Professional Documents

Culture Documents

A241e PDF

A241e PDF

Uploaded by

Noah IstreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A241e PDF

A241e PDF

Uploaded by

Noah IstreCopyright:

Available Formats

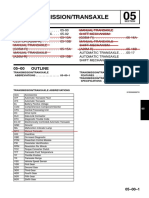

AX−1

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE SYSTEM

AUTOMATIC TRANSAXLE SYSTEM

AX050−02

PRECAUTION

When working with FIPG material, you must observe the followings.

S Using a razor blade and a gasket scraper, remove all the old FIPG material from the gasket surfaces.

S Thoroughly clean all components to remove all the loose material.

S Clean both sealing surfaces with a non−residue solvent.

S Apply FIPG in an approx. 1 mm (0.04 in.) wide bead along the sealing surface.

S Parts must be assembled within 10 minutes of application. Otherwise, the FIPG material must be re-

moved and reapplied.

If the vehicle is equipped with a mobile communication system, refer to the precautions in the IN section.

1996 RAV4 (RM447U)

AX−2

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE SYSTEM

AX051−02

OPERATION

Forward Clutch (C1)

No.2 One−Way Clutch (F2)

2nd Coast Brake (B1)

2nd Brake (B2)

1st & Reverse Brake (B3)

Direct Clutch (C2)

Front Planetary Gear Unit

No.1 One−Way Clutch (F1)

Rear Planetary Gear Unit

U/D Planetary Gear Unit

U/D Brake (B4)

U/D Clutch (C3)

U/D One−Way Clutch (F3)

Shift Shift

Shift Lever Solenoid

Gear Solenoid C1 C2 C3 B1 B2 B3 B4 F1 F2 F3

Position Valve No.1 Valve No.2

P Park ON OFF F

R Reverse ON OFF F F F

N Neutral ON OFF F

1st ON OFF F F F F

2nd ON ON F F F F F

D

3rd OFF ON F F F F F

O/D OFF OFF F F F F

1st ON OFF F F F F

2 2nd ON ON F F F F F F

3rd* OFF ON F F F F F

1st ON OFF F F F F F

L

2nd* ON ON F F F F F F

F : Operating

*: Down−shift only in the 3rd gear for the 2 position and 2nd gear for the L position − no up−shift

F00484

1996 RAV4 (RM447U)

AX−3

AUTOMATIC TRANSAXLE (A241E) − VEHICLE SPEED SENSOR

VEHICLE SPEED SENSOR AX0T4−02

ON−VEHICLE REPAIR

1. REMOVE NO.2 ENGINE UNDER COVER

2. DISCONNECT VEHICLE SPEED SENSOR ASSEMBLY

(a) Disconnect the vehicle speed sensor connector.

(b) Remove the bolt and vehicle speed sensor assembly.

Q08740

(c) Remove the clip and speedometer driven gear from the

Vehicle Speed Sensor

vehicle speed sensor.

Driven Gear (d) Remove the O−ring from the vehicle speed sensor.

3. INSTALL VEHICLE SPEED SENSOR ASSEMBLY

(a) Coat a new O−ring with ATF and install it to the vehicle

speed sensor.

(b) Install the speedometer driven gear to the vehicle speed

Clip sensor and clip.

Q08741 (c) Install the vehicle speed sensor assembly and torque the

bolts.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

(d) Connect the vehicle speed sensor connector.

4. INSTALL NO.2 ENGINE UNDER COVER

1996 RAV4 (RM447U)

AX−4

AUTOMATIC TRANSAXLE (A241E) − PARK/NEUTRAL POSITION (PNP) SWITCH

PARK/NEUTRAL POSITION (PNP)

SWITCH AX0T5−01

ON−VEHICLE REPAIR

1. REMOVE NO.2 ENGINE UNDER COVER

2. DISCONNECT PARK/NEUTRAL POSITION SWITCH

CONNECTOR

3. REMOVE PARK/NEUTRAL POSITION SWITCH

(a) Remove the nut and disconnect the shift control cable.

(b) Remove the nut and shift control lever.

(c) Using a screwdriver, pry off the lock plate.

(d) Remove the nut and lock plate.

(e) Remove the 2 bolts and pull out the park/neutral position

switch.

Q06565

4. INSTALL PARK/NEUTRAL POSITION SWITCH

(a) Temporarily install the park/neutral position switch with

the 2 bolts.

(b) Install a new lock plate and tighten the nut.

Torque: 6.9 N·m (70 kgf·cm, 61 in.·lbf)

(c) Stake the nut with the lock plate.

Q07898

(d) Adjust the park/neutral position switch (See page

DI−127).

Neutral Basic

Line HINT:

Align the groove and park/neutral basic line.

(e) Tighten the 2 bolts.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

Groove

Q07907

(f) Install the shift control lever with the nut.

(g) Connect the control cable with the nut.

