Quality Assurance/Quality

Control Plan

Office Address:2nd Floor Rudanel Building

SouthpointBrgyBanaybanayCabuyao

Laguna 4025Near Malayan colleges and

Cabuyao exit

Contact No.: (049)544-6786 (02)519-4620

Fax No.: (049)544-6773

Eric Limare BenjoPapagayo

EHS/Supervisor EHS/Manager

1

�Contents

1.0 Introduction....................................................................................................3

1.1 QA/QC Plan Structure ....................................................................................3

2.0 Project Organization………………………..............................................................4

3.0 Site Background .............................................................................................5

3.1 Project Scope……………………………………………….................................................5

3.2 Work Process Description…………………………….................................................5

4.0 Proposed Layout…………………………………………………………………………………………6

5.0 Metal Specification…………………………………………………………………………………….11

4. 0 Project Quality Assurance and Quality Controls............................................17

5.0 Documentation and Recordkeeping ..............................................................18

5.1 Review and Evaluation....................................................................................19

2

�1.0 Introduction

The purpose of this QA/QC Plan is to provide guidance and measures to be

employed to ensure that the project is completed in a safe manner that is

consistent with project goals. Given the scope and complexity of this project, it is

important that Site authority and practices are clearly defined and that the

practices and quality control methods are implemented consistently. This QA/QC

Plan is intended to identify Site controls/authority, general procedures such as

document/data control, and activity-specific controls and verification procedures.

1.1 QA/QC Plan Structure

The QA/QC Plan is organized into the following Sections:

• Introduction;

• Project Organization and Authority;

• Site Background;

• Project Scope and Process Description;

• Project Quality Assurance and Quality Control;

• Documentation and Recordkeeping;

• Review and Evaluation, and;

• Reporting.

3

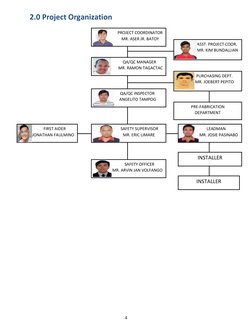

�2.0 Project Organization

PROJECT COORDINATOR

MR. ASER JR. BATOY

ASST. PROJECT COOR.

MR. KIM BUNDALLIAN

QA/QC MANAGER

MR. RAMON TAGACTAC

PURCHASING DEPT.

MR. JOEBERT PEPITO

QA/QC INSPECTOR

ANGELITO TAMPOG

PRE-FABRICATION

DEPARTMENT

FIRST AIDER SAFETY SUPERVISOR LEADMAN

JONATHAN FAULMINO MR. ERIC LIMARE MR. JOSIE PASINABO

INSTALLER

SAFETY OFFICER

MR. ARVIN JAN VOLFANGO

INSTALLER

4

�3.0 Site Background

Iron Mountain Philippines, Inc. Warehouse 2 & 8B Southern Luzon Complex

Purok 3 Brgy. Batino 4027 Calamba City, Laguna Philippines (4027) Iron Mountain

is a global business dedicated to storing, protecting and managing, information

and assets.

3.1 Project Scope

A. Removal of upright frame and beam for staircase provision.

B. Removal of boxes on the layer.

C. Installation of stair case with landing.

D. Making of new access tunnel.

E. Supply of staircase with landing.

F. Supply of safety pallets gates.

3.2 Work Process Description

A. Assessment of working area to properly appraise all potential hazard

during work execution.

B. Preparation and Inspection of Tools, equipment and personal Protective

Equipment to be used.

C. Preparation of man power requirements.

D. Preparation of work methodology and hazard Identification risk

Assessment and Control

E. Preparation of Work permits (i.e. General Work Permit, at Height.

Setting up Pre- Start Meeting with Sub- Contractor.

5

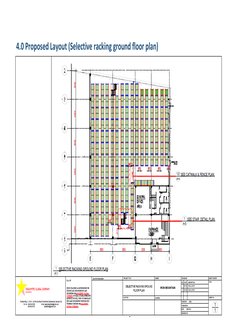

�4.0 Proposed Layout (Selective racking ground floor plan)

6

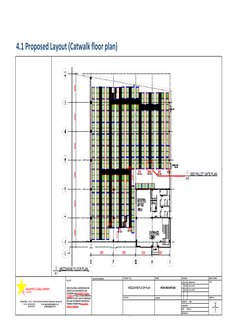

�4.1 Proposed Layout (Catwalk floor plan)

7

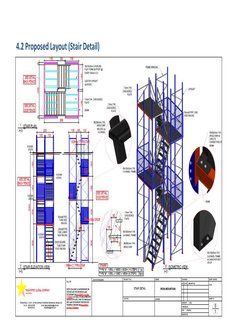

�4.2 Proposed Layout (Stair Detail)

8

�4.3 Proposed Layout (catwalk beam/catwalk fence/stair fence)

