Professional Documents

Culture Documents

2.9 Annexure-Book2 PDF

Uploaded by

samy005Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.9 Annexure-Book2 PDF

Uploaded by

samy005Copyright:

Available Formats

ANNEXURE

CHECKLISTS & TIPS FOR ENERGY EFFICIENCY

IN THERMAL UTILITIES

Boilers

• Preheat combustion air with waste heat.

(22 0C reduction in flue gas temperature increases boiler efficiency by 1%)

• Use variable speed drives on large boiler combustion air fans with variable flows.

• Burn wastes if permitted.

• Insulate exposed heated oil tanks.

• Clean burners, nozzles, strainers, etc.

• Inspect oil heaters for proper oil temperature.

• Close burner air and/or stack dampers when the burner is off to minimize heat loss up

the stack.

• Improve oxygen trim control (e.g. -- limit excess air to less than 10% on clean fuels).

(5% reduction in excess air increases boiler efficiency by 1% or: 1% reduction of

residual oxygen in stack gas increases boiler efficiency by 1%)

• Automate/optimize boiler blowdown. Recover boiler blowdown heat.

• Use boiler blowdown to help warm the back-up boiler.

• Optimize deaerator venting.

• Inspect door gaskets.

• Inspect for scale and sediment on the water side.

(A 1 mm thick scale (deposit) on the water side could increase fuel consumption by 5

to 8%.)

• Inspect for soot, flyash, and slag on the fire side.

(A 3 mm thick soot deposition on the heat transfer surface can cause an increase in

fuel consumption to the tune of 2.5%)

• Optimize boiler water treatment.

• Add an economizer to preheat boiler feedwater using exhaust heat.

• Recycle steam condensate.

• Study part-load characteristics and cycling costs to determine the most-efficient mode

for operating multiple boilers.

• Consider multiple or modular boiler units instead of one or two large boilers.

• Establish a boiler efficiency-maintenance program. Start with an energy audit and

follow-up, then make a boiler efficiency-maintenance program a part of your

continuous energy management program.

Steam System

• Fix steam leaks and condensate leaks.

(A 3 mm diameter hole on a pipe line carrying 7 Kg/cm2 steam would waste 33 Kilo

litres of fuel oil per year)

Bureau of Energy Efficiency 186

Checklists & Tips for Energy Efficiecy in Thermal Utilities

• Accumulate work orders for repair of steam leaks that can't be fixed during the heating

season due to system shutdown requirements. Tag each such leak with a durable tag with

a good description.

• Use back pressure steam turbines to produce lower steam pressures.

• Use more-efficient steam desuperheating methods.

• Ensure process temperatures are correctly controlled.

• Maintain lowest acceptable process steam pressures.

• Reduce hot water wastage to drain.

• Remove or blank off all redundant steam piping.

• Ensure condensate is returned or re-used in the process.

(60C raise in feed water temperature by economiser/condensate recovery corresponds to

a 1% saving in fuel consumption, in boiler)

• Preheat boiler feed-water.

• Recover boiler blowdown.

• Check operation of steam traps.

• Remove air from indirect steam using equipment

(0.25 mm thick air film offers the same resistance to heat transfer as a 330 mm thick

copper wall)

• Inspect steam traps regularly and repair malfunctioning traps promptly.

• Consider recovery of vent steam (e.g. -- on large flash tanks).

• Use waste steam for water heating.

• Use an absorption chiller to condense exhaust steam before returning the condensate to

the boiler.

• Use electric pumps instead of steam ejectors when cost benefits permit

• Establish a steam efficiency-maintenance program. Start with an energy audit and follow-

up, then make a steam efficiency-maintenance program a part of your continuous energy

management program.

Furnaces

• Check against infiltration of air: Use doors or air curtains

• Monitor O2 /CO2/CO and control excess air to the optimum level

• Improve burner design, combustion control and instrumentation.

• Ensure that the furnace combustion chamber is under slight positive pressure

• Use ceramic fibres in the case of batch operations

• Match the load to the furnace capacity

• Retrofit with heat recovery device

• Investigate cycle times and reduce

• Provide temperature controllers

• Ensure that flame does not touch the stock

Bureau of Energy Efficiency 187

Checklists & Tips for Energy Efficiecy in Thermal Utilities

Insulation

• Repair damaged insulation.

(A bare steam pipe of 150 mm diameter and 100 m length, carrying saturated steam at 8

kg/cm2 would waste 25,000 litres furnace oil in a year)

• Insulate any hot or cold metal or insulation.

• Replace wet insulation.

• Use an infrared gun to check for cold wall areas during cold weather or hot wall areas

during hot weather.

