Professional Documents

Culture Documents

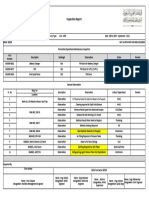

Weekly Executive Summary: Issues Path Forward Achievements

Uploaded by

Mohamed Arafa0 ratings0% found this document useful (0 votes)

16 views4 pagesThe weekly executive summary provides updates on:

1) Issues being addressed including reviewing electrical heat tracing and punch list items.

2) Path forwards such as recommendations for relocating check valves and confirming no extra access ways or plugs are needed.

3) Achievements including assessments of heat tracing capabilities and assisting with load calculations and building design.

Original Description:

weekly

Original Title

Weekly Report

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe weekly executive summary provides updates on:

1) Issues being addressed including reviewing electrical heat tracing and punch list items.

2) Path forwards such as recommendations for relocating check valves and confirming no extra access ways or plugs are needed.

3) Achievements including assessments of heat tracing capabilities and assisting with load calculations and building design.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views4 pagesWeekly Executive Summary: Issues Path Forward Achievements

Uploaded by

Mohamed ArafaThe weekly executive summary provides updates on:

1) Issues being addressed including reviewing electrical heat tracing and punch list items.

2) Path forwards such as recommendations for relocating check valves and confirming no extra access ways or plugs are needed.

3) Achievements including assessments of heat tracing capabilities and assisting with load calculations and building design.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Weekly Executive Summary Week No.

47

Issues Path Forward Achievements

EPROM Mechanical Projects Engineers reviewed

the selection philosophy of the electrical heat

tracing system of the pi[ping systems as per project

specification.

Process Technology Department requested Based on the specification EPROM Mechanical

Engineering Department to check and confirm Projects Engineers re-calculated the heat loss loads

Electrical Heat Tracing for fuel oil line the capability of the supplied electrical heat and required heat for the requested shutdown

#12-P-600127. tracing system to maintain the temperature of scenario and submitted a detailed assessment

the fuel oil blender line 12-P-600127 at 90 C report for line 12-P-600127 and cross checked the

during the shutdown scenario results with the supplied cables vendor data.

EPROM Mechanical Projects Engineers found that

the supplied electrical tracing system is capable to

handle the shutdown scenario and maintain the

temperature of the fuel oil at 90 C.

EPROM Mechanical Projects Engineers conducted a

site visit to check ERC request and found that as

Review GS reply to ERC mechanical punch per isometric drawing # P-110301-61 a 3” spool is

items # PLWD-68771 concerning ERC request installed between the check valve and the

Punch items #PLWD-68771 unit 11

to relocate the position of check valve of H2 spectacle blind of an isolation gate valve of line 3-

line # 3-P-110301 P-110301 which is not matching the submitted

P&ID # 7T04-PR-11-PI-003 at which the check valve

is directly installed downstream the spectacle

Weekly Executive Summary Week No. 47

blind of an isolation gate valve of line 3-P-110301

with no extra piping spool between them.

EPROM Mechanical Projects Engineers

recommended to re-allocate the check valve to be

D/S the spectacle blind & accordingly the spool will

be re-allocated D/S the check valve which will

minimize the quantity of H2 released to ATM

during positive isolation and turn over periods.

EPROM Mechanical Projects Engineers also

highlighted that there is no obstacles at site that

hinder implementation of above mentioned

request.

EPROM Mechanical Projects Engineers conducted a

site visit to check ERC request and held a meeting

Review GS reply to ERC mechanical punch with ERC concerned engineer to discuss possible

items # PLWD-74606 concerning ERC request solutions.

Punch items #PLWD-74606 unit 60

to install mechanical plugs to all EDG-EN01

indicator cocks. EPROM Mechanical Engineer confirmed that there

is no need to install any plugs to the indicator cocks

openings as per vendor drawings.

EPROM Mechanical Projects Engineers conducted a

Review GS reply to ERC mechanical punch site visit to check ERC request and held a meeting

items # PLWD-74279 concerning unavailability with ERC concerned engineer to discuss possible

of accepted access way (space) for solutions.

Punch items #PLWD-74279 unit 60

maintenance of the fuel accumulator of EDG-

EN01 fuel oil skid to perform the required EPROM Mechanical Engineer confirmed that there

maintenance activities. is no need to make any extra access way or

platforms for the fuel oil accumulator as it doesn’t

Weekly Executive Summary Week No. 47

contain any filter media to maintain or replace

during skid maintenance.

