Professional Documents

Culture Documents

06 Pi Daily Coating Insp Report

06 Pi Daily Coating Insp Report

Uploaded by

dilipCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 Pi Daily Coating Insp Report

06 Pi Daily Coating Insp Report

Uploaded by

dilipCopyright:

Available Formats

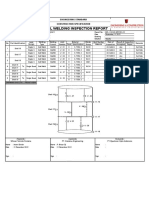

Paint Inspection Date: / / Su M Tu W Th F Sa Pg of

Project #: Copy to:

Daily Coating Inspection Report Inspector: QC Super Owner

Contr

Project/Client:

Location: Attachments:

DFT Sheet NCR/CAR

Description:

Requirements:

Contractor: Spec #: Revision #:

Description of Areas and Work Performed Hold Point Inspections Performed

1. Pre Surface Preparation/Condition and Cleanliness

2. Surface Preparation Monitoring

3. Post Surface Preparation/Cleanliness and Profile

4. Pre Application Prep/Surface Cleanliness

5. Application Monitoring/Wet Film Thickness (WFT)

6. Post Application/Application Defects

7. Post Cure/Dry Film Thickness (DFT)

8. Nonconformance/Corrective Actions Follow-Up

9. Final Inspection

Approved by:

Surface Conditions Ambient Conditions

: : : :

New Maint Primer/Paint Age/Dry/Cure Time (Indiciate AM or PM)

Steel Galvanize Concrete Other Dry Bulb Tempº (C/F) º º º º

Hazard Sample Report # Wet Bulb Tempº (C/F) º º º º

Degree of contamination: % Relative Humidity % % % %

Test: Cl µg/cm2 (µs/cm) Fe ppm pH Surface Tempº (C/F) Min/Max / º / º / º / º

Degree of Corrosion: Dew Point Tempº (C/F) º º º º

Scale Pitting/Holes Crevices Sharp Edges Wind Direction/Speed

Weld Moisture Oils Other Weather Conditions

Painted Surface Condition: Application

Dry to: Touch Handle Recoat Start Time: Finish Time: Est Sq Ft:

Dry/Over Spray Runs/Sags Pinholes Holidays Primer Intermediate Topcoat Touch-Up

Abrasion Fall Out Other Generic Type: Qty Mixed:

Surface Preparation Mfr: Mix Ratio:

Start Time: Finish Time: Est Sq Ft: Prod Name: Mix Method:

Solvent Clean Hand Tool Power Tool Prod #: Strain/Screen:

ºF

HP Wash PSI Other Color: Material Temp:

Min/Hrs

Abrasive Blast Abrasive Type Sample Kit Sz/Cond: Sweat-In Time:

Min/Hrs

Blast Hose Size Nozzle Size/PSI Shelf Life: Pot Life:

Air Supply CFM Air Supply Cleanliness Batch #s Reducer #:

Pt/Qt/Gal

Water/Oil Trap Check Equipment Condition Check (A) Qty Added:

%

Surface Cleanliness and Profile Measurement (B) % by Vol:

Mils

Job Specification SSPC/NACE SP (C) Specified WFT Avg:

Mils

SSPC/NACE Spec/Visual Stds Reducer: Achieved WFT Avg:

Profile Check Disc Tape Gage Airless/Conv Spray Brush Roller Other

Specified mils avg/Achieved mils Pump Pot: Hose Diameter: Air Check:

Surface Effect on DFT Gage/BMR mils Ratio/Size: Hose Length: SEP/Trap:

Dry Film Thickness (DFT) Gage Calibration Record GPM/CFM: Spray Gun: Filter:

Gage Type/

Model

Gage

Serial #

Plate/Shim

Mils/µm

Gage Adj

+/–

Spec Avg

DFT

DFT Last

Coat

DFT This

Coat

PSI: Tip Size: Agitator:

Inspector Signature: Date:

SSPC Sample Form

You might also like

- Painting Report TemplateDocument1 pagePainting Report TemplateMohd Fadzle85% (20)

- Painting Inspection ReportDocument1 pagePainting Inspection Reportakturkam8571% (7)

- Painting Inspection ReportDocument1 pagePainting Inspection ReportAlfian Imaduddin100% (4)

- Method Statement Sandblasting Rev. 0Document7 pagesMethod Statement Sandblasting Rev. 0spazzbgt82% (11)

