Professional Documents

Culture Documents

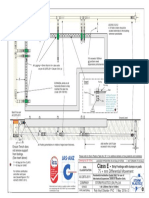

Simbols Painted On Top Surface: 28/10/2016 Unidades S/E MM Escala Project: Plano: Pot Bearing FREE Bearing Verdupot

Uploaded by

Miguel Belda DiezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simbols Painted On Top Surface: 28/10/2016 Unidades S/E MM Escala Project: Plano: Pot Bearing FREE Bearing Verdupot

Uploaded by

Miguel Belda DiezCopyright:

Available Formats

Corrosion protection

SIMBOLS PAINTED ON TOP SURFACE

Item

Sand blasting SA 2 1/2 PL: FREE BEARING (MOVEMENT ALLOWED IN "X" AND "Y")

metallization Zn: 120 m

Epoxy paint: 100 m

A

finish according to EN1337 PU: LONGITUDINALY GUIDED BEARING

(MOVEMENT ALLOWED IN "X"

Sand blasting SA 2 1/2

B Areas in contact with

concrete not painted

PT: TRANSVERSALY GUIDED BEARING

(MOVEMENT ALLOWED IN "Y"

C Dowels not painted

PF: FIXED BEARING (NO MOVEMENT ALLOWED)

A B 7 INDICATES POSITIVE SENSE OF "X" AXIS

X.: LONGITUDINAL AXIS OF THE STRUCTURE

8

INDICATES THE SLOPE OF THE BEARING.

9 PAINTED ON THE TOP SURFACE OF THE SLIDING PLATE.

10 IMPORTANT

Storage and installation of the bearings must be done in accordance to EN 1337-11

11 If the bearing is installed over a concrete element, a leveling pinth of mortar without shrinkage

must be executed with a minimum thickness of 20mm.

12 If the thickness is over the following values, the plinth must be reinforced:

0.1 Surface of contact area + 15mm, in milimeters

13 Perimeter of contact area

50mm

14 On the installation special attention must be paid to the location, leveling and aligment.

For more details see the "Recomendations for Transport, Maintenance and Installation".

Bearing designed in accordance to the norm: EN 1337

All dimensions in mm

COD. DESCRIPCION MATERIAL NORMA

C 1 2 3 4 5 6 C 1 Top nut 10 EN14399-4

2 Top washer EN15048

3 Top bolt 8.8 EN 15048

4 Bottom bolt 10.9 EN 14399-4

5 Bottom washer 300 - 370 HV EN14399-6

6 Bottom dowel C45 EN 10083

7 Top Plate S355JR EN10025

8 Stainless steel sheet AISI 316 EN10088-2

9 PTFE sheet PTFE

10 External Seal EPDM -

11 Piston S355JR EN10025

12 Internal Seal Brass EN 12164

13 Neoprene pad ISO 6446

14 Pot S355JR EN10025

28/10/2016

Project: BEARING VERDUPOT Escala Unidades

Plano: Pot Bearing FREE S/E mm

You might also like

- SD10-01 System DrawingDocument1 pageSD10-01 System DrawingnankinNo ratings yet

- Type AF by Lindapter 1226Document3 pagesType AF by Lindapter 1226Venkatesh PrasathNo ratings yet

- Type F9 by Lindapter 983Document1 pageType F9 by Lindapter 983Dan Dela PeñaNo ratings yet

- Full Flange Butterfly Valve Z 014-Wn Full Flange Butterfly Valve Z 014-WnDocument4 pagesFull Flange Butterfly Valve Z 014-Wn Full Flange Butterfly Valve Z 014-WnNguyen Quang NamNo ratings yet

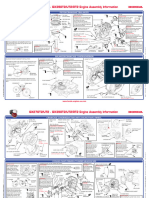

- GX270T2/UT2 GX390T2/UT2/RT2 Engine Assembly Information: Piston/Crankshaft/BalancerDocument2 pagesGX270T2/UT2 GX390T2/UT2/RT2 Engine Assembly Information: Piston/Crankshaft/BalancerAugusto BellezaNo ratings yet

- Hambro Joist Typical DetailsDocument27 pagesHambro Joist Typical DetailsjgjgNo ratings yet

- 20 - Anchor Bolt PERI 14-20 X 130Document2 pages20 - Anchor Bolt PERI 14-20 X 130Gaetano ScorsoneNo ratings yet

- RC Square Pile Brochure 2022Document8 pagesRC Square Pile Brochure 2022k33_hon87No ratings yet

- Lindapter Type f3 DatasheetDocument1 pageLindapter Type f3 DatasheetTarun SharmaNo ratings yet

- 1offtake Gates DesignDocument26 pages1offtake Gates Designprasadnn2001No ratings yet

