Professional Documents

Culture Documents

Reu Poster I

Uploaded by

api-355836337Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reu Poster I

Uploaded by

api-355836337Copyright:

Available Formats

Lead-Copper Alloys as High Capacity Anode Materials for Lithium Ion Batteries

August 1

Rothenberger , Alan 1

Guo , Adam 2

Heller , and C. Buddie Mullins 1,2

1. Department of Chemistry, 2. Department of Chemical Engineering, University of Texas at Austin

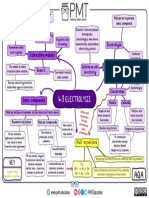

Introduction Experimental Methods Coin Cell Testing Cyclic Voltammetry

Traditional Li-ion Battery (LIB) Synthesis Procedure Slurry Casting Background

• Li metal oxide cathode, separator, graphite anode • Lead too malleable for mechanical milling • Standard slurry composed of active material, • CV involves varying the voltage at 0.1 mA/s and

• Li ions flow from anode to cathode when discharging • Synthesize Pb0.9Cu0.1 alloy in aqueous solution polymeric binder, and conductive carbon measuring the current through a 2032 coin cell

• 9 mmol Pb(NO3)2, 1 mmol CuCl2 • 8:1:1 wt PbO-Cu:CMC90k:Super-P Carbon Black • Peaks are used to determine intermediate lithiation

• Reduced by NaBH4 • Cast onto copper foil at 1.2mg and 0.6mg stages of active material

• HCl and 1,2-diaminopropane as stabilizer and 2032 Coin Cell Results

surfactant, respectively • Constructed a half cell using lithium foil as second

• Dark grey precipitate forms after about 30 min electrode Delithiation

• Centrifuge and wash with water, dry in oven

Top Metal Cap

Materials Characterization Metal Spacer

From Roy et al. “Nanostructured anode materials for lithium ion batteries.” Royal Society of Chemistry, Published 2014.

• LIBs could increase capacity/gram with anodes made Scanning Electron Microscospy (SEM) Lithium Foil

from other group IVA elements (Si, Ge, Sn, Pb) • Synthesized material composed of “layered” lead LiPF6 FEC:DEC Electrolyte

• 6𝐶 + 𝐿𝑖 + + 𝑒 − ⇌ 𝐿𝑖𝐶6 0.167 Li per C • Mostly micron scale particles (1-100 um) Celgard PP 2400 Separator

• 2𝑃𝑏 + 7𝐿𝑖 + + 7𝑒 − ⇌ 𝐿𝑖7 𝑃𝑏2 3.5 Li per Pb LiPF6 FEC:DEC Electrolyte Lithiation

Slurry on Copper Foil

Problems with Non-carbon Group IVA Anodes

Metal Spacer

• Volume change during cycling (up to 300%) pulverizes • Cycle 1 peaks at 1.35 V and 1.55 V suggests

anode structure, decreases battery life Metal Spring chalcogenide (oxide) pre-lithiation

• Solid Electrolyte Interphase (SEI) formation Plastic Cap • Peaks from 1.0 – 0 V correspond to Pb lithiation

• Li interaction with electrolyte at anode forms SEI Bottom Metal Cap

and removes ions from battery

• Larger particles can be broken up with agitation

Stabilizing Agents • Ionic characteristic, material not pure metal Conclusions

• Additives like chalcogenides and transition metals

can buffer volume expansion, increasing battery life Cycling Performance • EDX, XRD suggests material is PbO with imbedded Cu

Agitation on vortex

• Sub-stoichiometric (9:1) ratios increase amount of plate • CV supports oxide hypothesis

available active material

Background • Performing aqueous synthesis in air forms oxides

• Copper used as tin anode stabilizer at 9:1 Largest particles decrease in

• LIB cycling is (dis)charging battery at different c-rates • Carbon from organic surfactant

size or appear more broken up • 1C means the battery is fully charged in 1 hour • Despite this, the material still cycled very well

