Professional Documents

Culture Documents

Oral Powder Filling

Uploaded by

Rakshita MishraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oral Powder Filling

Uploaded by

Rakshita MishraCopyright:

Available Formats

Oral Powder Filling: Glucose-D

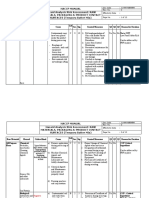

PM Requisition sent from Prod. (Packing) to Packing Material Store

PM Store checks and verifies requisition carefully (for quantity and package size)

Printed PM like ( labels, cartons, PCB) issued earlier for coding

Non-Printed like (bottles, caps, shipper’s ctc.) issued at time of

filling

Packing Material issued to Prod. (Packing)

Supervisor check Packing Materials (for damage and quantity)

Batch Coding (Batch no., Mfg. date, Exp. date & M.R.P.)

Line Clearance of machine/equipment & Area

Check cleaning

of equipment & area.

Absence of remnants from previous products.

Temp. & Humidity should be monitored.

Setting up of Machines/Equipment

Filling

By machine By manual

Material filling & sealing in linear pcb/pouches Jar Arrangement

Leakage Checking Filling

Cleaning Weighing

Shrink Tiger Sealing

Weighing Tiger Cutting

Cartoning Capping

Labelling

Cartoning

You might also like

- Print 3 VDocument15 pagesPrint 3 Vvaibhav raut100% (1)

- SAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Document1 pageSAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Tito GarciaNo ratings yet

- Work Flow in The OrganisationDocument10 pagesWork Flow in The OrganisationVishwanath KrNo ratings yet

- Coded Marking Procedure - CM-01Document7 pagesCoded Marking Procedure - CM-01carlosNo ratings yet

- Saftey-HACCP-of-Hersheys by MeeeDocument9 pagesSaftey-HACCP-of-Hersheys by MeeeFranz Marvin DuhaylungsodNo ratings yet

- Gaskit Saferpak RotacuTDocument7 pagesGaskit Saferpak RotacuTleila lolita leila lilasNo ratings yet

- ANNEXURE D Checklist For Area or Line ClearanceDocument3 pagesANNEXURE D Checklist For Area or Line ClearanceSaleha YounusNo ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- BMR SuspensionsDocument16 pagesBMR SuspensionsMohammed Zubair0% (1)

- Pressure Vessel ITP Rev 0Document21 pagesPressure Vessel ITP Rev 0Ahmad HasnanNo ratings yet

- Aspect Impact Hazard Risk Production and InspectionDocument19 pagesAspect Impact Hazard Risk Production and InspectionganrashNo ratings yet

- Ensayo de TrazabilidadDocument3 pagesEnsayo de TrazabilidadPatricia SevillaNo ratings yet

- Master Formula and Batch Manufacturing RecordDocument36 pagesMaster Formula and Batch Manufacturing RecordAbou Tebba SamNo ratings yet

- Part Number Part Name Customer Auditor Name: Audit DateDocument1 pagePart Number Part Name Customer Auditor Name: Audit DateBARDLYNo ratings yet

- Internship Report DesignerDocument12 pagesInternship Report DesignerQareena ChNo ratings yet

- Dispensing Procedure, JewelDocument24 pagesDispensing Procedure, JewelMd. JewelNo ratings yet

- Kertas Penerangan c01 - Composite Material Preparation P (1-2)Document7 pagesKertas Penerangan c01 - Composite Material Preparation P (1-2)Muhammad ZulfamiNo ratings yet

- Food Scrap Collection and Disposal ProcedureDocument3 pagesFood Scrap Collection and Disposal ProcedureLeya GepilanoNo ratings yet

- Haccp Documents 1Document26 pagesHaccp Documents 1olivia domingoNo ratings yet

- Tablet BMR Wenovo (New)Document30 pagesTablet BMR Wenovo (New)Muhammad ImranNo ratings yet

- Trip TO Medicamen Biotech Ltd. (BHIWADI) : Amit Anand VII Semester 04219611Document33 pagesTrip TO Medicamen Biotech Ltd. (BHIWADI) : Amit Anand VII Semester 04219611nitin0474161107No ratings yet

- Form ITP Pressure Vessel - RevDocument8 pagesForm ITP Pressure Vessel - Revsuratno 25No ratings yet

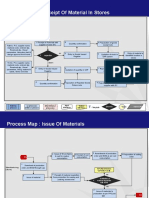

- Process Map: Receipt of Material in Stores: StartDocument4 pagesProcess Map: Receipt of Material in Stores: StartOumayma Niz100% (1)

- 5 - HYGIENE HACCP Study ReportDocument9 pages5 - HYGIENE HACCP Study ReportNam NguyenNo ratings yet

- PPGP-MFG - Oc B6 Act-S & I - G4Document7 pagesPPGP-MFG - Oc B6 Act-S & I - G4Isabel EsquijoNo ratings yet

- Store FW EAI HIRA BASIC EXERCISE SHEETDocument12 pagesStore FW EAI HIRA BASIC EXERCISE SHEETharesh.gadhaviNo ratings yet

- Assignment On MCDDocument8 pagesAssignment On MCDshamim hossainNo ratings yet

- FM - MKT - 02 Quality Control Process ChartDocument4 pagesFM - MKT - 02 Quality Control Process Chartbarja subarjaNo ratings yet

