Professional Documents

Culture Documents

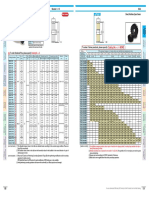

Industrial bearing selection guide for load types, arrangements and design features

Uploaded by

1988Bwaa1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial bearing selection guide for load types, arrangements and design features

Uploaded by

1988Bwaa1Copyright:

Available Formats

Suitability of rolling bearings for industrial applications

Symbols Load carrying capability Misalignment Arrangement Suitable for Design features

+++ excellent ↔ double direction

Separable ring mounting

Standard housings and

(few tenths of a degree)

Dynamic misalignment

++ good ← single direction

accessories available

+ fair ◻ non-locating displacement on the seat

Static misalignment

- poor ◾ non-locating displacement within the bearing

Long grease life

– – unsuitable ✓ yes

Integral sealing

High stiffness

✗ no

Tapered bore

Moment load

Non-locating

Low run-out

High speed

Low friction

Radial load

Axial load

Adjusted

Locating

Floating

Bearing type

A +++ A +++ A +++

Deep groove ball bearings + + ↔ A –, B + – –– ↔ ◻ ✗ ✓ + +++ A✓ ✗ ✗ ✗

A B B ++ B+ B ++

A, B +

Insert bearings + + ↔ –– ++ –– ↔ ↔ ✗ ✗ +++ ++ + ++ ✓ ✗ ✗ ✓

A B C C ++

Angular contact ball bearings, single row +1) ++ ← –– – –– ✗ ✗ ✓ ✗ ++ ++ +++ ++ ++ ✓ ✗ ✗ ✗

A, B ++ A, B ++ ↔ A ++, B + A, C – –, A, B ↔ A, B ◻

matched single row –– ✗ ✗ ++ ++ +++ ++ ++ ✗ ✗ ✗ ✗

A B C C ++1) C ++ ← C–– B– C ← C✗

double row ++ ++ ↔ ++ –– –– ←

→ ◻ ✗ ✗ ++ ++ ++ ++ ++ A✓ B✓ ✗ ✗

A B

four-point contact +1) ++ ↔ –– –– –– ↔1) –– –– –– + +++ ++ ++ ++ ✗ ✓ ✗ ✗

Self-aligning ball bearings + – –– +++ +2) ↔ ◻ ✗ ✓ +++ ++ ++ + +++ ✓ ✗ ✓ ✓

Cylindrical roller bearings, with cage ++ –– –– – –– ✗ ◾ ✗ ✗ ++ +++ +++ ++ +++ ✗ ✓ ✗ ✗

A B

A, B + ← A, B ← A, B ◾ ← A✓

++ –– – –– ✗ ++3) +++ ++ ++ +++ ✗ ✓ ✗ ✗

A B C D C, D + ↔ C, D ↔ C, D ✗ B, C, D ✗

A✗

full complement, single row +++ + ← –– – –– ← A, B ← ✗ ✓ – + + +++ – ✗ ✗ ✗

A B B✓

A – –, B + B ← A ◾ ↔

full complement, double row +++ –– – –– ✗ ✗ – + + +++ – D✓ ✗ ✗ ✗

A B C D ← C + ↔ C, D ↔ B ◾ ←

A, B –

Needle roller bearings, with steel rings ++ –– –– –– ✗ ◾ ←

→ ✗ ✗ ++ ++ + ++ + A✓ ✓ ✗ ✗

A B C C ++

A, B – – A, B ✗ A, B ◾

assemblies / drawn cups ++ –– – –– ✗ ✗ ++ ++ + ++ + B, C ✓ ✓ ✗ ✗

A B C C– C ← C ◾ ←

A –, B +

combined bearings ++ –– –– –– ← ✗ ✓ ✗ + + + ++ + ✗ ✓ ✗ ✗

A B C C ++

Tapered roller bearings, single row +++1) ++ ← –– – –– ← ✗ ✓ ✗ + ++ +++ ++ + ✗ ✓ ✗ ✗

A, B +++ A, B ++ ↔ A +, B ++ A– A, B ↔ A, B ◻ A, B ✗

matched single row –– ✗ + + ++ +++ + ✗ ✓ ✗ ✗

A B C C +++1) C ++ ← C–– B, C – – C ← C✗ C✓

A+

double row +++ ++ ↔ A –, B – – –– ←

→ ◻ ✗ ✗ + + ++ +++ + ✓ ✓ B✓ ✗

A B B ++

Spherical roller bearings +++ + ↔ –– +++ +2) ←

→ ◻ ✗ ✓ + ++ +++ ++ + ✓ ✗ ✓ ✓

CARB toroidal roller bearings, with cage +++ –– – ++ – ✗ ◾ ✗ ✗ + ++ +++ ++ + ✗ ✗ ✓ ✓