EPROM Civil Projects Engineers reviewed all

comments and replies of GS team for the following

Civil punch items:

Grating under compressor K-1301 A/B need to

Review GS reply to ERC civil punch items and be added (punch no. 80912 unit 13).

Civil Punch items in all project units cross check with reference codes and project Grating to be installed under compressor K-

specifications. 1302 A/B (punch no.82138 (unit 13).

Grating under compressor K-1202 A/B need to

be added (punch no. 81747 unit 12).

Ladder of PSV-0033 need concrete step be

added (punch no. 83944 unit 51).

EPROM Civil Engineers assisted EPROM

Assist EPROM maintenance team to calculate maintenance team to calculate the max load of

HCU unit steel structure of R-1501 & R- the max load of steel structure deck that can steel structure deck of HCU unit (R-1501&R-1502)

1502 be resist. that can be resist.

EPROM Civil Project Engineers assisted ERC team to

develop layouts drawings, interior design drawings

for EPROM new offices building and control rooms

Assist ERC team to design and draft all details

layouts

New roads, buildings & rooms layouts required for any new roads, buildings & rooms

ERPOM Civil Project Engineers also developed the

and interior design. layouts and furniture.

required layout and interior design drawings for

the new documents library for the project’s

documentation storing and managing.

Weekly Executive Summary Week No. 47

EPROM Civil Project Engineers assisted ERC team to

develop technical scope of work with all the

Assist ERC team to prepare the technical

interior design requirements and furniture of the

Interior design of new Documents scope of work for the Interior design of new

new Documents Library and specifying the

Library (Document Control Room) . Documents Library (Document Control Room)

minimum requirements for each item including for

.

all required details as (Architecture, Plumbing,

HVAC…etc.)

On daily basis EPROM Mechanical Projects

Engineers perform site survey for random units to

overview the progress of the construction activities

Site Survey for all units and technical Daily site visits and survey to overview

and random and cross check the existing situation

reports developing construction activities and progress.

against the design specification and requirements

and discuss with ERC concerned disciplines any

observations.

Both Mechanical and Civil Projects Engineers

started to develop the required QA/QC

documentation for the engineering department

Developing all the required QA/QC

which was submitted and reviewed by the

Engineering Department documentation for the department in

Engineering Projects Senior Engineer

Documentation. reference to the department scope of work

Job Description for each engineer

and project requirements.

Engineering Department Forms

Engineering Department Procedures

You might also like

- Sacmi MeenaDocument3 pagesSacmi MeenaKrishnendu GhoshNo ratings yet

- Estimates For Epcc/ Epcm SkidsDocument3 pagesEstimates For Epcc/ Epcm SkidsshrieersNo ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- BIDDER'S PRE-BID QUERIES FOR NEW AIR COMPRESSOR PROJECTDocument4 pagesBIDDER'S PRE-BID QUERIES FOR NEW AIR COMPRESSOR PROJECTPanchdev KumarNo ratings yet

- SCD-GR-FM-074 - SOW - EAF Process Optimization SMP1 Rev-02Document34 pagesSCD-GR-FM-074 - SOW - EAF Process Optimization SMP1 Rev-02Thiyagarajan JayaramenNo ratings yet

- TechnicalspecificationDocument15 pagesTechnicalspecificationorbits1s3No ratings yet

- Grouding System Field Test ProcedureDocument9 pagesGrouding System Field Test Proceduremilton1987No ratings yet

- SEC Electrical Installation GuideDocument38 pagesSEC Electrical Installation GuideThameemul BuhariNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNo ratings yet

- Inspection and Testing Transformer InstallationsDocument37 pagesInspection and Testing Transformer InstallationsJellyn Base100% (1)

- D-Approved Instaliiation ProcedureDocument8 pagesD-Approved Instaliiation Procedurevin ssNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- DH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0Document6 pagesDH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0hungNo ratings yet

- Method Statement For CB Replacement Job at MarmulDocument4 pagesMethod Statement For CB Replacement Job at MarmulJohn George100% (2)

- TD-esc-03-de-en-16-046 Rev000a Checklist For E-82 E3, E-82 E4 Pre-Assembly and Assembly PDFDocument7 pagesTD-esc-03-de-en-16-046 Rev000a Checklist For E-82 E3, E-82 E4 Pre-Assembly and Assembly PDFAnonymous 1GuxO3zH0% (1)

- DH3E-PAB-M-JEL-0047 Pressure Test Procedure For Circulating Water PipingDocument30 pagesDH3E-PAB-M-JEL-0047 Pressure Test Procedure For Circulating Water PipingDuy VuNo ratings yet

