1.) Reakcije U Osloncima Za Horizontalnu (X-Z) Osu: B Ax 1x 1z 4x 4z Ax 1x 1z 4x 4zelma spahicNo ratings yet

- StalpvDocument10 pagesStalpvAdrian LooZyNo ratings yet

- Hasil Perhitungan Percobaan Nozel HorizontalDocument18 pagesHasil Perhitungan Percobaan Nozel HorizontalLuiiz AziizNo ratings yet

- Projekt Kursi MetalikeDocument26 pagesProjekt Kursi MetalikeGledis Kallogjeri50% (2)

- Machine Foundation Natural FrequenciesDocument13 pagesMachine Foundation Natural FrequenciesArshad RazaNo ratings yet

- Annex 3 - Jose - Marino - Franco - Alzate - Task 3.Document15 pagesAnnex 3 - Jose - Marino - Franco - Alzate - Task 3.José marino Franco AlzateNo ratings yet

- CQQQQQDocument21 pagesCQQQQQanshumanbadgujarNo ratings yet

- Exercise 2 and 3 StagefinalDocument5 pagesExercise 2 and 3 StagefinalFernando SierraNo ratings yet

- 09 P Example Shear (Lecturenotes)Document5 pages09 P Example Shear (Lecturenotes)Matteo SoruNo ratings yet

- Compensation To Opening Sums NptelDocument9 pagesCompensation To Opening Sums NptelRADHE GRAPHICSNo ratings yet

- Sabuk-V - Muhammad Nurrizal Zabawi - 160511609258Document2 pagesSabuk-V - Muhammad Nurrizal Zabawi - 160511609258Slamet BarokahNo ratings yet

- Centrifugation Calculation ExamplesDocument18 pagesCentrifugation Calculation ExamplesAmitava BhowmikNo ratings yet

- Normalise wind turbine power curvesDocument6 pagesNormalise wind turbine power curvesSaibabakrishna KommulaNo ratings yet

- Dimensionamiento de Helicoidal (N1)Document16 pagesDimensionamiento de Helicoidal (N1)Rofer AldanaNo ratings yet

- E.3.1 Cheap Removal Process - Cutting ForceDocument34 pagesE.3.1 Cheap Removal Process - Cutting ForceMesfin SisayNo ratings yet

- Som Unit - 1.1.2 Prismatic Bar With FosDocument1 pageSom Unit - 1.1.2 Prismatic Bar With FosNagamani ArumugamNo ratings yet

- IspitOtpornost 03-09-2007Document6 pagesIspitOtpornost 03-09-2007Anonymous uJffWRZnNo ratings yet

- Waffle Slab-Plate TheoryDocument2 pagesWaffle Slab-Plate TheoryAbdur RahimNo ratings yet

- Design Steps For SlabsDocument7 pagesDesign Steps For SlabsdhanashekarVNo ratings yet

- QL 30 KN/M QD 23 KN/M + Berat Sendiri D HDocument5 pagesQL 30 KN/M QD 23 KN/M + Berat Sendiri D HAdam FaisalNo ratings yet

- ECS550NFB Introduction To Numerical Methods Using Matlab Day 5Document45 pagesECS550NFB Introduction To Numerical Methods Using Matlab Day 5Pham Hai YenNo ratings yet

- Flight Dynamics: Minimum Turn Radius and Ground Roll AnalysisDocument2 pagesFlight Dynamics: Minimum Turn Radius and Ground Roll AnalysisAaysha Anser BabuNo ratings yet

- Contoh Identifikasi Mineral: Max MinDocument6 pagesContoh Identifikasi Mineral: Max Mindeny saputro arifinNo ratings yet

- Maximum Glide Performance of AircraftDocument6 pagesMaximum Glide Performance of AircraftEmine YıldızNo ratings yet

- Mechanical Engineering TestDocument19 pagesMechanical Engineering TestKevin OnyangoNo ratings yet

- Annex 5 - ElectromagnetismoDocument16 pagesAnnex 5 - ElectromagnetismocarlosNo ratings yet

- Optical Fiber Solution2 HITDocument6 pagesOptical Fiber Solution2 HITMichael NaymarkNo ratings yet

- Mathcad - Zabatni Stup3Document10 pagesMathcad - Zabatni Stup3Martin BrnelićNo ratings yet

- PHYS 101 - General Physics-I, Final ExamDocument8 pagesPHYS 101 - General Physics-I, Final ExamhuuuzenNo ratings yet

- Step 2: Determine The Active Number of Coils Using Deflection EquationDocument10 pagesStep 2: Determine The Active Number of Coils Using Deflection Equationaravindangokul687No ratings yet

- Excentrica 6 DDocument5 pagesExcentrica 6 DMao Cristhian Pinto CruzNo ratings yet

- Design of FootingDocument15 pagesDesign of FootingRickyNo ratings yet

- Improving Overall Efficiency of The Cutting Machines by Implementation of Pillars of TPMDocument25 pagesImproving Overall Efficiency of The Cutting Machines by Implementation of Pillars of TPMYashrajNo ratings yet

- Is 2062 1999 PDFDocument9 pagesIs 2062 1999 PDFYashrajNo ratings yet

- Improving Overall Efficiency of The Cutting Machines by Implementation of Pillars of TPMDocument25 pagesImproving Overall Efficiency of The Cutting Machines by Implementation of Pillars of TPMYashrajNo ratings yet

