Professional Documents

Culture Documents

Procedure of Turbine Cold Startup

Procedure of Turbine Cold Startup

Uploaded by

king1q0 ratings0% found this document useful (0 votes)

13 views2 pagesturbine

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentturbine

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesProcedure of Turbine Cold Startup

Procedure of Turbine Cold Startup

Uploaded by

king1qturbine

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Procedure of turbine cold startup?

The startup condition of the turbine is considered as per inner casing

temperature of the turbine such as,

a) Cold start up If the casing temperature is < 200C.

b) Warm start up - If the casing temperature in between 200-300C.

c) Hot start up- If the casing temperature is > 450C.

Pre checklist for cold start up:-

1) Check all work completed and all permit is returned.

2) Confirm all interlock test of turbine is completed.

3) Check all level gauges and pressure gauges in operation.

4) Check cooling tower sump level should be normal level.

5) Check the oil level of MOT tank and control oil tank should be

normal.

6) Check the generator cooling water and lube oil cooling system is

normalized.

7) Check the compressor is system in running .

8) Check the ACW pump in running.

9) Check the circulating water pump(CW) in running.

10)Check the turbine lube oil pump is running and turbine is in barring

gear.

11) Check the generator air cooling system is in operation.

Procedure for turbine rolling:-

1) Start the CEP with minimum re circulation.

2) Start the gland steam system with auxiliary PRDS.

3) Start the gland steam blower and normalize Gland steam drain

system.

4) Maintain the gland steam temperature in between 121 to 177 deg c.

5) Start the vacuum pump or ejector for vacuum pulling.

6) Ensure the boiler develop rated pressure above 15 kg/cm2 &

temperature >360deg c

7) Put the HP and LP bypass system in operation for line warm-up.

8) Ensure all turbine drains are open condition.

9) Check the turbine lube oil temperature is in-between 38-42 deg c.

10) Check the differential expansion and eccentricity is normal.

11) Reset the turbine from governor panel.

12) Press the latching or start bottom to open the ESV.

13) Give command for rolling of turbine.

14) Check the turning gear and JOP automatically stopped when

speed reaches >300 rpm.

15) Press the hold button of turbine and hold the speed in 500rpm to

check the eccentricity < 0.076 mm, axial shift +- 1 mm and differential

expansion +- 6mm of turbine.

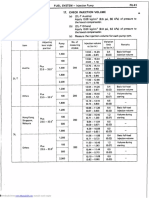

16) Continue the speed of the turbine with 40 rpm/min and speedup

the turbine speed during critical speed of 1850,2000 and 2200

respectively (as per designer).

17) Check the main oil pump comes in service and AOP is stopped

condition.

18) After turbine reached to full speed hold for some time and ensure

upper and lower casing temperature difference is within limit.

19) Ask the electrical people for synchronization.

20) Close all turbine drains after synchronization.

21) Increase load by follow of turbine cold startup load curve.

22) When the load is increase to 20% of full load charge the Extraction

line gradually.

23) Finally check all parameter of turbine is ok and increase turbine

load to full.

This is the most preferred BOE Preparation Book.

You might also like

- 1 X SeriesDocument321 pages1 X SeriesJair Merino Aguirre100% (1)

- Mongoose Pro User ManualDocument17 pagesMongoose Pro User Manualsunil601100% (1)

- MHI 700MW Turbine RollingDocument51 pagesMHI 700MW Turbine RollingSomnath Gupta100% (4)

- Projectile Motion ProblemsDocument7 pagesProjectile Motion Problemsomar_oj_4No ratings yet

- SV521Series Operator ManualDocument96 pagesSV521Series Operator ManualOggy ToffyNo ratings yet

- Boiler InterlocksDocument54 pagesBoiler InterlocksAhemadNo ratings yet

- Sample Method Statement Astm d1194Document6 pagesSample Method Statement Astm d1194Gio ReyesNo ratings yet

- Whitepaper APIDocumentationDXDocument19 pagesWhitepaper APIDocumentationDXsunil601No ratings yet

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pages020-SOP of H2 CYLINDER Room ChargingsambhuNo ratings yet

- Turbine Start Up Procedure-2Document2 pagesTurbine Start Up Procedure-2kumarmm1234100% (2)

- FSSS PresentationDocument28 pagesFSSS Presentationjp mishra100% (2)