- Bid Package: "Construction of Oil Collecting Station (OCS) at Barekuri/ Assam"Document1 pageBid Package: "Construction of Oil Collecting Station (OCS) at Barekuri/ Assam"shakuntla5bankerNo ratings yet

- Astm C 307-83Document8 pagesAstm C 307-83Luong Ho VuNo ratings yet

- AL-Rumailah 730MW Combined Cycle Power Plant CW Pipe FQPDocument49 pagesAL-Rumailah 730MW Combined Cycle Power Plant CW Pipe FQPMohammed KadhimNo ratings yet

- NS1-18PAB-M-JEE-1002 R1 Erection Procedure For CW Piping InstallationDocument106 pagesNS1-18PAB-M-JEE-1002 R1 Erection Procedure For CW Piping Installationnamdq-1No ratings yet

- AMUDI EMEKA CV For ChevronDocument4 pagesAMUDI EMEKA CV For ChevronAMUDI EMEKANo ratings yet

- Rework Quality in Focus 14Document3 pagesRework Quality in Focus 14AndersonNo ratings yet

- Eni's Program for Electrical Installation Checks and TestsDocument59 pagesEni's Program for Electrical Installation Checks and TestsAhmed MediniNo ratings yet

- JX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONDocument2 pagesJX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONAmyNo ratings yet

- Sogec - CP Cathodic Protection Training Manual-Module 9Document12 pagesSogec - CP Cathodic Protection Training Manual-Module 9Emre Erdem100% (1)

- Generic Test & Acceptance ChecklistDocument24 pagesGeneric Test & Acceptance ChecklistM Kashif JunaidNo ratings yet

- FPSO MYSTRAS DESCALING WORK EXECUTION PLANDocument10 pagesFPSO MYSTRAS DESCALING WORK EXECUTION PLANMOSES EDWINNo ratings yet

- Mitsui E&S Engineering Co., LTD.: 1 11 DEC 2020 TP EFD REV Date Prepared by Checked by Approved by DescriptionDocument47 pagesMitsui E&S Engineering Co., LTD.: 1 11 DEC 2020 TP EFD REV Date Prepared by Checked by Approved by Descriptionric leonisoNo ratings yet

- Sop Piping ErectionDocument8 pagesSop Piping Erectionsefina mecNo ratings yet

- 19-07 - 22 8.2 (F) VOLTAGE PHASING CHECKS WILL BE CARRIED OUT BETWEEN THE SUB-STATION OF THE RELEVANT UNIT OF THE COMPLEX AND THE GRID STATIONDocument6 pages19-07 - 22 8.2 (F) VOLTAGE PHASING CHECKS WILL BE CARRIED OUT BETWEEN THE SUB-STATION OF THE RELEVANT UNIT OF THE COMPLEX AND THE GRID STATIONsarmastNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPkarthi51289No ratings yet

- Ce 2Document6 pagesCe 2inertiadrift4uNo ratings yet

- Pre Safety ReviewDocument27 pagesPre Safety ReviewMagesh KumarNo ratings yet

- Example Technical ReportDocument4 pagesExample Technical ReportAhmed ElhoniNo ratings yet

- Electrical Feeder System Method StatementDocument7 pagesElectrical Feeder System Method StatementAngelo Castro100% (1)

- Flushing and Cleanning of Fire Fighting Piping SystemsDocument6 pagesFlushing and Cleanning of Fire Fighting Piping Systemsbani alsharifNo ratings yet

- Oa Rpa MCP Hsi 0002 20210930Document1 pageOa Rpa MCP Hsi 0002 20210930arainzada807No ratings yet

- BOQDocument3 pagesBOQarifurdescoNo ratings yet

- Annexure 7 - 220V Speci MSETCL Trombay Nerul 260419 20190903173116Document54 pagesAnnexure 7 - 220V Speci MSETCL Trombay Nerul 260419 20190903173116Anonymous cj7JdRbDbNo ratings yet

- Lessons Learned As oDocument4 pagesLessons Learned As oDeepak GoyalNo ratings yet

- MSRA For Chemical Cleaning Fuel Gas Line at UEN - Monophase - Rev ADocument249 pagesMSRA For Chemical Cleaning Fuel Gas Line at UEN - Monophase - Rev AMainrajNo ratings yet

- Saudi Aramco Hot Reheat Steam ChecklistDocument12 pagesSaudi Aramco Hot Reheat Steam ChecklistzhangNo ratings yet

