Professional Documents

Culture Documents

Ecoppia E4 Deployment General Requirments May16

Uploaded by

Tanmoy GhoraiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecoppia E4 Deployment General Requirments May16

Uploaded by

Tanmoy GhoraiCopyright:

Available Formats

Robotic Cleaning Solution

ECOPPIA E4

DEPLOYMENT -

GENERAL

REQUIREMENTS

DESIGN CONSIDERATIONS

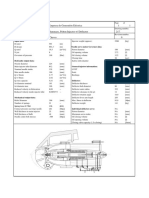

In order to minimize the number of required robotic The profiles shall be in closed rectangular shape and

units and the Capex accordingly, long and wide should allow free areas d1 and d2

arrays are recommended, up to a total of 2,000

square meter per array The profiles can be galvanized steel (1.4 mm

thickness) or extruded aluminum (2.4 mm thickness)

Allowing movement of the robotic units across the

entire array, no sensors, light reflectors or any other The profiles shall create continuous rails and should

major objects to be placed on the array itself be connected to each other by spacers to allow

thermal expansion between rails

Step between 2 neighboring solar tables shall be no

more than 15 mm (horizontally and vertically) The upper part of the rails can vary relative to the

modules surface, from the same level and up to 60

mm below the modules surface

Tolerances of the parallel distance between the rails

CONSTRUCTION RELATED should be +/- 5 mm

CONSIDERATIONS

Max slope of rails 8%

Supporting Rails:

The Ecoppia system requires set of 2 rails placed

on the lower and upper part of each array to allow

horizontal movement of the E4 unit alongside the row

L < 8,000 mm a

d1

d1 > 30 mm

d2 > 50 mm

d2

35 > a > 5

Rails' profiles specification

Robotic Cleaning Solution

Extension for the

units docking station: System's installation

For 21-23 hours a day, the E4 units are securely

locked in their docking stations, under a special Installation of the system (includes the

metal canopy protecting them from winds and UV. extensions, docking stations, robotic units,

The docking stations are located outside the array to and communication and remote management

avoid shading during energy production hours modules) will be done by Ecoppia as part of the

service. All required machinery and equipment

The width of the extension holding the docking for the deployment will be provided by Ecoppia.

station is typically 2.6 m. This width can be

narrowed if required, but may cause certain shading During the deployment time production will

At the other end of the array (the opposite side of not be affected in any way should the site be

the docking station), 0.6 m is required for a mini already opertaional.

extension, allowing the robotic unit to complete a

thorough cleaning even on the edges of the last

panel on row

Gap from the ground:

The gap between the lower part of the panels and

the ground level should be at least 350 mm to allow

space for the E4 unit dedicated solar panel charging

the units battery throughout the day

Empowering Solar For more information please visit www.ecoppia.com or send an email to info@ecoppia.com

You might also like

- Airtouch Data Sheet and Installation Requirements - August 2020Document5 pagesAirtouch Data Sheet and Installation Requirements - August 2020Royroute 999No ratings yet

- (PDF) Short Questions and Answers EE1251 Electrical Machines II - Mosybk Getto19 - Academia - EduDocument14 pages(PDF) Short Questions and Answers EE1251 Electrical Machines II - Mosybk Getto19 - Academia - EduSolomon MebrahtuNo ratings yet

- Catalogue in Word - MUST 2Document22 pagesCatalogue in Word - MUST 2Leonardo MaciasNo ratings yet

- Web Solar BrochureDocument120 pagesWeb Solar BrochureJuto SukogaNo ratings yet

- Maximizing Solar Power with an Efficient MPPT AlgorithmDocument199 pagesMaximizing Solar Power with an Efficient MPPT AlgorithmKetan TiwariNo ratings yet

- Chapter 1-2 - 3 Phase System To Part 3Document40 pagesChapter 1-2 - 3 Phase System To Part 3Hanis SyafiqNo ratings yet

- mMS4.0, processing station with pneumatic pressDocument10 pagesmMS4.0, processing station with pneumatic presskhairul fahmiNo ratings yet

- kc200gt PDFDocument2 pageskc200gt PDFYuvarekha SenthilkumarNo ratings yet

- Report - Next Generation Smart Substation Through GSM TechnologyDocument70 pagesReport - Next Generation Smart Substation Through GSM TechnologyRamsathayaNo ratings yet

- Name of Project: Solar Tracking System Hydraulic BasedDocument17 pagesName of Project: Solar Tracking System Hydraulic Basedvijay kokateNo ratings yet

- Mini-Hacksaw ProjectDocument8 pagesMini-Hacksaw ProjectPrajwal NayakNo ratings yet

- SOLAR PV PLANT PROPOSALDocument12 pagesSOLAR PV PLANT PROPOSALkartik kapoorNo ratings yet

