Professional Documents

Culture Documents

Gas Flowmeter Sizing

Gas Flowmeter Sizing

Uploaded by

Ashkan KhajouieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Flowmeter Sizing

Gas Flowmeter Sizing

Uploaded by

Ashkan KhajouieCopyright:

Available Formats

Gas Flowmeter Sizing

Variable area flowmeters suitable for liquid service have a capacity rating based on water at 70 Fahrenheit. Flowmeters suitable for gas service have a capacity rating based on air at STP (70F, 14.7 PSIA) conditions. The correction factors listed below are used to calculate the flow capacity when using a liquid other than water or a gas other than air at STP conditions. GAS CORRECTION FORMULA Air Equivalent Flow Rate = Customer Gas Flow Rate X Gas Correction Factor Step 1: Convert Customer Gas Flow Rate unit of measure to a standard unit of measure for air flow (SCFM or SCCM). Step 2: Calculate Gas Correction Factor from given values.

From

Step 2: Calculate Gas Correction Factor from given values This information is required to size for conditions other than air at STP: Operating Temperature: _________F Operating Back Pressure:_________ PSIG Specific Gravity of Gas: _________ @STP

Temperature Conversions To Fahrenheit (C X 1.8) + 32 (K 273.15) 1.8 + 32 R 459.67 From LBS/FT KG/M MolWt g/cm Pressure Conversions From To PSIG From Pa PSIA ATM Torr Bars To PSIG (Pa101,300) X 14.7 Minus 14.7 (ATM X 14.7) 14.7 ((Torr760) X14.7) 14.7 ((Bars1.013) X14.7) 14.7 Gas Density Conversions To Specific Gravity Divide by 0.075 Divide by 1.2 Divide by 29.0 Divide by 0.0012

Step 3 : Calculate the product of the Air Equivalent Flow Rate from the Customer Gas Flow Rate and the Gas Correction Factor. Step 4: Calculate the maximum or minimum flow rate for the customers conditions. Step 1: Convert Customer Gas Flow Rate unit of measure to a standardunit of measure for air flow Customer Gas Flow Rate ________________ Converted Gas Flow Rate ________________ SCFM / SCCM

Gas Flow Rate Conversions From SCFH SCIM SLPM SM/MIN SM/HR NM/MIN NM/HR SCCM KG/MIN KG/HR To SCFM Divide by 60 Divide by 1,728 Divide by 28.317 Multiply by 35.31 Multiply by 0.5885 Multiply by 37.99 Multiply by 0.6331 Divide by 28,317 Multiply by (29.39 SpGr) Multiply by (0.49 SpGr) From SCFM SCFH SCIM SLPM SLPH To SCCM Multiply by 28,317 Multiply by 472 Multiply by 16.39 Multiply by 1,000 Multiply by 16.67

Centigrade Kelvin Rankine

foot Water Divide by 2.308 Inch Water Divide by 27.73 mm Water inch Hg mm Hg kg/cm kPa Divide by 704 Divide by 2.036 Divide by 51.7 Multiply by 14.228 (kPa101.3) X 14.7

Millibar ((Millibars1013) X 14.7) 14.7

Gas Correction Factor (GCF) formula:

SM/MIN Multiply by 1,000,000 SM/HR Multiply by 16,667

NM/MIN Multiply by 1,075,785 NM/HR KG/MIN KG/HR Multiply by 17,929 Multiply by (832,000 SpGr) Multiply by (13,876 SpGr)

GCF = _________________ Step 3: Determine the Air Equivalent Flow Rate. Air Equivalent Flow Rate = Customer Gas Flow Rate x Gas Correction Factor Air Equivalent Flow Rate = ____________________ Step 4: Calculate the maximum or minimum flow rate for the customers conditions (Customer Gas Flow Rate Scale) Customer Gas Flow Rate Scale = Catalog Flow Rate Gas Correction Factor Customer Gas Flow Rate Scale = ______________________

LBS/MIN Multiply by (13.33 SpGr) LBS/HR Multiply by(0.2222 SpGr)

LBS/MIN Multiply by (377,500 SpGr) LBS/HR Multiply by (6,292 SpGr)

LBS/DAY Multiply by (0.00926 SpGr) ACFM

Multiply by [[(Operating PSIG+14.7)(530)] [(14.7)(Operating F+460)]]

Ph: (714) 891-0008 sales@kinginstrumentco.com 12700 Pala Drive Garden Grove, CA 92841

Mission Statement |

Quality Made In The U.S.A.