9

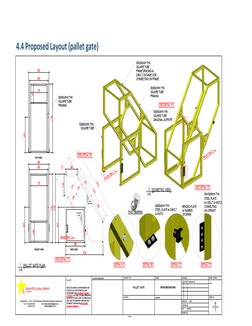

�4.4 Proposed Layout (pallet gate)

10

�5.0 Metal specification

ANGLE BAR 38 X 38 X 2mmTHK / 1 ½ x 1 ½ x 3/16

Est. Weight Width Dim 1 Dim 2

per Foot

1.8 3/16 1 1/2 1 1/2

CHECKERED PLATE 1219mm x 2438 x 1.5mmTHK / 4 x 8

Thickness Kg/pc Lb/pc Pcs/mt

(mm)

1.5 34.994 77.149 28.6

C-CHANNEL 50 X 100 X3mmTHK / 2 x 4 x 5/16

Dimension Weight Section Depth of Width Thickness Thickness Corner Moment Iyy Radius of Ryy Modules of Zyy

(mm) (Kg/mtr) Area Section of of flange of Web Radius of Inertia. (cm4) Gyration (cm) Selection. (cm3)

(Sq. mm) (mm) Flange (mm) (mm) (mm) Ixx (cm4) Rxx (cm) Zxx (cm3)

(mm)

100 x 50 9.2 11.7 100 50 7.5 4.7 9 186.7 24.9 4 1.49 37.3 7.5

11

�5.0 Metal specification

ANGLE BAR 50 X 50 X 3mmTHK / 50 x 50 x 5/16

Est. Weight Width Dim 1 Dim 2

per Foot

3.19 5/16 2 2

GI BOLT M12 X 40

Embedment Ultimate Safe Ultimate Safe Min. Edge Min

Depth (mm) Load kN Working Load kN Working Distance Spacing

Load kN Load kN (mm) (mm)

3:1 3:1 Tension

Tension Shear / Shear

40 14.6 4.87 25.5 8.5 40 / 80 80

SLEEVE ANCHOR BOLT HLV M10 X 120

Thread Hole Embedment Fixture Center Edge Structure Rec Tensile Rec Shear Rec Tight

Diameter diameter Depth (mm) Clearance Spacing Distance Thickness Load kN Load kN Torque Nm

(size) (mm) Hole (mm) (mm) (mm) (mm)

M10 12 68 13-14 180 90 90 8.5 8.6 65

12

�5.0 Metal specification

C purlins 50 x 75 x 3mmTHK / 2 x 3 x 5/16

H (mm) B (mm) A (mm) t (mm) Weight Area Ixx (cm4 ) Iyy (cm4 ) Zxx (cm3 ) Zyy (cm3 )

(kg/m) (mm2)

75 50 15 3 4.2 415 41 16 11 5

BI PIPE 50 (2”) SCHEDULE 40

Nominal Pipe OD Wall Pipe ID Weight per Standard Schedule Section Gallon

Pipe Size Thickness Foot to XXHY Pipe Modulus Capacity

in Inches Number per Linear

Foot

2 - 0.219 1.939 5.03 STD 40 0.5606 0.1743

13

�5.0 Metal specification

SQUARE TUBE 50 X 50 X 3mmTHK / 2 x 2 x 5/16

Tubing Wall Tubing Wall

Thickness Thickness

Nominal Tube Inches Inches Weight per

Size in Inches Length Width Decimal Fraction Foot Pounds

2x2 2 2 0.3125 5/16 6.32

BI PIPE 50 (2”) SCHEDULE 40

Nominal Pipe OD Wall Pipe ID Weight per Standard Schedule Section Gallon

Pipe Size Thickness Foot to XXHY Pipe Modulus Capacity

in Inches Number per Linear

Foot

1 1.315 0.133 1.049 1.68 STD 40 0.1328 0.0449

14

�5.0 Metal specification

GI BOLT M12 X 40

Embedment Ultimate Safe Ultimate Safe Min. Edge Min

Depth (mm) Load kN Working Load kN Working Distance Spacing

Load kN Load kN (mm) (mm)

