Professional Documents

Culture Documents

Standard Operating Procedure For Hy-Lp Bypass System: Objective

Uploaded by

SonratOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Operating Procedure For Hy-Lp Bypass System: Objective

Uploaded by

SonratCopyright:

Available Formats

STANDARD OPERATING PROCEDURE FOR HY-LP BYPASS SYSTEM

OBJECTIVE: the HP-LP pass system by passes the high pressure steam to the low

pressure steam circuit & then dumps to condenser after suitable depressurization &

tempration. This way actually the turbine is bypassed from the steam circuit.

SCOPE: This SOP is applicable HP and LP bypass system

INTRODUCTION: The major equipments in a Thermal Plant are Boiler, Turbine Generator &

Power Transmission ,equipments .For the stable operation of the plant, Boiler outlet parameters

should be matched with the condition of Turbine. But due to difference in boiler & turbine

dynamic characteristics, the flexibility of operation suffers. This problem can be overcome by

employing HP-LP by pass system in the steam cycle

PRE CHECKS:

HP LP BY-PASS SYTEM TECHNICAL DATA:-

1. HIGH PRESSURE BYPASS VALVE

Make CCI Switzerland Quantity ---

Type HBSE 280-250-1 Normal inlet pressure 16.67 Mpa

Normal outlet pressure 4.133Mpa Normal inlet temperature 538 ℃

Normal outlet temperature 335 ℃ Flow 716.27 t/h

Valve travel 110 mm Full travel time < 10s

2. HP BYPASS SPRAY-WATER REGULATING VALVE

Make CCI Switzerland Quantity ---

Type 100DSV Normal inlet pressure 22.73 Mpa

Normal outlet pressure 4.67 Mpa Normal temperature 185.2 ℃

Normal outlet temperature ---- Flow 95.57 t/h

Valve travel 63.5mm Full travel time < 10s

3. HP BYPASS SPRAY WATER ISOLATION VALVE

Make CCI Switzerland Quantity ---

Type 840G Normal inlet pressure 24.25 Mpa

Normal outlet pressure 22.73 Mpa Normal temperature 185.2 ℃

Normal outlet temperature ---- Flow 95.57 t/h

Valve travel 40 mm Full travel time < 2s

4. LOW PRESSURE BYPASS VALVE

Make CCI Switzerland Quantity ---

Type NBSE 60-600-3 Normal inlet pressure 3.72 Mpa

Normal outlet pressure 0.8 Mpa Normal inlet temperature 538 ℃

Normal outlet temperature 180 ℃ Flow 716.27 t/h

Valve travel 252 mm Full travel time < 10 S

5. LP BYPASS SPRAY- WATER ISOLATION VALVE

Make CCI Switzerland Quantity ---

Type 840G Normal inlet pressure 3. 1 Mpa

Normal outlet pressure 2.63 Mpa Normal temperature 46.7℃

Normal outlet temperature ---- Flow 205.17 t/h

Valve travel 40 mm Full travel time < 2s

6. LP BYPASS SPRAY-WATER REGULATING VALVE

Make CCI Switzerland Quantity ---

Type 840H Normal inlet pressure 2.63 Mpa

Normal outlet pressure 1.34 Mpa Normal temperature 46.7℃

Normal outlet temperature ---- Flow 205.17 t/h

Valve travel 50 mm Full travel time < 10s

PRECHECKS AND ACTION BY FIELD ENGINEER

S No Description Ok Not Ok Remarks

BYPASS CONTROL SYSTEM

1 All permits and cross permits have been returned.

2 Area is clear of any other materials.

3 1. The permanent system of BPC has been restored, with

the permanent valve plugs fitted.

2. Actuators have been installed up to standard.

3. Control cabinets (Local and Remote) are wired and

Cabling Complete and are operating normally.

4. The installation and wiring of measuring elements and

Transmitters is complete and have been checked up to

standard.

Adjustment the hydraulic power unit has been complete.