• C/2 = charge in 2 hours, 2C = charge in 30 min

• PbO/PbO-Cu exhibit great potential as future LIB

Energy-Dispersive X-Ray Spectroscopy (EDX) • Reversible capacity is the output charge per gram

anode materials

• Lead and copper well dispersed throughout material active material (mAh/g)

• Same amount of oxygen as lead, suggests PbO Results

• Atomic ratio about 40 Pb : 40 O : 10 Cu : 10 C

SEM images showing that adding 10% selenium into germanium electrodes decreases film EDX Spectrum Scan for Synthesized Material

C/20

Cycling Performance by Mass Loading Future Directions

delamination and dendritic growths during cycling, improving the performance of the battery. Element Norm. At % Norm. Wt %

Lead 38.8 85.2

• Cycle long term at C/2 to determine electrode stability

From Klavetter et al. “High tap density microparticles of selenium-doped germanium as a high efficiency, stable

cycling lithium-ion battery anode material.” Journal of Materials Chemistry A, Published 2015. Oxygen 38.34 6.5

1.2mg Average 0.6mg Average

Copper 9.9 6.7 C/5

Counts

Lead Anodes in LIBs

Carbon 12.9 1.6 • Identify unknown XRD peaks to determine true

• Lead has capacity of 453 mAh/g C/2

composition of synthesized material

• 35% more than graphite 1C

1C

• Compare cycling data to electrodes of pure PbO

2C

• Lead is malleable and may be able to better handle microparticles to determine function of copper

5C

• Perform hydrothermic/carbonthermic reduction to

Energy (keV)

volume strain during lithiation X-Ray Powder Diffraction (XRD)

• Copper additive is also a better electron conductor • XRD spectrum shows peaks for PbO remove oxides from material

• Incorporating Pb0.9Cu0.1 into LIBs anodes could lead • Unidentified peaks, full composition unknown • Attempt to synthesize pure Pb0.9Cu0.1

to development of smaller, more powerful batteries • Further investigate ability for Pb, Pb0.9Cu0.1, or PbO-Cu

to be used as anodes in Li+ or Na+ batteries

Research Questions • Electrodes stable during cycles, low capacity fade

Intensity (counts)

• Lower mass electrodes exhibit better performance Acknowledgments

• Can a sub-stoichiometric lead-copper alloy be • Thicker electrodes experience worse kinetics

incorporated as an anode material in a successful • Nearly 600 mAh/g at C/20, above theo. capacity

lithium ion battery? • Very small current, likely instrument error

• Will lead anodes experience similar problems as PbO Spectrum

• Effective recovery from 5C to 1C

other group IVA anodes? 2θ (degrees)

• Electrodes can handle fast charging rates

You might also like

- Tov Implant CatalogDocument24 pagesTov Implant CatalogMykolas LukoševičiusNo ratings yet

- A Detailed Lesson Plan in Science 10Document9 pagesA Detailed Lesson Plan in Science 10Maricae NathanielNo ratings yet

- Lecture - 03 Electroplating and ElectrolessDocument31 pagesLecture - 03 Electroplating and ElectrolessRidho QuluqNo ratings yet

- Basic Geotechnical Earthquake Engineering - (Malestrom)Document153 pagesBasic Geotechnical Earthquake Engineering - (Malestrom)Nguyen Dang Hanh100% (15)

- 7 Anthropometry and Workplace DesignDocument22 pages7 Anthropometry and Workplace DesignDeshanBenhurNo ratings yet

- Evaluation of Michaelis-Menten ParametersDocument109 pagesEvaluation of Michaelis-Menten ParametersAnonymous 0zrCNQ100% (1)

- Lecture 4 - Wafer CleanDocument24 pagesLecture 4 - Wafer Cleanimage05No ratings yet

- L01 Introduction To Particle TechnologyDocument35 pagesL01 Introduction To Particle TechnologyPhan NeeNo ratings yet

- Lab Report 8Document14 pagesLab Report 8api-355836337No ratings yet

- Industrial Automation and Control SyllabusDocument3 pagesIndustrial Automation and Control Syllabusyr48No ratings yet

- Inorganic Chemistry ReviewerDocument2 pagesInorganic Chemistry ReviewerKutoo BayNo ratings yet