Torque: 13 N·m (135 kgf·cm, 10 ft·lbf)

5. CONNECT PARK/NEUTRAL POSITION SWITCH CON-

NECTOR

6. INSTALL NO.2 ENGINE UNDER COVER

Q07906

1996 RAV4 (RM447U)

AX−5

AUTOMATIC TRANSAXLE (A241E) − VALVE BODY ASSEMBLY

VALVE BODY ASSEMBLY AX0T6−02

ON−VEHICLE REPAIR

1. REMOVE DRAIN PLUG AND DRAIN ATF

2. REMOVE OIL PAN AND GASKET

Remove the 18 bolts.

NOTICE:

Some fluid will remain in the oil pan. Remove all pan bolts,

and carefully remove the oil pan assembly. Discard the

gasket.

Q05259

3. EXAMINE PARTICLES IN PAN

Remove the magnets and use them to collect any steel chips.

Look carefully at the chips and particles in the pan and the mag-

net to anticipate what type of wear you will find in the transaxle.

S Steel (magnetic): bearing, gear and plate wear

S Brass (non−magnetic): bearing wear

Q05234

4. REMOVE OIL STRAINER AND APPLY PIPE BRACKET

NOTICE:

Be careful as some fluid will come out with the oil strainer.

(a) Remove the 3 bolts, oil strainer and gasket.

(b) Remove the 2 bolts and apply pipe bracket.

Q06417

5. REMOVE OIL PIPE CLAMP AND OIL PIPES

(a) Remove the bolt and oil pipe clamp.

(b) Pry up the both pipe ends with a large screwdriver and re-

move the 5 pipes.

NOTICE:

Be careful not to bend or damage the pipe.

Q06418

1996 RAV4 (RM447U)

AX−6

AUTOMATIC TRANSAXLE (A241E) − VALVE BODY ASSEMBLY

6. REMOVE MANUAL DETENT SPRING

Remove the bolt and manual detent spring.

7. REMOVE 3 SOLENOID CONNECTORS

AT8584

8. REMOVE VALVE BODY

(a) Disconnect the throttle cable.

AT8586

A (b) Remove the 11 bolts and wire retainer.

Bolt length:

A

A Bolt A: 20 mm (0.79 in.)

B

Bolt B: 30 mm (1.18 in.)

Bolt C: 55 mm (2.17 in.)

B

A B

C A

A

B

Z11664

(c) Disconnect the manual valve connecting rod.

(d) Remove the valve body.

AT3327

A 9. REMOVE 3 SOLENOID VALVES

(a) Remove the 3 solenoid valves.

B

(b) Remove the O−rings from each of the solenoid valves.

10. INSTALL SHIFT SOLENOID VALVE

(a) Coat new O−rings with ATF and install them to the each

of the solenoid valve.

(b) Install the 3 shift solenoid valves with the 2 bolts.

Torque:

Q06411 Bolt A: 6.4 N·m (65 kgf·cm, 56 in.·lbf)

Bolt B: 10 N·m (100 kgf·cm, 7 ft·lbf)

1996 RAV4 (RM447U)

AX−7

AUTOMATIC TRANSAXLE (A241E) − VALVE BODY ASSEMBLY

11. INSTALL VALVE BODY

(a) Install the valve body.

(b) Connect the manual valve connecting rod.

AT3327

A (c) Install the 17 bolts and wire retainer.

Bolt length:

A Bolt A: 20 mm (0.79 in.)

B

Bolt B: 30 mm (1.18 in.)

Bolt C: 55 mm (2.17 in.)

B Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

A B

C A

A

B

Z11664

(d) Connect the throttle cable.

12. CONNECT 3 SOLENOID CONNECTORS

AT8586

13. INSTALL MANUAL DETENT SPRING

Install the manual detent spring with the bolt.

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

HINT:

Check that the manual valve lever is in contact with the center

of the roller at the tip of the detent spring.

AT8584

14. INSTALL OIL PIPE CLAMP AND OIL PIPES

(a) Install the 5 pipes with a large screwdriver.

(b) Install the oil pump clamp with the bolt.

Torque: 10 N·m (100 kgf·cm, 7 ft·lbf)

Q06418

1996 RAV4 (RM447U)

AX−8

AUTOMATIC TRANSAXLE (A241E) − VALVE BODY ASSEMBLY

15. INSTALL OIL STRAINER AND APPLY PIPE BRACKET

Install the oil strainer, gasket with the 3 bolts.

Torque: 10 N·m (102 kgf·cm, 7 ft·lbf)

HINT:

Replace used the gasket with a new one.

Q06417

16. INSTALL 2 MAGNETS IN OIL PAN

Q05234

17. INSTALL OIL PAN AND GASKET

(a) Install a new gasket to the oil pan.

(b) Install the oil pan with the 18 bolts.

