Professional Documents

Culture Documents

Chapter No. 23 River and Canal Protection Work: Notes

Uploaded by

MANJEET SINGHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter No. 23 River and Canal Protection Work: Notes

Uploaded by

MANJEET SINGHCopyright:

Available Formats

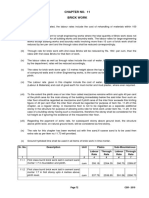

CHAPTER NO.

23

RIVER AND CANAL PROTECTION WORK

Notes:-

(i) The rates for carriage of materials manually upto 0.50 km and by mechanical means for

every km lead have been given. The actual lead is to be paid if the lead is in fraction , the

rate is to be worked out by interpolation.

Sr. No. Description Unit Rate for Plains as

well as Sub-

Mountainous Region

Labour Through

Rate Rate

1 2 3 4 5

23.1 Cutting pilchi, farash and sarkanda and carriage to work lead two

kms including loading and unloading :--

(a) Loose cum 48.41 -

(b) Compacted in rolls of required diameter and length. cum 201.44 -

23.2 Loading pilchi, farash and sarkanda in boats within 15 ms:--

(a) Loose cum 10.93 -

(b) Compacted in rolls. cum 24.20 -

23.3 Carriage of pilchi, farash and sarkanda by boats including loading

and unloading :--

(a) Loose :-

(i) One km cum 30.45 -

(ii) Two kms cum 56.55 -

(iii) Three kms cum 76.13 -

(iv) Four kms cum 92.22 -

(v) Five kms cum 106.58 -

(vi) Subsequent km per km cum 10.88 -

(b) Compacted :-

(i) One km cum 73.95 -

(ii) Two kms cum 136.59 -

(iii) Three kms cum 182.27 -

(iv) Four kms cum 222.72 -

(v) Five kms cum 265.18 -

(vi) Subsequent km per km cum 28.28 -

23.4 Unloading Pilchi, farash and sarkanda from boats and carriage to

yard upto one km :--

(a) Loose cum 24.20 -

Page 232 CSR- 2010

Sr. No. Description Unit Rate for Plains as

well as Sub-

Mountainous Region

Labour Through

Rate Rate

1 2 3 4 5

(b) Compacted cum 60.51 -

23.5 Making Pilchi, farash and sarkanda rolls excluding supply of

materials :--

(a) 20 cm or 23 cm dia. and 9 m long each 42.36 -

(b) 15 cm dia. and 9 m long each 28.24 -

(c) 15 cm dia. and 1.5 m long each 3.39 -

Note :- (i) The payment under item No. 23.5 is not to be made in

addition to those of item No. 23.1(b), 23.8, 23.9 and 23.10.

23.6 Making 0.75 m dia. and 5.5 m long pilchi rolls for permeable spurs.

each 190.59 -

23.7 Launching the above and placing in position. each 135.53 -

23.8 Pilchi, farash or sarkanda pitching on slope with rolls 15 cm dia. and

1.5 m long including supply of pilchi involving carriage within 2 kms

and labour for making rolls. sqm 173.67 -

Note :- (i) For above items, pitching shall be of 15cm dia. Layers of

pilchi laid as header and 1.5. ms in length alternating with 15

cm covering of earth for consolidation including pegs and

tying with wire (to be supplied by the department free of

cost.)

23.9 Extra for carriage beyond 2 kms of pilchi rolls 15 cm dia. and 1.5m

long (vide item No. 23.8)

(a) 3rd km sqm of

pitching

surface 34.80 -

(b) Subsequent km per km sqm of

pitching

surface 21.75 -

23.10 Pilchi, farash or sarkanda pitching one m depth. sqm of 80

pitching percent

surface rate of

item No.