- Gen NotesDocument1 pageGen NotesGian OrillosaNo ratings yet

- SP 101a Class e Perimeter Plumbing For Strip Footing - StumpsDocument1 pageSP 101a Class e Perimeter Plumbing For Strip Footing - StumpsDenise2512No ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Bridge Inspection Report 06 13 03Document4 pagesBridge Inspection Report 06 13 03Jason BentleyNo ratings yet

- Api 650 RF Pad CalculationDocument1 pageApi 650 RF Pad Calculationfauzy2504No ratings yet

- Type F9 by Lindapter 1124Document1 pageType F9 by Lindapter 1124Suzaikumar R SanglikarNo ratings yet

- Product Spec.: Wall-Smart Model: FamilyDocument1 pageProduct Spec.: Wall-Smart Model: FamilyMichael Ben-DorNo ratings yet

- Project Structure 250L Fuel Day Tank Base Slab DesignDocument6 pagesProject Structure 250L Fuel Day Tank Base Slab DesignKushan Dhanushka NanayakkaraNo ratings yet

- MT 10 2019-10 enDocument10 pagesMT 10 2019-10 entemaquijaNo ratings yet

- Effisus Vapour FR System Technical Data SheetDocument4 pagesEffisus Vapour FR System Technical Data SheetPaula MoçoNo ratings yet

- Shree Janpriya Secondary School - Sctructure Check - PP - 18112021Document3 pagesShree Janpriya Secondary School - Sctructure Check - PP - 18112021prateeksuperNo ratings yet

- Install New O-Rings and Caulk Lock Plate on RadiatorDocument3 pagesInstall New O-Rings and Caulk Lock Plate on RadiatorMiguel ruizNo ratings yet

- Wedge AnchorsDocument18 pagesWedge AnchorsΝικολιδάκης ΒαγγέληςNo ratings yet

- Updated Anchor C20Document6 pagesUpdated Anchor C20anwarNo ratings yet

- Z011-A 04-2017 en PDFDocument4 pagesZ011-A 04-2017 en PDFFerianto STNo ratings yet

- Engine Assembly Gx270 390 enDocument2 pagesEngine Assembly Gx270 390 enadhem ahedNo ratings yet

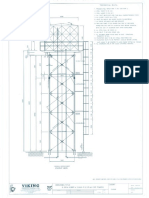

- PERIMETER FENCE-Layout2Document1 pagePERIMETER FENCE-Layout2Stefen SalvadorNo ratings yet

- Kenguru Pro Indoor Equipment Installation ManualDocument8 pagesKenguru Pro Indoor Equipment Installation ManualFlaNo ratings yet

- Bison Hollowcore Floors Bearing DetailsDocument4 pagesBison Hollowcore Floors Bearing DetailsAhmadNo ratings yet

- Bison Hollowcore Floors Bearing DetailsDocument4 pagesBison Hollowcore Floors Bearing DetailsAhmadNo ratings yet

- Hollow Core Floors: Bearing DetailsDocument4 pagesHollow Core Floors: Bearing DetailsAhmadNo ratings yet

- Design of Anchor BoltsDocument1 pageDesign of Anchor BoltsdineshNo ratings yet

- Solid Wall Pipe System Made With PP-MD According To DIN 14758Document2 pagesSolid Wall Pipe System Made With PP-MD According To DIN 14758Carjan BogdanNo ratings yet

- D O Cetop 3/Ng6: Irectional Control Valves Ther Operator IDocument3 pagesD O Cetop 3/Ng6: Irectional Control Valves Ther Operator IhaggNo ratings yet

- Hollowcore PSDocument2 pagesHollowcore PSPeter ParkerNo ratings yet

- 81 1 Catalogo Cilindri ENGDocument14 pages81 1 Catalogo Cilindri ENGsundyaNo ratings yet

- Metal Oxide Varistor-TVR-M SeriesDocument21 pagesMetal Oxide Varistor-TVR-M SeriesJhonatan Samuel Fernandez ChaconNo ratings yet

- Bending Axial WORKING STRESSDocument4 pagesBending Axial WORKING STRESSgade phaniNo ratings yet

- Technical data sheet for 6.1m x 4.88m x 3.66m pressed steel water tankDocument7 pagesTechnical data sheet for 6.1m x 4.88m x 3.66m pressed steel water tankAngus100% (2)

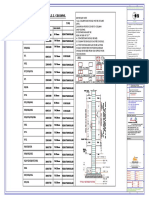

- Details of RCC ColumnDocument1 pageDetails of RCC ColumnRavi Kumar RaiNo ratings yet

- Multi-Monti: Technical ManualDocument16 pagesMulti-Monti: Technical ManualValeriuNo ratings yet

- Crack Width For Oht TankDocument1 pageCrack Width For Oht Tankselvakumar sNo ratings yet

- 1.deck SlabDocument3 pages1.deck SlabvibishnanNo ratings yet

- Frame Fi Xing SXS: AccessoriesDocument2 pagesFrame Fi Xing SXS: AccessoriesMNo ratings yet

- SXRL Data SheetDocument5 pagesSXRL Data SheetARYANo ratings yet

- Calculation Report: Type Z1Document10 pagesCalculation Report: Type Z1vtalexNo ratings yet

- Stress Analysis Report for Commercial Bank of Doha Stone Fixing SystemDocument10 pagesStress Analysis Report for Commercial Bank of Doha Stone Fixing SystemvtalexNo ratings yet

- Underground coalescence separatorDocument1 pageUnderground coalescence separatorKarthikeyan SankarrajanNo ratings yet

- Shear FrictionDocument15 pagesShear FrictionSyed KashifNo ratings yet

- Fig-970-G-OLD DESIGNDocument1 pageFig-970-G-OLD DESIGNAsmaaNo ratings yet

- Punch Typ C4Document10 pagesPunch Typ C4Suhail AhamedNo ratings yet

- X-Stream Product Specification SheetDocument1 pageX-Stream Product Specification SheetTamás KósaNo ratings yet

- Wafer Pattern Butterfly Valve Type Z 011-A Wafer Pattern Butterfly Valve Type Z 011-ADocument4 pagesWafer Pattern Butterfly Valve Type Z 011-A Wafer Pattern Butterfly Valve Type Z 011-AalvaroferroNo ratings yet

- LT21665Document2 pagesLT21665Manuel RoblesNo ratings yet

- H.Flyer - SN Housings - Fno3036 - SN - eDocument4 pagesH.Flyer - SN Housings - Fno3036 - SN - epcesar777No ratings yet

- Base Plate Incl Anchor Rods - Not CompleteDocument41 pagesBase Plate Incl Anchor Rods - Not CompleteSara KhanNo ratings yet

- MiTek PG 83Document1 pageMiTek PG 83Sam LeungNo ratings yet

- R.C.C. Design of Rectangular Sloped FootingDocument4 pagesR.C.C. Design of Rectangular Sloped FootingIbrahim MeharoofNo ratings yet

- High-strength Hilti HIT-HY 150 injection mortar anchorsDocument10 pagesHigh-strength Hilti HIT-HY 150 injection mortar anchorssahanNo ratings yet

- Bridge bearing installation guideDocument15 pagesBridge bearing installation guideMiguel Belda DiezNo ratings yet

- Installation Guide en 1337-11Document3 pagesInstallation Guide en 1337-11Miguel Belda DiezNo ratings yet

- The Wear Behaviour of Arch Bridge Bearings - FINALDocument120 pagesThe Wear Behaviour of Arch Bridge Bearings - FINALMiguel Belda DiezNo ratings yet

- Elastomeric Bearings: Polychloroprene Outperforms Natural RubberDocument4 pagesElastomeric Bearings: Polychloroprene Outperforms Natural RubberMiguel Belda DiezNo ratings yet

- 1JTS EtdDocument190 pages1JTS EtdNagaraj RamachandrappaNo ratings yet

- A Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Document48 pagesA Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Neeraj BhallaNo ratings yet

- Pot Bearing DrawingDocument1 pagePot Bearing DrawingMiguel Belda DiezNo ratings yet

- 1JTS EtdDocument190 pages1JTS EtdNagaraj RamachandrappaNo ratings yet

- Railway MatDocument12 pagesRailway MatMiguel Belda DiezNo ratings yet

- Verdú GeneralDocument36 pagesVerdú GeneralMiguel Belda DiezNo ratings yet

- Expansion Joint Drawing ExampleDocument1 pageExpansion Joint Drawing ExampleMiguel Belda DiezNo ratings yet

- Reference List PotDocument1 pageReference List PotMiguel Belda DiezNo ratings yet

- The Complete Book On Rubber Processing and Compounding TechnologyDocument5 pagesThe Complete Book On Rubber Processing and Compounding TechnologyMiguel Belda DiezNo ratings yet

- Elastomer I C Bearings PDFDocument8 pagesElastomer I C Bearings PDFMiguel Belda DiezNo ratings yet

- Verdú GeneralDocument36 pagesVerdú GeneralMiguel Belda DiezNo ratings yet

- Railway MatDocument12 pagesRailway MatMiguel Belda DiezNo ratings yet

- Pot Bearings: 1. Pot Bearings 2. Pot Bearing. Types. 3. Installation 4. Data SheetsDocument12 pagesPot Bearings: 1. Pot Bearings 2. Pot Bearing. Types. 3. Installation 4. Data SheetsMiguel Belda DiezNo ratings yet