- Earthing and LightingDocument1 pageEarthing and Lightingramshad ekNo ratings yet

- Postconsumer Recycled-Content CertificationDocument2 pagesPostconsumer Recycled-Content Certificationjames alexanderNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ненад КнежевићNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ansar Ali VemmullyNo ratings yet

- Global Supply Chain Management: Prepared By: Magdalena B. DascoDocument41 pagesGlobal Supply Chain Management: Prepared By: Magdalena B. DascoMhagz MaggieNo ratings yet

- QCTR-A-2013 Rev 0Document2 pagesQCTR-A-2013 Rev 0Madhan KannanNo ratings yet

- Re: Maltodextrine Inquiry - BRPO2122E1427: TH THDocument2 pagesRe: Maltodextrine Inquiry - BRPO2122E1427: TH THvishnuNo ratings yet

- Draft Bin CardDocument1 pageDraft Bin CardAnonymous t3CoRw7P100% (2)

- Control Plan & FmeaDocument9 pagesControl Plan & FmeaManu SharmaNo ratings yet

- Tablet BMR Ampsar 5 by 160Document31 pagesTablet BMR Ampsar 5 by 160Muhammad ImranNo ratings yet

- How To Prepare A Batch Manufacturing Record Template: What Should A BMR Contain?Document5 pagesHow To Prepare A Batch Manufacturing Record Template: What Should A BMR Contain?Taddele AbateNo ratings yet

- A. Batch Completion Details Manufacturing DateDocument30 pagesA. Batch Completion Details Manufacturing DateViswa Subramanian BharathanNo ratings yet

- Line Clearance ProcedureDocument3 pagesLine Clearance ProcedurePrince Moni67% (3)

- Process Map Powder CoatDocument2 pagesProcess Map Powder CoatMarcel PantanoNo ratings yet

- F.T. Barcode Solution Presenations - BlissDocument19 pagesF.T. Barcode Solution Presenations - BlissSingb BabluNo ratings yet

- 8D For ID Over sizeTECUMSEHDocument4 pages8D For ID Over sizeTECUMSEHKuldeep SinghNo ratings yet

- Haccp Manual Hazard Analysis Risk Assessment: RAW Materials, Packaging & Product Contact SURFACES (Tempura Batter Mix)Document10 pagesHaccp Manual Hazard Analysis Risk Assessment: RAW Materials, Packaging & Product Contact SURFACES (Tempura Batter Mix)clarisa martinezNo ratings yet

- UntitledDocument7 pagesUntitledpralexprajapatiNo ratings yet

- HOD-PPC-Form-01 Trial OrderDocument1 pageHOD-PPC-Form-01 Trial Orderhendra ramadhanNo ratings yet

- MVP Line Contamination ControlDocument4 pagesMVP Line Contamination Controlkrishan dalalNo ratings yet

- Scope of Work Qualificatin & ValidationDocument8 pagesScope of Work Qualificatin & ValidationPerdana Mandiri TekindoNo ratings yet

- Test EquiDocument18 pagesTest EquiGuido PeraltaNo ratings yet

- Company Logo Here: Checklist For ManagementDocument5 pagesCompany Logo Here: Checklist For ManagementAlphaNo ratings yet

- Vocabulary List, IndustryDocument2 pagesVocabulary List, IndustryRanim JOUININo ratings yet

- Appendix 25 VDA 6 3 Process AuditDocument14 pagesAppendix 25 VDA 6 3 Process AuditMaalaoui Hasna100% (1)

- 78 Cosmetics GMP Audit ChecklistDocument3 pages78 Cosmetics GMP Audit Checklistsandeshkuperkar95No ratings yet

- Post Production Process: Thread Trimming Washing & Drying Pressing Initial CheckingDocument4 pagesPost Production Process: Thread Trimming Washing & Drying Pressing Initial CheckingSakshiNo ratings yet

- BMR - Metro - 0.5 % - IP - 100 ML - 4800 LDocument32 pagesBMR - Metro - 0.5 % - IP - 100 ML - 4800 LJayDwarkadhish.15No ratings yet

- Master Formula CardDocument7 pagesMaster Formula CardTrilochan Ayurveda100% (1)

- SDL ATLAS TextileDocument1 pageSDL ATLAS TextilesamsinternationalNo ratings yet

- A Processing Manual of Individual Quick Frozen Green Peas from Raw Material to Cold Storage.From EverandA Processing Manual of Individual Quick Frozen Green Peas from Raw Material to Cold Storage.No ratings yet

- Boric Acid IP:: A. Benefits of Boric Acid I.P. For Health: 1. Treating Fungal InfectionsDocument1 pageBoric Acid IP:: A. Benefits of Boric Acid I.P. For Health: 1. Treating Fungal InfectionsRakshita MishraNo ratings yet

- PO SheetDocument33 pagesPO SheetRakshita MishraNo ratings yet

- Sheeba Malik: Career ObjectivesDocument2 pagesSheeba Malik: Career ObjectivesRakshita MishraNo ratings yet

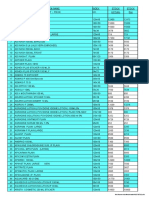

- PM Stock 25.9.20Document30 pagesPM Stock 25.9.20Rakshita MishraNo ratings yet