Professional Documents

Culture Documents

Calculo de K en Resortes

Uploaded by

Humberto GonzálezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculo de K en Resortes

Uploaded by

Humberto GonzálezCopyright:

Available Formats

Compression Spring Constant When determining a spring constant there are 2 different formulas you can use depending

which information you have available to you. The first formula is the one most commonly used when you know the dimensions on your spring but do not know your load and distance traveled on the spring. Compression Spring Constant k = Gd^4 / 8D^3N Explanation of Symbols: d = wire size (inches) D = Mean Diameter (inches) N = Number of active coils D / d = Index correction G = Shear Modulus of Material k = Spring Constant G-Value for Common Spring Materials Music Wire = 11.5 x 10^6 Stainless Steel = 11.2 x 10^6 Phospher Bronze = 5.9 x 10^6 Monel = 9.6 x 10^6 Inconel = 11.5 x 10^6 Copper = 6.5 x 10^6 Beryllium Copper = 6.9 x 10^6 Example of Calculating the Compression Spring Constant d = 0.035 inches OD = 0.500 inches D = 0.465 inches N=8 Wire Type = Music Wire G = 11.5 x 10^6 psi FL = 1.000 inches k = Gd^4 / 8D^3N k = (11.5 x 10^6) (0.035)^4) / 8 (0.465)^3 (8) k = 17.2571875 / 6.434856 k = 2.68 lbs / inch The other way to calculate the compression spring constant on your spring is if you know the load you want to achieve at a certain distance traveled. The formula to figure out your spring constant from a known load and distance traveled is Rate = Load / Distance Traveled For Example: Load = 10 pounds Travel = 4 inches Rate = 10 lbs / 4 inches Rate = 2.5 pounds / inch Extension Spring Constant Calculating your extension spring constant uses the same formula as the compression spring constant calculation. Make sure when measure your extension spring you have the correct measurement for each value. For more information on this please visit our spring measurement and specifications page.

Extension Spring Constant k = Gd^4 / 8D^3N Explanation of Symbols: d = wire size (inches) D = Mean Diameter (inches) N = Number of active coils D / d = Index correction G = Shear Modulus of Material k = Spring Constant G-Value for Common Spring Materials Music Wire = 11.5 x 10^6 Stainless Steel = 11.2 x 10^6 Phospher Bronze = 5.9 x 10^6 Monel = 9.6 x 10^6 Inconel = 11.5 x 10^6 Copper = 6.5 x 10^6 Beryllium Copper = 6.9 x 10^6

Example of Calculating the Extension Spring Constant d = 0.044 inches OD = 0.425 inches D = 0.381 inches N=5 Wire Type = Music Wire G = 11.5 x 10^6 psi FL = 1.250 inches k = Gd^4 / 8D^3N k = (11.5 x 10^6) (0.044)^4) / 8 (0.381)^3 (5) k = 43.103104 / 2.21225364 k = 19.472 lbs / inch The other way to calculate the extension spring constant on your spring is if you know the load you want to achieve at a certain distance traveled. The formula to figure out your spring constant from a known load and distance traveled is Rate = Load / Distance Traveled For Example: Load = 2 pounds Travel = 0.25 inches Rate = 2 lbs / 0.25 inches Rate = 8 pounds / inch Torsion Spring Constant: Calculating torsion spring constant is a little different than calculating the spring constant for compression or extension springs. Since a torsion spring travels in degrees and not linearly it needs a different formula. Below you can see the formula for torsion spring constant and an example of how the formula works. Rate Per 360 Degrees (R) = Ed^4 / 10.8 DN

Explanation of Symbols: d = wire size (inches) D = Mean Diameter (inches) N = Number of active coils R = Rate per 360 degrees S = Stress (lbs / square in) P = Load (lbs) M = Moment (inch-lbs) D / d = Index correction Modulus of Elasticity "E" for common spring wires. PSI x 10^6 Music Wire = 30 psi Stainless Steel = 28 psi Chrome Vanadium = 30 psi Chrome Silicon = 30 psi Phosphor Bronze = 15 psi Torsion Spring Rate Calculation Example: Formula: Rate Per 360 degrees = Ed^4 / 10.8 DN Spring Parameters d = 0.035 inches OD = 0.500 inches D = 0.465 inches N = 3 coils Wire Type = Music Wire E For Music Wire = 30 x 10^6