- Duties & Responsibilities of Shift EngineerDocument35 pagesDuties & Responsibilities of Shift EngineerNaveen ChodagiriNo ratings yet

- Turbine Shutting Down From Full LoadDocument7 pagesTurbine Shutting Down From Full Loadrohit_0123100% (2)

- Seal Oil and Hydrogen SystemDocument34 pagesSeal Oil and Hydrogen Systemashish_ntpcNo ratings yet

- Sop LRSB BlowerDocument6 pagesSop LRSB BlowerApnrl maincontrolroom100% (1)

- Operation Aspects & Boiler EmergenciesDocument54 pagesOperation Aspects & Boiler EmergenciesPravivVivpra100% (1)

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialDocument4 pagesRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargNo ratings yet

- Presentation On Steam Turbine Operation by S ChandDocument36 pagesPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Weldment Strength Excel CalculationsDocument33 pagesWeldment Strength Excel CalculationsYl WongNo ratings yet

- Turbine Operation - PreparationDocument30 pagesTurbine Operation - PreparationMadhav Pande75% (4)

- Mill Interlocks: Start PermissivesDocument6 pagesMill Interlocks: Start PermissivesNikhil100% (1)

- Turbine RollingDocument3 pagesTurbine RollingAnudeep Chittluri100% (2)

- Cold Startup Procedure PDFDocument6 pagesCold Startup Procedure PDFSai SwaroopNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- Generator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Document32 pagesGenerator & Auxillaries (Stator Water, Seal Oil and Hydrogen Gas System)Praveen Jagadev100% (3)

- Deh Governing 600,300,660 MWDocument28 pagesDeh Governing 600,300,660 MWdk.verma50% (2)

- Turbine Rolling & Synchronisation Indicative Flow PathDocument11 pagesTurbine Rolling & Synchronisation Indicative Flow Pathlp mishra100% (1)

- Submitted To GM/BTPP: Sub: NLC-BTPP-2X125 MW-Write-up On HP-LP BYPASS SYSTEMS - RegDocument7 pagesSubmitted To GM/BTPP: Sub: NLC-BTPP-2X125 MW-Write-up On HP-LP BYPASS SYSTEMS - RegPrakash ChoudharyNo ratings yet

- 500 MW Unit Startup ProcedureDocument39 pages500 MW Unit Startup ProcedureMohammad Asif50% (2)

- Cold Start Up ProcedureDocument18 pagesCold Start Up ProcedurerahulNo ratings yet

- Turbine OperationDocument30 pagesTurbine OperationGanesh Dasara100% (3)

- Power Plant Familiar Is at Ion V - IIIDocument164 pagesPower Plant Familiar Is at Ion V - IIISiva Kumar Tutika100% (2)

- CEP PresentatioDocument14 pagesCEP PresentatioVinod Mahajan100% (2)

- Hot Startup Checklist1Document6 pagesHot Startup Checklist1Selva ManianNo ratings yet

- Main Turbine: 1 General LayoutDocument16 pagesMain Turbine: 1 General LayoutPrakash Choudhary100% (2)

- Write Up On Turbine OperationDocument5 pagesWrite Up On Turbine OperationSarah Frazier100% (2)

- Turbine SopDocument8 pagesTurbine SopDominic Daniel100% (1)

- Master Fire Fighting BoqDocument15 pagesMaster Fire Fighting Boqhussam_98No ratings yet

- Steam Turbine Q & ADocument37 pagesSteam Turbine Q & Amy shift D50% (2)

- 31-Station Acwp - SopDocument3 pages31-Station Acwp - SopSiddhant Satpathy100% (1)

- Unit Normal Shutdown To ColdDocument100 pagesUnit Normal Shutdown To Coldishak100% (2)

- Three Lever ClassesDocument5 pagesThree Lever ClassesSourabh SharafNo ratings yet

- TG Ele Hydro Oil PumpDocument8 pagesTG Ele Hydro Oil Pumpsambhu100% (1)

- NPTI Boiler QuestionsDocument2 pagesNPTI Boiler QuestionsJoydev GangulyNo ratings yet

- Ing The Starting Device To Zero: M.S. Pr. 35-40 Ksc. HRH Pr. 12-14 Ksc. M.S. and HRH Tempr. - 320 To 3500C)Document3 pagesIng The Starting Device To Zero: M.S. Pr. 35-40 Ksc. HRH Pr. 12-14 Ksc. M.S. and HRH Tempr. - 320 To 3500C)Sourav SahaNo ratings yet

