Professional Documents

Culture Documents

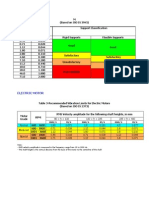

Vibration Severity - IsO 2372 Chart

Uploaded by

Jagga RaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vibration Severity - IsO 2372 Chart

Uploaded by

Jagga RaoCopyright:

Available Formats

E and EL Pulverizer Modifications for Optimum Performance

Since The Babcock & Wilcox E to EL conversions

Company (B&W) introduced the The EL-type pulverizer (Figures 1

E and EL pulverizers, a significant and 2) is a higher capacity pulverizer

number of functional and mechanical when compared to the original E-type

improvements have been made. These pulverizer of the same size. E to

improvements provide added benefits EL conversions have significantly

to our customers such as increasing improved the availability, capacity,

availability and reliability, and reduc- and reliability of E-type pulverizers.

ing maintenance. The EL-type pulverizer is also much

less prone to coal dribble problems

Several of these B&W improvements due to an improved bottom grinding

are described in this brochure. Also, ring and throat configuration. (see

many of these enhancements have Figure 3). The E-type pulverizer can be

more detailed literature available. The upgraded to the EL design at one time,

item number is indicated after the or it can be upgraded in stages. The

appropriate section. These items are most economical time to upgrade to

available through your regional B&W the EL design is when a grinding zone Figure 2

Sales or Service office, or by calling overhaul is being performed.

1-800-BABCOCK.

A complete conversion of an

E-type pulverizer to the EL design

typically includes a new top and

bottom grinding ring, throat, relief

gate, and housing units (wear

plates). If the E-type mill includes

a yoke-driven rotating classifier

and a top ring designed for use

with multi-coil springs and spider

guides, the E to EL conversion

would also include a stationary

classifier or DSVS® rotating

classifier, and single coil dual

purpose springs and spring bolt

assemblies. EL pulverizers may

require larger size drive motors to

grind the additional coal, as well

as higher capacity primary air

fans to supply the air flow needed

to transport the additional coal

through the mill. The existing

pulverizer drive motor and fan

can be retained after the retrofit

is made, however, the full EL

pulverizer capacity increase will

not be realized.

High spin stationary

classifier

Redesigned stationary classi-

fier louver sections recirculate

additional ground coal back to

the grinding zone for improved

fineness and/or throughput for a

Figure 1 given fineness.

13 5/8 in. dia.

12 1/4 in. dia.

Figure 5

standard 12-1/4 inch diameter balls

(see Figure 5). The larger balls are

used with a set of specially matched

top and bottom grinding rings all cast

in VAM-20 material. Increased wear

life translates to fewer grinding zone

overhauls. When using the 13-5/8

inch balls, B&W’s patented On-Track™

system is required. (Order Brochure #

PS-384)

Figure 3

On-Track™ retrofit package

These sections are available for most cast from B&W’s VAM®-20 material

sizes of E and EL pulverizers. A new and is recommended for applications B&W’s On-Track grinding element

classifier cone/tailings section is gener- using highly abrasive coals. The second package limits ball and top ring

ally required with this modification. flute adds wear material and helps movement that often leads to shaft

break up eddy currents in the coal failure, spring failure and grinding ring

flow patterns that can occur upstream chipping (see Figure 6). With B&W’s

Raw coal diverter chute On-Track package, rotational and

of the flute leading to excessive wear.

B&W provides a raw coal diverter In extreme cases with highly abrasive horizontal movement of the top grind-

chute to direct the incoming coal coals, the traditional housing unit ing ring is minimized with the use of a

towards the center of the pulverizer, may wear completely through causing snubber guidance system. Heavy-duty

or inboard of the grinding elements. erosion of the pulverizer housing. grinding rings feature deeper ball

Installation of a diverter chute will The two-fluted housing liners are tracks and additional material to

reduce the inventory of coal inside the interchangeable with the single flute better resist chipping. The On-Track

pulverizer resulting in a reduction in liners. The two-fluted housing units package can be added to any standard

pressure drop and increased fineness. are not available in the bolt-through EL-64, EL-70 or EL-76 pulverizer. It is

design. (Order Brochure # PS-385 and especially beneficial to those mills that

Bolt-through housing units PS-411) experience significant shaft or spring

failures or extensive ring chipping.

