Professional Documents

Culture Documents

SOP-Attachment 7 - General Project Procedures PDF

Uploaded by

tomychalilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP-Attachment 7 - General Project Procedures PDF

Uploaded by

tomychalilCopyright:

Available Formats

Chevron Nigeria Limited Specification 0.

01

0.01 - GENERAL PROJECT PROCEDURES

February 9, 1998; Revision B

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

TABLE OF CONTENTS

1.0 INTRODUCTION

2.0 GENERAL INSTRUCTIONS

2.1 Standards and Codes

2.2 Company-Furnished Designs and Drawings

3.0 SUBCONTRACTORS AND VENDORS

3.1 General

3.2 Procedure for Purchase Orders

4.0 MATERIALS STORAGE, INVENTORY, AND SECURITY

4.1 Storage and Inventory

4.2 Security

5.0 QUALITY ASSURANCE

5.1 General

5.2 Material Certification and Traceability

5.3 Testing

6.0 RELIABILITY, WARRANTIES AND GUARANTEES

6.1 Equipment Suitability

6.2 Conformance

6.3 New Technology

6.4 Supplier Guarantees

7.0 PROJECT MANAGEMENT

7.1 Staffing

7.2 Company-Contractor Communications

7.3 Work Plan

7.4 Project Controls

7.5 Payment

7.6 Progress Reports and Meetings

7.7 Contractor-Furnished Offices and Accommodations

February 9, 1998; Revision B Page 1 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

8.0 PROJECT DOCUMENTATION

8.1 General

8.2 Drawings and Calculations Sheet Formats

8.3 Documentation Submittal

APPENDIX

I CONTRACTOR-COMPANY COMMUNICATIONS

ATTACHMENTS

1 CONTRACTOR-FURNISHED OFFICE FACILITIES AND ACCOMMODATIONS

2 DOCUMENTATION DELIVERABLES

February 9, 1998; Revision B Page 2 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

1.0 INTRODUCTION

1.1 This General Specification CNL-0.01 covers the General Project Procedures,

including without limitation the general requirements for project management,

procurement, documentation, inspection, testing, and shipment. Any exceptions

to this General Specification shall be submitted in writing with Contractor’s tender

for resolution by Company.

2.0 GENERAL INSTRUCTIONS

2.1 Standards and Codes

2.1.1 Applicable industry codes and standards are referenced in the Project

Specification and the Technical Requirements. Any discrepancies or conflicts

among the documents provided by Company or the codes and standards

referenced therein shall be called to the attention of Company in writing for

resolution as soon as the discrepancy or conflict is discovered.

2.1.2 If, in Contractor's opinion, any portion of the Project Specification or of the

Technical Requirements is not considered good design, good operating practice,

or results in a deviation from Contractor's standard shop practice, Contractor

shall immediately refer such item(s) to Company in writing for resolution.

2.2 Company-Furnished Designs and Drawings

2.2.1 Contractor understands and agrees and hereby acknowledges such

understanding and agreement that Company basic design drawings furnished as

a portion of the Project Specifications are not intended as detailed construction

drawings. Use by Contractor of the basic design drawings shall not diminish

Contractor’s full responsibility for correction of dimensional accuracies,

clearances, piping and structural conflicts and details contained therein. It shall

be Contractor’s responsibility to identify any potential conflicts in Company basic

design drawings and to timely request resolution of same in writing from

Company Representative.

February 9, 1998; Revision B Page 3 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

3.0 SUBCONTRACTORS AND VENDORS

3.1 General

3.1.1 All proposed subcontractors shall have been submitted with Contractor’s tender

prior to contract award. If Contractor desires to add a subcontractor after its

tender submittal or after the Work commences, Contractor shall request approval

of the subcontractor in writing. Contractor shall not award work to the proposed

subcontractor until Company’s written approval of the subcontractor is received.

3.1.2 All purchase order packages by Contractor shall be submitted to Company for

technical review prior to soliciting bids from vendors or subcontractors.

3.1.3 Company approval of a particular subcontractor or a particular Vendor/Supplier

does not relieve Contractor of its responsibility for the quality, conformance to

Company specifications and performance requirements, adherence to delivery

schedule, and provision of all required documentation for the purchased items or

subcontracted Work. Contractor is responsible for communication and

management of changes, and for inspecting and expediting the Work hereunder

of any Subcontractor or Vendor.

3.2 Procedure for Purchase Orders

3.2.1 Prior to soliciting purchase order bids, Contractor shall submit the following to

Company for review. Company will review and provide written comment within

five (5) working days. If no comments have been issued by Company within five

(5) days, Contractor may proceed with the solicitation of bids.

a. Scope of the purchase.

b. Name, address, contact, and references for the proposed subcontractor(s).

c. Technical exhibits to be included in the agreement.

3.2.2 Prior to award of purchase orders, Contractor shall submit the following for

Company review:

February 9, 1998; Revision B Page 4 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

a. Any exceptions to Company Technical Requirements and proposed

resolution of these exceptions.

b. Completion schedule for the item(s), including design “hold points” and

schedule for Company inspection and acceptance during fabrication or

installation.

c. Plan for communication and implementation of changes.

4.0 MATERIALS STORAGE, INVENTORY, AND SECURITY

4.1 Storage and Inventory

4.1.1 Contractor shall suitably protect all major equipment items and materials, both

Company- and Contractor-furnished, from the environment and from all

fabrication processes which may impair future performance.

4.1.2 Contractor shall store and preserve all equipment in accordance with vendor

recommendations. Contractor shall submit, for Company approval, storage

procedures for all major equipment packages involving electrical or otherwise

delicate equipment.

4.1.3 All Company-furnished material and equipment delivered to Contractor’s yard or

to the jobsite shall be unloaded, stored, and protected at no cost to Company.

Upon receipt, Contractor shall inspect each item, sign delivery tickets, and

present to Company the original of each delivery ticket.

4.1.4 Contractor shall maintain a log of all Company-furnished materials received.

This log shall contain a description and count of the materials, the condition of

the materials received, the date received, and the name and position of the

person who received the materials.

4.1.5 Upon completion of the Work in Nigeria, unless otherwise advised in writing by

Company, all surplus Company-supplied material shall be returned and offloaded

at Company’s Escravos Terminal in Nigeria. Surplus Company-supplied

materials for Work completed in the United States shall be returned and

offloaded at the closest Chevron storage facility in the United States. All costs

associated with the return and offloading of Company-supplied materials shall be

borne by Contractor.

February 9, 1998; Revision B Page 5 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

4.2 Security

4.2.1 Once material and equipment have been delivered, Contractor shall assume

responsibility at no additional cost to Company to protect same at all times from

any possible damage due to weather, handling, fabrication processes, and

vandalism or thievery. Contractor shall replace or repair, at Company’s option,

any material or equipment that is lost or damaged after delivery to Contractor’s

facility.

5.0 QUALITY ASSURANCE

5.1 General

5.1.1 This section provides the general requirements for quality assurance. Detailed

requirements for testing of material and equipment are provided in the Technical

Requirements.

5.1.2 Contractor is responsible for furnishing the Company Representative with all

required certification for materials and shop tests verifying acceptability in

accordance with the Technical Requirements.

5.2 Material Certification and Traceability

5.2.1 Material certifications, heat numbers, and weld traceability documentation

requirements are detailed in the Technical Requirements and shall be available

for review by Company representatives at all times. The material certifications

and traceability documentation shall be organized and assembled into a binder

for easy reference during the Project. Prior to shipment of the purchased or

fabricated item, the binder shall be transferred to Company.

5.3 Testing

5.3.1 Prior to the initiation of any fabrication, an inspection and testing plan shall be

prepared by Contractor for Company approval. This plan shall list the testing and

inspection required by the Technical Requirements and the data sheets, and

define each test as a witness point (WP) or hold point (HP) for the Project.

February 9, 1998; Revision B Page 6 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

5.3.2 A written test procedure for each WP or HP test shall be submitted for Company

approval a minimum of 21 working days prior to the test date. Company shall be

notified a minimum of 10 working days prior to the test so that a representative to

witness the test may be arranged. Failure to comply with this notification

schedule shall be grounds for disqualification of the test results and requirement

to repeat the test with proper notification at no cost to Company. Contractor is

responsible for recording test results and for forwarding documentation to

Company for review and approval.

5.3.3 Deficiencies found as a result of inspections and testing shall be repaired and

then retested using the same method by which the deficiencies were found.