- Turbine StartupDocument16 pagesTurbine StartupSakthi Murugan100% (2)

- Sop of WHRPPDocument21 pagesSop of WHRPPHaider AliNo ratings yet

- Turbine Shutdown ProcedureDocument5 pagesTurbine Shutdown ProcedureSai Swaroop100% (1)

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (2)

- Deh Operation InstructionDocument19 pagesDeh Operation Instructionmuhammad nasimNo ratings yet

- Boiler Lightup SOPDocument3 pagesBoiler Lightup SOPSudipta DasNo ratings yet

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocument8 pagesStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratNo ratings yet

- Boiler Light UpDocument19 pagesBoiler Light Upabbutalibb5407100% (1)

- Turning Gear An Operation Point of ViewDocument22 pagesTurning Gear An Operation Point of ViewAshwin Narayan100% (2)

- API 2000 7th Summary of Changes From 6thDocument6 pagesAPI 2000 7th Summary of Changes From 6thRicoNo ratings yet

- Process Industry Practices Piping: PIP PNC00004 Piping Flexibility Analysis Criteria For ASME B31.3 Metallic PipingDocument5 pagesProcess Industry Practices Piping: PIP PNC00004 Piping Flexibility Analysis Criteria For ASME B31.3 Metallic Pipingsunil601No ratings yet

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Turbine Rolling ProcedureDocument4 pagesTurbine Rolling ProcedureSai Swaroop100% (1)

- Unit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemDocument13 pagesUnit Cold Start: 1. Start Service Water Pump 2. Start Auxiliary Cooling Water SystemMuhammad luqman100% (1)

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- Tripping of Turbine On High Differential PressureDocument3 pagesTripping of Turbine On High Differential Pressureatulbhogare7100% (1)

- Turbine Start Up ProcedureDocument3 pagesTurbine Start Up ProcedureShameer Majeed100% (1)

- Boiler Hydro Test by R K JaintDocument9 pagesBoiler Hydro Test by R K JaintRajeevAgrawalNo ratings yet

- Seal Oil SopDocument18 pagesSeal Oil SopSonrat100% (1)

- 660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCDocument6 pages660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCdjfffNo ratings yet

- BFP SopDocument2 pagesBFP SopCo-gen ManagerNo ratings yet

- IR CFBC Cold Start Up ProcedureDocument15 pagesIR CFBC Cold Start Up ProcedureJose Angie CabreraNo ratings yet

- Standard Operating Procedure FOR Vacuum PumpDocument7 pagesStandard Operating Procedure FOR Vacuum Pumpsambhu100% (2)

- Winkler Spring ModelDocument6 pagesWinkler Spring ModelCesar SerranoNo ratings yet

- SESI-TSPL-OPN-SOP-BTG-012 (APH Fire)Document9 pagesSESI-TSPL-OPN-SOP-BTG-012 (APH Fire)sourav mahapatraNo ratings yet

- Presentation OnDocument28 pagesPresentation OnAnonymous umnT4ZZcuNo ratings yet

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- ParKlamp Inch Tube ClampsDocument20 pagesParKlamp Inch Tube Clampssunil601No ratings yet

- 0417 2240Document5 pages0417 2240sunil601No ratings yet

- A2340Document1 pageA2340sunil601No ratings yet

- EON615 SpecSheet 4 28 15Document3 pagesEON615 SpecSheet 4 28 15sunil601No ratings yet

- Pressure Range - 200 To 1480 PSIG: PurposeDocument2 pagesPressure Range - 200 To 1480 PSIG: Purposesunil601No ratings yet

- JBLProfesional Catálogo de Toda La Línea 2015Document88 pagesJBLProfesional Catálogo de Toda La Línea 2015mensajero773No ratings yet

- What Is Commissioning and Related Terms Rev 01Document1 pageWhat Is Commissioning and Related Terms Rev 01sunil601No ratings yet

- Atta With Multi Grains/ Multi Whole Grains Flour: Central Food Technological Research Institute, Mysore-570 020, IndiaDocument1 pageAtta With Multi Grains/ Multi Whole Grains Flour: Central Food Technological Research Institute, Mysore-570 020, Indiasunil601No ratings yet