• Ensure that all insulated surfaces are cladded with aluminum

• Insulate all flanges, valves and couplings

• Insulate open tanks

(70% heat losses can be reduced by floating a layer of 45 mm diameter polypropylene

(plastic) balls on the surface of 900C hot liquid/condensate)

Waste heat recovery

• Recover heat from flue gas, engine cooling water, engine exhaust, low pressure waste

steam, drying oven exhaust, boiler blowdown, etc.

• Recover heat from incinerator off-gas.

• Use waste heat for fuel oil heating, boiler feedwater heating, outside air heating, etc.

• Use chiller waste heat to preheat hot water.

• Use heat pumps.

• Use absorption refrigeration.

• Use thermal wheels, run-around systems, heat pipe systems, and air-to-air exchangers.

Bureau of Energy Efficiency 188

You might also like

- Power Plant FamiliarizationDocument74 pagesPower Plant Familiarizationashish2086No ratings yet

- 105 Database of Solar Pump Companies 1Document559 pages105 Database of Solar Pump Companies 1Bhavin SagarNo ratings yet

- Principles of Gas LiftDocument31 pagesPrinciples of Gas LiftYassine Taktak67% (3)

- Fuels and CombustionDocument26 pagesFuels and CombustionEjaz AhmedNo ratings yet

- Multipass Heat ExchangersDocument21 pagesMultipass Heat ExchangersBrando_BalagonNo ratings yet

- Boiler NotesDocument34 pagesBoiler NotesRakesh Singh BhadoriyaNo ratings yet

- Air-Cond Electrical Load EstimationDocument3 pagesAir-Cond Electrical Load Estimationdto_otbNo ratings yet

- JBC Common Boiler FormulasDocument12 pagesJBC Common Boiler Formulasnesrine10No ratings yet

- Performance Improvement Strategies of Thermal O&MDocument30 pagesPerformance Improvement Strategies of Thermal O&MEjaz Ahmed100% (1)

- Boiler ParameterDocument2 pagesBoiler ParameterFieNo ratings yet

- Compressors & Compressed Gas Audit ChecklistDocument3 pagesCompressors & Compressed Gas Audit ChecklistPerwez21100% (1)

- Safety Valve SelectionDocument14 pagesSafety Valve Selectionakrouti100% (1)

- Boiler Mounting and AccessoriesDocument20 pagesBoiler Mounting and AccessoriesAshok Joshi92% (12)

- Asme Iii NH 2004 PDFDocument225 pagesAsme Iii NH 2004 PDFEjaz AhmedNo ratings yet

- Heat Recovery Steam Generator 5Document29 pagesHeat Recovery Steam Generator 5Hitesh SinglaNo ratings yet

- Boiler Efficiency CalculationDocument44 pagesBoiler Efficiency CalculationgARRYNo ratings yet

- Boiler EfficiencyDocument28 pagesBoiler EfficiencyRintu BiswasNo ratings yet

- Doc-2 Training Material On Coal Fired Thermal Power PlantsDocument21 pagesDoc-2 Training Material On Coal Fired Thermal Power PlantsSharan100% (2)

- Scope of Work ContractDocument6 pagesScope of Work ContractTiu TonNo ratings yet

- Steam System of Power PlantDocument34 pagesSteam System of Power PlantEjaz AhmedNo ratings yet

- Eskom 2017 Q2 Final Draft Report To ShareholderDocument132 pagesEskom 2017 Q2 Final Draft Report To ShareholderChris YellandNo ratings yet

- Boiler Operation On DcsDocument4 pagesBoiler Operation On Dcsarif100% (2)

- Fuel & CombustionDocument22 pagesFuel & CombustionMohammed GamalNo ratings yet

- Heat Rate of Thermal Power PlantDocument15 pagesHeat Rate of Thermal Power Plantsameer betal100% (1)

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- Captive Power PlantDocument6 pagesCaptive Power PlantAman SauravNo ratings yet

- 400kgs Steam Boiler Oil FiredDocument5 pages400kgs Steam Boiler Oil FiredManikandanNo ratings yet

- Presentacion Air Inlet Cooling SystemDocument41 pagesPresentacion Air Inlet Cooling Systemedaniel68100% (1)

- Presentation On Condensers and EvaporatorsDocument32 pagesPresentation On Condensers and Evaporatorsvipul sharma100% (1)

- Catalog Steam Turbines 2013 Engl PDFDocument36 pagesCatalog Steam Turbines 2013 Engl PDFvamsiklNo ratings yet

- Efficient Uses of Steam EnergyDocument67 pagesEfficient Uses of Steam EnergytojinboNo ratings yet

- Final Multi Rifled TubesDocument8 pagesFinal Multi Rifled TubesböhmitNo ratings yet

