Professional Documents

Culture Documents

Ucs-56 PWHT PDF

Uploaded by

Jaeup YouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ucs-56 PWHT PDF

Uploaded by

Jaeup YouCopyright:

Available Formats

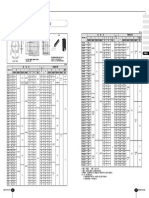

UCS-56 PWHT

NOTES (2) Post weld heat treatment is mandatory under the following conditions PWHT (a) For welded joints over 38mm nominal thickness. 38mm (b) For welded joints over 32mm nominal thickness Through 38mm nominal thickness unless preheat Is applied at a minimum temperature 93 Centigrade during welding 32mm~38mm 93 (c) For weld joints of all thickness if required by UW-2, except post weld heat treatment is not Mandatory under the conditions specified below UW-2 PWHT , PWHT . (1) For groove welds not over 13mm(1/2) size and Fillet welds with a throat not over 13mm(1/2) that Attach nozzle connections that have a finished inside Diameter not greater than 51mm(2), provided the Connections do not form ligaments that require an Increase in shell or head thickness, and preheat to a Minimum temperature of 93 Centigrade is applied. 13mm 51mm form ligaments 93 PWHT .

Form Ligaments

(2) For groove welds not over 13mm in (1/2) size or Fillet welds with a throat thickness of 13mm(1/2) Or less that attach tube to tubesheet when the tube Diameter does not exceed 50mm. A preheat of 95 Centigrade minimum must be applied When the carbon content of the tubesheet exceeds 0.22% 50mm 13mm 0.22% 95 PWHT . (3) For groove welds not over 13mm in (1/2) size or Fillet welds with a throat thickness of 13mm(1/2) Or less used for attaching nonpresure parts to Pressure parts provided preheat to a minimum temp. 95 Centigrade is applied when the thickness of the Pressure parts exceeds 32mm. 13mm 32mm 95 PWHT . (4) For studs welded to pressure parts provided preheat To a minimum temp. of 95 Centigrade is applied when The thickness of the pressure part exceed 32mm 32mm 95 PWHT . (5) For corrision resistant weld metal overlay cladding of For welds attaching corrision resistant applied lining

(see UCL-34) provided preheat to a minimum temp. of 95 Centigrade is maintained during application of the first layer when the thickness of the pressure part exceeds 32mm 32mm 95 PWHT . (c) (1) ~(5) (1) Shell plate Hole( 50mm ) (2) Tube to Tubsheet (3) Nonpresure parts to Pressure parts (4) For studs welded to pressure parts (5) For corrision resistant weld metal overlay cladding

PWHT Notch PWHT UCS-56 . UCS-56 (f)

Weld repairs to P-No 1 Group No 1,2 and 3 materials and P-No 3 Group No 1,2 and 3 materials and to the weld metals used to join These materials may be made after the final PWHT but prior to The final hydrostatic test, without additional PWHT PWHT P-No 1 (Gr1,2 &3) P-No 3 (Gr1,2 &3) 13mm 13mm 95 PWHT .

You might also like

- 용접사자격인증검증 (WQ)Document13 pages용접사자격인증검증 (WQ)이경철No ratings yet

- asme code해설 (용접)Document18 pagesasme code해설 (용접)김강형100% (1)

- (FLANGE) Catalog Korean 현대Document228 pages(FLANGE) Catalog Korean 현대이용호No ratings yet

- ASME Sec (1) .IX 정리Document10 pagesASME Sec (1) .IX 정리Hyunjong MoonNo ratings yet

- Base PlateDocument3 pagesBase Plate임동섭No ratings yet

- M-111-2015 - 압력용기의 용접설계에 관한 기술지침 PDFDocument12 pagesM-111-2015 - 압력용기의 용접설계에 관한 기술지침 PDFBDNo ratings yet

- 비파괴 강의교제 (CJ)Document43 pages비파괴 강의교제 (CJ)PARK, SANGYEOLNo ratings yet

- 배관설계 PDFDocument33 pages배관설계 PDFJaeup YouNo ratings yet

- PAUT 및 TOFD의 장단점 비교Document19 pagesPAUT 및 TOFD의 장단점 비교Yulkyung SungNo ratings yet