The original design housing units are (Order Brochure # PS-386)

held in place with a clamp at the top

while the bottom rests on the pulver-

izer throat plate. Occasionally the High inlet air temperature

housing unit may experience excessive operation

vibration, cracking, or erosion of the Coals with lower heating value and

top clamp causing the housing unit higher moisture content, such as

to shift out of position. B&W has Single Flute Powder River Basin coals, require

developed a housing unit design that a much higher pulverizer inlet air

uses bolts through the housing unit temperature. The following three

and the pulverizer housing. This new modifications were developed by B&W

design provides a more secure housing to optimize pulverizer operation when

unit mounting system and is easier to using these types of coals.

install.

Two Flutes Figure 4

High temperature bottom ring with

Two-fluted EL pulverizer heat shield

housing unit

When operating with inlet air

A new housing liner designed for EL LongLife™ 13-5/8 inch temperatures above 500F (260C),

pulverizers will include two flutes diameter grinding ball original design EL bottom grinding

instead of the traditional single flute The 13-5/8 inch diameter LongLifeTM rings are more susceptible to breaking

design for reduced localized wear and pulverizer balls for EL-64, EL-70 from excessive thermal stresses. B&W

extended life of the housing liner (see and EL-76 pulverizers provide 40% offers a bottom grinding ring designed

Figure 4). This new housing liner is more wear material compared to the specifically for use with high inlet

Spring bolt assemblies slide gate can be installed at the outer

Spring bolts and adjusting nuts are side of the fabricated box.

available with ACME threads for

installation in existing spring bolt Grinding zone access door

brackets. ACME threads minimize An access door located on the back

galling and require less torque to make side of the mill provides an additional

spring adjustments. opening for direct access to the area

Figure 6

of the grinding zone that is difficult to

Complete new ACME threads spring reach from the large maintenance door

air temperature applications. The bolt assemblies are also available (see Figure 7). Access can be gained

design utilizes a steel ring seat which with a new key/keyway design that through this opening to adjust springs

acts as a heat shield surrounding the includes a seal and wiper installed and remove tramp iron. The door is

outer perimeter of the bottom ring to between the spring bolt and lower included as part of the On-Track™

reduce the thermal stresses which can part of the bracket. A permanently package to provide access for installa-

sometimes cause premature failure. lubricated thrust washer is installed tion for the one snubber assembly that

between the adjusting nut flange and is not easily accessible from the large

High temperature throat plates the nut retainer to reduce the amount maintenance door. (Order Brochure

of torque required to rotate the nut. A # PS-384 and PS-386)

To maintain the required mass flow spring bolt bracket erosion guard and

of air per pound of coal, the higher spring bolt thread dust shield is also

temperature inlet air causes higher Cera-VAM® erosion

provided. (Order Brochure # PS-202)

volume flow and higher air velocity protection

entering the grinding zone. The higher Internal pulverizer components

velocity will upset coal circulation Pneumatically-operated can be protected from erosion by

within the pulverizer, which can lead pyrites gates using Cera-VAM® ceramic tile lining.

to mechanical damage and reduced Pneumatically-operated upper slide Ceramic-lined panels are available

reliability. To prevent this effect, the gates have been developed for some for the pulverizer housing and the

throat gap should be adjusted to of the larger size E and EL pulverizers. classifier cone. Special panels can be

provide proper air velocity. However, This system provides an improved made to protect just about any internal

standard throat plates will not allow design in the slide gates for long pulverizer component (see Figure 8).

sufficient throat gap adjustment to service and positive shutoff. The New design burner pipe swing valve

reach the desired velocity for primary minimal effort required to empty the assemblies, including ceramic-lined

air temperatures above 500F (260C). pyrites box can significantly reduce seats are also available. Extensive