Torque: 4.9 N·m (50 kgf·cm, 43 in.·lbf)

18. INSTALL DRAIN PLUG

Torque: 17 N·m (175 kgf·cm, 13 ft·lbf)

19. FILL ATF AND CHECK ATF (See page DI−127)

Q05259

1996 RAV4 (RM447U)

AX−9

AUTOMATIC TRANSAXLE (A241E) − THROTTLE CABLE

THROTTLE CABLE AX055−02

ON−VEHICLE REPAIR

1. DISCONNECT THROTTLE CABLE FROM ENGINE

2. REMOVE NO.2 ENGINE UNDER COVER

3. REMOVE PARK/NEUTRAL POSITION SWITCH (See

page AX−4)

4. REMOVE VALVE BODY (See page AX−5)

Q06117

5. REMOVE THROTTLE CABLE

(a) Remove the retaining bolt and plate.

(b) Pull out the cable from the transaxle case.

AT5641

6. INSTALL THROTTLE CABLE

If throttle cable is new, do the following operations (a) − (c).

(a) Bend the cable so there is a radius of about 200 mm (7.87

200 mm (7.87 in.)

in.).

(b) Pull theinner cable lightly until a slight resistance is felt,

and hold it.

(c) Stake the stopper 0.8 − 1.5 mm (0.031 − 0.059 in.) from

the end of outer cable.

0.8−1.5 mm (0.031−0.059 in.) (d) Be sure to push it in all the way.

Q05731

(e) Install the bolt.

7. INSTALL VALVE BODY (See page AX−5)

8. INSTALL PARK/NEUTRAL POSITION SWITCH (See

page AX−4)

9. INSTALL NO.2 ENGINE UNDER COVER

10. CONNECT THROTTLE CABLE

11. ADJUST THROTTLE CABLE (See page DI−127)

12. FILL ATF AND CHECK ATF (See page DI−127)

1996 RAV4 (RM447U)

AX−10

AUTOMATIC TRANSAXLE (A241E) − DIFFERENTIAL OIL SEAL

DIFFERENTIAL OIL SEAL AX056−03

ON−VEHICLE REPAIR

1. DRAIN ATF

2. REMOVE ENGINE UNDER COVER

3. REMOVE LH AND RH DRIVE SHAFTS

(See page SA−20)

SST 4. REMOVE LH AND RH SIDE OIL SEALS

Using SST, drive out the both side oil seals.

SST 09308−00010

Z02840

5. INSTALL LH AND RH SIDE OIL SEALS

LH Side

(a) Using SST and a hammer, drive in a new oil seal until its

surface is flush until the case surface.

SST LH side

09350−32014 (09351−32111, 09351−32130)

SST RH side

09350−32014 (09351−32130, 09351−32150)

Oil seal drive in depth:

Z02841 LH side: 5.2 ± 0.5 mm (0.205 ± 0.020 in.)

RH side: 0 ± 0.5 mm (0 ± 0.020 in.)

(b) Coat the oil seal lip with MP grease.

SST 6. INSTALL LH AND RH DRIVE SHAFTS

(See page SA−31)

7. FILL ATF AND CHECK ATF LEVEL (See page DI−127)

8. INSTALL ENGINE UNDER COVER

Z02842

1996 RAV4 (RM447U)

AX−11

AUTOMATIC TRANSAXLE (A241E) − SHIFT LOCK SYSTEM

SHIFT LOCK SYSTEM

AX04X−02

LOCATION

Stop Light Switch

Key Interlock Solenoid

Shift Lock Override Button Cover

HINT:

S The shift indicator housing ordered as

supply parts does not include the cover

of the shift−lock override button. Shift Lock Solenoid

So, if you replace the shift indicator Shift Lock Control Switch

housing, install cover from the old Shift Lock Control ECU

housing into the new housing.

S Install the cover with its cutout facing

toward the rear of the vehicle. Q08861

1996 RAV4 (RM447U)

AX−12

AUTOMATIC TRANSAXLE (A241E) − SHIFT LOCK SYSTEM

AX0T7−02

A B C INSPECTION

1. INSPECT SHIFT LOCK CONTROL ECU

SLS+

Using a voltmeter, measure the voltage at each terminal.

IG STP P1 P P2

E SLS− HINT:

ACC KLS+ Do not disconnect the ECU connector.

Wire Harness Side

Z19320

Connector Terminal Measuring condition Voltage (V)

5 − 4 (ACC − E) Ignition switch ACC 10 − 14

1 − 4 (IG − E) Ignition switch ON 10 − 14

2 − 4 (STP − E) Depress brake pedal 10 − 14

A

2. Ignition switch ACC and P position 0

6 − 4 (KLS+ − E) 3. Ignition switch ACC and except P position 7.5 − 11

4. (After−approx. 1 second) 5.5 − 10

1. Ignition switch ON and P position 0

B 1−2 (SLS+ − SLS−) 2. Depress brake pedal 8.5 − 14

3. Except P position 0

1. Ignition switch ON, P position and depress brake pedal 0

1 − 2 (P1 − P)

2. Shift except P position under condition above 10 − 14

C

1. Ignition switch ACC and P position 10 − 14

3 − 2 (P2 − P)

2. Shift except P position under condition above 0

2. INSPECT SHIFT LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Using an ohmmeter, measure the resistance between the

terminals.