Company may require other applicable testing methods be used. Contractor

shall be responsible for immediately repairing or replacing the defective item and

for retesting the item at no cost to Company.

5.3.4 Points of disagreement between Company’s third party inspector and Contractor

shall be referred to the Company Project Engineer for resolution.

5.3.5 Contractor shall provide full access to the Work in progress and all technical and

QA/QC data to Company’s inspectors, and inspectors representing the Nigerian

government.

5.3.6 Acceptance of shop tests does not constitute a waiver of requirements to meet

field tests under the specified operating conditions, nor does it relieve Contractor

of his responsibilities under the Agreement. Certified copies of test data shall be

submitted to the Company Representative for approval prior to shipment.

6.0 RELIABILITY, WARRANTIES AND GUARANTEE

6.1 Equipment Suitability

6.1.1 Company shall rely on Contractor to furnish equipment structurally, mechanically,

and electrically suited for the specified operating conditions and in compliance

with the Technical Requirements.

6.1.2 Contractor is responsible for the quality of design, materials, and workmanship of

the Work.

February 9, 1998; Revision B Page 7 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

6.2 Conformance

6.2.1 If construction materials or the equipment applications recommended by

Contractor do not conform to the manufacturer's recommendations, Contractor

shall assume the equivalent of the equipment manufacturer's guarantee. In the

event of malfunction or damage resulting from any such misapplication,

Contractor shall not be released from the guarantee requirement.

6.3 New Technology

6.3.1 Contractor shall disclose to Company each design manufacturing procedure,

component or assembly which does not have at least two (2) years' satisfactory

operating experience in similar service. The failure to make such disclosures

specifically and in writing shall extend Contractor's warranty to include all direct

costs to Company that may result from Contractor's use of such procedures,

components or assemblies.

6.4 Supplier Guarantees

6.4.1 All guarantees from Contractor or its suppliers shall name Company as the

recipient of the guarantee. Contractor shall not transfer the responsibility of

fulfilling a guarantee to a third party.

7.0 PROJECT MANAGEMENT

7.1 Staffing

7.1.1 General

7.1.1.1 Contractor’s Project Manager and all key project personnel including Lead

Engineers, Design Draftspeople, and Construction Managers shall be assigned

to the project for the duration of the Work and shall not be reassigned to other

projects without specific Company authorization. Contractor’s Project team shall

possess good written and oral skills in the English language and be experienced

in the design and construction of land, marsh or offshore production facilities

similar to the Project.

February 9, 1998; Revision B Page 8 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.1.2 Project Staff

7.1.2.1 Contractor’s proposed workforce for performance of the Work through to

completion of the Project shall be submitted for Company approval with

Contractor’s tender. Company reserves the right to review the qualifications of

key project personnel and to reject any personnel not judged as experienced to

perform the Work. Project personnel who will not devote 100% of their time to

the Project shall be identified within the tender. Temporary contract personnel,

versus long-term Contractor employees, shall be listed with their company of

origin.

7.1.3 Contractor Staff Experience Requirements

7.1.3.1 Experience levels for key project personnel are provided in the following table as

a guideline for Contractor to assemble its proposed Project team.

KEY PROJECT PERSONNEL MINIMUM EXPERIENCE IN PRODUCTION

FACILITIES DESIGN OR CONSTRUCTION

Project Manager 10 years - Project Management

Lead Engineers 8 years - Design Experience

Lead Purchasing Agent 5 years - Purchasing

Lead Draftsman & Designers 10 years - Design Drafting

Drafting Staff Minimum 2 years Drafting; and

Staff average of not less than 5 years

Site and Construction 5 years and applicable industry certification

Representatives & Inspectors

Secretary / Clerk Familiar with oil industry terminology,

competent in filing, typing, Word and Excel.

7.1.4 Project Manager

7.1.4.1 Contractor’s Project Manager will be Company’s primary contact and shall

oversee and coordinate Contractor’s completion of the Work. The Project

Manager will be responsible to Company for keeping the Project on schedule,

providing required Project documentation, and upholding the overall quality of

engineering, fabrication, construction, installation, or testing of the facilities in

accordance with Agreement requirements. The Project Manager shall have

proven experience in managing production facility design or construction projects

similar in scope and magnitude to the Project. The Project Manager shall

dedicate 100% of his or her working time to executing these responsibilities and

shall be available for all meetings between Company and Contractor.

February 9, 1998; Revision B Page 9 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.1.4.2 Contractor shall propose a Project Manager for Company’s approval. Company

reserves the right to request removal of the Project Manager from the Project at

any time during the Project. Company and Contractor shall then mutually agree

upon a suitable replacement from Contractor’s available candidates for the

position, or agree to hire a replacement to fill this position if a qualified candidate

is not available within Contractor’s workforce.

7.1.4.3 The Project Manager shall relocate to the primary Work Site -- design office,

construction yard, installation site or vicinity -- as the Work progresses to each

site unless specific Company approval is obtained for remote management of the

Project. If major portions of the Work are subcontracted, or if the Work is

widespread and does not permit the full-time attendance of the Project Manager

on site, Contractor shall place a full- time representative and support staff at each

Work Site. The representative shall have the full authority to act on behalf of

Contractor and shall be familiar with the Project Specification, Technical

Requirements and the Agreement. The size of the support staff shall be

sufficient to both oversee the Work of the subcontractor and to liaise with

Company.

7.2 Company-Contractor Communications

7.2.1 General

7.2.1.1 Company’s documentation system as outlined in Appendix 1 shall be used for all

Contractor/Company communications.

7.2.1.2 Company reserves the right to make changes at any time to this Agreement

subject to equitable adjustment for any increases or decreases in the price or

schedule of Work. If Company issues any directive or other communication

which is not clearly indicated as a “Change”, but which Contractor believes is a

“Change”, Contractor shall respond within 10 working days with a written

statement. In the time between issuance of the Company directive or

communication and Company’s response to Contractor’s written notification,

Contractor shall not proceed with any Work that is associated with this item

unless specifically ordered in writing by Company to do so.

7.2.1.3 Contractor shall never begin Work on a “Change” until instructed to do so in

writing by Company.

7.2.2 Transmittals, Instructions and Questions

7.2.2.1 Communications between Contractor and Company in which information is

exchanged without involving a “Change” shall use the following terms:

TRANSMITTAL’s, MEMO’s and RFI’s.

February 9, 1998; Revision B Page 10 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.2.2.2 In general, forms shall be used as follows:

a. RFI. (Request for Information.) Generated by either Contractor or

Company to request information, and to reply to requests for information.

b. TRANSMITTAL. Generated by either Contractor or Company to transmit

technical data such as data sheets and drawings.

c. MEMO. Generated by Company to instruct Contractor in a technical,

safety or administrative aspect of Work which is within the scope of the

Work, i.e., not a “Change”. This also may be used to transmit drawings or

other technical information for which a TRANSMITTAL is inadequate.

7.2.3 Changes

7.2.3.1 Communications between Company and Contractor in which instructions or

information are exchanged that involve a “Change” shall use RWE, CWE, AWE,

and ITP forms.

7.2.3.2 In general, the forms shall be used as follows:

a. RWE. (Request for Contractor Work Estimate.) Generated by Company

to request a Contractor estimate for a proposed “Change” in the scope of

Work.

b. CWE. (Contractor Work Estimate.) Issued by Contractor in response to

a RWE to provide an estimate (proposal) for performing the “Change”.

c. AWE. (Acceptance of Work Estimate.) Issued by Company to inform

Contractor that the CWE-proposed price for the Work has been accepted,

and to provide details on beginning the Work.

d. ITP. (Instruction to Proceed.) Supersedes the RWE to request that Work

be initiated immediately on a Time and Materials (T&M) basis. After Work

completion, a post-Work CWE with supporting (Company-signed) time

and material tickets is submitted by Contractor. Company will signify

approval of a CWE by issuance of a AWE.

7.2.3.3 Contract Variations (CV’s) are used to adjust the total value of the Contract to

reflect changes made in accordance with AWE’s. Company will periodically

issue CV’s to cover recent AWE’s so that Contractor may issue invoices for

completed “change” Work.