- Qatar Olympic Committee HVAC Testing ProcedureDocument2 pagesQatar Olympic Committee HVAC Testing ProcedureIbrahim SirpiNo ratings yet

- Double-Loop PI Controller Design of The DC-DC Boost Converter With A Proposed Approach For Calculation of The Controller ParametersDocument13 pagesDouble-Loop PI Controller Design of The DC-DC Boost Converter With A Proposed Approach For Calculation of The Controller ParametersTrình CôngNo ratings yet

- Pre-Com. Procedure For Tertiray - 415V SWGRDocument13 pagesPre-Com. Procedure For Tertiray - 415V SWGRBalamurugan SelvarajNo ratings yet

- Drawing Operating Flow ChartDocument2 pagesDrawing Operating Flow ChartMPA MasnizawatiNo ratings yet

- Method Statement: Electrical and Instrument Cable InstallationDocument5 pagesMethod Statement: Electrical and Instrument Cable InstallationLeoj Saliw-an Palaoag100% (1)

- Work Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of InspectionDocument10 pagesWork Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of Inspectionamith_kmNo ratings yet

- Section 6.0 SCH of Design Req - ACSUDocument2 pagesSection 6.0 SCH of Design Req - ACSUSHIDIBAHARNo ratings yet

- K2S-NG01007551-GEN-EA4606-00001 - C01 - Load Flow and Fault Level StudiesDocument48 pagesK2S-NG01007551-GEN-EA4606-00001 - C01 - Load Flow and Fault Level StudiesCHIBUIKE UKAIBENo ratings yet

- MS-E019 Installation of 11KV SwitchgearDocument8 pagesMS-E019 Installation of 11KV Switchgeara wasayNo ratings yet

- IEC-614391-1 &2 - For Switchgears - GMA-US - LRDocument12 pagesIEC-614391-1 &2 - For Switchgears - GMA-US - LRKapil GalwaniNo ratings yet

- Welding Consumable Control Procedure - Flare KOD Rev ADocument8 pagesWelding Consumable Control Procedure - Flare KOD Rev ARajesh K PillaiNo ratings yet

- Critical Valves Definitions for Block 5A ResumptionDocument3 pagesCritical Valves Definitions for Block 5A ResumptionTahir aminNo ratings yet

- HALAT AMMAR LAND PORT ELECTRICAL AND LIGHTING INSPECTION TEST PLANDocument3 pagesHALAT AMMAR LAND PORT ELECTRICAL AND LIGHTING INSPECTION TEST PLANWaleed SalihNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- Method Statement Elect Pipe UndergroundDocument67 pagesMethod Statement Elect Pipe Undergroundمقاول تكييف كهرباء وصحيNo ratings yet

- Steam Blow-Out: Click Here To Visit UsDocument15 pagesSteam Blow-Out: Click Here To Visit UsAnuraag HiremathNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Weekly (1) 11-11-2018Document1 pageWeekly (1) 11-11-2018Mohamed ArafaNo ratings yet

- Piping Interview QuestionsDocument22 pagesPiping Interview Questionsmsaad288% (34)

- Case Study: IEEE 515Document22 pagesCase Study: IEEE 515Mohamed ArafaNo ratings yet

- EGYPSCO Installations ObservationsDocument12 pagesEGYPSCO Installations ObservationsMohamed ArafaNo ratings yet

- Install VACONODECK Aluminium CoversDocument28 pagesInstall VACONODECK Aluminium CoversMohamed ArafaNo ratings yet

- Case Study: IEEE 515Document22 pagesCase Study: IEEE 515Mohamed ArafaNo ratings yet

- Book 1Document3 pagesBook 1Mohamed ArafaNo ratings yet

- Book 1Document3 pagesBook 1Mohamed ArafaNo ratings yet

- A 672Document73 pagesA 672Maulia SabrinaNo ratings yet

- Insulation Materials Spec Chart Updated JULY 2016Document14 pagesInsulation Materials Spec Chart Updated JULY 2016Mohamed ArafaNo ratings yet

- Case Study: IEEE 515Document22 pagesCase Study: IEEE 515Mohamed ArafaNo ratings yet

- E-PR-006 Projects Civil EngineerDocument4 pagesE-PR-006 Projects Civil EngineerMohamed ArafaNo ratings yet

- Weekly Progress Report 23-10 PDFDocument4 pagesWeekly Progress Report 23-10 PDFMohamed ArafaNo ratings yet