Standard resistance: 26 − 33 Ω

If resistance value is not as specified, replace the solenoid.

AT5027

(c) Apply battery positive voltage between the terminals.

Check that the solenoid can be heard operating.

If solenoid operation is not as specified, replace the solenoid.

Battery

AT5029

1996 RAV4 (RM447U)

AX−13

AUTOMATIC TRANSAXLE (A241E) − SHIFT LOCK SYSTEM

3. INSPECT KEY INTERLOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Using an ohmmeter, measure the resistance between the

terminals.

Standard resistance: 12.5 − 16.5 Ω

2 1 If resistance value is not as specified, replace the solenoid.

Q09052

(c) Apply battery positive voltage between the terminals.

Check that the solenoid can be heard operating.

If solenoid operation is not as specified, replace the solenoid.

2 1

Q09053

4. INSPECT SHIFT LOCK CONTROL SWITCH

Inspect that there is continuity between each terminal.

Shift position Tester connection Specified value

P position (Release button

2 − 3 (P − P1) Continuity

is not pushed)

P position (Release button 2 − 3 (P − P1)

Continuity

is pushed) 2 − 1 (P − P2)

3 (P1) 1 (P2)

2 (P) R, N, D, 2, L position 2 − 1 (P − P2) Continuity

Z19339

If continuity is not as specified, replace the switch.

1996 RAV4 (RM447U)

AX−14

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE UNIT

AUTOMATIC TRANSAXLE UNIT

AX0T8−01

COMPONENTS

Air Intake Connector

ABS Relay

RH Drive Shaft Engine Coolant Reservoir Tank

64 (650, 47)

Air Cleaner

64 (650, 47) Case Assembly

25 (250, 18)

64 (650, 47)

27 (280, 20)

19 (194, 14)

Torque Converter x6

Clutch 46 (470, 34)

25 (250, 18)

9.0 (95, 78 in.·lbf)

Stiffener Plate

Rear End Plate

PS Gear Assembly

64 (650, 47) z Snap Ring

37 (380, 27)

Clip LH Drive Shaft

z Gasket

9.0 (95, 78 in.·lbf) 49 (500, 36)

z Cotter Pin

Engine Wire

Plug for Line Clamp

13 (135, 10)

Pressure Test Lock Cap

Shift Control 64 (650, 47) z Cotter Pin

Cable 39 (400, 29)

Starter

z Gasket 216 (2,200, 159)

48 (490, 35)

z Gasket

7.0 (75, 65 in.·lbf)

Engine Mounting

113 (1,150 83)

Center Member

z 62 (630, 46) Front Exhaust Pipe

Front Suspension Crossmember

Assembly with Stabilizer Bar

35 (360, 26)

72 (730, 53)

73 (740, 54)

137 (1,400, 101)

RH Engine Under Cover

206 (2,100, 152)

LH Engine Under Cover 127 (1,300, 94)

N·m (kgf·cm, ft·lbf) : Specified torque

z Non−reusable part Z18886

1996 RAV4 (RM447U)

AX−15

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE UNIT

AX127−01

REMOVAL

1. DISCONNECT THROTTLE CABLE

2. REMOVE ENGINE COOLANT RESERVOIR TANK

3. REMOVE AIR CLEANER ASSEMBLY

(a) Disconnect the connector and ABS relay.

(b) Remove the 3 bolts and air cleaner assembly.

4. REMOVE GROUND CABLE

Remove the bolt from the transaxle.

D02186

Torque: 19 N·m (194 kgf·cm, 14 ft·lbf)

5. REMOVE SET NUT OF ENGINE WIRE CLAMP

Q08747

6. REMOVE STARTER

(a) Disconnect the connector and nut from the starter.

(b) Remove the 2 bolts and disconnect the engine wire.

Torque: 39 N·m (400 kgf·cm, 29 ft·lbf)

(c) Remove the starter.

Q08761

7. REMOVE 3 UPPER SIDE TRANSAXLE MOUNTING

BOLTS

Torque: 64 N·m (650 kgf·cm, 47 ft·lbf)

D02187

8. INSTALL ENGINE SUPPORT FIXTURE

Q08763

1996 RAV4 (RM447U)

AX−16

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE UNIT

9. REMOVE ENGINE LEFT MOUNTING BOLT AND NUTS

Torque:

Bolt: 64 N·m (650 kgf·cm, 47 ft·lbf)

Nut: 64 N·m (650 kgf·cm, 47 ft·lbf)

10. REMOVE LEFT AND RIGHT ENGINE UNDER COVERS

11. DRAIN ATF

12. REMOVE LEFT AND RIGHT DRIVE SHAFTS

(See page SA−20)

Q08764

13. REMOVE FRONT EXHAUST PIPE

(a) Remove the 2 bolts and gasket from the exhaust pipe.