- Gear Pump DesignDocument5 pagesGear Pump DesignYashrajNo ratings yet

- E MarketingDocument9 pagesE MarketingYashrajNo ratings yet

- H H L L Q V Q A V η Q Q η Q A d: s d s d actDocument4 pagesH H L L Q V Q A V η Q Q η Q A d: s d s d actYashrajNo ratings yet

- Diesel EngineDocument2 pagesDiesel EngineYashrajNo ratings yet

- Black BookDocument54 pagesBlack BookYashrajNo ratings yet

- Gears (Spur, Helical, Worm & Worm Wheel, Bevel) oDocument6 pagesGears (Spur, Helical, Worm & Worm Wheel, Bevel) oYashraj100% (1)

- Design of Belt ConveyorsDocument5 pagesDesign of Belt ConveyorsYashrajNo ratings yet

- Bearing Subjected To Varying Load Cond: Design Data - PSG TechDocument5 pagesBearing Subjected To Varying Load Cond: Design Data - PSG TechYashrajNo ratings yet

- Gears (Spur, Helical, Worm & Worm Wheel, Bevel) oDocument6 pagesGears (Spur, Helical, Worm & Worm Wheel, Bevel) oYashraj100% (1)

- DME 2 TheoryDocument3 pagesDME 2 TheoryYashrajNo ratings yet

- Forces & Motion, IGCSEDocument4 pagesForces & Motion, IGCSEsapiniNo ratings yet

- Design of Cable Trench - R0Document17 pagesDesign of Cable Trench - R0RahulNo ratings yet

- Statics and Kinematics With Applications To Robotics, 1996Document192 pagesStatics and Kinematics With Applications To Robotics, 1996mohsenNo ratings yet

- University of the Philippines College of Science Physics 72 Problem Set (LE1Document14 pagesUniversity of the Philippines College of Science Physics 72 Problem Set (LE1JM MendigorinNo ratings yet

- Ls-Dyna From Predictive EngineeringDocument119 pagesLs-Dyna From Predictive EngineeringNagrajThadurNo ratings yet

- ELECTRIC FLUX & GAUSS'S LAW - QuizDocument5 pagesELECTRIC FLUX & GAUSS'S LAW - QuizAariya KumariNo ratings yet

- Chapter 2 Force and Motion STUDENTS MODULEDocument44 pagesChapter 2 Force and Motion STUDENTS MODULEAfiqah RoshidiNo ratings yet

- Rcd. Eval 6.4a Question PDFDocument1 pageRcd. Eval 6.4a Question PDFJoanne EscolanoNo ratings yet

- DC Pandey Solutions Part 2Document202 pagesDC Pandey Solutions Part 2Ashish Sharma100% (1)

- Mechanical Properties of Fluids Class 11 Notes Physics Chapter 10 - Learn CBSEDocument6 pagesMechanical Properties of Fluids Class 11 Notes Physics Chapter 10 - Learn CBSEAjith kNo ratings yet

- Airfoil Project ReportDocument30 pagesAirfoil Project ReportmahirNo ratings yet

- Antima Prahar Batch Day 1Document8 pagesAntima Prahar Batch Day 1Naman MahawarNo ratings yet

- COBEM 2019 Evaluation of The Mechanical Properties of Balsa Wood and Composite Materials PDFDocument10 pagesCOBEM 2019 Evaluation of The Mechanical Properties of Balsa Wood and Composite Materials PDFParmeshwar KotnurNo ratings yet

- Water Cooled Duct DesignDocument8 pagesWater Cooled Duct DesignpavanNo ratings yet

- Fluid Mechanics and HydraulicsDocument54 pagesFluid Mechanics and HydraulicsJorge Dominic Conde81% (32)

- Steel Beam Design Module ReviewDocument3 pagesSteel Beam Design Module ReviewDan CasuraoNo ratings yet

- Centrifugal Governor PDFDocument5 pagesCentrifugal Governor PDFArthur100% (1)

- Sec 02Document4 pagesSec 02Jeffy ShannonNo ratings yet

- 1.answers To Physics Question BankDocument18 pages1.answers To Physics Question BankMuhammad YousafNo ratings yet

- Activity 3 A2021Document20 pagesActivity 3 A2021Nat RodríguezNo ratings yet

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- Lempriere 1968Document5 pagesLempriere 1968Paulo UtargNo ratings yet

- IGCSE Physics Screening Test 1Document19 pagesIGCSE Physics Screening Test 1antonylukNo ratings yet

- Steel Section Capacities BS 5950 SpreadsheetDocument362 pagesSteel Section Capacities BS 5950 Spreadsheetihpeter100% (1)

- t235 1blk8.5Document173 pagest235 1blk8.5Karl AngeloNo ratings yet

- Mechanics of Materials II:: Thin-Walled Pressure Vessels and TorsionDocument7 pagesMechanics of Materials II:: Thin-Walled Pressure Vessels and TorsionWolf LordNo ratings yet

- Chute Design Considerations For Feeding and TransferDocument22 pagesChute Design Considerations For Feeding and TransferIsaac Kendall100% (2)

- Fluid Machiney Module 1Document27 pagesFluid Machiney Module 1Jacob BenningsNo ratings yet

- Ch01 ReviewedDocument39 pagesCh01 ReviewedRayhan AhmedNo ratings yet

- Rheology Measurements of A Biomass Slurry: An Inter-Laboratory StudyDocument12 pagesRheology Measurements of A Biomass Slurry: An Inter-Laboratory StudyNicolaus AnelkaNo ratings yet