- Painting Inspection ReportDocument1 pagePainting Inspection Reportsandipthummar1743100% (3)

- Coating & Painting Inspection ChecklistDocument3 pagesCoating & Painting Inspection Checklisthans100% (3)

- Painting Report FormatDocument1 pagePainting Report FormatZulHafiz100% (1)

- Paint Inspection:: Daily Coating Inspection ReportDocument1 pagePaint Inspection:: Daily Coating Inspection ReportEhsan KhanNo ratings yet

- Paint Inspection Checklist I PDFDocument1 pagePaint Inspection Checklist I PDFanush_swaminathan0% (1)

- ITP - Painting & SandBlasting Rev00Document2 pagesITP - Painting & SandBlasting Rev00Sulist N Wahyudie80% (5)

- Blasting & Painting Report - FormatDocument2 pagesBlasting & Painting Report - FormatSenthil Kumaran100% (6)

- Blasting and Painting Inspection and Test PlanDocument3 pagesBlasting and Painting Inspection and Test PlanNnamdi Amadi80% (5)

- Paint Inspection:: Daily Coating Inspection ReportDocument1 pagePaint Inspection:: Daily Coating Inspection ReportEhsan KhanNo ratings yet

- Painting Report FormDocument6 pagesPainting Report FormAhmad Muzamil Ahmad MuradNo ratings yet

- Blaster Sprayer Trade TestDocument7 pagesBlaster Sprayer Trade TestSteven Flynn100% (1)

- Surface Preparation & Painting ReportDocument1 pageSurface Preparation & Painting ReportChethan100% (1)

- CSWIP - WIS5-90516b PART 1Document24 pagesCSWIP - WIS5-90516b PART 1Ehsan KhanNo ratings yet

- MEK Cure TestDocument1 pageMEK Cure TestjoseNo ratings yet

- Surface Prep & Primer PaintingDocument4 pagesSurface Prep & Primer PaintingrajuNo ratings yet

- Painting Report Cd2Document139 pagesPainting Report Cd2sivaNo ratings yet

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- Guide To SSPC Vis 3 PDFDocument3 pagesGuide To SSPC Vis 3 PDFMarco Orteza100% (2)

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDocument34 pages000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Sample Painting ReportDocument2 pagesSample Painting ReportvinothNo ratings yet

- GaugesDocument33 pagesGaugesUsman ansarNo ratings yet

- Report PaintDocument1 pageReport PaintEhsan KhanNo ratings yet

- Painting Inspection Report Angle Bars PDFDocument1 pagePainting Inspection Report Angle Bars PDFpstechnical_43312697No ratings yet

- AISC Paint Inspection LOG (Use This One)Document2 pagesAISC Paint Inspection LOG (Use This One)Richard100% (1)

- Painting Inspection Report-534 - GALVACOATDocument1 pagePainting Inspection Report-534 - GALVACOATRahul MoottolikandyNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- 3.painting InspectionDocument2 pages3.painting InspectionSRINIVASAN S M100% (1)

- Daily Painting Report System P 01ndDocument49 pagesDaily Painting Report System P 01ndArung IdNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Daily Painting & Inspection Report (WI-05-A2) 170&pipe 1Document1 pageDaily Painting & Inspection Report (WI-05-A2) 170&pipe 1pstechnical_433126970% (1)

- Painting 1Document2 pagesPainting 1Kilerz 91100% (2)

- Monthly Blasting and Painting Inspection ReportDocument1 pageMonthly Blasting and Painting Inspection ReportTayyab Mayo0% (1)

- 2 Painting Insp - Report (PN-001)Document1 page2 Painting Insp - Report (PN-001)Vimin Prakash100% (3)

- Painting Report TemplateDocument1 pagePainting Report TemplateFrancisco Ona Amponin Jr.0% (1)

- ITP Blasting Painting.Document2 pagesITP Blasting Painting.mohd as shahiddin jafri100% (4)

- Sandblasting Daily ReportDocument1 pageSandblasting Daily Reportkaito kidNo ratings yet

- Surface Preparation & Coating Application RecordDocument2 pagesSurface Preparation & Coating Application RecordANIL PLAMOOTTILNo ratings yet

- Daily Work Report - Structural Steel Painting: Field AppliedDocument2 pagesDaily Work Report - Structural Steel Painting: Field ApplieddilipNo ratings yet