You might also like

- Classnote 548fee8d37792Document46 pagesClassnote 548fee8d37792vinay guttNo ratings yet

- PMS PDFDocument215 pagesPMS PDFAlvin Smith100% (4)

- Gas MeasurementDocument126 pagesGas MeasurementDevend HarinkhedeNo ratings yet

- Cvsize (Control Valve Sizing)Document8 pagesCvsize (Control Valve Sizing)EslamSheblNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsRating: 4 out of 5 stars4/5 (9)

- API 12j Two Phase Separator Sizing - Api Rp520 Relief Valve SizingDocument13 pagesAPI 12j Two Phase Separator Sizing - Api Rp520 Relief Valve SizingOmer EkerNo ratings yet

- Halliburton TallybookDocument40 pagesHalliburton TallybookmimostarNo ratings yet

- Performance Galileo Mx521Document1 pagePerformance Galileo Mx521Juan AlarconNo ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- Gpa 2172-09 FaqDocument1 pageGpa 2172-09 FaqschabirgNo ratings yet

- Validation Report On The 2 Phase Line Sizing 3 PDFDocument18 pagesValidation Report On The 2 Phase Line Sizing 3 PDFJoseph MedinaNo ratings yet

- 02-Gas Compression Fundamentals-1Document47 pages02-Gas Compression Fundamentals-1Muhammad Asad100% (3)

- Gas Compression IIDocument13 pagesGas Compression IIAnuraag MulpuriNo ratings yet

- How To Take MMS and Its BenefitsDocument2 pagesHow To Take MMS and Its BenefitsBenjamin SteylNo ratings yet

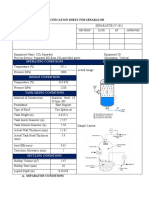

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Halliburton CalculationsDocument71 pagesHalliburton CalculationsIGNATIUS MANOSAYNo ratings yet

- Gas Condensate ReservoirDocument33 pagesGas Condensate ReservoirMohammad Iqbal Mahamad Amir100% (3)

- 03-Gas Compression FundamentalsDocument28 pages03-Gas Compression Fundamentalssyahrieza100% (1)

- Chemical Treatment ManualDocument42 pagesChemical Treatment Manualwertyyy100% (5)

- Flare Gas Recovery Helpful InformationDocument2 pagesFlare Gas Recovery Helpful InformationKalai SelvanNo ratings yet

- Halliburton Main Menu Calculations Grey BookDocument66 pagesHalliburton Main Menu Calculations Grey BookmimostarNo ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- Nano InkDocument16 pagesNano InkNeha SinghNo ratings yet

- Nomenclature For Gpsa Engineering Data Book, 12 ED. Section 9, Heat ExchangersDocument8 pagesNomenclature For Gpsa Engineering Data Book, 12 ED. Section 9, Heat ExchangersshikerNo ratings yet

- Steam Calculation On Basis of Flow-Temperature (1) 2222Document5 pagesSteam Calculation On Basis of Flow-Temperature (1) 2222hmaza shakeelNo ratings yet

- Process Calculations & Fan Audit Module in Cement IndustryDocument99 pagesProcess Calculations & Fan Audit Module in Cement IndustryNITITN ASNANINo ratings yet

- WorkBook - CalculationsDocument30 pagesWorkBook - CalculationsHunterNo ratings yet

- Halliburton Main Menu Ver 3Document83 pagesHalliburton Main Menu Ver 3Alejandro RivasNo ratings yet

- AER423 Lab - Thermal Conductivity and Contact ResistanceDocument10 pagesAER423 Lab - Thermal Conductivity and Contact ResistanceHassanKhanNo ratings yet

- PTM-68-P3-CS-002 - Fuel Gas Filter - Rev.0Document1 pagePTM-68-P3-CS-002 - Fuel Gas Filter - Rev.0Indraharja FerryNo ratings yet

- Baru Gas Plant DemandDocument4 pagesBaru Gas Plant DemandBop AlberthaNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Calculo Separador BifasicoDocument3 pagesCalculo Separador BifasicoLuisa Garcia100% (1)