Example: Rate Per 360 Degrees = (30 x 10^6) (0.035^4) / 10.8 (0.465)(3) Rate Per 360 Degrees = 45.01875 / 15.066 Rate Per 360 Degrees = 2.988 pounds / 360 degrees To determine your rate per degree divide the above answer by 360 Rate Per Degree = Rate Per 360 Degrees / 360 Rate Per Degree = 2.988 / 360 Rate Per Degree = 0.0083 pounds / degree

You might also like

- Lecture1-2 15852 SpringsDocument160 pagesLecture1-2 15852 SpringsL.K. BhagiNo ratings yet

- UNIT-4: Design of Energy Storing Elements & Engine ComponentsDocument36 pagesUNIT-4: Design of Energy Storing Elements & Engine ComponentsArun Pravin APNo ratings yet

- Connecting RodDocument15 pagesConnecting RodAafreen Mushtaq100% (2)

- Mechanical ShaftsDocument52 pagesMechanical ShaftsErnesto Elljr Landisan Locaben Jr.75% (16)

- Drilling Torque & DragDocument66 pagesDrilling Torque & DragShamit Rathi100% (1)

- Pipe or Tubing Support Span Calculations 5434Document2 pagesPipe or Tubing Support Span Calculations 5434engg_mech7750% (2)

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- Automotive Steel Design Manual PDFDocument773 pagesAutomotive Steel Design Manual PDFLuis Hamilton Ramos Córdova100% (1)

- Piping CalculationsDocument9 pagesPiping CalculationsSuper 7No ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Design of Connecting RodDocument8 pagesDesign of Connecting RodDarshan Shinde0% (1)

- Aluminium Alloy AMS 4050 T7451 Plate 223Document2 pagesAluminium Alloy AMS 4050 T7451 Plate 223raoz810% (1)

- Engine Building FormulasDocument4 pagesEngine Building FormulasAbhijeet FeelproudNo ratings yet

- Design of Helical SpringsDocument32 pagesDesign of Helical SpringsAHMAD FIRDAUS ILIAS100% (1)

- Workshop CalculationDocument64 pagesWorkshop Calculationbentapada100% (1)

- Aluminum BronzeDocument37 pagesAluminum Bronzepipedown456100% (1)

- Section 26 05 33-Electrical Raceways PDFDocument14 pagesSection 26 05 33-Electrical Raceways PDFmasoodaeNo ratings yet

- Pipe CalculationDocument26 pagesPipe CalculationRavindra S. JivaniNo ratings yet

- Aga-3 Orifice (Api Chapter 14.3.1) - Iphone App - DocumentationDocument4 pagesAga-3 Orifice (Api Chapter 14.3.1) - Iphone App - DocumentationLuis MclaffertyNo ratings yet

- Mexico, Solanum, V6Plus, HP140401 3,140411Document7 pagesMexico, Solanum, V6Plus, HP140401 3,140411Humberto GonzálezNo ratings yet

- Cold Form Steel PDFDocument70 pagesCold Form Steel PDFJohnnatan ViniciusNo ratings yet

- Pipie Size CalcDocument7 pagesPipie Size Calczaksonu91221No ratings yet

- Condenser DesignDocument26 pagesCondenser Designpavan100% (1)

- Design CalculationsDocument18 pagesDesign CalculationsPat SulaimanNo ratings yet

- Pipe or Tubing Support Span CalculationsDocument9 pagesPipe or Tubing Support Span CalculationskhaireddinNo ratings yet

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MNo ratings yet

- Design Case StudyDocument14 pagesDesign Case Studyp m yadavNo ratings yet

- Spring RatingDocument6 pagesSpring Ratingbrowar444No ratings yet

- Angles - Truss DesignDocument109 pagesAngles - Truss DesignSamia H. Bhuiyan100% (2)

- ASM Subject Guide - Aluminum PDFDocument5 pagesASM Subject Guide - Aluminum PDFzeeshaniqbalNo ratings yet

- Aviation Hand Tools For Cutting, Drilling, MachiningDocument40 pagesAviation Hand Tools For Cutting, Drilling, MachiningMohd KhairiNo ratings yet

- Valvulas Diafragma Asepticas BPEDocument104 pagesValvulas Diafragma Asepticas BPEHumberto GonzálezNo ratings yet

- Valvulas Diafragma Asepticas BPEDocument104 pagesValvulas Diafragma Asepticas BPEHumberto GonzálezNo ratings yet

- 90 Degree Elbow Weight Calculation Formula and Chart - Full DimensionsDocument3 pages90 Degree Elbow Weight Calculation Formula and Chart - Full Dimensionskokkeong.chongNo ratings yet