- Group 3ADocument35 pagesGroup 3AReenaNo ratings yet

- Larry Brown Tom Holme: Jacqueline Bennett - SUNY OneontaDocument8 pagesLarry Brown Tom Holme: Jacqueline Bennett - SUNY OneontaaaaaaNo ratings yet

- TOPIC Products Obtained by ElectrolysisDocument2 pagesTOPIC Products Obtained by Electrolysisvivek daveNo ratings yet

- Interatomic Bonding PDFDocument14 pagesInteratomic Bonding PDFFaysal Qadeer KhanNo ratings yet

- DGT P Block ElementsDocument7 pagesDGT P Block ElementsFreelance WorkerNo ratings yet

- 6 Cal-Contactors Lee Odell FinalDocument30 pages6 Cal-Contactors Lee Odell FinalDivine Jacob MathewNo ratings yet

- Metal FinishingDocument29 pagesMetal FinishingEeraúNo ratings yet

- Lithium Technical NoteDocument2 pagesLithium Technical NoteJGGNo ratings yet

- Cell Construction-AatDocument12 pagesCell Construction-Aatathalim1463No ratings yet

- ChemistryDocument3 pagesChemistryRosanna SessionsNo ratings yet

- The S-Block Elements: The Elements in Which Last Electron Enters The S-Subshell Are Called As S-Block ElementsDocument36 pagesThe S-Block Elements: The Elements in Which Last Electron Enters The S-Subshell Are Called As S-Block ElementstheDarknight2050 (Karthik Sunil)No ratings yet

- IST - Ni BatteriesDocument13 pagesIST - Ni Batteries19-801 Bhargav SreeramuluNo ratings yet

- PM Final ISMDocument17 pagesPM Final ISMnikhil tiwariNo ratings yet

- Metal and Nonmetal ElementsDocument64 pagesMetal and Nonmetal ElementsSherly Christina OctaviaNo ratings yet

- Electrochemistry - Choice of Electrode MaterialsDocument9 pagesElectrochemistry - Choice of Electrode MaterialsHoàng PhúcNo ratings yet

- Rubidium - WikipediaDocument12 pagesRubidium - WikipediakamaalNo ratings yet

- The Process Extracting Metals: 4.3 ElectrolysisDocument1 pageThe Process Extracting Metals: 4.3 ElectrolysisMei XiangNo ratings yet

- Paper Procesamiento de Barros Anódicos 2009Document13 pagesPaper Procesamiento de Barros Anódicos 2009Nelson PeñaNo ratings yet

- Periodic Table Sheet - Def PDFDocument2 pagesPeriodic Table Sheet - Def PDFSarmiento HerminioNo ratings yet

- 1.4 BI CompleteDocument9 pages1.4 BI CompleteRawid GoshanNo ratings yet

- Cobalt: Definition, Mineralogy and DepositsDocument19 pagesCobalt: Definition, Mineralogy and DepositsJesusSalamancaNo ratings yet

- Matter and SubstancesDocument32 pagesMatter and SubstancesnorazlanwahabNo ratings yet

- Types of BatteriesDocument37 pagesTypes of BatteriesvendralokeshNo ratings yet

- Voltaic Cell and Electrolytic Cell: by 5S3 Jocelyne LewDocument9 pagesVoltaic Cell and Electrolytic Cell: by 5S3 Jocelyne LewJocelyne LewNo ratings yet

- Module 2 Lesson 1Document6 pagesModule 2 Lesson 1Celine Marie CervantesNo ratings yet

- Recovery of Metal Values From Spent Lithium-Ion Batteries With Chemical Deposition and Solvent ExtractionDocument7 pagesRecovery of Metal Values From Spent Lithium-Ion Batteries With Chemical Deposition and Solvent Extraction25. Tejas RajabhojNo ratings yet

- PCB PCB Manufacturing Manufacturing 2 2: Me Me + e + e Me MeDocument25 pagesPCB PCB Manufacturing Manufacturing 2 2: Me Me + e + e Me MedanyNo ratings yet