4

PRECHECKS AND ACTION BY DESK ENGINEER

S No Description Ok Not Ok Remarks

Valves and measuring points transmission test and interlock,

1 protection test for high pressure bypass system

Valves and measuring points transmission test and interlock,

2 protection test for low pressure bypass system.

3 Pressure and temperature control of high pressure bypass

4 Pressure and temperature control of low pressure bypass

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

1. Ensure no permit to work is pending on regarding this system by checking with

EE/MRSE.

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

SPECIAL TOOLS/ EQUIPMENTS: NIL

OPERATING PROCEDURE -

Sr. RESPONSIBILITY

Description

No. UCE DE FE EE

PRE- START CHECKS:

1 All permits and cross permits have been returned. √ √ √ √

2 Power supply and control power supply available. √ √

3 Adjustment the hydraulic power unit has been complete. √ √

4 Valve action test and on/off time measurement √

√ √

5 Inspection of interlocks, protections, and alarms √ √

6 Switch on the power supply of HP and LP bypass system √ √

Pre-start conditions for charging of HP-LP Bypass

1 Turbine oil system is started & turbine is running on barring gear. √ √

2 Condensate extraction pumps are started & condensate discharge √ √

header pressure is normal.

3 CW system is established. √ √

4 Vacuum in the condenser is greater than 0.85 kg/cm2 √ √

5 Boiler feed pump is started & supplying adequate discharge header √ √

pressure

CONDITION BEFORE COMMISSIONING

1 The permanent system of BPC has been restored, with the permanent √

√

valve plugs fitted.

2 Actuators have been installed up to standard. √ √

3 Control cabinets (Local & Remote) are wired, Cabling Complete, √

√

Checked and operating normally.

4 The installation and wiring of measuring elements and Transmitters √

have been checked up to standard.

5 Before the start of the test, ensure that the OIL System is ready √ √

6 Check that HP and LP bypass valves, HP and LP bypass spray-water √

regulating valves act normally and the associated interlock and

protection is tested capable of functioning

7 Ensure that the services such as circulating water, cooling water, and

√

control oil system are running normally. √

8 Ensure that condensate water system and feed water system are √

running normally.

9 Ensure that vacuum inside the condenser is attained as require and √

the low vacuum protection is put into operation.

Operation of bypass

1 Warming of main steam line & HP bypass valves √ √

1.1 During cold startup the warming up of main steam line can be started √ √

after boiler blow down at 10 kg/cm2 pressure

1.2 Ensure that drain valves of main steam lines ,CRH & HRH line are open √ √

1.3 Charge the main steam line by opening integral bypass valves √ √

1.4 Open the warm up valves of HP bypass valves locally √ √

1.5 The warming up operation of MS line is completed when steam √ √

temperature before HP bypass is more than the mid-wall temperature

of MSV

1.6 Open the main boiler outlet valves √ √

2 Preparation of LP bypass system

2.1 Open the warm up valves of LPBP1 &LPBP2 √ √

2.2 Open drains of LP bypass line √ √

2.3 Put the LP bypass valve controller on “ AUTO “ √ √

3 Select the HP and LP bypass pressure valves and spray water regulating √

valves to ‘Manual’

4 After the furnace is lit up, when the main steam pressure increases √

gradually to 0.2 MPa, open the isolating valve of LP bypass tertiary

desuperheater

5 open the desuperheater regulating valve, properly open the LP bypass √

valve when the opening of desuperheater water regulating valve is

above 5%.

6 Control the pressure of reheater in relation to the boiler condition. √

Ensure that no severe vibration occurs on the pipes after the LP bypass

√

pressure valve opened.

7 After the LP bypass has been put into operation, manually open HP √

bypass valve to 5%, open the HP bypass spray water isolation valve

8 when HP bypass valve opens to 5%, adjust the opening of

desuperheater regulating valve based on the outlet temperature of HP √

bypass pressure valve. Be sure to open HP and LP bypass slowly.

