Professional Documents

Culture Documents

Product Op

Uploaded by

DonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Op

Uploaded by

DonCopyright:

Available Formats

MICHELBENSIHER.

J

PRODUCTION OPERATOR

Total Experience :10 years (Oil and Gas)

E-MAIL: michealebenisher101@gmail.com

Mobile: +91- 9442006613

Objective:

Well conversant production Operator eager to work in a challenging environment

with opportunity to use my current experience and to enrich my knowledge and

enhance my experience. Contribute towards the achievement of organizational

objective by applying my professional skills.

Experience Summary

9+ years of experience in Oil and Gas field

Name of the company Position Held Duration

Production

PETROEN, KUWAIT Feb 2017 to Feb 2019

Operator

Production NOV 2014 to Jan 2017

HAL OFFSHORE

Operator

BRUNEL INDIA PRIVATE LIMITED Production

April 2012 to Sep 2014

Operator

ONGC Field Operator Aug2009 to Jan 2012

Educational Qualification

Diploma in Mechanical Engineering

Safety Courses Attended

Personal Survival Techniques,

Fire Prevention and Fire Fighting.

Elementary First Aid.

H2S gas Breathing Apparatus

Job Description

Oil and Gas Gathering stations:

Operation and control of wells through different headers for optimum

production Oil Manifolds, Gas lift manifolds, Surge tanks, Separators ( Two / Three

Phase), Dehydration Tanks, Water disposal pumps, Crude transfer pumps, Chemical

injection, Gas/Oil line pigging operations, Well testing, Computerized well testing etc.,

Gas compressors, Inter-stage scrubbers, Gas Treatment, Glycol Contactors,

Glycol regeneration unit, Gas export, Routine sampling of oil, Gas Glycol and

Condensate, Isolations and De-isolations of Equipment’s, Vessels and Tank for

Maintenance, Familiar with work permits systems, Gas testing, Mechanical and

Electrical Isolation Procedures and Co-ordination with maintenance crew, Trouble

shooting and Reporting.

Offshore Production:

Well experienced in offshore production in Installations and rigs. Well Testing,

Well completion, Well Actuation, Choke and kill manifold, Start – Up and Shutdown

procedures, Control room operations, Emergency Procedures, Water Injections, Gas

Compression, Oil Shipment, Chemical Injection etc.,

WELL HEAD OPERATION & MAINTENANCE:

Well head Operations:

Monitoring of wells, well performance, well/fire SDP and shutdown system,

instrument gas, firewater, drains, vents, functional checking of SSSV, SSV, control

panel, preventive maintenance and trouble shooting, manifold valve operations,

different well activation methods, operation of X mass tree valves, controlling the well

flow with choke as per production requirement, gas lifting operation, well testing

placing new or re-completed wells on production, assisting during drilling and post

drilling operations such as well flow back, supervising the satellite platform while

conducting hot work. Calibration of the chemical injection pumps.

Operation knowledge on well head platform:

Inspection and operation of Christmas tree, flow line choke changing well

actuating, well equalizing, checking STHP, FTHP readings, well head panel operation,

annulus pressure bleeding, surface safety valve (SSV), sub surface safety valve (SSSV)

operation, Test separator handling, well testing oil/gas/water. Taking samples for

check specific gravity and BS & W. Checking of water injection and gas injection wells.

Gas dehydration unit (GDU), Tri-ethylene Glycol (TEG) is used as the dehydration

medium. Heating Medium- STEAM.

Process Platform:

Field operation activities of 3 phase separators, chemical dosing, booster

compressors, main oil line pumps, hot oil pumps, produced water conditioner, sump

and skimmer, skimmer pumps, GT driven export gas compressors, GDU, Glycol

regeneration unit, Water Processing for injection - SWLP, electro chlorinator, coarse

and fine filters, DOT, booster pumps, chemical dosing, main injection pumps, Utility

air and Instrument Air system, Pot water, Firewater and Fuel gas system.

CENTRAL PRODUCTION FACILITY & TANK FARM:

Receiving crude from different Gathering Stations, Gas Boot and Free water

Knockout Drum, Skimmer Tank – Storage Tank Operation - Emulsion Treatment by

Electrostatic Heater – Treater, Injection Rate calculations, Desalting Crude through

Electric DE salters, Crude Transfer pumps, CTM (Custody Transfer Meter) unit, Water

Injection pumps. CTM Meter Proving, Shipping Pumps, Trouble Shooting as per Cause

& Effect Logics.

Operation of Gas Turbines for generator, As well as Steam turbine. Well Test

Data Entry and DCS Operations, Well aware of plant Safety Equipments, Emergency

Procedures etc., Conversant in Handling Crude stabilization Unit, VRU Compressors.

Also successfully operated Central Production Facility Capacity of 2, 00,000 Bbls /

Day.

Gas Dehydration unit:

Natural Gas Dehydration, Glycol Purification, Regeneration, Coalescar Filter

Separator, Charcoal Filter, Glycol Flash Drum. Hot Oil Treatment, Glycol Scrubber

Operations, Glycol Booster Pump Operation. All Filter Changing , Glycol Pumping,

Glycol Storage Tank Level, Temperature Maintaining, Ground Flare System

Operation, Dew Point Setting, Taking of Plant Shut-down and Start-up Operation. Pre

and Super Heater for Fuel Gas Heating and Heat Exchangers.

Gas Compression & Gas plant Operations:

Handled Different types of Gas Compressors ( Reciprocating and Centrifugal)

Sweet Gas Purging, isolation & de- isolation of compressors, Start Stop Logics, Recycle

and Anti-surge functions, Scrubbers, Auxiliary pumps, Heat exchangers Etc., Handled

Gas Turbines (KWASAKI&SEMENS) as prime movers to Compressors, Gas Plant

Operations – Free Water Knockout drums, Degassing Vessels, Glycol Regeneration

unit, Mainline Gas Export and Control.

Oil & Gas Processing:

Control Room operation, Separator, Surge Drum Operations, Chemical

Injection, Gas and Water Injection, Generations, Glycol Regeneration, Gas Blanketing,

Cartridge and Charcoal Filter Changing etc. Dehydration Tanks, Simple Maintenance

of Gas Compressors, Free/ Smoke detection Systems and Utility Operation, Like Air

Dryers, Nitrogen Generation, Sea Water Cooling, Utility / Pot Water System etc.

PERSONAL DETAILS:

Permanent Address : 12/33A ,Antony street,

Rajavoor , Marungoor Post,

Kanyakumari Dist-629402

Date of Birth : 12 July 1989

Nationality : Indian

Marital status : UnMarried

Language known : English, Hindi, Tamil.

Passport Details:

Passport No. : L 2322193

Date of issue : 13 Jun 2013

Expiry date : 12 Jun 2023

DECLARATION:

I hereby confirm that the above information’s are correct to the best of my

knowledge and belief.

Place: Yours Sincerely,

Date: MICHEL BENSIHE. J

You might also like

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Control Room Operator RoleDocument5 pagesControl Room Operator RoleDonNo ratings yet

- Nathis OpeDocument3 pagesNathis OpeGodwin GodwinNo ratings yet

- Anandha Rajan.rDocument5 pagesAnandha Rajan.rjohn MNo ratings yet

- Resume: Post For Applied: Production / Commissioning/Field OperatorDocument5 pagesResume: Post For Applied: Production / Commissioning/Field OperatorRebel Add100% (1)

- CV for Production Operator RoleDocument4 pagesCV for Production Operator RoleImmanuelNo ratings yet

- Felix Production Operator 2018Document5 pagesFelix Production Operator 2018msk649No ratings yet

- Production Operator Resume - Over 14 Years Oil & Gas ExperienceDocument4 pagesProduction Operator Resume - Over 14 Years Oil & Gas Experiencejohn MNo ratings yet

- DM2 Production Operator1Document4 pagesDM2 Production Operator1Godwin GodwinNo ratings yet

- Resume 6643Document5 pagesResume 6643Subnevaash SvNo ratings yet

- BASKARDocument5 pagesBASKARGodwin GodwinNo ratings yet

- Benin Field Operator CV UpdateDocument5 pagesBenin Field Operator CV UpdatebeninNo ratings yet

- Antonyarulrogger: Antony Arul RogerDocument4 pagesAntonyarulrogger: Antony Arul Rogerjohn MNo ratings yet

- Curriculum Vitae: Alex Gnanamani.KDocument4 pagesCurriculum Vitae: Alex Gnanamani.KDIJUNo ratings yet

- Field Operator: Diploma in Mechanical EngineeringDocument5 pagesField Operator: Diploma in Mechanical Engineeringjohn MNo ratings yet

- Mob No: +91 9952659984. Skype Id: Praveen.MDocument5 pagesMob No: +91 9952659984. Skype Id: Praveen.Mjohn MNo ratings yet

- Resume 6643Document5 pagesResume 6643pubby313No ratings yet

- Well Test Operator: S.SivarajDocument3 pagesWell Test Operator: S.Sivarajjohn M100% (2)

- Compress - Anil Kumar.. - 20221007130449Document3 pagesCompress - Anil Kumar.. - 20221007130449munnasaw204No ratings yet

- MutharasanDocument4 pagesMutharasanGodwin GodwinNo ratings yet

- Antony Arul Roger: Production OperatorDocument6 pagesAntony Arul Roger: Production OperatorDonNo ratings yet

- Oil & Gas Veteran Seeks New OpportunityDocument5 pagesOil & Gas Veteran Seeks New OpportunityPazhamalairajan KaliyaperumalNo ratings yet

- Resume: Name: Bebin RoyDocument5 pagesResume: Name: Bebin RoyDIJUNo ratings yet

- ModelDocument8 pagesModelSubnevaash SvNo ratings yet

- Oil Gas Well OperatorDocument5 pagesOil Gas Well Operatorjohn MNo ratings yet

- DennyDocument5 pagesDennyGodwin GodwinNo ratings yet

- Field Operator: INDIA: +91 9791875175 Skype: Thiyagu RDocument4 pagesField Operator: INDIA: +91 9791875175 Skype: Thiyagu Rjohn MNo ratings yet

- Curriculum Vitae: S.Bebin RoyDocument3 pagesCurriculum Vitae: S.Bebin RoyDIJUNo ratings yet

- Pon Vijay Gas Processing OpDocument4 pagesPon Vijay Gas Processing Opjohn MNo ratings yet

- Curriculum Vitae: Post Applied For: Production OperatorDocument4 pagesCurriculum Vitae: Post Applied For: Production OperatorsureshNo ratings yet

- 4-Year Offshore Production Operator CVDocument3 pages4-Year Offshore Production Operator CVDonNo ratings yet

- Sunil Kumar. R: Supervisor (Pre-Commissioning & Commissioning)Document5 pagesSunil Kumar. R: Supervisor (Pre-Commissioning & Commissioning)JBKSV FAMNo ratings yet

- Delayed Coker UpdatedDocument7 pagesDelayed Coker UpdatedSubnevaash SvNo ratings yet

- Well Test Pon Vijay-AssistDocument4 pagesWell Test Pon Vijay-Assistjohn MNo ratings yet

- Ongc Report Abhyudya TiwariDocument38 pagesOngc Report Abhyudya TiwariYash ChouDharyNo ratings yet

- Mani Mech TechnicianDocument4 pagesMani Mech TechnicianManikandan VpNo ratings yet

- NaveenDocument4 pagesNaveenGodwin GodwinNo ratings yet

- CV Sathish RamasamYDocument4 pagesCV Sathish RamasamYGodwin GodwinNo ratings yet

- Field Operator ViralDocument5 pagesField Operator ViralGodwin GodwinNo ratings yet

- Mechanical Technician: Babu.M Tamil Nadu, IndiaDocument4 pagesMechanical Technician: Babu.M Tamil Nadu, Indiajohn MNo ratings yet

- T. Murugan: Post Applied For Well Testing OperatorDocument5 pagesT. Murugan: Post Applied For Well Testing Operatorjohn MNo ratings yet

- Production Op Pon VijayDocument4 pagesProduction Op Pon Vijayjohn MNo ratings yet

- Curriculum Vitae1Document4 pagesCurriculum Vitae1shabbir_hussain7No ratings yet

- Andrew Pravin - Field OperatorDocument6 pagesAndrew Pravin - Field OperatorVenkatesh VaradarajanNo ratings yet

- Academic Background: Professional ExperienceDocument3 pagesAcademic Background: Professional Experiencejohn M100% (1)

- CV of G H ChauhanDocument6 pagesCV of G H ChauhanRathinavel PerumalNo ratings yet

- Siva Raj Mechanical TechnicianDocument4 pagesSiva Raj Mechanical Technicianjohn MNo ratings yet

- Rafiq - S CV TerminalDocument3 pagesRafiq - S CV Terminalaqeelkhan7942No ratings yet