23.8 &

23.9. -

23.11 Pilchi revetment including carriage upto 2 km sqm 84.28 -

23.12 Surface protection with pilchi mattress lead upto 2 km sqm 56.47 -

23.13 Weaving mattresses of pilchi 30 cm thick. sqm 38.74 -

Page 233 CSR- 2010

Sr. No. Description Unit Rate for Plains as

well as Sub-

Mountainous Region

Labour Through

Rate Rate

1 2 3 4 5

23.14 Rolling pilchi mattress to river edge and floating after unrolling :-

(a) area of mattress upto 200 sqm sqm 15.81 -

(b) area of mattress exceeding 200 sqm but upto 250 sqm sqm 21.56 -

(c) area of mattress above 250 sqm sqm 22.59 -

23.15 Laying kahi mattress lead upto 2 km sqm 50.83 -

23.16 Special kahi revetment double lead upto 2 km sqm 105.96 -

23.17 Gachi pitching with average thickness of 30 cm (joints to be

broken) sqm 50.83 -

23.18 Gachi pitching (done with silt clearance and berm dressing) with

thickness of 30 cm (joints to be broken) sqm 48.41 -

23.19 Fixing floating spurs in channels with material from canal plantation

within 2 km :--

(a) upto F.S. depth 0.5m each 2.18 -

(b) F.S. depth exceeding 0.5 m but upto 1.0 m each 4.35 -

(c) F.S. depth exceeding 1.0 m but upto 1.25 m each 6.96 -

(d) above 1.25 m F.S. depth. each 8.70 -

23.20 Stacking and bushing with canal plantation within 1.0 km

(a)(i) Pegs 1.0 m long, 5 cm dia 100 nos 143.59 -

(ii) Driving pegs 1.0m long, 5 cm dia 100 nos 84.71 -

(iii) Wattling brush wood between stakes and intertwining.

m of one

row. 2.26 -

(b)(i) Pegs 1.25 m long, 7.5 cm dia. sharpened at one end. 100 nos 152.48 -

(ii) Driving pegs 1.25 m long, 7.5 cm dia. 100 nos 112.94 -

(iii) Wattling brush wood between stakes and intertwining.

m of one

row. 2.26 -

(c)(i) Pegs 1.5 m long, 7.5 cm dia. sharpened at one end. 100 nos 160.10 -

(ii) Driving pegs 1.5 m long, 7.5 cm dia. 100 nos 121.01 -

Page 234 CSR- 2010

Sr. No. Description Unit Rate for Plains as

well as Sub-

Mountainous Region

Labour Through

Rate Rate

1 2 3 4 5

(iii) Wattling brush wood between stakes and intertwining.

m of one

row. 2.82 -

(d)(i) Pegs 2 m long, 7.5 cm dia. sharpened at one end. 100 nos 228.71 -

(ii) Driving pegs 2 m long, 7.5 cm dia 100 nos 150.59 -

(iii) Wattling brush wood between stakes and intertwining.

m of one

row. 3.76 -

23.21 Filling brush wood only. cum 13.55 -

23.22 Filling cement bags with sand or earth and sewing including cost of

E.C. bag & strings. 100 nos 169.42 473.29

23.23 Loading cement bags filled with sand or earth into trucks or boats

within 100 ms. 100 nos 225.89 -

23.24 Carriage of sand filled in bags by boats :--

(a) Ist chain of 30 ms. 100 nos 34.80 -

(b) 2nd to 4th chain per chain of 30 ms. 100 nos 20.88 -

(c) 5th and subsequent chains per chain of 30 ms. 100 nos 13.92 -

23.25 Unloading from boats, bags filled with sand and :--

(a) Placing in dry. 100 nos 211.78 -

(b) Placing in water. 100 nos 423.55 -

23.26 Filling cement bags with sand, sewing and laying in position within

30 ms in dry including cost of E.C. bag & strings. 100 nos 338.84 676.48

23.27 Filling cement bags with sand sewing and laying in position within

30 ms in water including cost of E.C. bag & strings. 100 nos 564.73 931.66

23.28 Sewing empty cement bags in to sheets. 100 nos 112.95 414.80

23.29 Weaving wire netting for wire crates including binding sides and

partitions to make crates of 15 cm x 15 cm or 25cm x 7.5 cm mesh.

sqm 23.73 119.51

23.30 Filling brick bats in crates and hand packing. cum 39.86 643.94

23.31 Filling bricks in crates and hand packing. cum 75.30 1744.47

23.32 Filling stones or spalls into crates and hand packing. cum 104.26 650.78

23.33 Tipping wire crates including equipment. cum 75.30 -

Page 235 CSR- 2010

Sr. No. Description Unit Rate for Plains as

well as Sub-

Mountainous Region

Labour Through

Rate Rate

1 2 3 4 5

23.34 Opening out old wire crates and remaking after filling. sqm 8.93 -

23.35 Labour for dismantling existing portion of old protection work

including cutting old trangger and stacking old stones for re-use.

cum 90.21 -

23.36 Filling spaces and foundations with old stones obtained from

dismantling including labour for dismantling. cum 203.30 -

23.37 Spreading wire crates over pitching connecting with side protective

walls inclusive of wire etc. sqm 26.65 -

23.38 Wire crates of specified dimensions from all directions of G.I. wire

filled with boulders with square cut faces against the wire.