B&W offers high temperature throat maintenance time. Fabricated pyrites commercial application of Cera-VAM

plates to provide the necessary throat boxes can sometimes be attached to ceramic has proven to extend the life

gap for these types of coals. the existing pyrites box to increase of protected components, thereby

holding capacity. If space is available reducing overall operating costs.

between the pyrites box and floor, an (Order Brochure # PS-297)

Oil cooler additional pneumatically operated

During high inlet air temperature

operation it is possible for the pulver-

izer’s lubricating oil to exceed the

design temperature limits and degrade

its lubricating properties. To maintain

the oil’s lubricating properties, B&W

offers an external shell and tube water

cooled heat exchanger to reduce lube

oil temperatures. This system utilizes

the existing oil pump.

Main shaft air seal housing

with replaceable seal rings Access

Door

New design air seal housings are

available with replaceable seal rings.

This modification allows EL users to

reduce maintenance costs by replacing

only the labyrinth seals without the

need to replace the entire air seal

housing assembly. In some applications,

original design air seal housings can be

machined to accept the replaceable seals. Figure 7

DSVS® rotating classifier

The DSVS® rotating classifier provides

a means to increase coal fineness and/

or throughput (see Figure 1). This mill

retrofit goes well beyond the improve-

ments achievable with stationary

classifier retrofits, especially when

over 80% through a 200 mesh screen

is required. Rotating classifier pressure

drop is lower than that of stationary

classifiers. In addition, grinding

zone pressure drop is lower with the

rotating classifier because it does

not recirculate as many fine particles

back to the grinding zone as is the

case with stationary classifiers. Even

when higher throughput is required

at the expense of 200 mesh fineness,

rotating classifier has the ability to

maintain the very high percent passing

50 mesh fineness. (Order Brochure #

E101-3136)

Why choose B&W for your

pulverizer modifications?

Who knows more about your E or

EL-type pulverizer?

•

B&W invented them and is

continually researching, designing

and testing improvements.

•

B&W has extensive experience in

grinding all types and blends of Figure 8

coals.

•

All retrofit parts and materials are For more information on any of the

engineered and manufactured to modifications covered in this brochure,

the original specifications to ensure contact your regional Sales or Service

proper fit and performance. office, or call 1-800-BABCOCK.

www.babcock.com

Babcock & Wilcox Power Generation Group, Inc. Established in 1867, Babcock & Wilcox is a global leader in advanced

20 S. Van Buren Avenue energy and environmental technologies and services for the power

Barberton, Ohio 44203 USA and industrial markets, with operations, subsidiaries and joint

Phone: 330.753.4511 ventures worldwide.

Fax: 330.860.1886

The information contained herein is provided for general information For more information, or a complete listing of our sales and

purposes only and is not intended nor to be construed as a warranty, an

offer, or any representation of contractual or other legal responsibility.

service offices, send an e-mail to info@babcock.com, or access our

website at www.babcock.com.

DSVS, VAM, Cera-VAM, LongLife and On-Track are trademarks

of The Babcock & Wilcox Company.

© 2006 The Babcock & Wilcox Company. All rights reserved.

PS-410 500DC0I

You might also like

- Result Vibration Analysis: Picture MachineDocument2 pagesResult Vibration Analysis: Picture Machinefelix haryokoNo ratings yet

- ISO vibration standards extraction summaryDocument1 pageISO vibration standards extraction summarySeto M. PramonoNo ratings yet

- 121a45 PDFDocument51 pages121a45 PDFImran AhmadNo ratings yet

- Cirkan ZsDocument1 pageCirkan ZsbilalNo ratings yet

- VIBDI skriptaEN PDFDocument114 pagesVIBDI skriptaEN PDFЖивко ОрешковNo ratings yet

- Principle of Acceleration SensorsDocument7 pagesPrinciple of Acceleration SensorsEr Vijay MamoriaNo ratings yet

- Electrical Diagnostic Check ListDocument1 pageElectrical Diagnostic Check ListSergiSerranoNo ratings yet

- Spike Sorting TutorialDocument25 pagesSpike Sorting Tutorialtiger05No ratings yet