- Inspection Request For Blasting and Painting Revised - FinalDocument2 pagesInspection Request For Blasting and Painting Revised - Finalwookie1977No ratings yet

- Blasting & Painting Ops ProcedureDocument12 pagesBlasting & Painting Ops ProcedurekolaaruNo ratings yet

- Quality Control Form - 2Document1 pageQuality Control Form - 2ravi ajithNo ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Painting Repair Isnpection Report FormDocument2 pagesPainting Repair Isnpection Report FormDavid Frizt Siregar100% (3)

- Blasting Painting ProcedureDocument4 pagesBlasting Painting ProcedureRyanNo ratings yet

- Procedure For Surface Preparation and PaintingDocument13 pagesProcedure For Surface Preparation and Paintingwilliamsen50% (2)

- Itp Internal CoatingDocument4 pagesItp Internal CoatingkamlNo ratings yet

- 09-Surface Preparation and Painting RecordDocument1 page09-Surface Preparation and Painting RecordJOSHUA SULLEGUE100% (1)

- Blasting and Coating ProcedureDocument8 pagesBlasting and Coating Procedureaamirsaddiq100% (1)

- Painting ReportDocument2 pagesPainting ReporthikmahNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةNo ratings yet

- Painting ReportDocument2 pagesPainting ReportgstketutNo ratings yet

- Itp Concrete CoatingDocument4 pagesItp Concrete Coatingkaml100% (1)

- SSPC - SP3 PipingDocument2 pagesSSPC - SP3 Pipingvirus1999No ratings yet

- COM-EF-844-1: Coatings Inspection Report FormDocument9 pagesCOM-EF-844-1: Coatings Inspection Report FormMaulana Hendra100% (1)

- Form Daily Report Painting (TOP COAT)Document2 pagesForm Daily Report Painting (TOP COAT)PencarianbakatNo ratings yet

- Form Sandblast & Painting ReportDocument3 pagesForm Sandblast & Painting ReportKMPE Div PPICNo ratings yet

- Construction Testing Services Soils Compaction Testing by ASTM StandardsDocument3 pagesConstruction Testing Services Soils Compaction Testing by ASTM StandardsChikadibia OkoroNo ratings yet

- 28-29052022-Pull Off Test (Trial) - Pemb. Dermaga Terminal LPG Presurized Kupang (Piping) - PQT-Pertamina PN-NK-AMM-AKDDocument7 pages28-29052022-Pull Off Test (Trial) - Pemb. Dermaga Terminal LPG Presurized Kupang (Piping) - PQT-Pertamina PN-NK-AMM-AKDudin cupuNo ratings yet

- Form bbs2563Document3 pagesForm bbs2563Julián Tiburcio GonzálezNo ratings yet

- Question 8Document31 pagesQuestion 8Ehsan KhanNo ratings yet

- Question 51 To 60Document32 pagesQuestion 51 To 60Ehsan Khan0% (1)

- Question 9Document31 pagesQuestion 9Ehsan KhanNo ratings yet

- Bgas CswipDocument1 pageBgas CswipEhsan KhanNo ratings yet

- Question 11 To 20Document37 pagesQuestion 11 To 20Ehsan KhanNo ratings yet

- Report PaintDocument1 pageReport PaintEhsan KhanNo ratings yet

- BGAS-CSWIP Application Form For 5 Year RenewalDocument7 pagesBGAS-CSWIP Application Form For 5 Year RenewalEhsan KhanNo ratings yet

- All QuestionDocument38 pagesAll QuestionEhsan KhanNo ratings yet

- Vessel Maintenance and RepairDocument7 pagesVessel Maintenance and RepairEhsan KhanNo ratings yet

- WeeklyDocument1 pageWeeklyEhsan KhanNo ratings yet

- BGAS-CSWIP Application Form For 5 Year RenewalDocument7 pagesBGAS-CSWIP Application Form For 5 Year RenewalEhsan KhanNo ratings yet

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocument4 pagesWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanNo ratings yet

- Paint Notes BgasDocument4 pagesPaint Notes BgasEhsan Khan100% (1)

- 2015 Monthly CalendarDocument12 pages2015 Monthly CalendarEhsan KhanNo ratings yet