- Weekly (1) 11-11-2018Document1 pageWeekly (1) 11-11-2018Mohamed ArafaNo ratings yet

- Insulation Materials Spec Chart Updated JULY 2016Document2 pagesInsulation Materials Spec Chart Updated JULY 2016instagram agnesNo ratings yet

- E-LR-002 Mechanical Design EngineerDocument4 pagesE-LR-002 Mechanical Design EngineerMohamed ArafaNo ratings yet

- Client 29Document1 pageClient 29Mohamed ArafaNo ratings yet

- LogoDocument1 pageLogoMohamed ArafaNo ratings yet

- Chapter 2 RM - Research ProcessDocument46 pagesChapter 2 RM - Research ProcesseyasuNo ratings yet

- Service Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42ADocument2 pagesService Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42AAmjad AlQasrawi100% (1)

- Smoktech Vmax User ManualDocument9 pagesSmoktech Vmax User ManualStella PapaNo ratings yet

- Emilio Aguinaldo CollegeDocument1 pageEmilio Aguinaldo CollegeRakeshKumar1987No ratings yet

- Polygenic InheritanceDocument13 pagesPolygenic InheritanceSandeep Kumar RaghuvanshiNo ratings yet

- Virtio-Fs - A Shared File System For Virtual MachinesDocument21 pagesVirtio-Fs - A Shared File System For Virtual MachinesLeseldelaterreNo ratings yet

- PediculosisDocument14 pagesPediculosisREYMARK HACOSTA100% (1)

- Ringkasan LaguDocument4 pagesRingkasan LaguJoe PyNo ratings yet

- InteliLite AMF20-25Document2 pagesInteliLite AMF20-25albertooliveira100% (2)

- The Interview: P F T IDocument14 pagesThe Interview: P F T IkkkkccccNo ratings yet

- Appendix 1 Application FormDocument13 pagesAppendix 1 Application FormSharifahrodiah SemaunNo ratings yet

- Circuit AnalysisDocument98 pagesCircuit Analysisahtisham shahNo ratings yet

- POPULARITY OF CREDIT CARDS ISSUED BY DIFFERENT BANKSDocument25 pagesPOPULARITY OF CREDIT CARDS ISSUED BY DIFFERENT BANKSNaveed Karim Baksh75% (8)

- Appliance Saver Prevents OverheatingDocument2 pagesAppliance Saver Prevents OverheatingphilipNo ratings yet

- 2010-12 600 800 Rush Switchback RMK Service Manual PDFDocument430 pages2010-12 600 800 Rush Switchback RMK Service Manual PDFBrianCook73% (11)

- Solutions: Spheres, Cones and CylindersDocument13 pagesSolutions: Spheres, Cones and CylindersKeri-ann MillarNo ratings yet

- Interesting Facts (Compiled by Andrés Cordero 2023)Document127 pagesInteresting Facts (Compiled by Andrés Cordero 2023)AndresCorderoNo ratings yet

- DNA Affirmative - MSDI 2015Document146 pagesDNA Affirmative - MSDI 2015Michael TangNo ratings yet

- PAPERBOARD QUALITYDocument8 pagesPAPERBOARD QUALITYaurelia carinaNo ratings yet

- GKInvest Market ReviewDocument66 pagesGKInvest Market ReviewjhonxracNo ratings yet

- Business Analysis FoundationsDocument39 pagesBusiness Analysis FoundationsPriyankaNo ratings yet

- Communications201101 DLDocument132 pagesCommunications201101 DLAle SandovalNo ratings yet

- Scientology Abridged Dictionary 1973Document21 pagesScientology Abridged Dictionary 1973Cristiano Manzzini100% (2)

- ACL GRC Risk Manager - Usage Guide V1.1Document28 pagesACL GRC Risk Manager - Usage Guide V1.1Rohit ShettyNo ratings yet

- Telephone Triggered SwitchesDocument22 pagesTelephone Triggered SwitchesSuresh Shah100% (1)

- 02 MortarsDocument2 pages02 MortarsTarun kumar DigarseNo ratings yet

- Victor Mejia ResumeDocument1 pageVictor Mejia Resumeapi-510300922No ratings yet

- British Isles Composition GuideDocument4 pagesBritish Isles Composition GuidesonmatanalizNo ratings yet

- Stages of Intimate RelationshipsDocument4 pagesStages of Intimate RelationshipsKrystalline ParkNo ratings yet

- People v. Lagarto, 326 SCRA 693 (2000)Document43 pagesPeople v. Lagarto, 326 SCRA 693 (2000)GioNo ratings yet