- Key Words - Arduino UNO, Motor Shield L293d, Ultrasonic Sensor HC-SR04, DCDocument17 pagesKey Words - Arduino UNO, Motor Shield L293d, Ultrasonic Sensor HC-SR04, DCBîswãjït NãyàkNo ratings yet

- Proposal FOR: Design and Simulation of A Solar PV System University of GollisDocument24 pagesProposal FOR: Design and Simulation of A Solar PV System University of GollisYG DENo ratings yet

- Slotless Permanent Magnet Ind-Synmotor: in Modern Industrialized Country, About 65% of Electrical Energy IsDocument11 pagesSlotless Permanent Magnet Ind-Synmotor: in Modern Industrialized Country, About 65% of Electrical Energy IsRahmathullah Saleem Basha0% (1)

- Chapter 9 SensorsDocument48 pagesChapter 9 Sensorsامجد الغالبيNo ratings yet

- 35kV Substation Digital DesignDocument66 pages35kV Substation Digital DesignsamiaNo ratings yet

- Kaizen - Motor Selection GuideDocument11 pagesKaizen - Motor Selection GuideAmory Sabri AsmaroNo ratings yet

- Group 15 EMD332 Machine Design Report - 2D Camera SliderDocument33 pagesGroup 15 EMD332 Machine Design Report - 2D Camera SliderMark SelvanNo ratings yet

- Design and Construction of Earth Fault Relay For Single Phase SystemDocument3 pagesDesign and Construction of Earth Fault Relay For Single Phase SystemGururaj BandaNo ratings yet

- Deye Inverter Single Phase 5-12kw ManualDocument51 pagesDeye Inverter Single Phase 5-12kw ManualRostislav PetrovNo ratings yet

- Maintenance On Rotating MachinesDocument8 pagesMaintenance On Rotating MachinesMario ArmelaoNo ratings yet

- Flying Windmills: Conventional WindmillDocument7 pagesFlying Windmills: Conventional WindmillGógul100% (1)

- Walker PV TechnologyDocument53 pagesWalker PV TechnologyaakashtrivediNo ratings yet

- Hybrid Vehicles Syllabus B.E VI SemesterDocument1 pageHybrid Vehicles Syllabus B.E VI Semesterashoku24007No ratings yet

- Start Sequence of MotorsDocument4 pagesStart Sequence of MotorsSamuel AdamuNo ratings yet

- Advanced Speed Control Techniques of Brushless DC MotorDocument17 pagesAdvanced Speed Control Techniques of Brushless DC Motorsrinupid100% (1)

- Lab Manual Electrical Machines Lab PTUKDocument151 pagesLab Manual Electrical Machines Lab PTUKTareq FoQhaNo ratings yet

- Tutorial: Lecture Delivered By: Anusha VaddeDocument5 pagesTutorial: Lecture Delivered By: Anusha Vaddevaddeanusha203100% (1)

- Magenn Air Rotor System 4kWDocument2 pagesMagenn Air Rotor System 4kWMohamed RadwanNo ratings yet

- ES101 - Baisc Electrical & Electronics EngineeringDocument2 pagesES101 - Baisc Electrical & Electronics EngineeringMyWBUT - Home for EngineersNo ratings yet

- Vegetable-Vending-Carts Cart CorporationDocument7 pagesVegetable-Vending-Carts Cart Corporationmanavseva credit100% (1)

- GTU Solar Tracking Project ReportDocument18 pagesGTU Solar Tracking Project ReportVathsal MehtaNo ratings yet

- Electromagnetic Compatibility of Industrial Networks and FieldbusesDocument38 pagesElectromagnetic Compatibility of Industrial Networks and FieldbusesCarlos ChocobarNo ratings yet

- Design and Implementation of a 5kVA Solar Powered InverterDocument17 pagesDesign and Implementation of a 5kVA Solar Powered InverterBayeNo ratings yet

- Solar PowerDocument10 pagesSolar PowerLipun SamalNo ratings yet

- Solar Panel Cleaning Drone - ReportDocument49 pagesSolar Panel Cleaning Drone - ReportAtchayha P M100% (1)

- WindmillDocument23 pagesWindmillManav KohliNo ratings yet

- Unit IV Wind and Solar Energy System 7thDocument12 pagesUnit IV Wind and Solar Energy System 7thmalik shafkatNo ratings yet

- Photovoltaic Design and Installation Full Presentation COMPRESSEDDocument113 pagesPhotovoltaic Design and Installation Full Presentation COMPRESSEDVanu ShaNo ratings yet

- Protection of AlternatorsDocument19 pagesProtection of AlternatorsVaira PerumalNo ratings yet

- Microsoft Word - STATOR PROTECTION. Final ReportDocument11 pagesMicrosoft Word - STATOR PROTECTION. Final ReportHari Krishna.MNo ratings yet