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Heat Exchanger DesignDocument22 pagesHeat Exchanger DesignRupack HalderNo ratings yet

- Formulas and Calculations For Drilling, Production and Work-Over - Norton J. LapeyrouseDocument6 pagesFormulas and Calculations For Drilling, Production and Work-Over - Norton J. LapeyrouseElias GonzalezNo ratings yet

- Equivalent Circulating Density 2Document3 pagesEquivalent Circulating Density 2Miguel VelazcoNo ratings yet

- Equivalent Circulating Density (ECD) in PPG Equivalent Circulating Density (ECD) in PPGDocument1 pageEquivalent Circulating Density (ECD) in PPG Equivalent Circulating Density (ECD) in PPGMiguel VelazcoNo ratings yet

- Spring DesignDocument2 pagesSpring DesignSoobash PradhanNo ratings yet

- How To Calculate The Unit Weight of Steel BarsDocument10 pagesHow To Calculate The Unit Weight of Steel BarsRon Gerald RicaNo ratings yet

- CalculationsDocument23 pagesCalculationsMuhammad Hamza SaleemNo ratings yet

- How To Calculate The Unit Weight of Steel BarsDocument11 pagesHow To Calculate The Unit Weight of Steel BarsProperty Baguio ListingNo ratings yet

- Mod-3A. Spur GearDocument7 pagesMod-3A. Spur GearSharthak GhoshNo ratings yet

- Flash Drum (FD-01) A. Menghitung Faktor Pemisah (FP) : L V V LDocument8 pagesFlash Drum (FD-01) A. Menghitung Faktor Pemisah (FP) : L V V LliaNo ratings yet

- Calculating The Unit Weight of Steel BarsDocument8 pagesCalculating The Unit Weight of Steel BarsDaren ModestoNo ratings yet

- Sample Problems SPRINGSDocument15 pagesSample Problems SPRINGSKara KruzNo ratings yet

- Analisa Tegangan Perpipaan 6 (P) - Widian Rienanda Ali - 0819040041 - TP6BDocument5 pagesAnalisa Tegangan Perpipaan 6 (P) - Widian Rienanda Ali - 0819040041 - TP6BYudiNo ratings yet

- TD of EdtDocument28 pagesTD of EdtOussama SouidNo ratings yet

- Reporte 3Document7 pagesReporte 3حسين عمريNo ratings yet

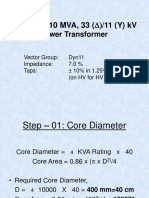

- Design of Induction Motor v3Document17 pagesDesign of Induction Motor v3hamzaNo ratings yet

- Mechanical Engineering DepartmentDocument7 pagesMechanical Engineering Departmentحسين عمريNo ratings yet

- Rotary Dryer PDFDocument13 pagesRotary Dryer PDFHead of Dept. Utility LJF100% (1)

- Homework#3 RakeshDocument4 pagesHomework#3 RakeshRakesh KumarNo ratings yet

- PED Ch1Document17 pagesPED Ch1dpatel 2310No ratings yet

- Me 533project1Document26 pagesMe 533project1api-284224507No ratings yet

- 4.6.1. Chain SpecificationDocument5 pages4.6.1. Chain SpecificationMezgebu MekonnenNo ratings yet

- Design of Belt: To Find The RPM of The Lager PulleyDocument3 pagesDesign of Belt: To Find The RPM of The Lager PulleySooraj SuryaNo ratings yet

- Project SeminarDocument36 pagesProject SeminarPratikNo ratings yet

- Research (Design of Water Tank-Appendix)Document19 pagesResearch (Design of Water Tank-Appendix)Alyssa Mae GomezNo ratings yet

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- NumericalDocument14 pagesNumericalUsman PervaizNo ratings yet

- Mechanische WellenDocument62 pagesMechanische WellenScribdTranslationsNo ratings yet

- Conversion of Units Is The Conversion Between DifferentDocument31 pagesConversion of Units Is The Conversion Between DifferentElmerDolendoTorrevillaNo ratings yet

- Column at Node No. A. General DataDocument9 pagesColumn at Node No. A. General DataTarkeshwar Lal SrivastavaNo ratings yet

- Appendix C1Document193 pagesAppendix C1alif wahyuNo ratings yet

- Finite Element Analysis of Connecting Rod Using Ansys: Nikhil U.Thakare, Nitin D. Bhusale, Rahul P.Shinde, Mahesh M.PatilDocument5 pagesFinite Element Analysis of Connecting Rod Using Ansys: Nikhil U.Thakare, Nitin D. Bhusale, Rahul P.Shinde, Mahesh M.Patilaravindan476No ratings yet