7.3 Work Plan

7.3.1 General

February 9, 1998; Revision B Page 11 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.3.1.1 Contractor shall prepare a Work Plan that includes:

a. Project Organization

b. Detailed Work Completion Plan

c. QA/QC Plan

d. Safety Plan

e. Environmental Compliance Plan

f. Site Security Plan

g. Communication Plan

h. Project Controls Baseline

i. Project Controls Update Procedure

7.3.1.2 Contractor shall include the following components of the Work Plan with its

tender:

• Project Organization

• Work Completion Plan

• QA/QC Plan

• Project Controls Baseline, including WBS, schedules, cost forecasts, and

“S” curves as applicable to the Project

• Standard Safety Plan, Contractor’s standard, to be modified to Project

requirements if Contractor is the successful bidder

• Standard Environmental Compliance Plan, Contractor’s standard, to be

modified to Project requirements if Contractor is the successful bidder

• Site Security Plan

7.3.1.3 The final Work Plan shall be submitted for Company approval within 14 days

after contract award. Company will notify Contractor of any required changes to

the Work Plan. Company and Contractor shall ultimately agree on the complete

plan within 30 days after award of the Agreement.

7.3.2 Project Organization

7.3.2.1 The Project Organization section of the Work Plan shall contain the following:

a. Complete organization charts for Contractor’s Project Team, including

personnel at foreign and domestic locations who will participate in the project.

b. Abbreviated organization charts for key subcontractors that show personnel

such as Subcontractor Project Managers, Safety Managers, Shop and QC

Foremen, and Site Representatives.

c. Reporting relationships, clearly marked on all organization charts, especially

for Project teams operating in several locations.

February 9, 1998; Revision B Page 12 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

d. List of addresses, telephone numbers and fax numbers of all Contractor

Project personnel and those of key subcontractor personnel. This list shall

be updated monthly as a minimum.

7.3.3 Detailed Work Completion Plan

7.3.3.1 The Work Completion Plan shall contain a detailed description of the methods

and sequence of Work to be employed during the completion of the Project. This

plan shall cover all aspects of the Work, including:

a. Work location and sequence

b. Description of labor force skills and origin (for Work in Nigeria)

c. Description of installation equipment, including vessel names for offshore

barges

d. Procurement plan for Contractor-provided equipment

e. Subcontracting plan

7.3.4 QA/QC Plan

7.3.4.1 The QA/QC plan shall be designed to ensure and document Contractor’s

conformance with the Technical Requirements.

February 9, 1998; Revision B Page 13 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.3.4.2 The QA/QC plan shall include, but not be limited to, the following:

a. (Contractor internal) design calculation and drawing review procedure.

b. Staffing plans for visual and NDT inspection (including structural, paint and

electrical/instrumentation inspection) of materials, fabricated items, and

fabrication completed or supplied by Contractor, or by Contractor’s Suppliers

or Subcontractors.

c. Staffing plan for visual, NDT inspection (including structural, paint and

electrical/instrumentation inspection), and hydrotesting of installation Works.

d. Plan for Company inspection points and witnessing of shop tests.

e. Plan for documentation and reporting of QA/QC results.

7.3.5 Safety Plan

7.3.5.1 The safety plan shall include, but not be limited to, the following:

a. Contractor’s safety policies and Contractor’s specific safety plan for

completion of the Project.

b. Plan for recording, monitoring, and reporting lost time accidents.

c. Plan for routine safety meetings during fabrication and installation.

7.3.6 Environmental Protection Plan

7.3.6.1 The environmental protection plan shall include, but not be limited to, the

following:

a. Plan for disposal of trash and human waste in accordance with local law

during fabrication, construction, and installation. If local laws do not provide

guidance for disposal, Contractor shall detail the proposed disposal plans for

Company review prior to commencement of the Work.

b. Plan for disposal of nonhazardous oilfield waste and hazardous waste, if any,

in accordance with local and national laws. If local laws do not provide

guidance for disposal, Contractor shall detail the proposed disposal plans for

Company review.

February 9, 1998; Revision B Page 14 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

c. Plan for provision of air and water quality permits as needed for the Work and

to comply with applicable government regulations. If temporary Work sites

will be established, plan for initial site survey to establish baseline levels of

pollutants.

d. Plan for protection of natural wildlife habitats and existing vegetation,

including community fishing grounds and cultivated fields. Plan for

restoration of these areas, should Contractor’s Work result in damage.

7.3.7 Community Relations and Site Security Plan

7.3.7.1 At Company’s option prior to commencement of the Work, Contractor shall

submit a plan for establishing good relations with local communities, and training

and employment of the local Workforce.

7.3.7.2 Contractor shall provide a plan detailing the security to be provided during all

phases of the Work. The security shall be adequate to protect its workers,

visitors, and Company Representatives. The plan shall also provide for the

security of all Contractor- and Company-supplied materials and equipment.

7.3.8 Communication Plan

7.3.8.1 Contractor’s plan for Contractor-Company communications shall be based on the

Documentation Systems provided in Appendix 1. Revisions, additions, or

deletions to this system must be submitted in writing for Company review and

approval.

7.3.8.2 Contractor shall include details of the proposed method for distribution of

Contractor-Company communications that impact the Work of Subcontractors

and Vendors. Included in this plan shall be a section detailing the method for

implementation of “Changes”, with special emphasis on “Changes” that may

affect the Work of more than one Vendor or Subcontractor.

7.3.8.3 Contractor shall be responsible for retaining and filing all paperwork and Project

Documentation in a system of Contractor’s choice. Contractor shall cross-

reference all Project documentation using Company’s filing system codes.

Company will provide a copy of the Company filing system for use by Contractor.

February 9, 1998; Revision B Page 15 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.3.9 Project Controls Baseline

7.3.9.1 Project Controls shall be composed of the following:

a. Work Breakdown Structure (WBS)

b. Project Schedules

c. Cost Accounts and Forecast

d. Progress and Cost “S” Curves

7.3.9.2 The Project Controls included in the Work Plan shall be used as a baseline for

measurement of any schedule or cost growth over the life of the Project.

7.3.9.3 The Work Breakdown Structure (WBS) included in the Work Plan shall be the

Company-approved WBS. Details on the development of the WBS are provided

in Section 7.4.1 “Project Controls - Work Breakdown Structure”.

7.3.9.4 The Project Schedules included in the Work Plan shall consist of:

a. Summary Schedule. Approximately 20 activities, shown in bar chart form,

including critical path items. Submitted with Contractor’s tender and included

in the Agreement.

b. Coordination Schedule. Approximately 60-80 activities in bar chart form and

including critical path highlights.

7.3.9.5 The Cost Forecast included in the Work Plan shall be based on the approved

WBS and Project Schedule.

7.3.9.6 The Progress and Cost “S” Curves shall be based on the approved WBS and

Project Schedule.

7.3.10 Procedure for Updating Project Controls

7.3.10.1 The Work Plan shall include procedures for updating the project schedules, cost

forecasts and progress curves as required for the monthly meetings and reports,

and for including the effect of approved “Changes” to the scope of Work.

7.4 Project Controls

7.4.1 Work Breakdown Structure (WBS)

7.4.1.1 The Work Breakdown Structure (WBS) shall establish a set of accounts to be

used for measurement of progress, cost, and schedule control. The WBS shall

be used as a basis for Contractor’s progress analysis upon which progress

payments will be computed.

February 9, 1998; Revision B Page 16 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.4.1.2 A general WBS may be provided by Company as a basis for the detailed WBS to

be established by Contractor. The WBS, whether provided by Company or

Contractor, shall be based on measurable quantities of products that can be

readily reviewed by Company such as design documentation, drawings (at a

given revision or review stage), materials, fabricated items, etc.

7.4.1.3 A preliminary WBS, constructed in alignment with the Schedule of Prices

provided in the Agreement, shall be submitted with Contractor’s Tender.

7.4.1.4 Points or percentage weights proposed in the WBS shall be based on Work

completed in accordance with the Project Schedule for the Agreement, or in the

most logical sequence for timely and efficient construction, if details are not

provided in the Project Schedule. Items completed out of sequence from the

Project Schedule require Company approval prior to beginning the out-of-

sequence Work. Out-of-sequence Work completed without Company approval

will not be paid until all previous Work items are completed.

7.4.1.5 The Work Breakdown Structure shall be mutually acceptable to both Company

and Contractor, and shall be agreed upon prior to submittal of the first invoice.

7.4.2 Project Schedules

7.4.2.1 Unless otherwise specified, all schedules shall be submitted on the latest version

of Microsoft Project software.