- PipDocument89 pagesPipsunil601No ratings yet

- No. 001 - Abbreviations - : Please Write Your Answers WITHOUT Hyphens For Example: Dcs DigitalcontrolsystemDocument1 pageNo. 001 - Abbreviations - : Please Write Your Answers WITHOUT Hyphens For Example: Dcs Digitalcontrolsystemsunil601No ratings yet

- WheatFlour (Atta)Document10 pagesWheatFlour (Atta)sunil601No ratings yet

- India: An Emissions Trading Case StudyDocument12 pagesIndia: An Emissions Trading Case Studysunil601No ratings yet

- CAP v1.2 PR03Document47 pagesCAP v1.2 PR03sunil601No ratings yet

- Analysis of Liquidity-Study On Indian Mid-Cap StocksDocument14 pagesAnalysis of Liquidity-Study On Indian Mid-Cap Stockssunil601No ratings yet

- 05 en PDFDocument10 pages05 en PDFsunil601No ratings yet

- History Book LR en PDFDocument24 pagesHistory Book LR en PDFsunil601No ratings yet

- Mon God Band MongooseDocument27 pagesMon God Band Mongoosesunil601No ratings yet

- TS 500-2000 (R2018) Example 001 PDFDocument4 pagesTS 500-2000 (R2018) Example 001 PDFHenry TuganoNo ratings yet

- LEO XST DatasheetDocument3 pagesLEO XST DatasheetELBAGHATI MohammadNo ratings yet

- Piping DesignOnline PDFDocument4 pagesPiping DesignOnline PDFTushar DoshiNo ratings yet

- Impact of Oxytactic Microorganisms and Variable Species Diffusivity On Blood Gold Reiner-Philippoff NanofluidDocument13 pagesImpact of Oxytactic Microorganisms and Variable Species Diffusivity On Blood Gold Reiner-Philippoff NanofluidtonyjeeNo ratings yet

- Quadcopter Plant Model and Control System Development With MATLAB/Simulink ImplementationDocument129 pagesQuadcopter Plant Model and Control System Development With MATLAB/Simulink ImplementationBharath Kumar PNo ratings yet

- Effect of Number of Blades and Blade Chord Length On The Performance of Darrieus Wind TurbineDocument10 pagesEffect of Number of Blades and Blade Chord Length On The Performance of Darrieus Wind TurbineNEDALNo ratings yet

- Review of Plane Failure in Rock SlopesDocument9 pagesReview of Plane Failure in Rock Slopespggopal_85No ratings yet

- Control de Trasm 410gDocument2 pagesControl de Trasm 410gdavidNo ratings yet

- Chemical Engineering Science: N. Ratkovich, P.R. Berube, I. NopensDocument15 pagesChemical Engineering Science: N. Ratkovich, P.R. Berube, I. Nopensvasumalhotra2001No ratings yet

- Solutions Chapter 5 (WǪ) PDFDocument34 pagesSolutions Chapter 5 (WǪ) PDF黃羿傑No ratings yet

- Elfa enDocument8 pagesElfa enmtschNo ratings yet

- Combustion - Applied Thermodynamics 2021Document84 pagesCombustion - Applied Thermodynamics 2021Auto Veteran100% (1)

- Automobile Engineering-III 221117 152639Document26 pagesAutomobile Engineering-III 221117 152639SINK IS ALIVENo ratings yet

- Schematic Circuits: Section C - ElectricsDocument1 pageSchematic Circuits: Section C - ElectricsIonut GrozaNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- General Expressions For Flow Through Beds in Terms of Carman-Kozeny EquationsDocument6 pagesGeneral Expressions For Flow Through Beds in Terms of Carman-Kozeny Equationsحاتم غيدان خلفNo ratings yet

- 1.0 INTRODUCTIONS Electronic Fuel Injection (EFI)Document28 pages1.0 INTRODUCTIONS Electronic Fuel Injection (EFI)Sravan GundamNo ratings yet

- 18 BrakingDocument50 pages18 BrakingMuvinda JayasingheNo ratings yet

- Giancoli Lecture - Ch12Document47 pagesGiancoli Lecture - Ch12Leadership IncNo ratings yet

- Design of Machinery: Assignment Gear TrainsDocument15 pagesDesign of Machinery: Assignment Gear Trainshasan bishNo ratings yet

- 5f63d7e2500dc5233bfaef5c COSASCO Access Under PressureDocument4 pages5f63d7e2500dc5233bfaef5c COSASCO Access Under PressureExleider Sanchez PerezNo ratings yet