9 Regulation of HP and LP bypass valve is achieved for the required main

steam , reheat steam parameters. √ √

10 During bypass system operation, closely observe all components in

system and make following adjustment timely as parameters deviate

from the normal value to keep system running in good condition

a Pressure adjustment √

√

b Pressure adjustment √ √

c Flow adjustment √ √

9 Maintain the following parameters normally in operation √ √

a HP bypass outlet temperature √ √

b HP bypass desuperheater pressure √ √

c LP bypass outlet temperature and tertiary attemperator outlet √ √

temperature

d LP bypass desuperheater pressure √ √

Turbine bypass system in integral unit commissioning √ √

1 HP and LP bypass should be operating in “Auto” mode during √ √

integral unit commissioning

Make record of the following parameter readings, both local and

computer displayed

1 HP bypass inlet and outlet pressure √ √

2 HP bypass inlet and outlet temperature √ √

3 HP bypass spray pressure √ √

4 LP bypass inlet and outlet pressure √ √

5 LP bypass inlet and outlet temperature √

√

6 LP bypass spray pressure √ √

INTERLOCKS :

1 Fast close allowable condition

1. HP bypass valve after temperature >390℃

2. LP bypass fast close condition

2 Fast open allowable condition

Turbine trip or generator switch trip

3 HP bypass spray-water regulating valve

1. The position of HP bypass valve >3%, auto put in the automatic condition

2. The position of HP bypass valve≤3%,auto close.

3. The open permit of HP bypass valve desurperheater control valve: he back

temperature of HP bypass valve>230℃

4 HP bypass spray water isolation valve

1. The position of HP bypass valve >3%, auto open

2. The position of HP bypass valve≤3%, auto close

5 LP bypass valve

Fast close allowable condition(OR)

1. Condenser press is High

2. Condenser temperature is H(>80℃)

3. Condenser water level is H(>1200mm)

4. The LP bypass spray water pressure is L(<1.5Mpa)

5. The back temperature of LP bypass valve>120℃

6 LP bypass spray-water regulating valve

1. The position of LP bypass valve >3%, auto put in the automatic condition

7 LP bypass spray water isolation valve

1. The position of LP bypass valve >3%, auto open

2. The position of LP bypass valve≤3%, auto close

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o EE: Electrical Shift Engineer

Note:- During operation of the valve all records should be maintain

You might also like

- One PA Fan TrippingDocument3 pagesOne PA Fan TrippingSubrahmanyam100% (1)

- C&I Part of SCDocument28 pagesC&I Part of SCLakshmi Narayan100% (1)

- Emergency Operations: Shaikh Feroz AliDocument15 pagesEmergency Operations: Shaikh Feroz AliEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Drum Level Control: Presented by Rudra Pratap SinghDocument19 pagesDrum Level Control: Presented by Rudra Pratap SinghRudra Pratap SinghNo ratings yet

- Stopping of One Pa FanDocument1 pageStopping of One Pa FanShift Incharge BrbclNo ratings yet

- EmergencyDocument24 pagesEmergencySanjeevImproveNo ratings yet

- ID FD PA Logic SystemDocument11 pagesID FD PA Logic SystemThirumalNo ratings yet

- APHDocument3 pagesAPHMallinatha PNNo ratings yet

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pages020-SOP of H2 CYLINDER Room ChargingsambhuNo ratings yet

- Secondary Air Damper Control in BoilerDocument10 pagesSecondary Air Damper Control in BoilerSourav DasNo ratings yet

- Vaccuum Killing and PullingDocument2 pagesVaccuum Killing and PullingMY NAME IS NEERAJ..:):)No ratings yet

- Technical Diary Turbine KSKDocument31 pagesTechnical Diary Turbine KSKdreamboy87100% (1)

- Secondary Air Damper ControlDocument3 pagesSecondary Air Damper ControlRajesh Kumar MohantyNo ratings yet

- Scanner Air FanDocument3 pagesScanner Air FanSamNo ratings yet

- Jindal Power SOP Load Shedding RelayDocument4 pagesJindal Power SOP Load Shedding RelayChandramani PatelNo ratings yet

- Secondary Air Damper ControlDocument6 pagesSecondary Air Damper ControlRajesh Kumar MohantyNo ratings yet