7.4.2.2 As a minimum, Project schedules shall be updated monthly. Additionally,

schedules shall be updated immediately upon notification of delays or changes

that are expected to significantly affect the Project schedule.

7.4.2.3 Schedules and plans shall be assembled into a Schedule Package and issued to

the Company every month during the Monthly Review Meeting.

7.4.2.4 The following schedules are required:

a. Summary Schedule. Approximately 20 activities in bar chart form, including

critical path items, submitted with Contractor’s tender and included in the

Agreement.

b. Coordination Schedule. Approximately 60-80 activities in bar chart form and

including critical path highlights.

February 9, 1998; Revision B Page 17 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

c. Detailed Schedules. Specific thirty and ninety day Work schedules presented

in Critical Path Method (CPM) network form.

d. Two Week Work Plan. Presented in Gantt Chart form, updated and

submitted to Company every two weeks.

7.4.2.5 Contractor shall submit for Company approval a written plan of recovery in the

event of schedule slippage. This plan shall detail the remedial measures

Contractor will take to accelerate Work to meet the schedule if Contractor falls

behind its original schedule.

7.4.3 Cost Accounts and Forecasts

7.4.3.1 Project costs shall be updated monthly, and forecast estimates re-calculated

based on actual and projected progress. Cost estimates and forecasts shall be

provided in actual Naira/foreign currency expended. Additionally, at Company’s

request, Contractor will provide cost estimates and forecasts in approximate

equivalent U.S. dollars based on an exchange rate provided by Company.

7.4.4 “S” Curves

7.4.4.1 “S” curves shall be updated monthly, and shall show actual versus planned

progress and costs, and projected progress and costs. Actual progress shall be

based on approved WBS percentages and actual costs shall be based on

approved invoices. The following “S” curves are required, as applicable to the

Project:

• Design

• Procurement

• Fabrication

• Transportation

• Installation

• Hookup & Commissioning

• Overall Project

7.5 Payment

7.5.1 Invoice Data

February 9, 1998; Revision B Page 18 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.5.1.1 The following information is required on all invoices. Separate invoices shall be

submitted for Naira payment vs. payments in other currencies in accordance with

the Agreement:

a. Contractor name

b. Contract Number or Code

c. Documentation (approved WBS progress, approved T&M tickets, etc.)

d. Work Period

e. Total Contract Value (or total Contract Variation value)

f. % Work Completed this period, per the WBS

g. Value of Work Completed this month, subdivided into four categories as

applicable:

• Design

• Procurement

• Fabrication

• Installation

h. Location of the Work, subdivided by categories if this varies

7.5.2 Invoice Calculations

7.5.2.1 Detailed Invoice Calculations shall be provided on every invoice for the following:

a. Nigerian Tax to be Withheld. Based on total value of Work completed in

Nigeria.

b. Nigerian Value Added Tax. Based on total value of Work completed in

Nigeria.

c. Retainage, based on Agreement.

7.5.3 Lien Releases

7.5.3.1 Partial lien releases, signed by Contractor and all subcontractors, vendors, and

subvendors, will be required for each progress payment. The lien release for one

period will be attached to the invoices submitted for the next period. (Lien

releases will “run” one period behind progress payment periods.)

7.5.4 Last Progress Payment

February 9, 1998; Revision B Page 19 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.5.4.1 The last Progress Payment, minus retention, will not be made before all required

data, materials, and documentation have been received and approved by

Company in accordance with this Agreement.

7.6 Progress Reports and Meetings

7.6.1 General

7.6.1.1 Contractor shall submit progress reports and conduct progress meetings on a

regular basis for all engineering, procurement, fabrication, installation and

commissioning Work.

7.6.1.2 Contractor shall be responsible for recording and distributing Meeting Minutes for

all meetings. Meeting Minutes shall be submitted for Company approval and

comment prior to distribution. Meeting Minutes shall be completed and submitted

for Company review no later than 2 business days after the meeting is

completed.

7.6.2 Monthly Meeting

7.6.2.1 Contractor shall conduct a progress and administrative review meeting with

Company monthly. The meeting shall be hosted by Contractor at either design

office, fabrication yard, or installation site as appropriate for the Project's stage.

Contractor shall present status for all responsibilities within the scope of this and

shall identify any concerns regarding Project execution and plans for their

resolution.

7.6.3 Other Meetings

7.6.3.1 Contractor shall conduct a weekly review meeting with Company. The meeting

shall address weekly progress, items of concern, outstanding changes or RFI’s,

and technical items of interest. Every second week, the detailed two-week

schedule shall be submitted by Contractor and reviewed.

7.6.3.2 Contractor hereby agrees that Company's onsite representatives may attend any

Contractor meetings (with subcontractors, vendors, or within the Contractor

Project Team) conducted for coordination or scheduling of Work.

February 9, 1998; Revision B Page 20 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

7.6.4 Monthly Reports

7.6.4.1 Contractor shall submit a Monthly Report to Company by the fifteenth calendar

day of the month. The report shall indicate progress through the end of the

month prior and planned activity for the next month. The report shall include:

a. Executive Summary, addressing Contractor's overall Project performance

(accomplishments compared with goals) and summarized progress and cost

forecasts.

b. Project Review, addressing:

• Discussion of Project Status

• Milestone Progress

• Work in Progress

• Work Planned for next 30 days

• Critical Path Items

• Items of Concern

• Correction Proposals for Problems

• Open Issues

c. Progress Analyses, including summary schedules and reports from the

Schedule Package. Discussion shall also include changes since last report

and explanations for project slippage or acceleration.

d. Cost Analysis, with updated documents including:

• Project Cost Statement from the WBS

• Contract Change Log

e. Drawing Status

• Drawings completed and reviewed

• Drawings pending or on hold

• Forecast for drawing completion

f. Procurement Status

• Progress on each order

• Bar chart comparison of actual versus anticipated

• Discussion of long delivery items or items of concern

• Material and Traffic Reports with discussion of shipping and importation

schedule

February 9, 1998; Revision B Page 21 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

g. Photographs of significant Work in progress, labeled

h. Quality Assurance Activity

• Weld acceptance rate

• Efficiency rates

• Items for concern

i. Safety Activity

• Log of Safety Meeting and Reviews

• List and Description of Lost Time Accidents and Prevention Plan to avoid

similar accidents

7.6.4.2 A monthly report will not be required for Projects of 2 months' duration or less.

Instead of a monthly report, a final report containing the schedules, progress

curves and photographs of the project as detailed in 7.6.4.1 shall be provided.

7.7 Contractor-Furnished Offices and Accommodations

7.7.1 Detailed requirements for Contractor-furnished offices or accommodations, if

required, are provided in the Attachments.

7.7.2 Unless otherwise advised by Company, all offices (except for clerk and secretary

offices) provided by Contractor shall be equivalent to Contractor’s senior staff

offices.

7.7.3 Contractor shall provide access at all locations to telephone, photocopy, and fax

machines.

8.0 DOCUMENTATION

8.1 General

8.1.1 A schedule of documentation requirements is included in the Attachments.

Contractor shall submit, with his tender, a fully detailed plan listing all documents

and their scheduled submittal for approval by Company.

8.1.2 All designs and documentation that require Company review or approval shall be

submitted immediately to Company upon completion of Contractor’s internal

review.

February 9, 1998; Revision B Page 22 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

8.1.3 Company will require five working days for document review. This time shall be

measured from receipt of designs or drawings by Company until mailing or

sending of the documents from Company.

8.2 Drawings and Calculations Sheet Formats

8.2.1 All calculations, reports and drawings shall be in the English language, in duel

(English and SI) units of measurement.

8.2.2 All drawings shall be submitted in both 11 by 17 inch and in 22 by 34 inch size, or

as required by the Project Specification.

8.2.3 All calculation sheets and data sheets shall be submitted on 8-1/2” X 11” or “A4”

size paper, except calculations which are integral with drawings. These

calculations may be included on 11” X 17” paper with the drawing.

8.3 Documentation Submittal

8.3.1 Unless otherwise stated in the Technical Requirements, all documentation shall

be submitted in triplicate.

8.3.2 Upon completion of the Work, Contractor shall assemble all design documents

into neatly labeled binders, subdivided by work or design category, and submit to

Company as final design documentation.

8.3.3 If not otherwise required for submittal in the Technical Requirements, Contractor

shall assemble information for equipment provided by Contractor’s vendors and

suppliers into binders subdivided by equipment category or packaged systems,

as applicable.