- Alkali and Alkali Earth Metals - SRDocument20 pagesAlkali and Alkali Earth Metals - SRMuzahidul IslamNo ratings yet

- Chapter4 140108061342 Phpapp01Document32 pagesChapter4 140108061342 Phpapp01Nitya DewiNo ratings yet

- The Element of LifeDocument27 pagesThe Element of LifeNubar MammadovaNo ratings yet

- Cobalt: Cobalt Is A Chemical Element With Symbol Co and AtomicDocument14 pagesCobalt: Cobalt Is A Chemical Element With Symbol Co and AtomicKailash DhirwaniNo ratings yet

- Boron FamilyDocument52 pagesBoron FamilyTol Ralph SabNo ratings yet

- The D - and F-Block ElementsDocument12 pagesThe D - and F-Block ElementsSHIVANSHU NemaNo ratings yet

- Chapter7-Electrochemistry (Part2)Document13 pagesChapter7-Electrochemistry (Part2)Annisah MardiyyahNo ratings yet

- Groupings of Elements in The Periodic Table Group I A - The Alkali Metals NaDocument6 pagesGroupings of Elements in The Periodic Table Group I A - The Alkali Metals NaGlad YsNo ratings yet

- Cathodic Protection Applications of Sacrificial AnodeDocument7 pagesCathodic Protection Applications of Sacrificial AnodeSurya PrakashNo ratings yet

- L2 Structure of The Atom ActivityDocument4 pagesL2 Structure of The Atom ActivityFe Anne Thea De Guzman100% (1)

- NTU FYP PresentationDocument46 pagesNTU FYP PresentationchingkeatNo ratings yet

- ElectrolysisDocument3 pagesElectrolysisMohit RawatNo ratings yet

- Cathodic Protection Corrosion Control and PreventionDocument67 pagesCathodic Protection Corrosion Control and PreventionRully KurniawanNo ratings yet

- Hydro Tal CitesDocument1 pageHydro Tal CitesMohamed EL AmineNo ratings yet

- Lithium PresentationDocument1 pageLithium PresentationEthan NaylorNo ratings yet

- Electrolysis of Lead (II)Document3 pagesElectrolysis of Lead (II)Kean San ChinNo ratings yet

- RubidiumDocument12 pagesRubidiumjosevitorromualdoNo ratings yet

- Geometallurgy and Mineral Processing PresentationDocument12 pagesGeometallurgy and Mineral Processing PresentationArnold AsieduNo ratings yet

- GDCH PresentationDocument11 pagesGDCH PresentationSohail Aziz Ahmad MalikNo ratings yet

- Pin Điện Hóa - Bùi Thị Thảo NguyênDocument68 pagesPin Điện Hóa - Bùi Thị Thảo NguyênĐặng Xuân ThắngNo ratings yet

- Chiang - 2011 - MIT-New Electrode Designs For Ultrahigh Energy DensityDocument22 pagesChiang - 2011 - MIT-New Electrode Designs For Ultrahigh Energy DensityvituruchNo ratings yet

- Babbitt Casting and Babbitt Spraying Processes Case Study PDFDocument3 pagesBabbitt Casting and Babbitt Spraying Processes Case Study PDFsaurabhjerps231221No ratings yet

- MBRF2045CT Datasheet PDFDocument3 pagesMBRF2045CT Datasheet PDFPablo AllosiaNo ratings yet

- C1 - Notes 1 of 2 - Solid StateDocument5 pagesC1 - Notes 1 of 2 - Solid StateAtharva BhavsarNo ratings yet

- Bi Drop Electrode: A Novel Non-Toxic Alternative For Metal Analysis Down To The PPT RangeDocument2 pagesBi Drop Electrode: A Novel Non-Toxic Alternative For Metal Analysis Down To The PPT RangeAna PalomaresNo ratings yet

- Electrochemistry Ol Notes 2Document7 pagesElectrochemistry Ol Notes 2Ahmed SherifNo ratings yet

- Chem CH4 F4 SwaDocument5 pagesChem CH4 F4 Swanaseem wanNo ratings yet

- Autochem2920 Brochure 2017 - 2Document5 pagesAutochem2920 Brochure 2017 - 2bau.bau.bau.bauuNo ratings yet