Torque: 48 N·m (490 kgf·cm, 35 ft·lbf)

HINT:

At the time of installation, please refer to the following item.

Replace used gasket with new gasket.

(b) Remove the 3 nuts, front exhaust pipe and gasket.

Torque: 62 N·m (630 kgf·cm, 46 ft·lbf)

Q08765 HINT:

At the time of installation, please refer to the following item.

Replace used nuts and gasket with new nuts and gasket.

14. DISCONNECT SHIFT CONTROL CABLE

(a) Remove the nut from the control shaft lever.

Torque: 13 N·m (135 kgf·cm, 10 ft·lbf)

(b) Remove the clip and disconnect the control cable.

Q08766

(c) Remove the 2 shift cable mounting bolts.

Torque: 7.0 N·m (75 kgf·cm, 65 in.·lbf)

Q08767

1996 RAV4 (RM447U)

AX−17

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE UNIT

15. DISCONNECT FOLLOWING CONNECTORS

S Shift solenoid valve SL connector

S Park/neutral position switch connector

S Vehicle speed sensor connector

Q08774

16. DISCONNECT 2 OIL COOLER HOSES

Loosen the 2 clips and disconnect the 2 oil cooler hoses.

Q08768

17. REMOVE 2 POWER STEERING GEAR MOUNTING

BOLTS AND NUTS

Torque: 113 N·m (1,150 kgf·cm, 83 ft·lbf)

NOTICE:

Support the power steering gear housing securely.

D01757

C 18. REMOVE FRONT SUSPENSION CROSSMEMBER AS-

C SEMBLY WITH STABILIZER BAR

D Remove the 10 bolts, 2 nuts and front suspension crossmem-

D

ber assembly with stabilizer bar.

A Torque:

A bolt: 206 N·m (2,100 kgf·cm, 152 ft·lbf)

Nut B B bolt: 137 N·m (1,400 kgf·cm, 101 ft·lbf)

A Nut B

C bolt: 35 N·m (360 kgf·cm, 26 ft·lbf)

B B Q08769 D bolt: 72 N·m (730 kgf·cm, 53 ft·lbf)

Nut: 73 N·m (740 kgf·cm, 54 ft·lbf)

19. REMOVE STIFFENER PLATE

Remove the 3 bolts and stiffener plate.

Torque: 37 N·m (380 kgf·cm, 27 ft·lbf)

Q08770

1996 RAV4 (RM447U)

AX−18

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE UNIT

20. REMOVE REAR END PLATE

Remove the 4 bolts and rear end plate.

Torque:

A A bolt: 9.0 N·m (95 kgf·cm, 78 in.·lbf)

B bolt: 19 N·m (195 kgf·cm, 14 ft·lbf)

B A Z18887

21. REMOVE TORQUE CONVERTER CLUTCH MOUNT-

ING BOLT

Turn the crankshaft to gain access and remove the 6 bolts with

holding the crankshaft pulley set bolt by a wrench.

Torque: 27 N·m (280 kgf·cm, 20 ft·lbf)

HINT:

At the time of installation, please refer to the following item.

First install the gray bolt. Then install 5 black bolts while turning

Q08772 the crankshaft to grain access.

22. SUPPORT TRANSAXLE WITH A TRANSMISSION

JACK

23. REMOVE TRANSAXLE

Remove the rear side transaxle mouting 2 bolts and transaxle.

A Torque:

A bolt: 25 N·m (250 kgf·cm, 18 ft·lbf)

B bolt: 46 N·m (470 kgf·cm, 34 ft·lbf)

Q08773

1996 RAV4 (RM447U)

AX−19

AUTOMATIC TRANSAXLE (A241E) − AUTOMATIC TRANSAXLE UNIT

AX059−03

INSTALLATION

1. INSTALL TORQUE CONVERTER CLUTCH

Using calipers and a straight edge, measure from the installed

surface to front surface of the transaxle housing.

Correct distance: More than 12.75 mm (0.502 in.)

2. INSTALL TRANSAXLE

Installation is in the reverse order of removal (See page

AX−15).

AT3412

HINT:

After installation, check and inspect items as follows.

S Fluid level (See page DI−127)

S Front wheel alignment (See page SA−4)

S Road test the vehicle

1996 RAV4 (RM447U)

AX−20

AUTOMATIC TRANSAXLE (A241E) − TORQUE CONVERTER CLUTCH AND DRIVE PLATE

SST

TORQUE CONVERTER CLUTCH

AND DRIVE PLATE AX05A−02

INSPECTION

1. INSPECT ONE−WAY CLUTCH

(a) Install SST into the inner race of the one−way clutch.