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanNo ratings yet

- Pac Seal CatalogDocument76 pagesPac Seal CatalogSuresh Kumar Mittapalli100% (1)

- United States Patent (10) Patent No.: US 7.498,471 B2: Schultz Et Al. (45) Date of Patent: Mar. 3, 2009Document7 pagesUnited States Patent (10) Patent No.: US 7.498,471 B2: Schultz Et Al. (45) Date of Patent: Mar. 3, 2009m yusuf syafzaNo ratings yet

- Rules For Building and Classing Mobile Offshore Drilling Units - 2015Document177 pagesRules For Building and Classing Mobile Offshore Drilling Units - 2015Adriano CostaNo ratings yet

- Apex Steel Catalogue - UpdatedDocument64 pagesApex Steel Catalogue - UpdatedAmos MutoroNo ratings yet

- Fabricf37 PDFDocument8 pagesFabricf37 PDFGerardo HernándezNo ratings yet

- Section 22 60 00 - Medical Vacuum and Gas PipingDocument14 pagesSection 22 60 00 - Medical Vacuum and Gas PipingFeroz KhanNo ratings yet

- English Instructions 1Document2 pagesEnglish Instructions 1api-397845913No ratings yet

- Metallographic Properties: 1. Mild SteelsDocument4 pagesMetallographic Properties: 1. Mild SteelsmuralidharanNo ratings yet

- 5baee5df 4235 4aee 930d 13671813b398 Investment Workshop 3 Oilfield ChemicalsDocument40 pages5baee5df 4235 4aee 930d 13671813b398 Investment Workshop 3 Oilfield ChemicalsamitNo ratings yet

- Industrial Sector of PakistanDocument14 pagesIndustrial Sector of PakistanMohammad AzamNo ratings yet

- Angular ContactDocument3 pagesAngular ContactAnonymous s40NYAUJKdNo ratings yet

- 2A-8C-CHILANGA DC-DETAILED PUMP AND MOTOR DATA SHEET 8B-I1 & 8C-A1 Rev 12Document12 pages2A-8C-CHILANGA DC-DETAILED PUMP AND MOTOR DATA SHEET 8B-I1 & 8C-A1 Rev 12pierre olivierNo ratings yet

- SpectraLOCK PRO Grout PDFDocument3 pagesSpectraLOCK PRO Grout PDFFachuDARNo ratings yet

- Visual Inspection ReportDocument17 pagesVisual Inspection ReportAlif Rahmat Febrianto0% (1)

- Siemen HMS 9200en PDFDocument44 pagesSiemen HMS 9200en PDFSholhan AzizNo ratings yet

- R of in Fine Welding With LaserDocument52 pagesR of in Fine Welding With LaserMaher ShehabNo ratings yet

- Pre Fabricated House ModelsDocument72 pagesPre Fabricated House ModelsjayakumargarudaNo ratings yet

- MCB AbbDocument6 pagesMCB AbbajiewyNo ratings yet

- Sherwin Williams Extreme Bond PrimerDocument2 pagesSherwin Williams Extreme Bond PrimerSmilie ChawlaNo ratings yet

- Codes & StandardsDocument5 pagesCodes & Standardsesakkiraj1590No ratings yet

- Bitumen Compound (MSDS)Document4 pagesBitumen Compound (MSDS)meor azrieNo ratings yet

- Die DitchingDocument1 pageDie DitchingChandrikaReddyReddyNo ratings yet

- Evaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteDocument62 pagesEvaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteRomeo R Chinguel DelgadoNo ratings yet

- Paraffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Document8 pagesParaffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Jit MukherheeNo ratings yet

- EXPORT PRICE LIST 2011 BIOGAS Al 01-06-2011Document10 pagesEXPORT PRICE LIST 2011 BIOGAS Al 01-06-2011Oscar PinaNo ratings yet

- Metal FormingDocument40 pagesMetal Formingsreeeram100% (1)

- Assembly Line BalancingDocument18 pagesAssembly Line BalancingsyedamiriqbalNo ratings yet

- 10 Assignmnt Heat TransferDocument5 pages10 Assignmnt Heat Transferabcd efghNo ratings yet

- Micromechanics of Crack Bridging in Fibre-Reinforced ConcreteDocument9 pagesMicromechanics of Crack Bridging in Fibre-Reinforced ConcreteTran Tuan KietNo ratings yet