- Dacnis SH 68 TdsDocument1 pageDacnis SH 68 TdsMedo MedooNo ratings yet

- AzimaDLI Severity Chart 2013 PDFDocument1 pageAzimaDLI Severity Chart 2013 PDFEswin Paico de la CruzNo ratings yet

- Carter EpDocument1 pageCarter EpNguyễn Quang HưngNo ratings yet

- Nevada Reports 1992 (108 Nev.) PDFDocument1,028 pagesNevada Reports 1992 (108 Nev.) PDFthadzigsNo ratings yet

- ABB Nema MotorDocument44 pagesABB Nema MotorAlejandroInostrozaNo ratings yet

- Model 3741E1210G DC Response Accelerometer Installation and Operating ManualDocument16 pagesModel 3741E1210G DC Response Accelerometer Installation and Operating ManualfazzlieNo ratings yet

- Screw CompressorDocument2 pagesScrew CompressorRiti AdhikariNo ratings yet

- Synthetic ester oils for air compressorsDocument1 pageSynthetic ester oils for air compressorsironiteNo ratings yet

- DatasheetDocument7 pagesDatasheetTrọng Vỹ TrươngNo ratings yet

- Developing an ISO Standard for Gearbox Vibration MonitoringDocument27 pagesDeveloping an ISO Standard for Gearbox Vibration MonitoringKaradiasNo ratings yet

- Electrical Machine: Understanding How Rotating Magnetic Fields WorkDocument50 pagesElectrical Machine: Understanding How Rotating Magnetic Fields WorkTanvi SuryawanshiNo ratings yet

- Machinery fault diagnosis guide to vibration analysisDocument42 pagesMachinery fault diagnosis guide to vibration analysisAbdurrhman AlzhraniNo ratings yet

- VA Report - BPCL Bangalore - 16.8.22Document43 pagesVA Report - BPCL Bangalore - 16.8.22keshava RNo ratings yet

- Laser Alignment Systems For Shafts, Turbines, and MachinesDocument16 pagesLaser Alignment Systems For Shafts, Turbines, and MachinesMarcosNo ratings yet

- Visga 68Document2 pagesVisga 68cajascNo ratings yet

- Anomalert Motor Anomaly Detector Datasheet-286754k WWW - Ihi.clDocument12 pagesAnomalert Motor Anomaly Detector Datasheet-286754k WWW - Ihi.clBraian GomezNo ratings yet

- Velocity Severity Velocity Range Limits and Machine Classes ISO Standard 10816-1Document1 pageVelocity Severity Velocity Range Limits and Machine Classes ISO Standard 10816-1Karthik VkNo ratings yet

- Forbes Monec 8964 ManualDocument48 pagesForbes Monec 8964 Manualrajanarsu12No ratings yet

- Field Alignment Kit: Hardware ManualDocument12 pagesField Alignment Kit: Hardware ManualAnonymous dPyHoLNo ratings yet

- Vibration Measurement and Analysis of Rotational Machines: at Makstil Hotplate MillDocument4 pagesVibration Measurement and Analysis of Rotational Machines: at Makstil Hotplate MillMarija PetkovskaNo ratings yet

- Compressor - 101Document66 pagesCompressor - 101Juan Pablo Chavez IxtepanNo ratings yet

- Catalog - Rotating Electrical MachinesDocument24 pagesCatalog - Rotating Electrical MachinesAshhAlexNo ratings yet

- SKF 6402 EN 11 10 19 GB High TCM 12-55843Document60 pagesSKF 6402 EN 11 10 19 GB High TCM 12-55843AlvaroNo ratings yet

- AS 4171-1994 Rolling Bearings - Static Load Ratings PDFDocument5 pagesAS 4171-1994 Rolling Bearings - Static Load Ratings PDFSAI Global - APACNo ratings yet

- Problemas Rotor UTDocument35 pagesProblemas Rotor UTClaudio PinoNo ratings yet

- Test Equipment Buyers GuideDocument29 pagesTest Equipment Buyers GuideMojoshe MonasheNo ratings yet

- Frequency of Free Damped Vibrations (Viscous DampingDocument25 pagesFrequency of Free Damped Vibrations (Viscous DampingAnonymous TW8IjRCkFaNo ratings yet