- 7 - Performance Test PLTMGDocument11 pages7 - Performance Test PLTMGEfria Nto100% (1)

- Reactors and Separations Design Project Production of CumeneDocument7 pagesReactors and Separations Design Project Production of CumeneAli RahimiNo ratings yet

- Gas Flowmeter SizingDocument1 pageGas Flowmeter SizingtungluongNo ratings yet

- Variable Area Flowmeter PresentationDocument17 pagesVariable Area Flowmeter PresentationRoger GimenesNo ratings yet

- Well Control Concurent MethodeDocument4 pagesWell Control Concurent MethodeRakhmad HanifNo ratings yet

- 4 Marstein M Corrections Related To Operation and Calibration of Liquid Flow Meters PDFDocument38 pages4 Marstein M Corrections Related To Operation and Calibration of Liquid Flow Meters PDFAmilkar Kindelan GonzalezNo ratings yet

- Rotameter SizingDocument1 pageRotameter SizingDave ToExtreme100% (1)

- Unit ConversionDocument28 pagesUnit ConversionSofia MermingiNo ratings yet

- Gas DensityDocument4 pagesGas DensityjollyNo ratings yet

- Nomenclature For Gpsa Engineering Data Book, 12 ED. Section 9, Heat ExchangersDocument8 pagesNomenclature For Gpsa Engineering Data Book, 12 ED. Section 9, Heat ExchangersRajesh PanchalNo ratings yet

- Boys Gas CalorimeterDocument10 pagesBoys Gas CalorimeterAbood Al-atiyatNo ratings yet

- Distillation Column SizingDocument12 pagesDistillation Column SizingNitin Kurup0% (1)

- Tarea 8 Bombas Damian A61610 Minor B06661Document7 pagesTarea 8 Bombas Damian A61610 Minor B06661Orlando Porras MoraNo ratings yet

- Flow Formulas: For Computing Gas and Liquid Flow Through Regulators and ValvesDocument4 pagesFlow Formulas: For Computing Gas and Liquid Flow Through Regulators and ValvesAhmed AbdelatyNo ratings yet

- Annexure-II: West Kuwait GC-01 01-FIT-5102 9/nov/18 Crude OilDocument3 pagesAnnexure-II: West Kuwait GC-01 01-FIT-5102 9/nov/18 Crude Oila.r.sarateNo ratings yet

- Biogas CompressorDocument5 pagesBiogas CompressorPeace AdetunmibiNo ratings yet

- 9.10 Hydrocarbon Equivalence Issues 9.10.1 Gas Conversion To Oil Equivalent. Converting Gas Volumes To An Oil Equivalent IsDocument4 pages9.10 Hydrocarbon Equivalence Issues 9.10.1 Gas Conversion To Oil Equivalent. Converting Gas Volumes To An Oil Equivalent IsMarcelo AyllonNo ratings yet

- Surfce ProductionDocument28 pagesSurfce ProductionIffatNo ratings yet

- MELAB3 Experiment 3Document19 pagesMELAB3 Experiment 3Russelle GoNo ratings yet

- Gaseous Emissions CalculationsDocument6 pagesGaseous Emissions CalculationsGXGGXGNo ratings yet

- Reduction of Nitrobenzene To AnilineDocument37 pagesReduction of Nitrobenzene To AnilineRollerCNo ratings yet

- Compressor RefrigeranteDocument19 pagesCompressor RefrigeranteAlbert CalderonNo ratings yet

- Circulation Heaters Engineering InformationDocument3 pagesCirculation Heaters Engineering InformationWaqasNo ratings yet

- Quasi-Steady State Model of An Ice Rink Refrigeration System PDFDocument14 pagesQuasi-Steady State Model of An Ice Rink Refrigeration System PDFSantanu DattaNo ratings yet

- Nomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangersDocument8 pagesNomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangerstizeskiNo ratings yet

- Natural Gas Measurement ConversionsDocument2 pagesNatural Gas Measurement ConversionsGolub MarkoNo ratings yet