full complement +++ –– – ++ – ✗ ◾ ✗ ✗ – + +++ ++ – ✓ ✗ ✓ ✓

A + ← A ←

Thrust ball bearings –– –– –– –– ✗ ✗ ✗ + – ++ + + ✗ ✓ ✗ ✗

A B B + ↔ B ↔

A + ← A ←

with sphered housing washer –– –– ++ –– ✗ ✗ ✗ + – + + + ✗ ✓ ✗ ✗

A B B + ↔ B ↔

Cylindrical roller thrust bearings –– ++ ← –– –– –– ← ✗ ✗ ✗ – – + +++ + ✗ ✓ ✗ ✗

Needle roller thrust beairngs –– ++ ← –– –– –– ← ✗ ✗ ✗ – – + +++ + ✗ ✓ ✗ ✗

Spherical roller thrust bearings +1) +++ ← –– +++ +2) ← ✗ ✓ ✗ – + + +++ + ✗ ✓ ✗ ✗

1) Provided the F

a/Fr ratio requirement is met

2) Reduced misalignment angle – contact SKF 3) Depending on cage and axial load level

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- 0901d196805fd45c PDF Preview MediumDocument1 page0901d196805fd45c PDF Preview MediumMohamed SalemNo ratings yet

- 0901d19680909802 PDF Preview MediumDocument1 page0901d19680909802 PDF Preview MediumYash ChavanNo ratings yet

- Vol-I Part-II Section 5.B.3 1 Technical Investigation Report 487Document1 pageVol-I Part-II Section 5.B.3 1 Technical Investigation Report 487mayank dixitNo ratings yet

- DFAFD ModelfacutDocument4 pagesDFAFD ModelfacutDaniela LungNo ratings yet

- Dis Coupling - Misumi 1Document1 pageDis Coupling - Misumi 1SenthilNo ratings yet

- Screened Backshell Product FinderDocument1 pageScreened Backshell Product Finderpaula09No ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- 2019 Us 3140 PDFDocument1 page2019 Us 3140 PDFBenjamin PeterNo ratings yet

- Fullen PINZA DE FARDO Catalog May21Document4 pagesFullen PINZA DE FARDO Catalog May21xrealqimicoNo ratings yet

- Tiago EvDocument20 pagesTiago EvAnil KumarNo ratings yet

- Carbonate rock classificationDocument1 pageCarbonate rock classificationPaolo BraseyNo ratings yet

- Typical Normal Cut & Fill (Rural Section)Document1 pageTypical Normal Cut & Fill (Rural Section)Rebi HamzaNo ratings yet

- PinPointPDF - Charges - ElectricityDocument12 pagesPinPointPDF - Charges - ElectricityP. V. GAMINGNo ratings yet

- SSG Module 0.5, 0.8 Ground Spur Gears SpecsDocument8 pagesSSG Module 0.5, 0.8 Ground Spur Gears SpecsMarlon EvangelistaNo ratings yet

- World of Lazarus - Character SheetDocument1 pageWorld of Lazarus - Character SheeteduNo ratings yet

- Relationships of Characteristics and Causes of DamageDocument1 pageRelationships of Characteristics and Causes of DamageZeeshan Sajid100% (1)

- Masterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Document1 pageMasterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Anas BasarahNo ratings yet

- Cutting Tool Material PDFDocument43 pagesCutting Tool Material PDFsandeepNo ratings yet

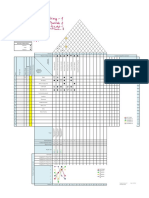

- QFD TesisDocument1 pageQFD TesisGabriel VazquezNo ratings yet

- Eixo 3 - Elemaq 3 V2Document1 pageEixo 3 - Elemaq 3 V2Tainan Guimaraes CostaNo ratings yet

- Shafts precision standards and effective hardened layer depthsDocument1 pageShafts precision standards and effective hardened layer depthsJean AlexNo ratings yet

- 22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYDocument2 pages22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYPSNo ratings yet

- 04 PDFDocument1 page04 PDFsesostrisserbiusNo ratings yet

- Link-Thyssenkrupp Rothe Erde Turntables BrochureDocument9 pagesLink-Thyssenkrupp Rothe Erde Turntables BrochureBang TwoNo ratings yet

- 1102 Crestview Street PDFDocument1 page1102 Crestview Street PDFOliver Blagojevic100% (1)

- Character Sheet ModernAGEDocument1 pageCharacter Sheet ModernAGEEricNo ratings yet

- Comau Medium Payload Eng NJDocument2 pagesComau Medium Payload Eng NJHakan BayrakNo ratings yet