- Design of A Steam Power PlantDocument19 pagesDesign of A Steam Power PlantAbhishek MeenaNo ratings yet

- Boilers - Thermal EngineeringDocument45 pagesBoilers - Thermal Engineeringommech2020No ratings yet

- Diesel PPDocument58 pagesDiesel PPManvendra Pratap Singh Bisht100% (1)

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- NTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I IDocument44 pagesNTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I Ihaxxo24No ratings yet

- Gas Turbine Power Plant: By: Ms. Monika DeshwalDocument19 pagesGas Turbine Power Plant: By: Ms. Monika DeshwalKeshantSharma100% (1)

- Experiment 1 - Marcet BoilerDocument10 pagesExperiment 1 - Marcet BoilerWee Chuan YeanNo ratings yet

- Lec 3 BoilerDocument20 pagesLec 3 BoilerRajiv SharmaNo ratings yet

- Chandrapur CTPS 15 Days Training ReportDocument21 pagesChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- 3194 PDF PDFDocument7 pages3194 PDF PDFdillipsh123No ratings yet

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajNo ratings yet

- IP (Power Plant Building)Document26 pagesIP (Power Plant Building)Josue Carubio Ricalde Jr.No ratings yet

- Presentation of PressureDocument44 pagesPresentation of PressureMuskan GargNo ratings yet

- Write Up For Boiler Interlock System (TCL) - Rev.1Document26 pagesWrite Up For Boiler Interlock System (TCL) - Rev.1raveekas6148No ratings yet

- National Power Training Institute New Delhi: B. TechDocument14 pagesNational Power Training Institute New Delhi: B. TechAditya PandeyNo ratings yet

- Boiler Fundamental & Water Circulation SystemDocument30 pagesBoiler Fundamental & Water Circulation SystemSamNo ratings yet

- 413 Topic IV-3 (Fossil Fuels and Boiler Efficiency)Document60 pages413 Topic IV-3 (Fossil Fuels and Boiler Efficiency)Sabina Suljic100% (1)

- IEEE BoilerDocument9 pagesIEEE Boiler4nagNo ratings yet

- HRSG ReportDocument46 pagesHRSG Reportoverlord5555No ratings yet

- PMS Theory Chapter3Document47 pagesPMS Theory Chapter3moulitechNo ratings yet

- 34 Boiler AccessoriesDocument21 pages34 Boiler AccessoriesSwaraj TodankarNo ratings yet

- Continuum Mechanics For EngineersDocument53 pagesContinuum Mechanics For Engineersshushant kumarNo ratings yet

- Coal Fired Power Plant PDFDocument1 pageCoal Fired Power Plant PDFboyzes100% (2)

- The Indian Boilers Act 1923Document16 pagesThe Indian Boilers Act 1923Anand Swami100% (1)

- Efficiency of Waste Heat Boiler, HRSGDocument13 pagesEfficiency of Waste Heat Boiler, HRSGHasan Ahmed100% (1)

- ME519 Power Plant DesignDocument6 pagesME519 Power Plant DesignJosef Vill VillanuevaNo ratings yet

- Aarti Steel WHR PDDDocument34 pagesAarti Steel WHR PDDKvvPrasadNo ratings yet

- 7 - Schematic of A Thermal Power PlantDocument29 pages7 - Schematic of A Thermal Power PlantAnonymous 4SIk3AdnNo ratings yet

- Tatyasaheb Kore Institute of Engineering and Technology, WarananagarDocument17 pagesTatyasaheb Kore Institute of Engineering and Technology, WarananagarajayNo ratings yet

- Prism Letter of ExclusivityDocument1 pagePrism Letter of ExclusivityMohammad Mahdi MozaffarNo ratings yet

- Unit - 4 Vapour Power Cycles Session 4 NotesDocument19 pagesUnit - 4 Vapour Power Cycles Session 4 NotesFlamboyantAttittudeNo ratings yet

- Boiler Operation Made Easy - Procedure For Starting and Stopping A Boiler PDFDocument13 pagesBoiler Operation Made Easy - Procedure For Starting and Stopping A Boiler PDFDavid WilliamsNo ratings yet

- ME6701-Power Plant EngineeringDocument16 pagesME6701-Power Plant EngineeringNizam MANo ratings yet

- Heat Rate of TG PDFDocument9 pagesHeat Rate of TG PDFTapash Nag0% (1)

- Condenser Graphical AnalysisDocument24 pagesCondenser Graphical Analysissaisrikanths5168No ratings yet

- Thermal Energy ManagementDocument8 pagesThermal Energy ManagementlucasNo ratings yet

- Improvingeffy Boiler + Steam System-140821063516 SshareDocument8 pagesImprovingeffy Boiler + Steam System-140821063516 SshareAnonymous nw5AXJqjdNo ratings yet