8.3.4 Contractor shall assemble all test reports, material certification, traceability, and

other QA/QC documentation for equipment and materials supplied by Contractor

or his suppliers into binders subdivided by equipment category or packaged

systems, as applicable.

8.3.5 “As-Builts” shall be prepared on the original drawings or data sheets, redrafted as

necessary to incorporate final information. Mark-thru, sketch, referencing, and

other field marking techniques are not acceptable. “As-Builts” shall be issued as

the next sequential revision from previous releases. The revision block shall

state “Certified As-Built”.

February 9, 1998; Revision B Page 23 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

8.3.6 All “As-Builts” shall be submitted for Company review and approval within two

weeks after notification that equipment is ready for shipment, or completion of

commissioning as appropriate. Contractor shall provide one set of mylar and two

photocopied sets of approved “As-Built” drawings.

February 9, 1998; Revision B Page 24 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

COMPANY-CONTRACTOR COMMUNICATION

PAPERWORK AND FILING SYSTEM

DOCUMENT SYSTEM 1:

Document control and filing system for TRANSMITTAL, RFI and MEMO forms.

• Used to exchange information and to document Company’s instructions to Contractor.

• Used ONLY when the transmitted information or instructions are not expected to result in

a change in the monetary value or completion schedule of the contract.

DOCUMENT SYSTEM 1 FORMS:

Transmittal Forms:

Use: Used by Contractor and Company to transmit basic information, data sheets, and

drawings.

Request for Information (RFI)

Used by Contractor to request information from Company. Company will reply on the same

sheet or an attached sheet. Also will be used by Company to request information from

Contractor in the same way.

Technical, Safety and Administrative Memos (MEMO)

• Company instruction to Contractor on items which are NOT changes in scope.

If Contractor receives an RFI or MEMO and believes that a change in the monetary

value or the completion schedule of the contract will result, it has ten (10) working days

to inform Company in writing that the MEMO or RFI is a “Change”. In return, Company

will issue a DOCUMENT SYSTEM 2 form (see attached), with a copy of the RFI or

MEMO attached for reference.

NO WORK ON RFI’s or MEMO’s which Contractor disputes as a “Change” shall be

initiated until Company issues the DOCUMENT SYSTEM 2 form to further instruct

Contractor in the resolution of the dispute.

• Transmit (unsolicited) information from Company to Contractor, and to clarify technical

and commercial items. Issued by Company to direct Contractor’s attention to items that

are clearly required by the Agreement but which Company believes are being done

incorrectly. (Warning of Condemnation.)

February 9, 1998; Revision B Page 25 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

COMPANY-CONTRACTOR COMMUNICATION

PAPERWORK AND FILING SYSTEM

DOCUMENT SYSTEM 1 FILING:

Transmittals will be numbered sequentially and filed in a dedicated system.

All RFI’s and MEMO’s will be coded by Company’s clerk and filed together. Contractor may

assign his own code numbers for use within his own organization and filing system, however

Company-assigned code shall be used in all referrals to Company.

The code issued by Company will include Contractor’s name, Company-assigned contract

code, issuer’s name, sequential numbering, type of form and use. By using the same code

with different suffixes, related subjects (such as questions and answers) are filed together.

Example Code: C101-001-ABC-RFI-Q

(1) (2) (3) (4) (5)

CODE EXPLANATION:

Position Code Used Description Code Options for

in Example Position

(1) C101 Company-assigned Contract number, Assigned by

unique to Contractor and Project Company

(2) 001 Sequential number of MEMO or RFI 001- 999, assigned

assigned by Company in sequence as

received by

Company’s clerk

(3) ABC The initials of the Company Representative Initials of all

who issued the RFI or MEMO Company

OR Representatives

If the RFI is issued by Contractor to ask a

question of Company, these are the initials

of the Company Representative assigned to

reply to the RFI .

(4) RFI Indicates that the form is an RFI rather than MEMO or RFI

some other form.

(5) Q Indicates that this RFI is a question. The A=answer

reply to this Question would be coded I=instruction or

identically in positions (1)-(4), but position information

(5) would be coded “A”. Q=question

February 9, 1998; Revision B Page 26 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

COMPANY-CONTRACTOR COMMUNICATION

PAPERWORK AND FILING SYSTEM

DOCUMENT SYSTEM 2:

• RWE-CWE-AWE forms are used for work defined as a Change by the Contract.

• ITP is used in time-critical situations when immediate action is required and the normal

RWE-CWE-AWE cycle cannot be followed.

DOCUMENT SYSTEM 2 FORMS:

Request for Work Estimate (RWE)

Issued by Company to solicit Contractor estimates for proposed changes. If a MEMO or RFI

is disputed by Contractor as a Change, Company will issue an RWE or an ITP.

Contractor Work Estimate (CWE)

Issued by Contractor to submit an estimate for the work.

Acceptance of Work Estimate (AWE)

Issued by Company to formally accept Contractor’s proposed price (CWE) and to instruct

Contractor to proceed with the Change. Also may be used by Company to formally reject

Contractor’s price and notify Contractor that the Change will not be performed.

Instruction to Proceed (ITP)

Issued by Company in time-critical situations when the usual RWE-CWE-AWE system cycle

would result in unacceptable delay. Work ordered by ITP shall begin immediately without

further instruction from Company. ITP’s will be used for work:

• Defined by Company as a Change, or

• NOT defined by Company as a Change but defined by Contractor as a

Change.

Unless the status of the work is resolved by Contractor and Company as “NOT a Change”,

time and material tickets shall be recorded by Contractor and signed daily by Company.

After Work completion, Company-signed T&M tickets will be used by Contractor to prepare

a CWE. Upon approval of the CWE, Company will issue an AWE.

In the event that Contractor and Company fail to agree on the classification of instructions, or in the

resulting adjustment in contract compensation, refer to the Changes section of the Agreement Terms

and Conditions.

February 9, 1998; Revision B Page 27 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

COMPANY-CONTRACTOR COMMUNICATION

PAPERWORK AND FILING SYSTEM

DOCUMENTATION SYSTEM 2 FILING:

RWE’s, CWE’s, AWE’s, and ITP’s will be coded by Company’s clerk and filed together.

Related RWE-CWE-AWE’s will be assigned the same file code number with only the form

identity code (position 4) varied. Similarly, CWE’s and AWE’s resulting from ITP’s will be

assigned the same file code number with only the form identity code (position 4) varied.

Example Code: C101-001-ABC-RWE-01

(1) (2) (3) (4) (5)

CODE EXPLANATION:

Position Code Used Description Code Options for

in Example Position

(1) C101 Company-assigned Contract number, Assigned by Company

unique to Contractor and Project

(2) 001 Sequential number of RWE/CWE/AWE 001- 999, assigned in

or ITP/CWE assigned by Company sequence as received

by Company’s clerk

(3) ABC The initials of the Company Initials of all Company

Representative who issued the RWE or Representatives

ITP.

(4) RWE Indicates that the form is an RWE • RWE

rather than some other form. • CWE

• AWE

• ITP

(5) 01 Indicates that this RWE is the first 01-99, assigned as

request regarding this work. If the Contractor and

CWE was unsatisfactory, a second Company resolve

RWE requesting another estimate on pricing and scope

the work might be issued. issues on a subject.

Note: CWE’s and AWE’s are filed with the originating RWE or ITP of the same code.