- Design of A Shell and Tube Heat Exchanger Ijariie6039Document15 pagesDesign of A Shell and Tube Heat Exchanger Ijariie6039Evans Azka FNo ratings yet

- Algebra Lineal de V. V. VoevodinDocument425 pagesAlgebra Lineal de V. V. VoevodinTyler SmithNo ratings yet

- Pipe Flow Expert User GuideDocument193 pagesPipe Flow Expert User GuidepatricioepNo ratings yet

- Valvulas NovasepticDocument2 pagesValvulas NovasepticHumberto GonzálezNo ratings yet

- Properties of MetalsDocument25 pagesProperties of MetalsRegalado Cereza IIINo ratings yet

- Abtech GRP Electrical Enclosures Abtech BPG Junction BoxesDocument38 pagesAbtech GRP Electrical Enclosures Abtech BPG Junction BoxesrocketvtNo ratings yet

- Iron (Pig Iron, Cast Iron, Wrought Iron)Document18 pagesIron (Pig Iron, Cast Iron, Wrought Iron)Bhanu Pratap SinghNo ratings yet

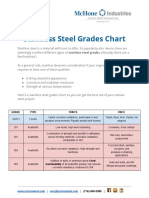

- MCHONE Stainless Grades Chart DownloadableDocument3 pagesMCHONE Stainless Grades Chart DownloadableSagar TikoneNo ratings yet

- Design and Installation Guide: Commercial - Industrial - ResidentialDocument115 pagesDesign and Installation Guide: Commercial - Industrial - ResidentialPlumberguy101No ratings yet

- Textor Lipped CDocument2 pagesTextor Lipped Candrewb2005No ratings yet

- VMFP 06HTDocument11 pagesVMFP 06HTRobertIsaiRuizAcostaNo ratings yet

- L-BV5 Vacuum Pump Data SheetDocument4 pagesL-BV5 Vacuum Pump Data SheetBJ TiewNo ratings yet

- N ch5 17Document3 pagesN ch5 17yashNo ratings yet

- Specific Heat MetalsDocument1 pageSpecific Heat Metalsagibson556No ratings yet

- The References Are Taken From Nidi (Nickel Development Institute) Twi (The Welding Institute) Lincoln Electric International Molybdenum AssociationDocument21 pagesThe References Are Taken From Nidi (Nickel Development Institute) Twi (The Welding Institute) Lincoln Electric International Molybdenum Associationarif maulanafNo ratings yet

- Types of PipesDocument17 pagesTypes of PipesSandip PatelNo ratings yet

- 02-NCSCM Volume 2 - Techical Specifications PDFDocument498 pages02-NCSCM Volume 2 - Techical Specifications PDFsadi3013No ratings yet

- Section 9.5: Stoichiometry of Solutions: 0.25 Mol / L 0.500 Mol/lDocument16 pagesSection 9.5: Stoichiometry of Solutions: 0.25 Mol / L 0.500 Mol/lrashmi_harryNo ratings yet

- Is 1285 PDFDocument11 pagesIs 1285 PDFrk36266_732077041No ratings yet

- End Sem Exam TA201 20170923 Final SolutionDocument5 pagesEnd Sem Exam TA201 20170923 Final SolutionSaumya ShahNo ratings yet

- Powered Vegetable Cutting Machine RDocument36 pagesPowered Vegetable Cutting Machine RMubarak ShaikNo ratings yet

- Seminar Topic ON Galvanic Corrosion Parameters: Prepared byDocument16 pagesSeminar Topic ON Galvanic Corrosion Parameters: Prepared byDevashish JoshiNo ratings yet

- Jindal Stainless LTDDocument11 pagesJindal Stainless LTDAnup MittalNo ratings yet

- CKV 05 Ex PDFDocument4 pagesCKV 05 Ex PDFengp3077No ratings yet

- Script Smksbs Group 2 - Petrosains Science Show Competition 2017Document4 pagesScript Smksbs Group 2 - Petrosains Science Show Competition 2017malaomar0% (1)

- Casting Defects and Design Issues: ME 6222: Manufacturing Processes and Systems Prof. J.S. ColtonDocument37 pagesCasting Defects and Design Issues: ME 6222: Manufacturing Processes and Systems Prof. J.S. ColtonpahuljotNo ratings yet

- A3-50 External TimberworkDocument16 pagesA3-50 External Timberworklwin_oo2435No ratings yet