- MEE 1038 - Solar Photovoltaic Systems Design: Inverter For PV ApplicationsDocument26 pagesMEE 1038 - Solar Photovoltaic Systems Design: Inverter For PV ApplicationsgauravNo ratings yet

- Solar Roadways: A Seminar Report OnDocument19 pagesSolar Roadways: A Seminar Report OnMetpalli AshwiniNo ratings yet

- Solar Energy Technologies Unit 2 LightingDocument111 pagesSolar Energy Technologies Unit 2 LightingTharun RagavNo ratings yet

- Tip Speed RatioDocument4 pagesTip Speed Ratiomaantom3No ratings yet

- Solar RoadwaysDocument23 pagesSolar RoadwaysMohammed rafeeqNo ratings yet

- Moog Valves D633 D634 Catalog enDocument14 pagesMoog Valves D633 D634 Catalog enPritam SinghNo ratings yet

- JMC Pick Up BrochureDocument2 pagesJMC Pick Up BrochureChristine TumNo ratings yet

- LIM Motor ExplainedDocument5 pagesLIM Motor ExplainedAshish MehraNo ratings yet

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- Assignment 1Document2 pagesAssignment 1ramakrishnaprasad9080% (1)

- Dual-Three Phase Induction Machine Drives Control SurveyDocument11 pagesDual-Three Phase Induction Machine Drives Control SurveyMoyasserengAlattarNo ratings yet

- Safety issues in PV systemsDocument12 pagesSafety issues in PV systemsjayapal100% (1)

- Brochure LV Switchboard & MCC - Capitole 40 enDocument20 pagesBrochure LV Switchboard & MCC - Capitole 40 enHamid SuliamanNo ratings yet

- Tech Man Eng 3590 Hwinst 10.11Document24 pagesTech Man Eng 3590 Hwinst 10.11Zin Linn KhantNo ratings yet

- R2V2PX310R Ultra Wide Band Base Station Antenna: Global, ExternalDocument1 pageR2V2PX310R Ultra Wide Band Base Station Antenna: Global, Externaleduardo2307No ratings yet

- Low Voltage Distribution and Control Systems Eaton Cap 40Document20 pagesLow Voltage Distribution and Control Systems Eaton Cap 40Hugo Dennis Mattos EspinozaNo ratings yet

- Xenergy CA EN 10 2011Document10 pagesXenergy CA EN 10 2011Nal MénNo ratings yet

- Syllabus Leading With Finance PDFDocument1 pageSyllabus Leading With Finance PDFTanmoy GhoraiNo ratings yet

- Floatingsolarpv Anintroduction 180206061112Document19 pagesFloatingsolarpv Anintroduction 180206061112Pochareddy RameshNo ratings yet

- Sustainability 11 00180 PDFDocument11 pagesSustainability 11 00180 PDFTanmoy GhoraiNo ratings yet

- Guard Cabin-01Document1 pageGuard Cabin-01Tanmoy GhoraiNo ratings yet

- Sustainability 11 00180 PDFDocument11 pagesSustainability 11 00180 PDFTanmoy GhoraiNo ratings yet

- DukeDocument1 pageDukeTanmoy GhoraiNo ratings yet

- GUARD CABIN-01 - EditedDocument1 pageGUARD CABIN-01 - EditedTanmoy GhoraiNo ratings yet

- Sustainability 12 00650 PDFDocument36 pagesSustainability 12 00650 PDFTanmoy GhoraiNo ratings yet

- Electricity Charge WorkingsDocument5 pagesElectricity Charge WorkingsTanmoy GhoraiNo ratings yet

- BXPHARMADocument4 pagesBXPHARMASayeedNo ratings yet

- Design Document ATM+PEM 13.01.17Document31 pagesDesign Document ATM+PEM 13.01.17Tanmoy GhoraiNo ratings yet

- Oil Gas and Coal Markets ReadingsDocument186 pagesOil Gas and Coal Markets ReadingsTanmoy GhoraiNo ratings yet

- Is 2911 1 1 2010 PDFDocument26 pagesIs 2911 1 1 2010 PDFAnupamPanjaNo ratings yet

- Manali Balance SheetDocument4 pagesManali Balance SheetTanmoy GhoraiNo ratings yet

- 2 1 PDFDocument14 pages2 1 PDFMuhammad AamirNo ratings yet

- IRC Method of Designing Flexible PavementsDocument6 pagesIRC Method of Designing Flexible PavementsVinay RathoreNo ratings yet

- Ecoppia E4 Deployment General Requirments May16Document2 pagesEcoppia E4 Deployment General Requirments May16Tanmoy GhoraiNo ratings yet