- SGA MP 415 W6 - 1 Corrosion 1Document33 pagesSGA MP 415 W6 - 1 Corrosion 1Phillip WeyersNo ratings yet

- Lab Report 1Document14 pagesLab Report 1api-355836337No ratings yet

- Final Medicines ReportDocument5 pagesFinal Medicines Reportapi-355836337No ratings yet

- Chem 457 Final Project PosterDocument1 pageChem 457 Final Project Posterapi-355836337No ratings yet

- Resume August RothenbergerDocument1 pageResume August Rothenbergerapi-355836337No ratings yet

- Astm D2573 D2573M 18Document4 pagesAstm D2573 D2573M 18deptrailaikieuNo ratings yet

- Double Integration MethodDocument10 pagesDouble Integration Methodmau_boi16100% (1)

- 18-202: Mathematical Foundations of Electrical EngineeringDocument29 pages18-202: Mathematical Foundations of Electrical EngineeringxxqwertyxxNo ratings yet

- BOARD EXAMINATION REVIEWER (Conversion Factors & Some Basic Constants) PDFDocument4 pagesBOARD EXAMINATION REVIEWER (Conversion Factors & Some Basic Constants) PDFGerald RoblesNo ratings yet

- Physics - 11Document11 pagesPhysics - 11Ishika GuptaNo ratings yet

- Water Stagnant of Solar ModulesDocument6 pagesWater Stagnant of Solar ModulesNITIN MISHRANo ratings yet

- Adaptive Control PDFDocument2 pagesAdaptive Control PDFArjun PrasadNo ratings yet

- LUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketDocument7 pagesLUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketThobiasNo ratings yet

- Ce2253 Applied Hydraulic Engg Qus Bank PDFDocument13 pagesCe2253 Applied Hydraulic Engg Qus Bank PDFthamilarasuNo ratings yet

- Pharmaceutical ChemistryDocument19 pagesPharmaceutical ChemistryRaj Nemala Raj NemalaNo ratings yet

- Contherm® Core Scraped-Surface Heat ExchangerDocument2 pagesContherm® Core Scraped-Surface Heat ExchangerKhánh NgânNo ratings yet

- Sinumerik 810T 820T GA3 ProgrammingDocument219 pagesSinumerik 810T 820T GA3 ProgrammingNedret BajramovicNo ratings yet

- Ch. 9 (B) LecDocument38 pagesCh. 9 (B) LecTom UlesNo ratings yet

- Technical Documentation - Regulation (EU) N. 2281 - 2016 - NECS 1314 - 3218 SEERDocument59 pagesTechnical Documentation - Regulation (EU) N. 2281 - 2016 - NECS 1314 - 3218 SEERAlexandru GNo ratings yet

- GeomaticaDocument5 pagesGeomaticaAlcantaraSusyNo ratings yet

- Sri Chaitanya Physics Integer Type Question BANKkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkDocument74 pagesSri Chaitanya Physics Integer Type Question BANKkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkSai GokulNo ratings yet

- An Alternative Method For The Removal of Surfactants From WaterDocument7 pagesAn Alternative Method For The Removal of Surfactants From WatervahidNo ratings yet

- Chapter 7 - TrigonometryDocument30 pagesChapter 7 - TrigonometryAnna MethyldaNo ratings yet

- PIPA BV Eflex - p015 - e PDFDocument8 pagesPIPA BV Eflex - p015 - e PDFNur Cholis HadiNo ratings yet

- Fan7529 Critical Conduction Mode PFC ControllerDocument20 pagesFan7529 Critical Conduction Mode PFC ControllerPompei RusuNo ratings yet

- 1-5 Practice - ADocument2 pages1-5 Practice - AStanleyNo ratings yet

- St501-Ln1kv 04fs EnglishDocument12 pagesSt501-Ln1kv 04fs Englishsanthoshs241s0% (1)

- Phenol Vs Alcohol PDFDocument18 pagesPhenol Vs Alcohol PDFSonNo ratings yet