- Ac Induction Motor Data Sheet: General Specification Performance DataDocument2 pagesAc Induction Motor Data Sheet: General Specification Performance DataBhavik PrajapatiNo ratings yet

- Turbo Gears of G SeriesDocument4 pagesTurbo Gears of G SeriesrisegraNo ratings yet

- Motor Analysis Techniques: 2 November 2017Document48 pagesMotor Analysis Techniques: 2 November 2017Anonymous PVXBGg9TNo ratings yet

- Data 3863 CR Motores PDFDocument2 pagesData 3863 CR Motores PDFRaul CruzNo ratings yet

- Electric Motor: Satisfactory UnsatisfactoryDocument2 pagesElectric Motor: Satisfactory UnsatisfactoryZuli HarismanNo ratings yet

- Cylindrical Roller BearingsDocument106 pagesCylindrical Roller BearingsArbnorMorinaNo ratings yet

- SCOUT140EX Vibration Data Collector Datasheet 323330 PDFDocument9 pagesSCOUT140EX Vibration Data Collector Datasheet 323330 PDFShouqi ErmanNo ratings yet

- EIT IDC Machinery Vibration Rev5Document26 pagesEIT IDC Machinery Vibration Rev5nabil160874No ratings yet

- Bently Nevada Services Support Fact SheetDocument2 pagesBently Nevada Services Support Fact SheetFaruk IbisevicNo ratings yet

- Ac Motor Data SheetDocument2 pagesAc Motor Data SheetelakiyaNo ratings yet

- Nico International: Hazards Identification & Risk AssessmentDocument4 pagesNico International: Hazards Identification & Risk AssessmentkazishahNo ratings yet

- Software Operational Manual: Hybrid Servo Drive HBS57/86/86HDocument25 pagesSoftware Operational Manual: Hybrid Servo Drive HBS57/86/86Hhuutan12345No ratings yet

- Simotics HV M Catalog d84 3 2018 en PDFDocument360 pagesSimotics HV M Catalog d84 3 2018 en PDFD4 SKL ENo ratings yet

- vb8 DatasheetDocument9 pagesvb8 DatasheetPedro Gabriel González GarcíaNo ratings yet

- Catalog New Motor 1LG0Document40 pagesCatalog New Motor 1LG0bajricaNo ratings yet

- Downhill Mountain Bike Gearbox: Josh Filgate, Jesse Kuhn, Morgan Misek Jay Seiter, Michael WitonisDocument38 pagesDownhill Mountain Bike Gearbox: Josh Filgate, Jesse Kuhn, Morgan Misek Jay Seiter, Michael WitonisaddymailidNo ratings yet

- Low Speed Fans Application Guide MiningDocument20 pagesLow Speed Fans Application Guide MiningsanthoshdonNo ratings yet

- Especificación Técnica: Espesador de RelavesDocument17 pagesEspecificación Técnica: Espesador de RelavesAlexis GodoyNo ratings yet

- 0076J1 (330500)Document47 pages0076J1 (330500)susealiNo ratings yet

- Webinar - Troubleshooting Torsional Vibration Challenges With Rotating Machinery - tcm27-77700Document64 pagesWebinar - Troubleshooting Torsional Vibration Challenges With Rotating Machinery - tcm27-77700Huang XiaodianNo ratings yet

- Vibration Analysis: How Does It Work?Document18 pagesVibration Analysis: How Does It Work?Rahul TaleNo ratings yet

- Efr Technical DataDocument1 pageEfr Technical DataPhung TuanNo ratings yet

- Turbines EnglishDocument3 pagesTurbines Englishroberto luckyNo ratings yet

- Technicky Manual 1 enDocument66 pagesTechnicky Manual 1 enSherif AdelNo ratings yet

- Renk Water Power Pbr170sbDocument6 pagesRenk Water Power Pbr170sbhumayun121No ratings yet

- New Brutalist Architecture ClassDocument16 pagesNew Brutalist Architecture ClassVeeraNo ratings yet