- TG Ele Hydro Oil PumpDocument8 pagesTG Ele Hydro Oil PumpsambhuNo ratings yet

- Turbine Tripping on High DTDocument3 pagesTurbine Tripping on High DTatulbhogare7No ratings yet

- Surging & Blow Out of Loop Seals in A CFBC BoilerDocument9 pagesSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragNo ratings yet

- Turbine Stress Evaluator PDFDocument16 pagesTurbine Stress Evaluator PDFLakshmi NarayanNo ratings yet

- Essential Interlocks and Protections for Feed Water and Condensate SystemsDocument18 pagesEssential Interlocks and Protections for Feed Water and Condensate SystemsSanjay GuptaNo ratings yet

- Role of Maintenance in Boiler Energy ConservationDocument125 pagesRole of Maintenance in Boiler Energy ConservationkkannanmtpsNo ratings yet

- Turbine Working & ItsComponentsDocument88 pagesTurbine Working & ItsComponentsHimanshu spoliaNo ratings yet

- IAC PAC Power Plant BarhDocument19 pagesIAC PAC Power Plant BarhMohammad AtaullahNo ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- This Bhel ProjectDocument51 pagesThis Bhel ProjectRaj_005No ratings yet

- Steam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestDocument10 pagesSteam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestAakash RanjanNo ratings yet

- Boiler Protection Gyanendra Sharma NPTI DelhiDocument24 pagesBoiler Protection Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocument41 pagesBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNo ratings yet

- Secondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Document3 pagesSecondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Bineet Kumar VarmaNo ratings yet

- 500 MW Turbine Cycle DescriptionDocument8 pages500 MW Turbine Cycle DescriptionAhemadNo ratings yet

- Technical Diary TurbineDocument29 pagesTechnical Diary TurbineDurjoy Chakraborty100% (1)

- Presentation OnDocument28 pagesPresentation OnAnonymous umnT4ZZcuNo ratings yet

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFDocument4 pagesKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)

- MANAGEMENT OF 24V DC SUPPLY FAILURE FOR SG/TG SYSTEMDocument23 pagesMANAGEMENT OF 24V DC SUPPLY FAILURE FOR SG/TG SYSTEMShiftinchargeengineer dadri coalNo ratings yet

- TDBFP Over Speed ProtocolDocument2 pagesTDBFP Over Speed ProtocolAnoop Kumar AllankiNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- Gen-Seal&cool-New - 500 MWDocument98 pagesGen-Seal&cool-New - 500 MWharisankar100% (2)

- Deh System CommissioningDocument11 pagesDeh System Commissioningdreamboy87No ratings yet

- PA Fan-Blade PitchDocument1 pagePA Fan-Blade PitchSamNo ratings yet

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDocument27 pagesFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNo ratings yet

- How To Deal Emergencies in Thermal Power PlantDocument4 pagesHow To Deal Emergencies in Thermal Power PlantEr Mahendra KeshriNo ratings yet

- Emergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingDocument4 pagesEmergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingPrakash ChoudharyNo ratings yet

- Turbine Emergency Handling GuideDocument3 pagesTurbine Emergency Handling Guideron1234567890No ratings yet

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- Ipcv Not OpeningDocument2 pagesIpcv Not OpeningSAROJNo ratings yet

- Station Black Out Handling and Restoration St1Document8 pagesStation Black Out Handling and Restoration St1Shift Incharge BrbclNo ratings yet

- Final YearDocument51 pagesFinal YearAnand Kumar0% (1)

- Slagging in Steam Generators: Root Cause AnalysisDocument8 pagesSlagging in Steam Generators: Root Cause AnalysispiyushagaNo ratings yet

- Modification in 500MW CBD Line For Proper Boiler Water SamplingDocument54 pagesModification in 500MW CBD Line For Proper Boiler Water SamplingJackSparrow86No ratings yet

- Advanced Cycles JIPTDocument26 pagesAdvanced Cycles JIPTjp mishraNo ratings yet