- 10장 접합부 설계 이론부분Document50 pages10장 접합부 설계 이론부분Mark JooNo ratings yet

- 국가규격해설Document14 pages국가규격해설서진석No ratings yet

- MDMT 결정방법Document22 pagesMDMT 결정방법최승원No ratings yet

- Asme Impact TestDocument66 pagesAsme Impact TestNeelam AhmadNo ratings yet

- asmesecviiicode의요약 PDFDocument12 pagesasmesecviiicode의요약 PDF윤종주No ratings yet

- ASME Ⅰ - Ⅷ - B31.1 code NDE요건 정리Document4 pagesASME Ⅰ - Ⅷ - B31.1 code NDE요건 정리이훈100% (1)

- WPS & PQR 작성지침 및 해설Document34 pagesWPS & PQR 작성지침 및 해설백종균0% (1)

- lpg저장탱크-용접시방 시편 등Document8 pageslpg저장탱크-용접시방 시편 등Kyeong Cheol LeeNo ratings yet

- Cswip번역교재 03 Weld ImperfectionsDocument18 pagesCswip번역교재 03 Weld Imperfectionskyeong cheol leeNo ratings yet

- 2013KEPIC 용어집Document627 pages2013KEPIC 용어집kangsungjin100% (1)

- Astm 주요 재료 TableDocument6 pagesAstm 주요 재료 Table임동섭No ratings yet

- 펌프 집합체 유동 및 구조해석Document30 pages펌프 집합체 유동 및 구조해석kiyong71.cho2554No ratings yet

- API 1104 - Module 5Document18 pagesAPI 1104 - Module 5kyeong cheol lee0% (1)

- 금속표준용어집 (2009) PDFDocument435 pages금속표준용어집 (2009) PDFJaehong JangNo ratings yet

- M-118-2016 배관제작 및 설치에 관한 기술지침Document16 pagesM-118-2016 배관제작 및 설치에 관한 기술지침정재열No ratings yet

- RE500-철근 앵커메뉴얼 2007Document9 pagesRE500-철근 앵커메뉴얼 2007Jae Huan YooNo ratings yet

- M-69-2012 압력용기의 잔여수명 평가에 관한 기술지침Document27 pagesM-69-2012 압력용기의 잔여수명 평가에 관한 기술지침정재열No ratings yet

- 압력용기 제작기준․안전기준 및 검사기준Document6 pages압력용기 제작기준․안전기준 및 검사기준Lim DongseopNo ratings yet

- D-03-2001 (배관 등의 비파괴검사 및 열처리에 관한 기술지침)Document13 pagesD-03-2001 (배관 등의 비파괴검사 및 열처리에 관한 기술지침)정재열No ratings yet

- 추출 2.en.koDocument35 pages추출 2.en.kowjdghk2104No ratings yet

- 추출 2.en.koDocument38 pages추출 2.en.kowjdghk2104No ratings yet

- 교육일지 230613 (김정훈)Document16 pages교육일지 230613 (김정훈)성운황No ratings yet

- 용기검사기준Document10 pages용기검사기준BS AhnNo ratings yet

- KDS143125 File 20171226Document50 pagesKDS143125 File 20171226최광민No ratings yet

- C05300 깊은기초Document25 pagesC05300 깊은기초igaecNo ratings yet

- D-16-2002 (위험물 저장, 취급 화학설비의 고무라이닝에 관한 기술지침)Document20 pagesD-16-2002 (위험물 저장, 취급 화학설비의 고무라이닝에 관한 기술지침)정재열No ratings yet

- 국내외설계기준비교분석 철근정착길이및겹침이음길이Document9 pages국내외설계기준비교분석 철근정착길이및겹침이음길이Dong-Yong KimNo ratings yet

- E-117-2014 분진 폭발위험장소에서의 전기설비 선정 및 설치에 관한 기술지침Document22 pagesE-117-2014 분진 폭발위험장소에서의 전기설비 선정 및 설치에 관한 기술지침정재열100% (1)

- Dine2006 KoreaDocument242 pagesDine2006 KoreaErlangga Nur Alamsyah100% (1)

- LC (Ulkep-T002)Document16 pagesLC (Ulkep-T002)손선호No ratings yet

- K60614 2 6Document16 pagesK60614 2 6segomezpNo ratings yet

- 61100시멘트모르터바름Document3 pages61100시멘트모르터바름Paul SongNo ratings yet

- 카타로그 (창성기공)Document20 pages카타로그 (창성기공)Nshuti Rene FabriceNo ratings yet

- ASTM D624 고무 Tearing 강도시험 SB PDFDocument10 pagesASTM D624 고무 Tearing 강도시험 SB PDFMinKyu ParkNo ratings yet