- Wall TypeDocument21 pagesWall TypeHussain Al SanonaNo ratings yet

- Bread SpreadDocument7 pagesBread SpreadChetanBansalNo ratings yet

- Sangoma Vega Sbct-smb-020 For SMB - 20 Simultaneous Calls l1Document3 pagesSangoma Vega Sbct-smb-020 For SMB - 20 Simultaneous Calls l1lykorianNo ratings yet

- Elliptic Curve Cryptography (ECC) ExplainedDocument19 pagesElliptic Curve Cryptography (ECC) ExplainedRathin RajNo ratings yet

- Service Manual ARC-14SHDocument11 pagesService Manual ARC-14SHBrian Richmond67% (3)

- Us Navy Practical Guide Flame Bending PipeDocument102 pagesUs Navy Practical Guide Flame Bending PipeBrian DohertyNo ratings yet

- PT 100 Za TemperaturaDocument21 pagesPT 100 Za Temperaturawarmaster81No ratings yet

- AVEVA Standard Reporting Reference ManualDocument36 pagesAVEVA Standard Reporting Reference ManualArtem YadegarianNo ratings yet

- Submarine CableDocument19 pagesSubmarine CableCzarina BaranghayNo ratings yet

- A Beginner'S Guide To The Wide-Angle Lens: PhotzyDocument19 pagesA Beginner'S Guide To The Wide-Angle Lens: PhotzyRio ReaNo ratings yet

- Manual of Green Building MaterialsDocument153 pagesManual of Green Building MaterialsKawser HossainNo ratings yet

- A Generic DMM Test and CalibrationDocument11 pagesA Generic DMM Test and CalibrationrobertNo ratings yet

- Legends of SkyloftDocument30 pagesLegends of SkyloftAnonymous WaLbdWNo ratings yet

- Sop UwmDocument2 pagesSop UwmAshraful HaqNo ratings yet

- Thong So Ky Thuat Cua ScheuerleDocument6 pagesThong So Ky Thuat Cua ScheuerleCuong DinhNo ratings yet

- The Future of CRM Lies in Value Networks and CollaborationDocument9 pagesThe Future of CRM Lies in Value Networks and CollaborationNishant BhartiNo ratings yet

- ASTRO 500: 10 Year LED Array WarrantyDocument2 pagesASTRO 500: 10 Year LED Array WarrantyJerome Cardenas TablacNo ratings yet

- Sistema Contra IncendiosDocument4 pagesSistema Contra IncendiosMIGUEL ÁNGEL TOMÉNo ratings yet

- CV Purwo SusantoDocument3 pagesCV Purwo SusantoPurwo SusantoNo ratings yet

- The Store Case Writtern by Marshall FisherDocument13 pagesThe Store Case Writtern by Marshall Fishershawn2207No ratings yet

- GTIN SetupsDocument8 pagesGTIN Setupsgmmahesh123100% (1)

- HMT 113401 Anna UnivDocument4 pagesHMT 113401 Anna Univsathiya_ramNo ratings yet

- Experiments and Modeling of Bubble Column Dehumidifier PerformanceDocument11 pagesExperiments and Modeling of Bubble Column Dehumidifier PerformanceAl-Kawthari As-SunniNo ratings yet

- 111 Kepner - TregoeDocument12 pages111 Kepner - Tregoeiresendiz100% (1)

- Updating Program Felcom18-19.Document2 pagesUpdating Program Felcom18-19.Ivo CastroNo ratings yet

- Low Pressure Switch Technical SpecsDocument10 pagesLow Pressure Switch Technical Specsdcf67myNo ratings yet

- Aindumps.1z0 808.v2015!10!08.by - Minnie.58qDocument66 pagesAindumps.1z0 808.v2015!10!08.by - Minnie.58qmaile4scribdNo ratings yet

- It Lab 1 .Document7 pagesIt Lab 1 .carl billNo ratings yet

- 0106-7 Section A-BDocument161 pages0106-7 Section A-BAliArababadiNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Power Quality in Power Systems and Electrical MachinesFrom EverandPower Quality in Power Systems and Electrical MachinesRating: 4.5 out of 5 stars4.5/5 (11)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet