Professional Documents

Culture Documents

WPS ISO 15609 Template PDF

WPS ISO 15609 Template PDF

Uploaded by

AnilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS ISO 15609 Template PDF

WPS ISO 15609 Template PDF

Uploaded by

AnilCopyright:

Available Formats

Doc. No.

:

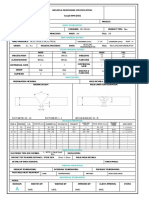

WELDING PROCEDURE SPECIFICATION (WPS)

(As Per EN ISO 15609-1) Date:

WPS Method of preparation and cleaning

WPQR No. Parent Material Designation

Manufacturer Material Thickness Range (mm)

Mode of metal transfer Outside Diameter (mm)

Joint type and Weld Position As Per EN ISO 6947

type

Weld Preparation Details (Sketch)*

Joint Design Welding sequences

Welding Details

Type of Wire Feed

Welding Size of filler Travel Speed Heat Input

Run Current Range (A) Voltage Range (V) Current & Speed

Process material (mm) (mm/min) (kJ/mm)

Polarity (mm/sec)

Note:- 1.The upper limit of heat input shall not cross 25% more than that used in welding the WPQR.

& The lower limit heat input shall not minimized 25% lower than that used in welding the WPQR

2.Weld joint area (covering 25mm both side) shall be cleaned by wire brushing.

Filer Material designation and Make

Any specific Baking or Drying

Designation Gas/Flux- Shielding

Designation Gas/Flux- Backing

Gas Flow Rate- Shielding

Gas Flow Rate- Backing

Tungsten Electrode Type/ size

Details of Back Gouging/ Backing

Pre- Heat temperature

Inter-pass Temperature

Post - Heating

Post Weld Heat Treatment (time, temp., method, heating, cooling rates)*

Other Information*

Weaving (maximum width of run)

Oscillation (amplitude, frequency & Dwell time)

Pulse Welding Details

Distance contact tube/work piece

Plasma Welding Details

Torch Angle

Other information :

Date of Issue: Location:

Prepared By Reviewed By Approved By Approved By

Sign Sign Sign Sign

Name: Name: Name: Name

Date:- Date:- Date:- Date

You might also like

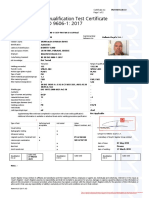

- Typical Welder Qualification CertificateDocument1 pageTypical Welder Qualification CertificateSatish Keskar100% (3)

- Weld MapDocument4 pagesWeld MapSatish Keskar50% (2)

- Technical Review For ISO 3834Document1 pageTechnical Review For ISO 3834Satish Keskar100% (3)

- Technical Review For ISO 3834Document1 pageTechnical Review For ISO 3834Satish Keskar100% (3)

- Iso 9606-3Document30 pagesIso 9606-3Aleksandar StojanovicNo ratings yet

- BS en Iso 9606-4 - 1999Document26 pagesBS en Iso 9606-4 - 1999jesoneliteNo ratings yet

- Template For Technical ReviewDocument1 pageTemplate For Technical ReviewSatish Keskar100% (1)

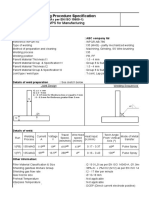

- WPQR - Form As Per EN PDFDocument3 pagesWPQR - Form As Per EN PDFAnilNo ratings yet

- En 15085 - 1 & 2Document34 pagesEn 15085 - 1 & 20502ravi100% (4)

- PWPS - ISO EN 15614-1 - DNV-GLDocument1 pagePWPS - ISO EN 15614-1 - DNV-GLvinoth100% (1)

- A Comparison of ISO 15614 Part 1 and ASME IXDocument3 pagesA Comparison of ISO 15614 Part 1 and ASME IXsusanweb100% (1)

- What's New in ISO 15614-12017Document13 pagesWhat's New in ISO 15614-12017alevent100% (1)

- ISO 3834 Mandatory ProceduresDocument1 pageISO 3834 Mandatory ProceduresSatish KeskarNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- WPS Creation Sample ISODocument1 pageWPS Creation Sample ISOmusheerNo ratings yet

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Welding Procedure Qualification Certificate (EN ISO 15614-1)Document8 pagesWelding Procedure Qualification Certificate (EN ISO 15614-1)Jagjeet SinghNo ratings yet

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Poster en ISO 9606 1 2013 English PDFDocument1 pagePoster en ISO 9606 1 2013 English PDFmarkoredsNo ratings yet

- WPS Format For ISO 15614-1 PWPSDocument1 pageWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityNo ratings yet

- WPQR PipeDocument3 pagesWPQR PipeThanasis KyrgiazoglouNo ratings yet

- Procedure For Qualification of Welders or Welding OperatorsDocument1 pageProcedure For Qualification of Welders or Welding OperatorsSatish KeskarNo ratings yet

- Template For "Review of Requirements"Document1 pageTemplate For "Review of Requirements"Satish KeskarNo ratings yet

- ISO 3834 Evaluation TestDocument2 pagesISO 3834 Evaluation TestSatish KeskarNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Miscon ElementsDocument16 pagesMiscon Elementsapi-400692183No ratings yet

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Document1 pageTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints Qualifiedmurshid badshahNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Minimum Requirements IweDocument52 pagesMinimum Requirements IweIonutz TelteuNo ratings yet

- En Iso 9606 1 GDocument2 pagesEn Iso 9606 1 GAnonymous dziHEjc7Y100% (1)

- Welding Qualification SAMI CMI - AWS D1.2Document26 pagesWelding Qualification SAMI CMI - AWS D1.2Ouni AchrefNo ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument2 pagesA Comparison of ISO 15614 Part 1 and ASME IXtuanNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Iso 15610-2003Document12 pagesIso 15610-2003Asan Beinur100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Document12 pagesPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNo ratings yet

- EN 15085 Part 5 - GaneshDocument36 pagesEN 15085 Part 5 - GaneshNiranjan Rajavel TigerNo ratings yet

- Esab E7018-1-H4r Ebds1-Ok 55Document2 pagesEsab E7018-1-H4r Ebds1-Ok 55PubcrawlNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- BS EN 14700-2014 - (Welding Consumables For Hard Facing)Document18 pagesBS EN 14700-2014 - (Welding Consumables For Hard Facing)HuiFrankyNo ratings yet

- P1 To P8Document9 pagesP1 To P8Pat AuffretNo ratings yet

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- Preheat RequirementsDocument3 pagesPreheat RequirementsVJG369No ratings yet

- Model WopqDocument2 pagesModel WopqAnilkumarGopinathanNairNo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Iso 15609-1-2019Document19 pagesIso 15609-1-2019HarikeshRana100% (2)

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- EWF QualificationDocument42 pagesEWF Qualificationromanosky11No ratings yet

- En 13445 WPS PQR WPQDocument5 pagesEn 13445 WPS PQR WPQmuhammad hadiNo ratings yet

- IIW IWE Syllabus PDFDocument27 pagesIIW IWE Syllabus PDFசுரேஷ் பாலமுருகன்100% (1)

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaNo ratings yet

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- WPSDocument5 pagesWPSParshottam Brahmxatriya100% (1)

- WPS FormatDocument1 pageWPS FormatbalamuruganNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDocument1 pageWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- Business Process Department Manual DI - Reference Issue No/Date Rev - No/Date Page NoDocument1 pageBusiness Process Department Manual DI - Reference Issue No/Date Rev - No/Date Page NoSatish KeskarNo ratings yet

- Procedure For WPSDocument7 pagesProcedure For WPSSatish KeskarNo ratings yet

- EN 15085 Program Evaluation TestDocument2 pagesEN 15085 Program Evaluation TestSatish KeskarNo ratings yet

- Procedure For WPSDocument7 pagesProcedure For WPSSatish KeskarNo ratings yet

- Need of ISO 3834 To Welding Fabrication IndustryDocument4 pagesNeed of ISO 3834 To Welding Fabrication IndustrySatish Keskar100% (1)

- Plan of Typical Welder Training ProgramDocument1 pagePlan of Typical Welder Training ProgramSatish KeskarNo ratings yet

- FCAW Unit TestDocument4 pagesFCAW Unit TestSatish KeskarNo ratings yet

- Plan of Typical Welder Training ProgramDocument1 pagePlan of Typical Welder Training ProgramSatish KeskarNo ratings yet

- Welding Training Program Evaluation TestDocument2 pagesWelding Training Program Evaluation TestSatish KeskarNo ratings yet

- ISO 3834 Awareness Program OutlineDocument1 pageISO 3834 Awareness Program OutlineSatish KeskarNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Outline of Awareness Program For WPS PQR WPQDocument1 pageOutline of Awareness Program For WPS PQR WPQSatish KeskarNo ratings yet

- Training Progams by Satish KeskarDocument3 pagesTraining Progams by Satish KeskarSatish KeskarNo ratings yet

- Template For List of DocumentsDocument1 pageTemplate For List of DocumentsSatish KeskarNo ratings yet

- The Outline of Welder Training ProgramDocument1 pageThe Outline of Welder Training ProgramSatish KeskarNo ratings yet

- WPS Flow Proceess Chart PDFDocument1 pageWPS Flow Proceess Chart PDFSatish KeskarNo ratings yet

- WPS Flow Proceess ChartDocument1 pageWPS Flow Proceess ChartSatish KeskarNo ratings yet

- Production Planning RecordDocument1 pageProduction Planning RecordSatish Keskar100% (1)

- Comparision of Fabrication TolerancesDocument4 pagesComparision of Fabrication TolerancesSatish Keskar100% (1)

- Basic SM AW (2 Days Course) : Target ParticipantsDocument1 pageBasic SM AW (2 Days Course) : Target ParticipantsSatish KeskarNo ratings yet

- PC5200 V2.0 - Manual Instalare PDFDocument2 pagesPC5200 V2.0 - Manual Instalare PDFDarie SilviuNo ratings yet

- Seis Wide How ToDocument10 pagesSeis Wide How ToLeslie Ruo100% (2)

- A.S.L. Pauls: Lesson PlanDocument6 pagesA.S.L. Pauls: Lesson Planravi1afsb_1968@yahoo.co.inNo ratings yet

- 4019 OXE User Guide PDFDocument2 pages4019 OXE User Guide PDFIonut Gabriel DascaluNo ratings yet

- Product Fact Sheet: Optional Productivity ValuesDocument4 pagesProduct Fact Sheet: Optional Productivity ValuesTOLYBERTNo ratings yet

- Alkenes by Dehydration of AlcoholsDocument7 pagesAlkenes by Dehydration of Alcoholssbgowda100100% (1)

- Sony Sdm-s93 ManualDocument21 pagesSony Sdm-s93 ManualInaRovanNo ratings yet

- Features Description: Ltc1966 Precision Micropower Rms-To-Dc ConverterDocument38 pagesFeatures Description: Ltc1966 Precision Micropower Rms-To-Dc ConverterGermán GarcíaNo ratings yet

- SFP 1G CWDM 1270 40 T02#151023Document8 pagesSFP 1G CWDM 1270 40 T02#151023GLsun MallNo ratings yet

- Ap1501a 2Document14 pagesAp1501a 2GOW_23No ratings yet

- IC-706MKIIG Cheat SheetDocument1 pageIC-706MKIIG Cheat Sheetcurt bennettNo ratings yet

- StoichiometryDocument47 pagesStoichiometryPaul Jhon EugenioNo ratings yet

- (Week 4, Day 1, Activity # 7) : TLE 9 - ICT (Fourth Quarter)Document3 pages(Week 4, Day 1, Activity # 7) : TLE 9 - ICT (Fourth Quarter)armand lagriaNo ratings yet

- Importance of ExcitationDocument26 pagesImportance of Excitationtokamaka100% (4)

- DC Servo Systems Catalog 053106Document64 pagesDC Servo Systems Catalog 053106miencattrang878No ratings yet

- Quick Selection GuideDocument60 pagesQuick Selection GuidemihailojovicNo ratings yet

- Littelfuse Fuse LLNRK LLSRK DatasheetDocument3 pagesLittelfuse Fuse LLNRK LLSRK DatasheetLuis RomeroNo ratings yet

- Reg. No: Name:: Q.No. Sub. Sec. Question Description MarksDocument2 pagesReg. No: Name:: Q.No. Sub. Sec. Question Description MarksWINORLOSENo ratings yet

- Yordyqlq LQLQLQLQ LQLQLQLQ LQLLQLQL QLQLQL: Professional Development Seminar Series - NEC Requirements For GeneratorsDocument17 pagesYordyqlq LQLQLQLQ LQLQLQLQ LQLLQLQL QLQLQL: Professional Development Seminar Series - NEC Requirements For GeneratorsYordi AlvitresNo ratings yet

- OPAL RT MicrogridDocument8 pagesOPAL RT MicrogridmarcoNo ratings yet

- Fangpusun MPPT 2010 PDFDocument3 pagesFangpusun MPPT 2010 PDFFriedrich MedNo ratings yet

- Bxa 80090 8CF FPDocument1 pageBxa 80090 8CF FPalexteixeira1No ratings yet

- E510 Compact QuickstartDocument2 pagesE510 Compact QuickstartEduardo LegorretaNo ratings yet

- mrr1 eDocument18 pagesmrr1 eAyan MajiNo ratings yet

- h11-515 - Rev - 6 Ruud Wiring PicDocument12 pagesh11-515 - Rev - 6 Ruud Wiring PicElvis FariasNo ratings yet

- Phillip Allen Short Course NotesDocument633 pagesPhillip Allen Short Course NotesGunwant Chaudhari100% (2)

- Netoutlook: Network Management SoftwareDocument2 pagesNetoutlook: Network Management Softwareder_teufelNo ratings yet

- E7 Data and Results PUT RELAXATION OSCILLATORDocument3 pagesE7 Data and Results PUT RELAXATION OSCILLATORAaron Cyril NuisaNo ratings yet

- Solid State Chemistry 13102066Document43 pagesSolid State Chemistry 13102066Loveroop Singh62% (13)