February 9, 1998; Revision B Page 28 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

COMPANY-CONTRACTOR COMMUNICATION

PAPERWORK AND FILING SYSTEM

DOCUMENT SYSTEM 2: EXAMPLES

Example #1:

Engineer ABC requests a cost for proposed extra work: C101-001-ABC-RWE-01

Contractor (C101) returns an estimate: C101-001-ABC-CWE-01

ABC decides the price is too expensive and reduces

the scope of proposed extra work: C101-001-ABC-RWE-02

Contractor (C101) returns an estimate: C101-001-ABC-CWE-02

ABC accepts the reduced price: C101-001-ABC-AWE-02

Example #2:

Engineer ABC instructs Contractor (C101) to perform extra

work immediately: C101-201-ABC-ITP-01

Contractor (C101) performs the work, and based on T&M

tickets, issues a CWE for the work: C101-201-ABC-CWE-01

Engineer ABC accepts the price: C101-201-ABC-AWE-01

February 9, 1998; Revision B Page 29 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

TRANSMITTAL

Subject Description: TRANSMITTAL #:

Contractor Name: Contract Code:

Project Name: Charge/AFE Code: Date:

A TO: VENDOR OR CONTRACTOR

ATTN:

B TO: VENDOR OR CONTRACTOR, C/O CNL

ATTN:

C TO: CNL FACILITIES ENGINEERING

ATTN:

D TO: CNL CONSTRUCTION

ATTN:

E TO: CHEVRON OVERSEAS PETROLEUM

ATTN:

DOCUMENT TITLE AND DESCRIPTION REVISION DISTRIBUTION

A B C D E

REMARKS:

[ ] COMMENTS/REVIEW [ ] APPROVAL [ ] INFORMATION [ ] SIGNATURE [ ]

USE IN WORK

SIGNATURE OF ORIGINATOR:

IN HOUSE DISTRIBUTION: LEGEND:

P=Bond Print Z=Copy B=Blackline M=Mylar

R=Reduced O=Original S=Sepia V=Vellum

Should these transmitted items, in the opinion of CONTRACTOR, result in a "Change," written notice

thereof must be given to COMPANY within ten (10) days of the receipt of these Instructions. Any Work

that may result from this TRANSMITTAL which Contractor considers a “Change” shall not commence

until written notification has been submitted to Company and Company has issued further instructions

giving Contractor authority to proceed.

February 9, 1998; Revision B Page 30 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

TECHNICAL OR ADMINISTRATIVE MEMO

MEMO

Subject Description: FILING CODE:

______-_____-____-MEMO-I

Contractor Name: Charge/AFE Code:

Project Name: Date:

Originator (please print name) (Signature)

Instruction:

Should these Instructions be, in the opinion of CONTRACTOR, a "Change," this MEMO shall be returned

by CONTRACTOR to COMPANY within ten (10) days of the receipt of this MEMO, with explanatory text

included below. Any work that may result from this MEMO which Contractor considers a “Change” shall

not commence until written notification has been submitted to Company and Company has issued

further instructions giving Contractor authority to proceed.

TO BE FILLED OUT BY CONTRACTOR AND RETURNED TO COMPANY WITHIN TEN

(10) DAYS IF CONTRACTOR CONSIDERS THIS MEMO A CHANGE:

We consider these instructions a Change because:

CONTRACTOR SIGNATURE: DATE:

February 9, 1998; Revision B Page 31 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

REQUEST FOR INFORMATION

RFI

Subject Description: FILING CODE:

_____-_____-____-RFI-Q / A

Contractor Name: Charge/AFE Code:

Project Name: Date Issued: Date

Responded:

/

Issued By (please print name) (Signature)

Response By (please print name) (Signature)

Question:

Response:

RECEIVED BY COMPANY: DATE:

RECEIVED BY CONTRACTOR: DATE:

Should this RFI be, in the opinion of CONTRACTOR, a "Change," written notice thereof must be given to

COMPANY within ten (10) days of the receipt of these Instructions. Any work that may result from this

RFI which Contractor considers a “Change” shall not commence until written notification has been

submitted to Company and Company has issued further instructions giving Contractor authority to

proceed.

February 9, 1998; Revision B Page 32 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

REQUEST FOR CONTRACTOR WORK ESTIMATE

RWE

Subject Description: FILING CODE:

______-______-_____-RWE-__

Contractor Name: Charge/AFE Code:

Project Name: Date:

Originator (please print name) (Signature)

Scope of Work to be Estimated:

Why Scope is a Change:

RECEIVED BY: DATE:

Contractor shall reply in writing within ten (10) days, using the attached Contractor

Work Estimate (CWE) form, with a cost and schedule estimate for the Work.

February 9, 1998; Revision B Page 33 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

CONTRACTOR WORK ESTIMATE

CWE Summary

Subject Description: FILING CODE:

_____-_____-_____-CWE-__

Contractor Name: Charge/AFE Code:

Project Name: Date:

RWE Originator (Company Representative)

Contractor Estimator (please print name) (Signature)

Detailed Scope of Work, including exceptions and clarifications to Company’s RWE:

Unit Rates provided in the Agreement shall be used as a basis for estimating the unit costs of the work.

Amount of Change:

FC Naira

Engineering

Materials

Fabrication

Installation

TOTAL

Schedule Impact: Revised Completion Date:

RECEIVED BY: DATE:

February 9, 1998; Revision B Page 34 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

CONTRACTOR WORK ESTIMATE

Detailed Work Estimate

Description Unit Rate Duration TOTAL

DESIGN

DESIGN

TOTAL

PROCURE

PROCURE

TOTAL

FABRICATE

FABRICATE

TOTAL

INSTALL

INSTALL

TOTAL

February 9, 1998; Revision B Page 35 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

ACCEPTANCE OF WORK ESTIMATE

(AWE)

Subject Description: FILING CODE:

_____-_____-_____-AWE-__I

Contractor Name: Charge/AFE Code:

Project Name: Date:

Originator (please print name) (Signature)

Approval (please print name and sign):

Contractor Work Estimate accepted for the amount specified below. Please proceed

with work immediately.

Contractor Work Estimate accepted for the amount specified below. Do not proceed

with work until written notification from Company is received.

Contractor Work Estimate -- supplied in response to ITP initiated work -- is accepted for

the amount specified below.

Contractor Work Estimate is NOT accepted. The scope of work considered WILL NOT

BE ASSIGNED TO CONTRACTOR.

Summary of Scope of Work Accepted OR Reason CWE was rejected:

Amount of Change: FC: Naira:

Schedule Impact: Revised Completion Date:

RECEIVED BY: DATE:

February 9, 1998; Revision B Page 36 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

INSTRUCTION TO PROCEED WITH WORK

ITP

Subject Description: FILING CODE:

_____-_____-_____-ITP-___

Contractor Name: Charge/AFE Code:

Project Name: Date:

Originator (please print name) (Signature)

Approval (please print name and sign):

UPON RECEIPT OF THESE INSTRUCTIONS, CONTRACTOR SHALL BEGIN WORK IMMEDIATELY.

LABOR, MATERIAL, AND EQUIPMENT (T&M) CHARGES DIRECTLY ATTRIBUTABLE TO THE WORK

SHALL BE RECORDED BY CONTRACTOR, AND SIGNED DAILY BY THE COMPANY REPRESENTATIVE

TO ACKNOWLEDGE RECEIPT. CONTRACT COMPENSATION, IF ANY, WILL BE BASED ON THESE

RECORDS DULY RECORDED BY CONTRACTOR AND SIGNED BY COMPANY.

Instruction:

These instructions are classified by Company as:

A Change Disputed Status (Contractor and Company fail to

agree on the classification of this work.)

IN THE EVENT THAT CONTRACTOR AND COMPANY FAIL TO AGREE ON THE CLASSIFICATION OF

THESE INSTRUCTIONS OR RESULTING ADJUSTMENT IN CONTRACT COMPENSATION, IF ANY, REFER

TO THE CHANGES SECTION OF THE CONTRACT TERMS AND CONDITIONS.

Why Is Scope is a Change:

RECEIVED BY: DATE:

February 9, 1998; Revision B Page 37 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

CONTRACT VARIATION FORM

(CV)

CONTRACT NUMBER: CHANGE NUMBER:

CONTRACTOR:

The requirements of the above-designated Contract are changed as follows:

Revision of Completion Date:

Company and Contractor agree that Contractor’s compensation shall be adjusted as follows:

U.S. Dollar Naira

Original Contract Value:

Total of Previous CV’s:

Total of This Variation:

Total Revised Contract Value:

This adjustment covers the entire compensation for the Change set forth above and includes, but is not

limited to compensation for all engineering, material, equipment, subcontracts, labor, overhead, changes

in scheduling, and delays resulting directly or indirectly from the Change.

CONTRACTOR: COMPANY:

Work Completed: Signed: Date:

Invoice No.: Date:

Amount: Date Rec’d:

Charge Account No. Charge Job No.

Remarks:

February 9, 1998; Revision B Page 38 of 38

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

ATTACHMENT 1

CONTRACTOR FURNISHED

OFFICE FACILITIES

REQUIRED AT FABRICATION YARD

Number of Offices Required:

2 Inspector Office

1 Visiting Engineer/JV Partner Office

Basic Office Requirements:

No. Item Description Comments

Req’d.