- Replacement Wheels For Casters Wheel Shafts / Grooved Wheels / Caster HoldersDocument1 pageReplacement Wheels For Casters Wheel Shafts / Grooved Wheels / Caster HoldersPugynNo ratings yet

- AC Forwardcalculation SIDocument1 pageAC Forwardcalculation SIMarcela DE AcevedoNo ratings yet

- Gear SsaDocument4 pagesGear Ssa3DSNo ratings yet

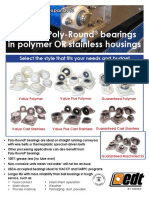

- Solution Poly-Round Bearings in Polymer OR Stainless HousingsDocument3 pagesSolution Poly-Round Bearings in Polymer OR Stainless HousingsLeroy AraoNo ratings yet

- Stand-Alone RF Antenna Perfect for Narrow SpacesDocument2 pagesStand-Alone RF Antenna Perfect for Narrow SpacesYanai ValdésNo ratings yet

- SikaAnchorFix-Selection Chart-ENDocument1 pageSikaAnchorFix-Selection Chart-ENjcunha4740No ratings yet

- Flow Meter Selection GuideDocument1 pageFlow Meter Selection GuidePavendhan PavNo ratings yet

- MGP0634X: Product Data SheetDocument1 pageMGP0634X: Product Data Sheetmoussa jameelNo ratings yet

- Toyota Forklift 8fgdu 150es 25Document2 pagesToyota Forklift 8fgdu 150es 25sharemw100% (1)

- Free GD T Wall Chart PDFDocument1 pageFree GD T Wall Chart PDFAnonymous tGFxtqNNo ratings yet

- Quality Assurance Matrix: PulleyDocument2 pagesQuality Assurance Matrix: PulleySudhakar Mars ConsultantsNo ratings yet

- Stainless Steel Worms: Spur Gears Spur GearsDocument3 pagesStainless Steel Worms: Spur Gears Spur GearsOriental BearingNo ratings yet

- BPW BERGISCHE ACHSEN MAINTENANCE INSTRUCTIONSDocument1 pageBPW BERGISCHE ACHSEN MAINTENANCE INSTRUCTIONSsemu cNo ratings yet

- Passingen PDFDocument1 pagePassingen PDFAnonymous Z4Jo4fXVNo ratings yet

- Bearing replacement guideDocument28 pagesBearing replacement guideAvila Dhanu KNo ratings yet

- Upazila Keraniganj: District Dhaka Road MapDocument1 pageUpazila Keraniganj: District Dhaka Road MapshakilsaiNo ratings yet

- Precision linear guide specifications and pricingDocument1 pagePrecision linear guide specifications and pricingkicsnerNo ratings yet

- Head loss calculation for Souq Waqif car parking projectDocument1 pageHead loss calculation for Souq Waqif car parking projectKarthy GanesanNo ratings yet

- Acme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5Document1 pageAcme Thread General Purpose - Class 2G: Reference PWM Drawing PC50563, Rev. 5metroroadNo ratings yet

- QFD: House of Quality: Project: Revision: DateDocument1 pageQFD: House of Quality: Project: Revision: DateME20M015 Jaspreet SinghNo ratings yet

- Development Psychology 2Document2 pagesDevelopment Psychology 2lovely sowmiNo ratings yet

- QFD Matrix for Pressure Resistant, Durable, and Remotely Controlable LightDocument1 pageQFD Matrix for Pressure Resistant, Durable, and Remotely Controlable Lightsudar1477No ratings yet

- Machinery Fault DiagnosisDocument1 pageMachinery Fault DiagnosisVLD DiagnosticsNo ratings yet

- MachineryFaultsDiagnosis PUTRANATADocument1 pageMachineryFaultsDiagnosis PUTRANATAdaniel_silabanNo ratings yet

- Robus In-Line H: Elical GearboxDocument24 pagesRobus In-Line H: Elical Gearboxjegadish RNo ratings yet

- Evaluation Sheet FormDocument1 pageEvaluation Sheet FormKhaled RamzyNo ratings yet

- WEG Severe Duty Is Standard With Weg w22 Motors Brochure Usaw22sevduty Brochure EnglishDocument16 pagesWEG Severe Duty Is Standard With Weg w22 Motors Brochure Usaw22sevduty Brochure EnglishNickNo ratings yet

- Project 220kV Monopoles SummaryDocument1 pageProject 220kV Monopoles SummaryMOHAMMAD ZUEF - SKIPPER LIMITEDNo ratings yet

- Conaire Standard Construction: Revision History REV Description Date ApprovedDocument1 pageConaire Standard Construction: Revision History REV Description Date ApprovedShabbir AliNo ratings yet