- D-37-2012 화학설비 등의 공정설계에 관한 기술지침Document37 pagesD-37-2012 화학설비 등의 공정설계에 관한 기술지침최재원No ratings yet

- Anchoring To Concrete of ACI 318-11Document6 pagesAnchoring To Concrete of ACI 318-11it's me. moonNo ratings yet

- 국도건설공사 설계실무요령2021 5-02설계요령Document11 pages국도건설공사 설계실무요령2021 5-02설계요령이동욱No ratings yet

- D-39-2000 (수소 벤트스택 및 배관의 공정설계 지침)Document11 pagesD-39-2000 (수소 벤트스택 및 배관의 공정설계 지침)정재열No ratings yet

- Rg 목재타공흡음패널 시방서Document7 pagesRg 목재타공흡음패널 시방서Daesung JiNo ratings yet

- P19 ManualDocument43 pagesP19 ManualAjin SNo ratings yet

- Ms 01 107Document21 pagesMs 01 107황철No ratings yet

- 화기감시자 교육자료 (신버전) -1Document7 pages화기감시자 교육자료 (신버전) -1Juhyung LeeNo ratings yet

- Acoplamiento Engranajes WCH PDFDocument18 pagesAcoplamiento Engranajes WCH PDFRobert SimmonsNo ratings yet

- Acoplamiento Rejilla WCH PDFDocument17 pagesAcoplamiento Rejilla WCH PDFRobert SimmonsNo ratings yet

- SIL SWL 문제 체결Document68 pagesSIL SWL 문제 체결Juhyung LeeNo ratings yet

- ★스트럿-타이 모델링 개선등을 통한 교각 코핑 설계 방안 검토 (최종)Document16 pages★스트럿-타이 모델링 개선등을 통한 교각 코핑 설계 방안 검토 (최종)Suzon IkramNo ratings yet

- 벽체 결로 계산 예시Document5 pages벽체 결로 계산 예시최우혁No ratings yet

- 철골공장+시험+및+검사+작업절차서Document10 pages철골공장+시험+및+검사+작업절차서MagicmomNo ratings yet

- api 1104 - module 4 - (9,10장)Document12 pagesapi 1104 - module 4 - (9,10장)kyeong cheol leeNo ratings yet

- D3566 1999 PDFDocument16 pagesD3566 1999 PDFYongSun ChoNo ratings yet

- 유압실린더 90-F33-01-1152Document1 page유압실린더 90-F33-01-1152임동섭No ratings yet

- Ootp TransDocument6 pagesOotp TransJaeup YouNo ratings yet

- 건설 용어 - 부분7Document1 page건설 용어 - 부분7Jaeup YouNo ratings yet

- 밸브 부분14Document2 pages밸브 부분14Jaeup YouNo ratings yet

- 밸브 부분3Document2 pages밸브 부분3Jaeup YouNo ratings yet

- 건설 용어 - 부분7Document1 page건설 용어 - 부분7Jaeup YouNo ratings yet

- 건설 용어 - 부분3Document1 page건설 용어 - 부분3Jaeup YouNo ratings yet

- 건설 용어 - 부분5Document1 page건설 용어 - 부분5Jaeup YouNo ratings yet

- 건설 용어 - 부분6Document1 page건설 용어 - 부분6Jaeup YouNo ratings yet

- 건설 용어 - 부분1Document1 page건설 용어 - 부분1Jaeup YouNo ratings yet

- astm (미국재료표준협회) 분류표 - 부분4 PDFDocument2 pagesastm (미국재료표준협회) 분류표 - 부분4 PDFJaeup YouNo ratings yet

- sus탱크강도계산 PDFDocument2 pagessus탱크강도계산 PDFJaeup YouNo ratings yet

- 도면용어 (version 1) PDFDocument4 pages도면용어 (version 1) PDFJaeup YouNo ratings yet

- astm (미국재료표준협회) 분류표 - 부분2 PDFDocument2 pagesastm (미국재료표준협회) 분류표 - 부분2 PDFJaeup YouNo ratings yet