1 Office desk & chair

2 Visitors chairs

1 Speaker phone

1 Table Visitors office to have

conference table and

four chairs

2 File cabinet

2 Bookcase

1 Drawing rack

1 IBM 486 (or equivalent) PC Only one PC is required.

complete with keyboard, mouse, It will be shared among

mousepad, and all cables the three offices.

1 HP Laserjet 3si printer Ditto

1 Computer software Ditto

Microsoft Windows 3.1

Microsoft Word 6.0

Microsoft Excel 5.0

Microsoft Scheduler (latest

version)

1 Copying machine complete with Ditto

multiple paper trays for 8-1/2” x

11” to 11” x 17” paper, zoom and

enlargement

1 Fax machine Ditto

ANCILLARY EQUIPMENT AND SERVICES PROVIDED BY CONTRACTOR

Phone service to have access to international phone lines.

Support services for computer hardware and software, and copier.

February 9, 1998; Revision B Page 1 of 1

Attachment 1

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

ATTACHMENT 2

DOCUMENTATION DELIVERABLES

1.1 General

1.1.1 All documentation shall be in the English language and in English AND SI units of

measurement. Primary responsibility for submittal of documentation is assigned

to the vendor or subcontractor (manufacturer) however the contractor or primary

vendor (purchaser) is not relieved of this responsibility should the subcontractor or

vendor default.

1.1.2 All documentation (including drawings reports, studies, analyses, etc.) prepared

as part of Contractor’s work scope shall become the property of Company. Any

scale models of the facilities made by Contractor shall at the completion of the

Work become the property of the Company.

1.1.3 Correspondence, drawings, and other documents in connection with projects shall

show the purchase order or Contract number and the Project. The nature of the

documents shall be clearly identified (e.g., either certified, for approval, production

manual, or for information).

1.2 Document Approval

1.2.1 Company will review and return documentation with two of the following marks:

MARK #1 DRAFTING ACTION REQUIRED

Approved As Submitted No additional drawing submittals are required

No Change pending changes or revisions.

Approved as Noted Revised drawings showing the mark-ups shall be

returned to Company within 2 weeks unless

otherwise noted.

Not Approved Drawings shall be revised and resubmitted for

See Comments approval by Company unless otherwise noted.

Receipt Noted Company approval is not required.

MARK #2 FABRICATION ACTION REQUIRED

Proceed with Fabrication Fabrication may proceed without further notification

by Company.

Hold Fabrication Fabrication shall not proceed without written

authorization by Company. Fabrication completed

without this written authorization may be rejected by

Company with no compensation to Contractor.

1.2.2 Company shall have five working days from receipt of Contractor documentation

to comment on the submittal. Should comment/approval not be received by

February 9, 1998; Revision B Page 1 of 2

Attachment 2

Chevron Nigeria Limited Specification 0.01

GENERAL PROJECT PROCEDURES

Contractor after the five-day period, Contractor may proceed with Work as though

the submittal had been marked "Receipt Noted”.

1.2.3 Any remedial Work or purchase of material resulting from Contractor's failure to

comply with the Technical Requirements, regardless of Company's approval

response, shall not be included in a compensation adjustment.

1.2.4 During fabrication/construction, Contractor shall maintain on file current mark-ups

of all drawings and data sheets to agree with actual Work.

2.0 Schedule of Contractor Documentation Requirements

2.1 Design Manual

2.1.1 Design calculations, reports, and design drawings shall be submitted for Company

review in accordance with the attached schedule of Contractor Documentation

submittals. Upon completion of the Work, these calculations and drawings shall

be organized and compiled into a Design Manual.

2.2 Construction Manual

2.2.1 Prior to acceptance and shipment of the Project, the following shall be furnished to

Company in a Construction Manual:

• Material certifications and traceability documentation (weld maps, MTR’s,

etc.)

• Fabrication test and QA/QC reports (NDT, slump tests, cylinder tests, paint

reports, etc.)

• Manufacturing and fabrication Compliance and Exception Reports

• Vendor data sheets and descriptive literature for all components, including

Company-provided items, collected and bound for reference

• “As-Built” drawings (1 reproducible plus 2 copies)

• Change order log

• Special shipping, handling, or maintenance instructions

February 9, 1998; Revision B Page 2 of 2

Attachment 2

You might also like

- Peso - Gas Cylinder Rules-ExtractDocument2 pagesPeso - Gas Cylinder Rules-ExtractSachin DarneNo ratings yet

- Engineering Standard: IPS-E-PR-260Document66 pagesEngineering Standard: IPS-E-PR-260davoodsalimiNo ratings yet

- Og&C Standard Work Process Procedure Welder Training and Instructor QualificationDocument8 pagesOg&C Standard Work Process Procedure Welder Training and Instructor QualificationGordon LongforganNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document16 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Demolition Environmental Management Plan PDFDocument73 pagesDemolition Environmental Management Plan PDFjamsheedNo ratings yet

- DHU-NOCL - JOB EXECUTION PLAN - SupersededDocument37 pagesDHU-NOCL - JOB EXECUTION PLAN - SupersededTaofiqNo ratings yet

- Life CycleCarbonFootprintingandEconomicsDocument55 pagesLife CycleCarbonFootprintingandEconomicsAr Abhinav SrivastavNo ratings yet

- Instructions FOR Supplier Documentation: Document No.: Winz-Pm-Dc-0001Document17 pagesInstructions FOR Supplier Documentation: Document No.: Winz-Pm-Dc-0001Anil JaxNo ratings yet

- EPC - Schedules - NH 2BDocument102 pagesEPC - Schedules - NH 2BOllie BhattNo ratings yet

- General Purpose Gear Units: ScopeDocument10 pagesGeneral Purpose Gear Units: ScopeAnonymous fvO1W3No ratings yet

- Annex To Engineering 003-Civil Structural Design Criteria On ShoreDocument84 pagesAnnex To Engineering 003-Civil Structural Design Criteria On ShoreagaricusNo ratings yet

- Design Basis KLMDocument19 pagesDesign Basis KLMKVRamananNo ratings yet

- Arquid-Technical Due DiligenceDocument35 pagesArquid-Technical Due DiligenceomarNo ratings yet

- Scope of WorksDocument77 pagesScope of Workstroyel99No ratings yet

- Cryogenic Standard Tanks PDFDocument12 pagesCryogenic Standard Tanks PDFprakash07343No ratings yet

- Vdocuments - MX Dep 30460031 Gen Rev Sep 2011thermal InsulationDocument56 pagesVdocuments - MX Dep 30460031 Gen Rev Sep 2011thermal InsulationMuthu SaravananNo ratings yet

- Coal To Methanol: Technical ReportDocument32 pagesCoal To Methanol: Technical ReportAhmad Nur MU AqilNo ratings yet

- Minimum Technical Requirements (Indice Delle Norme Da Applicare in KSA)Document183 pagesMinimum Technical Requirements (Indice Delle Norme Da Applicare in KSA)senkum279342100% (1)

- How To Prepare Planning Deliverables For LNG Project?: Sapto Hari WibowoDocument17 pagesHow To Prepare Planning Deliverables For LNG Project?: Sapto Hari WibowoSalman Syafar RamzyNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document67 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- Saep 42 PDFDocument11 pagesSaep 42 PDFRami ElloumiNo ratings yet

- Code For Construction Quality Acceptance and Evaluation of Electric Power Construct-2Document836 pagesCode For Construction Quality Acceptance and Evaluation of Electric Power Construct-2ecsuperalNo ratings yet

- TA-143-D00-G-TD005 - 0 - Employer's Requirements PDFDocument78 pagesTA-143-D00-G-TD005 - 0 - Employer's Requirements PDFshareyhouNo ratings yet

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- Cost Estimation of Reactor - 060Document36 pagesCost Estimation of Reactor - 060Muhammad UsamaNo ratings yet

- 10430-25200 Att.02-LOD Rev.0Document41 pages10430-25200 Att.02-LOD Rev.0Gorkem DoraNo ratings yet

- Pistep Act ModDocument13 pagesPistep Act ModkamlNo ratings yet

- NES 802 Part 4 Requirements For Acoustic and Thermal Insulation MaterialDocument28 pagesNES 802 Part 4 Requirements For Acoustic and Thermal Insulation MaterialJEORJENo ratings yet

- Combined Cycle ConversionDocument61 pagesCombined Cycle ConversionDomingo PintoNo ratings yet