SST 09350−32014 (09351−32010)

(b) Install SST so that it fits in the notch of the converter clutch

AT0953

hub and outer race of the one−way clutch.

SST 09350−32014 (09351−32020)

(c) With the torque converter clutch standing on its side,the

Hold clutch locks when turned counterclockwise, and rotates

freely and smoothly clockwise.

If necessary, clean the converter clutch and retest the clutch.

Lock Replace the converter clutch if the clutch still fails the test.

Turn Free

AT3306

2. MEASURE DRIVE PLATE RUNOUT AND INSPECT

RING GEAR

Set up a dial indicator, measure the drive plate runout.

Maximum runout: 0.20 mm (0.0079 in.)

If the runout is not within the specification or if the ring gear is

damaged, replace the drive plate. If installing a new drive plate,

note the orientation of spacers and tighten the bolts.

Torque: 83 N·m (850 kgf·cm, 61 ft·lbf)

D00776

3. MEASURE TORQUE CONVERTER CLUTCH SLEEVE

RUNOUT

Temporarily mount the torque converter clutch to the drive

plate. Set up a dial indicator, measure the torque converter

clutch sleeve runout.

Maximum runout: 0.30 mm (0.0118 in.)

If the runout is not within the specification, try to correcting by

reorienting the installation of the converter clutch.

AT4184

1996 RAV4 (RM447U)

AX−21

AUTOMATIC TRANSAXLE (A241E) − TORQUE CONVERTER CLUTCH AND DRIVE PLATE

HINT:

Mark the position of the torque converter clutch to ensure cor-

rect installation.

1996 RAV4 (RM447U)

You might also like

- Technical Service Information: AW81-40LEDocument16 pagesTechnical Service Information: AW81-40LECatalin Iordache83% (12)

- Aa80e EngDocument772 pagesAa80e EngMarco MeloncelliNo ratings yet

- Checklist King Air 350 - Black SquareDocument4 pagesChecklist King Air 350 - Black SquarePhilippe MagnoNo ratings yet

- A 442FDocument142 pagesA 442FJan Eklund100% (3)

- Renault Ad4: 4 SPEED FWD (Full Electronic Con Trol)Document4 pagesRenault Ad4: 4 SPEED FWD (Full Electronic Con Trol)José Antonio GutiérrezNo ratings yet

- A750 TransmissionDocument30 pagesA750 Transmissionjohnatan chui100% (2)

- AA80EDocument2 pagesAA80EMothana HusbanNo ratings yet

- Transmission/transaxle Fn4aelDocument68 pagesTransmission/transaxle Fn4aelJoe MontanaNo ratings yet

- Transmission AD4Document140 pagesTransmission AD4tyf00s50% (4)

- ZF Vt1f MiniDocument31 pagesZF Vt1f Minibaccara180% (5)

- Toyota U151E-U250E Zip Kit: Electronic CautionsDocument8 pagesToyota U151E-U250E Zip Kit: Electronic CautionsMajdy Alsobhi100% (2)

- A442F Automatic Transmission Service and Repair ManualDocument142 pagesA442F Automatic Transmission Service and Repair Manualstephany castroNo ratings yet

- ZF 4 HP 20Document4 pagesZF 4 HP 20Irina VeresininaNo ratings yet

- A43Document126 pagesA43Василий ДимовNo ratings yet

- Honda f4 Atsg Automatic Transmission Service GroupDocument88 pagesHonda f4 Atsg Automatic Transmission Service GroupCông Trần Minh0% (1)

- 03 Picanto atDocument0 pages03 Picanto atfrancisca19No ratings yet

- TL-80SN (AA80E) : 8 Speed RWD (Electronic Control) LS460/470, GS460/470, IS F (Lexus), Crown Majesta (Toyota)Document4 pagesTL-80SN (AA80E) : 8 Speed RWD (Electronic Control) LS460/470, GS460/470, IS F (Lexus), Crown Majesta (Toyota)Mothana HusbanNo ratings yet

- At Re7r01aDocument212 pagesAt Re7r01aสนั่น วิริยะเจริญกุลNo ratings yet

- Daihatsu Type A4q A4r Series Automatic Transmission Electrically Controlled Service Manual No9738Document48 pagesDaihatsu Type A4q A4r Series Automatic Transmission Electrically Controlled Service Manual No9738Guillermo Rosas GonzalezNo ratings yet

- Oversized Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Document1 pageOversized Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2belchior0% (1)

- M24ADocument74 pagesM24ALuis Pérez mujicaNo ratings yet

- KM-177 ManualDocument120 pagesKM-177 Manualcarlos100% (1)

- U150E / U151E / U250E: FWD 5 SpeedDocument6 pagesU150E / U151E / U250E: FWD 5 SpeedJD Dionisio100% (2)