- Ejv 52Document1 pageEjv 52Miguel Belda DiezNo ratings yet

- Epoc 2010 070711Document64 pagesEpoc 2010 070711mikekyrNo ratings yet

- CH 7. Elasticity (Phy - 1)Document22 pagesCH 7. Elasticity (Phy - 1)kingstar122004No ratings yet

- Swep ReportDocument91 pagesSwep ReportAjayi Adebayo Ebenezer-Success100% (2)

- Introduction to Diesel Engine Combustion and Fuel Injection SystemsDocument14 pagesIntroduction to Diesel Engine Combustion and Fuel Injection SystemsMarcelo DieselNo ratings yet

- Control and On-Off Valves GuideDocument87 pagesControl and On-Off Valves Guidebaishakhi_b90100% (3)

- On Concrete - Tanzeela Yaqoob BhatDocument9 pagesOn Concrete - Tanzeela Yaqoob BhatTanzeela BhatNo ratings yet

- IWCF COMBINED DRILLER EQUIPMENT PAPER NO. 1Document21 pagesIWCF COMBINED DRILLER EQUIPMENT PAPER NO. 1andrzema67% (3)

- Life Prediction ConcreteDocument79 pagesLife Prediction Concrete100livNo ratings yet

- TNL12K TNL12: CNC Swiss and Non-Swiss Turning CenterDocument12 pagesTNL12K TNL12: CNC Swiss and Non-Swiss Turning CenterAndréManciniHeinigNo ratings yet

- Dispering Agents Guide Form Water Based Pigment Concentrates Inorganic Pigments en 8e4080b15cDocument26 pagesDispering Agents Guide Form Water Based Pigment Concentrates Inorganic Pigments en 8e4080b15cThuyNo ratings yet

- Coating Process of Melamine - 18092012Document2 pagesCoating Process of Melamine - 18092012Dillibabu RamanujamNo ratings yet

- Genersys 1850Document2 pagesGenersys 1850Villalobos EduardoNo ratings yet

- Concrete Formwork Loads and Pressure Calculations PDFDocument8 pagesConcrete Formwork Loads and Pressure Calculations PDFmohamed.s.elsayedNo ratings yet

- HDD Design and MethodologyDocument14 pagesHDD Design and MethodologyVipin Gupta100% (4)

- Skytrack - G9-43A-10-31-12 Service ManualDocument244 pagesSkytrack - G9-43A-10-31-12 Service ManualGrover49No ratings yet

- Installation Module: Xarios RangeDocument20 pagesInstallation Module: Xarios Rangefaza1111No ratings yet

- 11aDocument44 pages11agegegegNo ratings yet

- Old Room Thermostat en Up To Nov2017Document4 pagesOld Room Thermostat en Up To Nov2017BilalNo ratings yet

- SCS Completion Tool CatalogDocument118 pagesSCS Completion Tool CatalogBAGHFAY16100% (1)

- Equivalent Weight Class XI DPPDocument3 pagesEquivalent Weight Class XI DPPAshwin Jambhulkar0% (1)

- TDS Nitobond SBR IDDocument4 pagesTDS Nitobond SBR IDIyus SopandiNo ratings yet

- 13709e2a-4be0-43bd-ab3d-95779c29a596Document15 pages13709e2a-4be0-43bd-ab3d-95779c29a596devNo ratings yet

- Loos Parni Kotlovi enDocument20 pagesLoos Parni Kotlovi enŽarko Krkeljić100% (1)

- Line Calculation & Sizing (HYSYS) - PPT Professional Development Course-Bangladesh - 2015.10.05Document18 pagesLine Calculation & Sizing (HYSYS) - PPT Professional Development Course-Bangladesh - 2015.10.05AriefNo ratings yet

- Production Engineering Questions and Answers Indo German Tool Room Ahmedabad by Sudhir ChauhanDocument37 pagesProduction Engineering Questions and Answers Indo German Tool Room Ahmedabad by Sudhir ChauhanSUDHIR CHAUHAN91% (23)

- Catalog-I PS41Document2 pagesCatalog-I PS41rahmadazharisNo ratings yet

- NWJ s2 Meryem BoutgoullaDocument10 pagesNWJ s2 Meryem BoutgoullaoussamaNo ratings yet

- Calculating and Displaying Fatigue ResultsDocument42 pagesCalculating and Displaying Fatigue ResultsBekirHanNo ratings yet

- DIY Rear Aircon Vents for Indigo MarinaDocument35 pagesDIY Rear Aircon Vents for Indigo MarinaHarshal DhanawadeNo ratings yet

- Automated HPTLC for Sophisticated Chromatographic AnalysisDocument25 pagesAutomated HPTLC for Sophisticated Chromatographic AnalysisIshfaq AhmadNo ratings yet

- Solving Common Coating ProblemsDocument1 pageSolving Common Coating ProblemsNguyên Nguyễn100% (1)