- Calculation: Fire Water Demand - Sepco and Labor Camp: Saudi Arabian Oil CompanyDocument5 pagesCalculation: Fire Water Demand - Sepco and Labor Camp: Saudi Arabian Oil Company龙琦No ratings yet

- CONOCO PHILLIPS SpecDocument21 pagesCONOCO PHILLIPS SpecYuda Satria100% (1)

- PGS 35 HRS Netherlands PDFDocument90 pagesPGS 35 HRS Netherlands PDFquesnel SebNo ratings yet

- Itb Part I - Instruction To BiddersDocument16 pagesItb Part I - Instruction To BiddersilsaNo ratings yet

- Hvac Precommisioning ExecutionDocument13 pagesHvac Precommisioning ExecutionOmar TocmoNo ratings yet

- Project Handover Kickoff Meeting ProcedureDocument9 pagesProject Handover Kickoff Meeting ProcedureAhmed MohamedNo ratings yet

- What Does An EPC Contractor DoDocument10 pagesWhat Does An EPC Contractor DoTechnical TubaneginNo ratings yet

- PSEC Standard Rev 02 (DRAFT) 16-09-2020Document156 pagesPSEC Standard Rev 02 (DRAFT) 16-09-2020Irf NavaneethNo ratings yet

- Plant LayoutDocument8 pagesPlant Layoutrsmallwood395895100% (1)

- NUREG-0313 - Rev-2 - Material Selection and Processing For BWR PipingDocument46 pagesNUREG-0313 - Rev-2 - Material Selection and Processing For BWR PipingOtso CronvallNo ratings yet

- EPC or EPCM Contracts: Which One Can Drive Stronger Outcomes For Project Owners?Document7 pagesEPC or EPCM Contracts: Which One Can Drive Stronger Outcomes For Project Owners?Đặng Trung AnhNo ratings yet

- 2 Manfred WaidhasDocument18 pages2 Manfred WaidhasMuhammad Ali100% (1)

- Define Your PetrochemicalProject Execution PlanDocument9 pagesDefine Your PetrochemicalProject Execution PlanLiu Yangtze100% (1)

- ESPC GuideDocument223 pagesESPC GuidejoechengshNo ratings yet

- RC443 DS 000 2542 0001 Rev2 LNG Storage TankDocument13 pagesRC443 DS 000 2542 0001 Rev2 LNG Storage TankDjamel EeddinNo ratings yet

- GM-TEG1-6220-010 (Risk Management Plant)Document9 pagesGM-TEG1-6220-010 (Risk Management Plant)Sulist N Wahyudie100% (1)

- 8q1pQq PDFDocument100 pages8q1pQq PDFJonathan Riveros RojasNo ratings yet

- Cra - Hdpe - Technical Specifications-Version 1.1Document13 pagesCra - Hdpe - Technical Specifications-Version 1.1XaviorNo ratings yet

- 5247-MS-500-00-104 (Rev 0)Document20 pages5247-MS-500-00-104 (Rev 0)Suneel MatchalaNo ratings yet

- Site Explanation For Mechanical WorkDocument36 pagesSite Explanation For Mechanical WorkĐình Nam0% (1)

- Technical Submittal - Opt PDFDocument49 pagesTechnical Submittal - Opt PDFkdpmansiNo ratings yet

- T14 - Project Turnover Standard 2022Document61 pagesT14 - Project Turnover Standard 2022Mohamed AtefNo ratings yet

- GS112 2 PDFDocument25 pagesGS112 2 PDFGabriel Patruno100% (1)

- FDes Training ManualDocument138 pagesFDes Training ManualpmanotherNo ratings yet

- Essential LV Room, Z8-0880Document10 pagesEssential LV Room, Z8-0880bhima irabattiNo ratings yet

- WI-SSA-ENGTEC-001-E - 1 - Verification of Process Engineering DocumentsDocument14 pagesWI-SSA-ENGTEC-001-E - 1 - Verification of Process Engineering Documentsanghel_florin82No ratings yet

- TOR Wind Farm - Technical Due Diligencev1 - 0Document9 pagesTOR Wind Farm - Technical Due Diligencev1 - 0Alexandru IonescuNo ratings yet

- Section 02Document16 pagesSection 02wsc1141a wsc1141No ratings yet

- SOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12Document20 pagesSOP-Attachment 3b - CNL JV-EGTL SWP 401 - Permit To Work - Dec12tomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Sos SystemDocument50 pagesSos SystemtomychalilNo ratings yet

- Annex C Robust Analysis: (Normative)Document1 pageAnnex C Robust Analysis: (Normative)tomychalil0% (1)

- Dr2 - Spec - Non-Destructive Examination Req of PipingDocument20 pagesDr2 - Spec - Non-Destructive Examination Req of Pipingtomychalil100% (1)

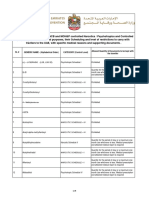

- Annex To Travellers Guidelines 28-10-2018Document25 pagesAnnex To Travellers Guidelines 28-10-2018tomychalilNo ratings yet

- Vickers Calibration DetailsDocument1 pageVickers Calibration DetailstomychalilNo ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- Interlaboratory Comparison of FatigueDocument26 pagesInterlaboratory Comparison of FatiguetomychalilNo ratings yet

- CNC Table Waterjet Cutting MachineDocument9 pagesCNC Table Waterjet Cutting MachinetomychalilNo ratings yet

- Temperature Recording SystemDocument12 pagesTemperature Recording SystemtomychalilNo ratings yet

- Admission Instruction Ug18Document2 pagesAdmission Instruction Ug18tomychalilNo ratings yet

- Toolroom Selection Chart 7505Document1 pageToolroom Selection Chart 7505tomychalilNo ratings yet

- Surface Grinding 440 C StainlessDocument3 pagesSurface Grinding 440 C StainlesstomychalilNo ratings yet

- IcpDocument15 pagesIcpOng Yang LimNo ratings yet

- Invoice 1525160661Document1 pageInvoice 1525160661Ivan ZlatevskiNo ratings yet

- ZUGFeRD-2.1.1 - SpecificationDocument25 pagesZUGFeRD-2.1.1 - SpecificationgerstenblunaNo ratings yet

- RefundDocument34 pagesRefunddhruv MahajanNo ratings yet

- Consumption Taxes: Business Tax Is A Form of Consumption TaxDocument8 pagesConsumption Taxes: Business Tax Is A Form of Consumption TaxDenvyl MangsatNo ratings yet

- Oracle Apps Order Management Interview QuestionsDocument9 pagesOracle Apps Order Management Interview Questionsnet6351100% (2)

- Exchange Control Regulations - ExportsDocument52 pagesExchange Control Regulations - ExportsAkanksha Singh100% (1)

- Lim Hui Ching Ivy: Bachelor Degree in Banking and FinanceDocument5 pagesLim Hui Ching Ivy: Bachelor Degree in Banking and FinanceshaubNo ratings yet

- Telephone No Amount Payable Due Date: Pay NowDocument3 pagesTelephone No Amount Payable Due Date: Pay NowJAYNo ratings yet

- Request For Quotation Template - GoodsDocument5 pagesRequest For Quotation Template - GoodskalawaanelemschoolNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Sourav SamaddarNo ratings yet

- (Emerson) Lead Magnet - CompressedDocument4 pages(Emerson) Lead Magnet - CompressedJohn BuenviajeNo ratings yet

- India Localization VAT URMDocument95 pagesIndia Localization VAT URMgagan2001No ratings yet

- Košická 24/1 SK-94501 Komárno: Tel.: +421-9-05729685 Open Ways Delivery, S.R.ODocument3 pagesKošická 24/1 SK-94501 Komárno: Tel.: +421-9-05729685 Open Ways Delivery, S.R.OChri xtinaNo ratings yet

- Rtgs InvoiceDocument1 pageRtgs InvoicePanaNo ratings yet

- P.C.R.A - Domestic Workshop & Youth Programme English ManualDocument27 pagesP.C.R.A - Domestic Workshop & Youth Programme English ManualMinatiBindhaniNo ratings yet

- FICO Real Time ProjectDocument105 pagesFICO Real Time ProjectsowmyanavalNo ratings yet

- Toaz - Info Kashato Shirts Entries PRDocument64 pagesToaz - Info Kashato Shirts Entries PRTylerNo ratings yet