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- Oversized 3/5/reverse & Underdrive Pressure Control Valve KitDocument2 pagesOversized 3/5/reverse & Underdrive Pressure Control Valve KithidraulicNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Helps Cure:: Time Tested - Industry TrustedDocument1 pageHelps Cure:: Time Tested - Industry TrustedMauricio Exequiel ChavezNo ratings yet

- A Closer Look at The Toyota A750E Valve Body PDFDocument68 pagesA Closer Look at The Toyota A750E Valve Body PDFTomas E. EcheverriaNo ratings yet

- 6L456L90ZipInD 5041434601Document12 pages6L456L90ZipInD 5041434601Julio ChalbaudNo ratings yet

- A340 VacTestLocationsDocument8 pagesA340 VacTestLocationsMauricio Exequiel ChavezNo ratings yet

- 700R4 / 4L60E / 4L65E: RWD 4 SpeedDocument8 pages700R4 / 4L60E / 4L65E: RWD 4 SpeedGesalNo ratings yet

- Daihatsu Terios 2000-2006 Automatic Transmission Type A4Q, A4R General Information PDFDocument7 pagesDaihatsu Terios 2000-2006 Automatic Transmission Type A4Q, A4R General Information PDFRock KetphilNo ratings yet

- Toyota U660E: Fill and Overflow Plug LocationsDocument8 pagesToyota U660E: Fill and Overflow Plug LocationsAlex Maceira Graterol100% (1)

- Print: K411 CVT Continuously Variable Transaxle Assembly PreparationDocument1 pagePrint: K411 CVT Continuously Variable Transaxle Assembly PreparationLUISNo ratings yet

- U151e U250e Zip inDocument10 pagesU151e U250e Zip inĐức phạm ngọcNo ratings yet

- U140Document6 pagesU140HectorNo ratings yet

- A340HDocument3 pagesA340HUbaidurRehman Qundeel JanjuaNo ratings yet

- Ha1005 PDFDocument18 pagesHa1005 PDFhidraulic50% (2)

- JF 404 eDocument4 pagesJF 404 evaskaserv100% (2)

- AW4 Jeep AW4Document112 pagesAW4 Jeep AW4dimitarusa99100% (2)

- Aw80 40leDocument3 pagesAw80 40leAbbode HoraniNo ratings yet

- Index: T H M 4 4 0 - T 4Document104 pagesIndex: T H M 4 4 0 - T 4Anonymous eExWojLxNo ratings yet

- K111 Continuously Variable Transaxle: DescriptionDocument35 pagesK111 Continuously Variable Transaxle: Descriptionhungchagia1100% (2)

- AWTF80SC / 81SC (AF21/AF40-6) AWTF80SC / 81SC (AF21/AF40-6) : FWD 6 Speed FWD 6 SpeedDocument1 pageAWTF80SC / 81SC (AF21/AF40-6) AWTF80SC / 81SC (AF21/AF40-6) : FWD 6 Speed FWD 6 SpeedFSR1407No ratings yet

- A960e Transmission SolenoidDocument2 pagesA960e Transmission SolenoidDenis KonovalovNo ratings yet

- Automatic Transmission Serial Numbers T-tc004-96Document3 pagesAutomatic Transmission Serial Numbers T-tc004-96emboko100% (1)

- 1 4906800698873610302 PDFDocument112 pages1 4906800698873610302 PDFGabrielNo ratings yet

- U 250eDocument132 pagesU 250eRoman Filatov83% (6)

- RE0F10A CVT Parts Catalogue 2019-07Document65 pagesRE0F10A CVT Parts Catalogue 2019-07Андрей ЛозовойNo ratings yet

- JR405 PDFDocument111 pagesJR405 PDFGeorgi AleksievNo ratings yet

- Precision 2013Document469 pagesPrecision 2013Cornell Jackson50% (2)

- 07 Automatic Transaxle PDFDocument144 pages07 Automatic Transaxle PDFEd KruseNo ratings yet

- Automatic Transaxle (A540h) - Rav4 Sxa1Document23 pagesAutomatic Transaxle (A540h) - Rav4 Sxa1Christian Linares AbreuNo ratings yet

- Planetary Gear Unit 1. Construction: Chassis - A340E, A340F, A343E and A343F Automatic Transmissions CH-14Document5 pagesPlanetary Gear Unit 1. Construction: Chassis - A340E, A340F, A343E and A343F Automatic Transmissions CH-14Maxi SardiNo ratings yet

- At (2jz-Ge)Document24 pagesAt (2jz-Ge)Jafar SadiqNo ratings yet

- Dokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFDocument5 pagesDokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFAleksandr Kuznichenko0% (1)

- Automatic TransaxleDocument37 pagesAutomatic TransaxlejasonphxNo ratings yet

- Automatic Transaxle1Document5 pagesAutomatic Transaxle1Dang Tien PhucNo ratings yet

- Operation: Automatic Transmission (A650E)Document1 pageOperation: Automatic Transmission (A650E)Marten ReedNo ratings yet