- Commissioning Supervisor Vignesh RajaDocument3 pagesCommissioning Supervisor Vignesh RajaRathinavel PerumalNo ratings yet

- Mechanical TechnicianDocument4 pagesMechanical TechnicianSiva SabarishNo ratings yet

- Sunil Raja Mech CVDocument3 pagesSunil Raja Mech CVRaj AryanNo ratings yet

- Well Test OperatorDocument16 pagesWell Test Operatorjohn MNo ratings yet

- Field Engineer with 7+ years experienceDocument5 pagesField Engineer with 7+ years experienceRaj PalatiNo ratings yet

- Well Testing Operator - VigneshwarDocument5 pagesWell Testing Operator - Vigneshwarhusain albaqaliNo ratings yet

- Utility Plant Operator ResumeDocument4 pagesUtility Plant Operator ResumeGRANELNo ratings yet

- Mechanical Technician: Manikandan.V.PDocument3 pagesMechanical Technician: Manikandan.V.PManikandan VpNo ratings yet

- Balakumaran CVDocument4 pagesBalakumaran CVjohn MNo ratings yet

- Project Report Abhishek JainDocument22 pagesProject Report Abhishek JainBharat KhandekarNo ratings yet

- CV for Oil & Gas Control Room OperatorDocument7 pagesCV for Oil & Gas Control Room Operatormsk649No ratings yet

- Tamilnadu Nursing College ContactsDocument15 pagesTamilnadu Nursing College ContactsDonNo ratings yet

- DCS/CCR Operator: Sri Ramraj.GDocument4 pagesDCS/CCR Operator: Sri Ramraj.GDonNo ratings yet

- M.S.Kirubhananth: Senior Instrument TechnicianDocument4 pagesM.S.Kirubhananth: Senior Instrument TechnicianDonNo ratings yet

- Antony Vikas Coil Tubing Operator ResumeDocument3 pagesAntony Vikas Coil Tubing Operator ResumeDonNo ratings yet

- Mechanical Technician - Bala DineshDocument4 pagesMechanical Technician - Bala DineshDonNo ratings yet

- CV Coiled Tubing Operator IndonesiaDocument5 pagesCV Coiled Tubing Operator IndonesiaDonNo ratings yet

- Dine EshDocument11 pagesDine EshDonNo ratings yet

- C.Babu: Production OperatorDocument4 pagesC.Babu: Production OperatorDonNo ratings yet

- Magesh.M OPTDocument3 pagesMagesh.M OPTDonNo ratings yet

- CV: Coil Tubing Supervisor with 14+ Years ExperienceDocument3 pagesCV: Coil Tubing Supervisor with 14+ Years ExperienceDonNo ratings yet

- Antony Vikas Coil Tubing Operator ResumeDocument3 pagesAntony Vikas Coil Tubing Operator ResumeDonNo ratings yet

- SVZDFHDocument3 pagesSVZDFHDonNo ratings yet

- Vibin Raja CVDocument5 pagesVibin Raja CVDonNo ratings yet

- APPLYING FOR Coil Tubing Operator: Antony Arul RogerDocument4 pagesAPPLYING FOR Coil Tubing Operator: Antony Arul RogerDonNo ratings yet

- Antony Vikas Coil Tubing Operator ResumeDocument3 pagesAntony Vikas Coil Tubing Operator ResumeDonNo ratings yet

- APPLYING FOR Coil Tubing Operator: Antony Arul RogerDocument4 pagesAPPLYING FOR Coil Tubing Operator: Antony Arul RogerDonNo ratings yet

- Babu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDocument9 pagesBabu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDonNo ratings yet

- Arul Alex CVDocument3 pagesArul Alex CVDonNo ratings yet

- Babu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDocument9 pagesBabu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDonNo ratings yet

- 3 Phase Separator BrochureDocument6 pages3 Phase Separator BrochureRandy SooknananNo ratings yet

- Swaminathan CVDocument6 pagesSwaminathan CVDonNo ratings yet

- SWT Book03B2 PDFDocument117 pagesSWT Book03B2 PDFbuat unduhNo ratings yet

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocument27 pagesNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- Choke Manifold PDFDocument2 pagesChoke Manifold PDFluciano_ferreira_80No ratings yet