3:1 3:1 Tension

Tension Shear / Shear

40 14.6 4.87 25.5 8.5 40 / 80 80

SQUARE TUBE 30 X 30 X 2mmTHK / 1 x 1 x 3/16

Tubing Wall Tubing Wall

Thickness Thickness

Nominal Tube Inches Inches Weight per

Size in Inches Length Width Decimal Fraction Foot Pounds

1x1 1 1 0.3125 5/16 6.32

15

�5.0 Metal specification

SQUARE TUBE 20 X 20 X 2mmTHK / 3/4 x 3/4 x 3/16

Tubing Wall Tubing Wall

Thickness Thickness

Nominal Tube Inches Inches Weight per kg

Size in Inches Length Width Decimal Fraction metre

3/4 x 3/4 3/4 3/4 0.1875 3/16 1.11

SQUARE TUBE 40 X 40 X 2mmTHK / 1 1/2 x 1 1/2 x 3/16

Tubing Wall Tubing Wall

Thickness Thickness

Nominal Tube Inches Inches Weight per kg

Size in Inches Length Width Decimal Fraction metre

1 1/2 x 1 1 1/2 1 1/2 0.1875 3/16 2.37

1/2

STEEL MATTING GAUGE 8 6ft X 20ft

Wire diameter Aperture

(mm) Inch Mm Width (m) Length

3.2 2 50.8 1.83 Length does

not limit

16

�4.0 Project Quality Assurance and Quality Controls

This section includes quality assurance and quality controls implemented at the

Site. Quality assurance items are primarily procedures/processes that are

implemented to ensure successful completion of the project. Quality control

items are used to evaluate the implemented project procedures/protocols and

identify deviations.

Quality Assurance

Specific project components require strict management methods in order to

ensure a successful outcome. These aspects of the job are established below, but

may be augmented as necessary during the performance of the project.

Quality Controls

Individual controls will be implemented to ensure that project components are

being carried out in a safe, efficient manner and in compliance with project

specifications. Each item below describes the activity required, the primary

personnel in charge of the activities, recording/documentation requirements, and

required frequency of evaluation. The various quality control items have been

separated according to the following groups:

• Plan Compliance Quality Control

• Health and Safety Quality Control

Plan Compliance Quality Control

Performance Personnel Documentation

Control Type Description Frequency in Charge Method

Review personnel compliance with

restrictions for individual buildings.

Plan Evaluate condition of signage, Lead

Compliance barriers, knowledge of personnel Once Weekly Man/Safety Action taken

on buildings undergoing active Officers

demolition. Note deviations and

make corrections as needed.

Dust Control - Evaluate

effectiveness of dust control Weekly/As Safety Action taken

measures. Evaluate aesthetics needed Officers

warehouse area.

17

� Noise Monitoring - Review

monitoring logs and frequency of

data collection. Evaluate levels Lead

from the road. Ensure proper As needed Man/ Document

document control. Safety Inspection in

Officers Daily Log

PPE -Observe personnel use of

PPE. Notify worker of minor Ongoing Safety Document

deviations (i.e.; ear plugs). Record Officers Inspection in

serious and/or consistent Daily Log

deviations.

Health and Safety Quality Control

Performance Person Documentation

Control Type Description Frequency nel in Method

Charge

General – Select a specific

area/activity being performed at

Activity Watch the Site. Observe conduct and Three events Safety Document

adherence to safety, Site, and weekly Officers Inspection in

activity protocols. Make notes minimum Daily Log

and notify personnel of required

corrective action.

Review the safety/training

Safety/Training certifications for on-site At Project Safety Document

Certification personnel. Verify documents are Start and Once Officers Inspection in

Review available and up-to-date quarterly Daily Log

5.0 Documentation and Recordkeeping

This section provides documentation and recordkeeping procedures will be

implemented at the Site. Well organized and consistent methods of maintaining

project information will be critical for project success.

The items presented below include Site procedures for control, management, and

organization of documents.

Document Control

Tadashitec global company is responsible for documentation and recordkeeping

of project information. Project information will be primarily maintained on Site

with the goal of allowing ready access and review by project staff and personnel.

18

�Additional measures will be employed by Tadashitec to ensure that documents

are protected against loss. Tadashitec will focus on the following document

control objectives during the project:

• Ensure that contractors/subcontractors provide all forms, documents, permits,

monitoring results, etc. to the field office in a timely fashion.

• Maintain hardcopy and electronic files on Site and organize the files according

to a set filing

• Provide access to all project plans, procedures, and Right-to-Know area.

Document Organization

Documents that are generated during the course of the project will be filed

according to a consistent file structure. A draft file structure has been included in

Appendix A in order to establish a preliminary basis to be used at the Site. It is

typical for filing needs to change as the project develops, therefore this structure

may be modified as required. All personnel who are responsible for filing

information will be made aware of the file structure and will not create new

files/folders without the knowledge of other personnel.

5.1 Review and Evaluation

Review and evaluation of quality data/information is a fundamental component

of overall quality management. Following collection of quality control data, it is

the responsibility of the QA/QC Officer to review any information or observations,

evaluate the effect on the project, and initiate any changes or necessary

corrective measures. Some of the main review components include:

Compile and review assessment information from QC activities;

• Evaluate deviations and (if necessary) prioritize the effect on project safety

and/or success;

• Determine the appropriate required actions/corrective measures;

• Coordinate implementation of protocol changes;

• Documentation and distribution of any plan modifications, and;

• Perform verification of implemented protocols.

19