- Pressure TableDocument9 pagesPressure TableJL PerezNo ratings yet

- A3 SeparatorDocument59 pagesA3 SeparatorHaziq YussofNo ratings yet

- 2-S Petrol EngineDocument5 pages2-S Petrol EngineAbNo ratings yet

- Assignment 1 Key Learning Objectives: Figure 1 Evans DiagramDocument7 pagesAssignment 1 Key Learning Objectives: Figure 1 Evans DiagramAnke FanNo ratings yet

- SFH6106 SFH6116 SFH6156 SFH6186 SFH6206 SFH6286: 5.3 KV TRIOS High Reliability OptocouplersDocument1 pageSFH6106 SFH6116 SFH6156 SFH6186 SFH6206 SFH6286: 5.3 KV TRIOS High Reliability OptocouplersMOAZNo ratings yet

- Polymers: Versatile Polypropylene Copolymers From A Pilot-Scale Spheripol II ProcessDocument16 pagesPolymers: Versatile Polypropylene Copolymers From A Pilot-Scale Spheripol II ProcessArfan MushtaqNo ratings yet

- Hau Tier 2011Document14 pagesHau Tier 2011imaneabdelrhaforNo ratings yet

- Ofc Important QuestionsDocument2 pagesOfc Important QuestionsPriyabrat DashNo ratings yet

- 152 Lab 4 Report Thermodynamics I Calorimetry Take-Home SubmissionDocument8 pages152 Lab 4 Report Thermodynamics I Calorimetry Take-Home Submissionapi-708935718No ratings yet

- Attachment of 3 - (Aminopropyl) Triethoxysilane On Silicon Oxide Surfaces: Dependence On Solution TemperatureDocument9 pagesAttachment of 3 - (Aminopropyl) Triethoxysilane On Silicon Oxide Surfaces: Dependence On Solution TemperatureJosé Manuel UsuriagaNo ratings yet

- Avalure Flex-6 Skin and ColorDocument4 pagesAvalure Flex-6 Skin and ColorKirk BorromeoNo ratings yet

- Formula Mass and Mole Calculation Practice WorksheetDocument4 pagesFormula Mass and Mole Calculation Practice WorksheetKelsey NuñezNo ratings yet

- KineticsDocument1 pageKineticsWinsletJoyDauagNo ratings yet

- Whatsnew - v2021.4 To v2023.1Document18 pagesWhatsnew - v2021.4 To v2023.1Ian MannNo ratings yet

- General Organic ChemistryDocument5 pagesGeneral Organic ChemistryG RNo ratings yet

- X-Ray Emission Spectroscopy, MethodsDocument5 pagesX-Ray Emission Spectroscopy, MethodstahriNo ratings yet

- Environmental Engineering-I Lab Open Ended Lab: Engr. Muhammad WaleedDocument13 pagesEnvironmental Engineering-I Lab Open Ended Lab: Engr. Muhammad WaleedSaroosh ul Musatafa CheemaNo ratings yet

- 314 Topic 01 Pages 27-64Document40 pages314 Topic 01 Pages 27-64ehmedNo ratings yet

- Adsorption of Metal-Phthalocyanine Molecule On Aluminum (100) Surface: The DFT StudyDocument10 pagesAdsorption of Metal-Phthalocyanine Molecule On Aluminum (100) Surface: The DFT Studyayari samiNo ratings yet

- 65408a2e8680950018b0ed5a - ## - Amines Practice SheetDocument18 pages65408a2e8680950018b0ed5a - ## - Amines Practice SheetdevanshbcollabNo ratings yet

- Review Table of Surface TensionDocument4 pagesReview Table of Surface TensionmariyanaNo ratings yet

- Drop Wise and Film Wise CondensationDocument20 pagesDrop Wise and Film Wise CondensationRamya MNo ratings yet

- Header DesignDocument12 pagesHeader DesignGun SmithNo ratings yet

- Solubility Enhancement of Poorly Water Soluble Drugs by Solid DispersionDocument10 pagesSolubility Enhancement of Poorly Water Soluble Drugs by Solid Dispersiondini hanifaNo ratings yet

- By: Audrey PriddyDocument10 pagesBy: Audrey PriddydheenathayalNo ratings yet

- CHM 131 2Document10 pagesCHM 131 2Zunnurain AmniNo ratings yet

- Chemistry: Higher 2 (2017) (Syllabus 9647)Document45 pagesChemistry: Higher 2 (2017) (Syllabus 9647)Ng Shu QingNo ratings yet