- GermanyDocument6 pagesGermanyTanmoy GhoraiNo ratings yet

- Electricity Charge WorkingsDocument1 pageElectricity Charge WorkingsTanmoy GhoraiNo ratings yet

- Gravity Dam DesignDocument58 pagesGravity Dam Designgigiosss100% (1)

- 25 Newsletter 20 August 2013Document98 pages25 Newsletter 20 August 2013Anna LaClair0% (1)

- Chalmers Master Thesis Planning ReportDocument4 pagesChalmers Master Thesis Planning Reporttsfublhld100% (2)

- NTPC Limited: (A Government of India Enterprise)Document7 pagesNTPC Limited: (A Government of India Enterprise)Amit VijayvargiNo ratings yet

- KSB MIL Controls Overview and HistoryDocument6 pagesKSB MIL Controls Overview and HistoryVauntedNo ratings yet

- Training at Ingersoll RandDocument20 pagesTraining at Ingersoll RandArnab MidyaNo ratings yet

- Strategic Capacity PlanningDocument3 pagesStrategic Capacity PlanningLesterAntoniDeGuzmanNo ratings yet

- GEA PHE Fullywelded Phe en 1Document12 pagesGEA PHE Fullywelded Phe en 1gemagdyNo ratings yet

- The Singapore EngineerDocument52 pagesThe Singapore EngineerGary GohNo ratings yet

- Chemical Factory Marginal Costs & Sweater Regulation AnalysisDocument2 pagesChemical Factory Marginal Costs & Sweater Regulation AnalysisHariz Kaeni, S.T.No ratings yet

- Eaton Lighting Lightingsolutions2018 Lowres PDFDocument496 pagesEaton Lighting Lightingsolutions2018 Lowres PDFgilbertomjcNo ratings yet

- Report On The Industrial Visit To Voltas Thane PlanDocument4 pagesReport On The Industrial Visit To Voltas Thane PlansnehalaicarNo ratings yet

- Attachment D - Transport Management Plan PDFDocument41 pagesAttachment D - Transport Management Plan PDFmaxamaxaNo ratings yet

- IntroductionDocument49 pagesIntroductionSUDDHA CHAKRABARTYNo ratings yet

- A Cost-Benefit Analysis of Power Generation From Commercial Reinforced Concrete Solar Chimney Power PlantDocument10 pagesA Cost-Benefit Analysis of Power Generation From Commercial Reinforced Concrete Solar Chimney Power PlantAgung Aryo WibowoNo ratings yet

- Supply Chain Management and IoT in Smart CitiesDocument56 pagesSupply Chain Management and IoT in Smart Citiesavnish100% (1)

- Edge Material HandlingDocument20 pagesEdge Material HandlingcachitNo ratings yet

- Delham Engineering's Flare Package GuideDocument6 pagesDelham Engineering's Flare Package Guidesujaysarkar85No ratings yet

- TNB Meter DepositDocument3 pagesTNB Meter DepositKhay SaadNo ratings yet

- Construction Method Statement SafetyDocument4 pagesConstruction Method Statement SafetyRaiZaNo ratings yet

- Vacuum DegasserDocument3 pagesVacuum DegasserkosunlucyNo ratings yet

- Pelton Injector SummaryDocument1 pagePelton Injector SummaryJulio ChavarriNo ratings yet

- MB6S DatasheetDocument3 pagesMB6S Datasheetnonyabizness2003No ratings yet

- Soda AshDocument2 pagesSoda AshswNo ratings yet

- Sago Industry Problems and Prospects in TamilnaduDocument39 pagesSago Industry Problems and Prospects in Tamilnadujohn aeron castilloNo ratings yet

- Erc Petition For Intervention Vs Meralco Psas and Motion For InterventionDocument19 pagesErc Petition For Intervention Vs Meralco Psas and Motion For Interventionapi-366375289No ratings yet

- Seven SistersDocument5 pagesSeven SistersMursid SispamuntraNo ratings yet

- LT E-BillDocument2 pagesLT E-Billrajesh chavanNo ratings yet

- Lightbook CatalougeDocument83 pagesLightbook CatalougeRajasekhar0% (1)

- Til 1509 R3 F-Class Front End (R0, S0, and R1) Compressor InspectionsDocument11 pagesTil 1509 R3 F-Class Front End (R0, S0, and R1) Compressor InspectionsMichael Sanchez100% (2)

- Indian Oil Corporation LTD Guwahati RefineryDocument27 pagesIndian Oil Corporation LTD Guwahati Refineryelectram67% (6)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Estimator's General Construction Manhour ManualFrom EverandEstimator's General Construction Manhour ManualRating: 4.5 out of 5 stars4.5/5 (20)

- Building Construction and DrawingFrom EverandBuilding Construction and DrawingRating: 2.5 out of 5 stars2.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)