- Automatic Transaxle SystemDocument28 pagesAutomatic Transaxle SystemEduardo SantosNo ratings yet

- Toyota Camry 2005 Electrical System586uDocument20 pagesToyota Camry 2005 Electrical System586uedgar100% (37)

- How Far Should Parkers WalkDocument4 pagesHow Far Should Parkers WalkYusfita Chrisna WikartaNo ratings yet

- PowerRail Catalog - V23 FINALDocument102 pagesPowerRail Catalog - V23 FINALJohnny R.No ratings yet

- Servomotor DBL2H00040-0R2-000-S40 0.9a 0.22KW 6000umin Kollmorgen Seidel DatasheetDocument72 pagesServomotor DBL2H00040-0R2-000-S40 0.9a 0.22KW 6000umin Kollmorgen Seidel Datasheetmoyali25176750No ratings yet

- Gancho 429Document41 pagesGancho 429camiloguayazanNo ratings yet

- Aircraft Design Unit 1Document39 pagesAircraft Design Unit 1Vinoth AeroNo ratings yet

- Introduction To Informatics AssignmentDocument12 pagesIntroduction To Informatics AssignmentMunyaradzi ZhouNo ratings yet

- 400 Identifaction and MaintenanceDocument15 pages400 Identifaction and MaintenanceMrAlbert2009No ratings yet

- UNI (Italian) Standards For Steel MaterialsDocument2 pagesUNI (Italian) Standards For Steel MaterialstrieuNo ratings yet

- DTC B1803/51 Short in D Squib Circuit (To B+)Document5 pagesDTC B1803/51 Short in D Squib Circuit (To B+)julio montenegroNo ratings yet

- DPG Information: Address From Which Detailed Information On The Polluting and Dangerous Cargo May Be ObtainedDocument33 pagesDPG Information: Address From Which Detailed Information On The Polluting and Dangerous Cargo May Be Obtainedenciu georgeNo ratings yet

- Cec 413 - Highway EngDocument16 pagesCec 413 - Highway EngMuhammed SaniNo ratings yet

- Purpose: Part 100 Matrix - Safety Management SystemDocument5 pagesPurpose: Part 100 Matrix - Safety Management SystemDYNA CALAUAGANNo ratings yet

- English For Travel and TourismDocument11 pagesEnglish For Travel and TourismAchmad Rizki MaulanaNo ratings yet

- Genie Scissors Lift A Gs 2032 2632 Before SN 60000 Parts ManualsDocument10 pagesGenie Scissors Lift A Gs 2032 2632 Before SN 60000 Parts Manualschad100% (50)

- Speed AND Acceleration: Form 2 Pa G E 2 2 5Document18 pagesSpeed AND Acceleration: Form 2 Pa G E 2 2 5HJ Teo100% (1)

- Updated170301-Sangdong CatalogueDocument45 pagesUpdated170301-Sangdong CatalogueBassSuper75% (4)

- John Deere Tractors 5055e 5065e 5075e Operators ManualDocument23 pagesJohn Deere Tractors 5055e 5065e 5075e Operators Manualgeraldfleming230990yka100% (136)

- Phuket - Flight Timing - SummaryDocument1 pagePhuket - Flight Timing - SummaryAtul JainNo ratings yet

- E Glide ST LCD InstructionsDocument18 pagesE Glide ST LCD InstructionsNam VũNo ratings yet

- Cruise Control Izusu CamionesDocument12 pagesCruise Control Izusu CamionesAnonymous KOtSfT6qNo ratings yet

- Preparation of Load Line SurveyDocument7 pagesPreparation of Load Line Surveyijderi100% (1)

- Manual Horno Jon ZinkDocument82 pagesManual Horno Jon ZinkJonathan ZentenoNo ratings yet

- Ceor Module 10 Explain NotesDocument7 pagesCeor Module 10 Explain NotesCHRISTINE MERTOLANo ratings yet

- IHO Koboat FinalDocument12 pagesIHO Koboat FinalWVLT NewsNo ratings yet

- 209 Coastwise Lighterage Corp. v. CA (Uy)Document2 pages209 Coastwise Lighterage Corp. v. CA (Uy)Avie UyNo ratings yet

- I PartialOral Test - Docxana CristinaDocument7 pagesI PartialOral Test - Docxana CristinaLilliana Jirón GutiérrezNo ratings yet

- COSA SS4A One-Pager Grant Award 2.2.23Document2 pagesCOSA SS4A One-Pager Grant Award 2.2.23Cody KingNo ratings yet

- BHPHC23006582 20230804173709Document2 pagesBHPHC23006582 20230804173709Thanh Tùng NguyễnNo ratings yet

- Model RPM: Contractor: Engineer: End User: GPM TDH HP Effic. Service Condition: Project: StagesDocument49 pagesModel RPM: Contractor: Engineer: End User: GPM TDH HP Effic. Service Condition: Project: StagesAdonay HqzNo ratings yet