- Major Opportunities of Energy Savings - BoilersDocument2 pagesMajor Opportunities of Energy Savings - BoilersDebasis MisraNo ratings yet

- Energy Conservation in Steam Systems: Som Derashri CEO Academy For Conservation of EnergyDocument32 pagesEnergy Conservation in Steam Systems: Som Derashri CEO Academy For Conservation of EnergyPrudhvi RajNo ratings yet

- Energy Conservation: Topic "Boiler"Document38 pagesEnergy Conservation: Topic "Boiler"Ghazanfar GulNo ratings yet

- Asme Iii Ne 2004 PDFDocument177 pagesAsme Iii Ne 2004 PDFEjaz AhmedNo ratings yet

- ASME III Div.3 2004 PDFDocument173 pagesASME III Div.3 2004 PDFEjaz AhmedNo ratings yet

- ASME III Div. 1 Apend. 2004 PDFDocument491 pagesASME III Div. 1 Apend. 2004 PDFEjaz AhmedNo ratings yet

- WASTE HEAT RECOVERY (HRSG) PerformanceDocument17 pagesWASTE HEAT RECOVERY (HRSG) PerformanceEjaz AhmedNo ratings yet

- ClearSCADA Getting StartedDocument25 pagesClearSCADA Getting StartedEjaz AhmedNo ratings yet

- Steam Turbine Axial ShiftDocument1 pageSteam Turbine Axial Shiftjp mishra100% (1)

- 6 Supercharging and TurbochargingDocument21 pages6 Supercharging and TurbochargingCh ArsalanNo ratings yet

- Procedure Heat ExchangerDocument3 pagesProcedure Heat ExchangerxxooNo ratings yet

- Figure PG-53.3 Diagram For Determining Equivalent Longitudinal Efficiency of Diagonal Ligaments Between Openings in Cylindrical ShellsDocument6 pagesFigure PG-53.3 Diagram For Determining Equivalent Longitudinal Efficiency of Diagonal Ligaments Between Openings in Cylindrical ShellsaruntpeNo ratings yet

- Me2202 Engineering Thermodynamics - Uq - April May 2010Document4 pagesMe2202 Engineering Thermodynamics - Uq - April May 2010BIBIN CHIDAMBARANATHANNo ratings yet

- Bomba de Grasa 9979Document1 pageBomba de Grasa 9979ventas freyreNo ratings yet

- 3.1 Photovoltaic System PDFDocument141 pages3.1 Photovoltaic System PDFCHOON CHEAK YOKNo ratings yet

- 381 En-Bi 201408 Air Treatment Planning 13Document4 pages381 En-Bi 201408 Air Treatment Planning 13RomanCHubaNo ratings yet

- 5 Chain r1Document13 pages5 Chain r1Seaw Rio Rj100% (1)

- Cummins 1250 KW DFLC KTA50 G3 SN 33145179 Load Test ReportDocument1 pageCummins 1250 KW DFLC KTA50 G3 SN 33145179 Load Test ReportRaul BxinNo ratings yet

- ECS2 Lab Report - GensetDocument7 pagesECS2 Lab Report - GensetUI Career ExpoNo ratings yet

- Gte Mock Exam QuestionsDocument1 pageGte Mock Exam QuestionsJohn Gabriel DecenaNo ratings yet

- Kajian Teknis IncenDocument9 pagesKajian Teknis Incenagun bebenNo ratings yet

- This House Believes That The Philippines Should Use Nuclear Energy This House Believes That The Philippines Should NOT Use Nuclear EnergyDocument4 pagesThis House Believes That The Philippines Should Use Nuclear Energy This House Believes That The Philippines Should NOT Use Nuclear EnergyRyzeNo ratings yet

- 02 Semi Continuous DeodorizingDocument12 pages02 Semi Continuous DeodorizingMaicon Espindola Dos SantosNo ratings yet

- CH 9 CalorimetryDocument9 pagesCH 9 Calorimetrycarleston thurgoodNo ratings yet

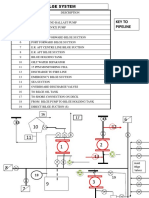

- Key To Pipeline: Bilge SystemDocument23 pagesKey To Pipeline: Bilge SystemvivekNo ratings yet

- Fire Fighting LayoutDocument1 pageFire Fighting LayoutNaqqash SajidNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidGiancarlo CervantesNo ratings yet

- Power Plant - 402 - 7.JSW - Energy - LTD - 0Document20 pagesPower Plant - 402 - 7.JSW - Energy - LTD - 0Ojas SonarNo ratings yet

- Nek 6187 ZDocument3 pagesNek 6187 ZBalaji SaravNo ratings yet