- Derrick Anthony Das: Career ObjectivesDocument1 pageDerrick Anthony Das: Career ObjectivesDonNo ratings yet

- Turbine Operational ProblemsDocument35 pagesTurbine Operational Problemsna2011100% (1)

- WT Training ManualDocument429 pagesWT Training Manualbilmard100% (4)

- IHS Fekete Software Installation GuideDocument26 pagesIHS Fekete Software Installation GuideDonNo ratings yet

- Gheewala SAUDI Recrutment Interview 3rd Week 2018 at ChennaiDocument7 pagesGheewala SAUDI Recrutment Interview 3rd Week 2018 at ChennaiImthiyas MohamedNo ratings yet

- VGS 8.1.2 Rev.20 - UTDocument29 pagesVGS 8.1.2 Rev.20 - UTPaul-Petrus MogosNo ratings yet

- Assign4 RANSDocument2 pagesAssign4 RANSankitsaneetNo ratings yet

- Case Study Cracked Oil Tanks Investigations Web PDFDocument2 pagesCase Study Cracked Oil Tanks Investigations Web PDFyamakunNo ratings yet

- FGGDocument12 pagesFGGSridharan VenkatNo ratings yet

- Technical Presentation - Arik Ethan Kinajil (25231)Document5 pagesTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanNo ratings yet

- Fajs FSXDocument8 pagesFajs FSXJunhy Bandeira CassandraNo ratings yet

- SportOptics 2014-2015Document31 pagesSportOptics 2014-2015ivaldeztNo ratings yet

- Challenges in PavementsDocument23 pagesChallenges in PavementsSomeshwar Rao ThakkallapallyNo ratings yet

- Biogas Calculator TemplateDocument27 pagesBiogas Calculator TemplateAlex Julian-CooperNo ratings yet

- Scania 12L - EMS - Operator - Manual - enDocument60 pagesScania 12L - EMS - Operator - Manual - enАнатолий ЩербаковNo ratings yet

- SBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811Document1 pageSBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811vitor marianoNo ratings yet

- LUCY SwitchgearDocument8 pagesLUCY SwitchgearHillary McgowanNo ratings yet

- JU P-Tool Engineering DataDocument1 pageJU P-Tool Engineering Dataazze bouzNo ratings yet

- CA2E AdminGuide ENUDocument170 pagesCA2E AdminGuide ENUomarNo ratings yet

- CompoundingDocument5 pagesCompoundingMajester RigsNo ratings yet

- Saint Gobain - CertainTeed Roofing ShinglesDocument14 pagesSaint Gobain - CertainTeed Roofing ShinglesJagriti KashyapNo ratings yet

- Bilge Alarm Monitor OMD 11Document22 pagesBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- ESD Protection in CMOS: Characterization and Failure AnalysisDocument113 pagesESD Protection in CMOS: Characterization and Failure AnalysisElisavNirolfNo ratings yet

- Thinking ForthDocument311 pagesThinking ForthCristianNo ratings yet

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDocument3 pagesSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- V8fr-Ii V8r7-IiDocument1 pageV8fr-Ii V8r7-Iiaeroseb1No ratings yet

- Inspection and Adjustment of Pump Ls ControlDocument10 pagesInspection and Adjustment of Pump Ls ControlHai Van100% (1)

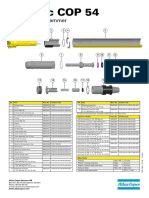

- 9853 1239 01 - COP 54 Service Poster - LOWDocument1 page9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNo ratings yet

- Application of PLC and SCADA in Auto-Control Systems For Silo Grain HandlingDocument4 pagesApplication of PLC and SCADA in Auto-Control Systems For Silo Grain Handlingshahid_scribdNo ratings yet

- BTS Training Fiber Optic Advanced SplicingDocument5 pagesBTS Training Fiber Optic Advanced Splicingjama99No ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)

- Operation Manual: Daikin Room Air ConditionerDocument92 pagesOperation Manual: Daikin Room Air ConditionerbenNo ratings yet

- How to Operate AAS with SignPal & PhotoPRINTDocument25 pagesHow to Operate AAS with SignPal & PhotoPRINTLucian DogariuNo ratings yet

- Setting vpn1Document10 pagesSetting vpn1Unink AanNo ratings yet

- Previews AGA XQ9902 PreDocument6 pagesPreviews AGA XQ9902 PreAldrin HernandezNo ratings yet