- Definition and Activation of Consumable Materials at the Organization LevelDocument1 pageDefinition and Activation of Consumable Materials at the Organization Leveltucu23456100% (1)

- Avensis Retro-Fit Cruise ControlDocument2 pagesAvensis Retro-Fit Cruise ControlKaren CairneyNo ratings yet

- Aquasnap Product Data 30RA 3PDDocument48 pagesAquasnap Product Data 30RA 3PDYocxan Josue Aguilar OviedoNo ratings yet

- Philippine Material Prices ReferenceDocument69 pagesPhilippine Material Prices Referencestygwygyr86% (7)

- Cassette Inverter (2020) Technical Specification SheetDocument1 pageCassette Inverter (2020) Technical Specification SheetOwais AhmedNo ratings yet

- Aircon Installation Plan for QSU Campus BuildingDocument1 pageAircon Installation Plan for QSU Campus BuildingAYSON N. DELA CRUZNo ratings yet

- Machine Shop ActivitiesDocument6 pagesMachine Shop ActivitiesCllyan ReyesNo ratings yet

- Understanding MEP 1st, 2nd and 3rd Fix WorksDocument4 pagesUnderstanding MEP 1st, 2nd and 3rd Fix WorksAddis MekuriaNo ratings yet

- Manual HomeDocument26 pagesManual HomeRicardo V.No ratings yet

- JNTUK METAL CUTTING & MACHINE TOOLSDocument2 pagesJNTUK METAL CUTTING & MACHINE TOOLSsanyasirao1No ratings yet

- 3 Electrical P120 6VDocument28 pages3 Electrical P120 6Vmalte winbaldNo ratings yet

- Diag - Cab HVAC Connector DiagramDocument2 pagesDiag - Cab HVAC Connector DiagramJoseGarzaNo ratings yet

- Chapter 5Document16 pagesChapter 5aregawi weleabezgiNo ratings yet

- Adapter Obd Yamaha MT09Document3 pagesAdapter Obd Yamaha MT09Stephane sauNo ratings yet

- Plumbing EstimateDocument11 pagesPlumbing EstimateJanina Ruzzle SilangNo ratings yet

- 2002 Sandvik Tamrock Corp. Tampere Plant P.O.Box 100 FIN - 33311 TAMPERE, FINLAND Trade Reg. No. 2.852 Tel. +358 205 44 121, Telex 22335 Parts Fi Telefax +358 205 44 4771Document30 pages2002 Sandvik Tamrock Corp. Tampere Plant P.O.Box 100 FIN - 33311 TAMPERE, FINLAND Trade Reg. No. 2.852 Tel. +358 205 44 121, Telex 22335 Parts Fi Telefax +358 205 44 4771Haianh ChauNo ratings yet

- Routing 1Document191 pagesRouting 1CARLOSNo ratings yet

- RefnetJoint KHRPSeriesDocument2 pagesRefnetJoint KHRPSeriesmohamad dimyatiNo ratings yet

- Part Suce RodDocument17 pagesPart Suce RodAnonymous CpnTXZNWXNo ratings yet

- 206-05-Parking Brake and Actuation 206-05Document11 pages206-05-Parking Brake and Actuation 206-05Tiến Phát Công ty TNHH Đầu Tư Xây DựngNo ratings yet

- BSV RF-240 WHS HV 001 Heating DiagramDocument1 pageBSV RF-240 WHS HV 001 Heating DiagramStroe GeorgeNo ratings yet

- San Jose City College: Symbols Lists, General Notes and Sheet Index - Fire AlarmDocument12 pagesSan Jose City College: Symbols Lists, General Notes and Sheet Index - Fire AlarmRobel MTNo ratings yet

- Series Border Installation GuideDocument1 pageSeries Border Installation GuideSpenNo ratings yet

- SS Speaker HargaDocument9 pagesSS Speaker HargaAllaganur RochmanNo ratings yet

- Hyundai HD78 Transmission M2S5, M3S5Document42 pagesHyundai HD78 Transmission M2S5, M3S5Bigfair HD78100% (1)

- Basic Hand Tools GuideDocument33 pagesBasic Hand Tools GuideNan OoNo ratings yet

- Toilet PPR Pipe & FittingDocument4 pagesToilet PPR Pipe & FittingFaysal ahmedNo ratings yet

- Pump Blow Up DrawingDocument1 pagePump Blow Up DrawingRitche Lim BragaisNo ratings yet

- Instruction Manual Project OverviewDocument603 pagesInstruction Manual Project Overviewtrizzmercado100% (1)

- 2013 Carrier Price ListDocument97 pages2013 Carrier Price ListYessy HernandezNo ratings yet

- Spec BookDocument194 pagesSpec BookCataNo ratings yet