- Sop For Gauge Glass ChargingssDocument2 pagesSop For Gauge Glass ChargingssKUSH SHARMANo ratings yet

- 500MW Boiler Fans and ProtectionsDocument5 pages500MW Boiler Fans and Protectionsshashank100% (1)

- SOP For BFPDocument2 pagesSOP For BFPsambhuNo ratings yet

- 测试仪合集Document24 pages测试仪合集jackNo ratings yet

- Bag Filter Installation - Manual-3Document23 pagesBag Filter Installation - Manual-3kISHORE100% (1)

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- SPX - 2 - 3 - 4 - 5 - Operating Manual PDFDocument89 pagesSPX - 2 - 3 - 4 - 5 - Operating Manual PDFYaseen JamilNo ratings yet

- Technical Sheet 2910 enDocument4 pagesTechnical Sheet 2910 enSomaia Al-AkrasNo ratings yet

- Bidirectional Sphere Type Prover: Smith Meter ProversDocument2 pagesBidirectional Sphere Type Prover: Smith Meter Proversk ONo ratings yet

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- Bah Side ViewDocument1 pageBah Side ViewSonratNo ratings yet

- KSK Mahanadi Thermal Power Project Control Write UpDocument10 pagesKSK Mahanadi Thermal Power Project Control Write UpSonratNo ratings yet

- Bah ElevationDocument1 pageBah ElevationSonratNo ratings yet

- Part List - BEL0800 PDFDocument1 pagePart List - BEL0800 PDFSonratNo ratings yet

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Vacuum PumpDocument9 pagesSMP For Vacuum PumpSonratNo ratings yet

- SMP For Ba Overflow PumpDocument14 pagesSMP For Ba Overflow PumpSonratNo ratings yet

- SMP For Sealing Water Pump Multi Stage.Document13 pagesSMP For Sealing Water Pump Multi Stage.SonratNo ratings yet

- PM For Fly Ash Dry SystemDocument31 pagesPM For Fly Ash Dry SystemSonratNo ratings yet

- SMP For Slurry PumpDocument14 pagesSMP For Slurry PumpSonrat100% (1)

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- Sop For Vent FilterDocument6 pagesSop For Vent FilterSonratNo ratings yet

- HCSD PDFDocument1 pageHCSD PDFSonratNo ratings yet

- SMP For Agitator (Slurry Sump)Document9 pagesSMP For Agitator (Slurry Sump)SonratNo ratings yet

- FluidizingDocument13 pagesFluidizingSonratNo ratings yet

- FluidizingDocument13 pagesFluidizingSonratNo ratings yet

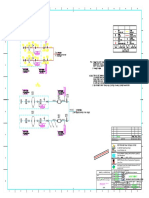

- ESP-FLD. BLOWER-Model PDFDocument1 pageESP-FLD. BLOWER-Model PDFSonratNo ratings yet

- ASH WATER PUMP HOUSE-Model PDFDocument1 pageASH WATER PUMP HOUSE-Model PDFSonratNo ratings yet

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDocument1 pageECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratNo ratings yet

- StructureDocument1 pageStructureSonratNo ratings yet

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDocument1 pageBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratNo ratings yet

- Compressor House ModelDocument1 pageCompressor House ModelSonratNo ratings yet

- Over Flow Pump Concentrator Buffer Tank ModelDocument1 pageOver Flow Pump Concentrator Buffer Tank ModelSonratNo ratings yet

- Pdi EspDocument1 pagePdi EspSonratNo ratings yet

- Silo Unloading ModelDocument1 pageSilo Unloading ModelSonratNo ratings yet

- Water & Slurry BalanceDocument1 pageWater & Slurry BalanceSonratNo ratings yet

- Silo Blower Compressor ModelDocument1 pageSilo Blower Compressor ModelSonratNo ratings yet

- SEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingDocument1 pageSEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingSonratNo ratings yet

- VP To Buffr Hopper-ModelDocument1 pageVP To Buffr Hopper-ModelSonratNo ratings yet

- Benkelman-Beam KCE076BCE058Document7 pagesBenkelman-Beam KCE076BCE058Prabhav DeujaNo ratings yet

- Automatic TransmissionDocument14 pagesAutomatic TransmissionRajanikantJadhav100% (4)

- Astm A 139 - A 139M - 00 QTEZOS9BMTM5TS1SRUQ - PDFDocument9 pagesAstm A 139 - A 139M - 00 QTEZOS9BMTM5TS1SRUQ - PDFMercedes Villacis TroncosoNo ratings yet

- Flowserve LR LRV LLR ManualDocument48 pagesFlowserve LR LRV LLR Manualmahdi tabasianNo ratings yet

- Rheology of PolymersDocument7 pagesRheology of PolymersAnshul GautampurkarNo ratings yet

- Chapter 4 DC MachinesDocument80 pagesChapter 4 DC MachinesKorsa KorsaNo ratings yet

- Sa 387 2019Document6 pagesSa 387 2019CK CkkouNo ratings yet

- Asme B20.1 2006Document26 pagesAsme B20.1 2006Diar Azzis SNo ratings yet

- Hazards of SteamDocument25 pagesHazards of SteamGilles Mathieu100% (3)

- VG602Document2 pagesVG602LucasNo ratings yet

- BOULEVARD M1800 vzr1800 MANUAL SUPLEMENTAR SERVICEDocument50 pagesBOULEVARD M1800 vzr1800 MANUAL SUPLEMENTAR SERVICEMatheusNo ratings yet

- Flow AssuranceDocument58 pagesFlow AssuranceAbdomatar100% (2)

- Boilermate ManualDocument12 pagesBoilermate Manualpaps33No ratings yet

- Partial Vapour Pressure of SO2 Over H2ODocument1 pagePartial Vapour Pressure of SO2 Over H2OJia Yuan ChngNo ratings yet

- Manual de Taller Mitsubishi 4g64Document108 pagesManual de Taller Mitsubishi 4g64MirellaGonzalezGarrido100% (1)

- Nor30p Serv ManDocument187 pagesNor30p Serv Manjason_meyer_14100% (2)

- Boeing-Bump-Index - MoventorDocument5 pagesBoeing-Bump-Index - Moventordavid quinteroNo ratings yet

- 32-A Tension Set Packer Technical DatasheetDocument3 pages32-A Tension Set Packer Technical DatasheetEvolution Oil ToolsNo ratings yet

- ElectroProject Soft Torque Brochure PDFDocument4 pagesElectroProject Soft Torque Brochure PDFGreg CerrutiNo ratings yet

- IPM ModelDocument66 pagesIPM Modelbobo249No ratings yet

- ANSI Standard Fits.-Tables 3 Through 9 Inclusive Show A Series of Standard Types andDocument11 pagesANSI Standard Fits.-Tables 3 Through 9 Inclusive Show A Series of Standard Types andmohamadelsb3No ratings yet

- Solar Car Vehicle DesignDocument224 pagesSolar Car Vehicle Designsheraaz8775% (4)

- 2021 EOA Chemical Feeder SubmittalsDocument2 pages2021 EOA Chemical Feeder Submittalsraquelow68No ratings yet

- Report On Thermal ConductionDocument8 pagesReport On Thermal ConductionSanTosh BirajdarNo ratings yet

- TRC Unit SpecDocument12 pagesTRC Unit SpecJohn ChirinosNo ratings yet

- Afterburners Systems of Turbine EnginesDocument5 pagesAfterburners Systems of Turbine EnginesAzmah EskandriNo ratings yet

- FDBZ290 Air Sampling Smoke Detection Kit: Building TechnologiesDocument6 pagesFDBZ290 Air Sampling Smoke Detection Kit: Building TechnologiesMukesh PadwalNo ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- Tutorial 23 Anchored Sheet Pile WallDocument22 pagesTutorial 23 Anchored Sheet Pile WallHuitzilopochtli Quetzalcóatl0% (1)

- Midterms 1.2Document1 pageMidterms 1.2Jehana NaolNo ratings yet