(a) 4 mm dia. G.I. wire 25 cm x 7.5 cm mesh cum 196.24 -

(b) 4 mm dia. G.I. wire 15 cm x 15 cm mesh (diagonal wise)

cum 196.24 -

(c) 4.75 mm dia. GI wire 25 cm x 7.5 cm mesh (diagonal wise)

cum 196.24 -

(d) 4.75 mm dia. G.I. wire 15 cm x 15 cm mesh (diagonal wise)

cum 196.24 -

(e) 3.25 mm dia. G.I. wire 25 cm x 7.5 cm mesh (diagonal wise)

cum 196.24 -

(f) 3.25 mm dia. G.I. wire 15 cm x 15 cm mesh (diagonal wise)

cum 196.24 -

Note :- (i) The through rate of the above item is dependent on the size

of the crate which varies as per the site conditions and

design/drawing.

23.39 Dumping stone. cum 56.47 602.99

23.40 Extra for anchoring boat for dumping in position. cum 17.40 -

23.41 Dismantling brush wood boulder bund. cum 150.59 -

23.42 Stone or kankar block pitching :--

(a) Horizontal cum 188.24 -

(b) On slopes of guide banks and protection works. cum 242.02 -

23.43 Stone pitching top coping only. cum 418.56 965.08

23.44 Filling stone or spall :--

(a) On level cum 56.47 602.99

Page 236 CSR- 2010

Sr. No. Description Unit Rate for Plains as

well as Sub-

Mountainous Region

Labour Through

Rate Rate

1 2 3 4 5

(b) On side slopes behind pitching cum 59.79 446.32

23.45 Grouting stone filling or pitching :--

(a) With bajri or shingle sqm 24.20 47.77

(b) With mortar sqm 41.02 76.56

23.46 Grouting masonry joints of floors including finishing :--

(a) When stones are upto 23 cm square sqm 19.14 -

(b) When stones are more than 23 cm square but under 45 cm

square sqm 12.35 -

Note :- (i) The through rate of the above item varies as per thickness of

stone & richness of mix as per requirements.

23.47 Sand grouting stone apron with high pressure hose. sqm 6.96 -

23.48 Weaving Coir rope netting for Coir rope crates including binding

sides and partitions to make crates of 22.5 cm x 22.5 cm mesh

(including cost of coir rope).

(Min. weight per crate = 2.80 Kg) Size 8' x 4' x 3' sqm 5.88 13.54

Note :- (i) The Chief Engineer in-charge of works concerned, may

allow on works of temporary nature, the use of black

annealed MS Wire number 6 or 8 SWG (4.75 mm or 4.00

mm) conforming to the relevant ISI specifications, in lieu of

G.I. Wire.

Page 237 CSR- 2010

You might also like

- KD5: Final Feasibility Report for 149.7 km Tamu-Kyigone-Kalewa Road in MyanmarDocument1 pageKD5: Final Feasibility Report for 149.7 km Tamu-Kyigone-Kalewa Road in MyanmarQ C ShamlajiNo ratings yet

- SK Chapter-8 PDFDocument95 pagesSK Chapter-8 PDFSOUVIK MAJUMDERNo ratings yet

- Question Bank HighwayDocument6 pagesQuestion Bank HighwaySadam PathanNo ratings yet

- Nepal Road Standard 2027 Revision 2045Document22 pagesNepal Road Standard 2027 Revision 2045erjuniorsanjip0% (1)

- Government of India Ministry of Railways (Railway Board)Document6 pagesGovernment of India Ministry of Railways (Railway Board)Naresh KumarNo ratings yet

- D:/IRPWM With cs/ACS To IRPWM/ACS 122Document6 pagesD:/IRPWM With cs/ACS To IRPWM/ACS 122Ajeeth KumarNo ratings yet

- 1605612737213-PWAY QuestionDocument174 pages1605612737213-PWAY QuestionNANP VITAL0% (1)

- ExampleDocument3 pagesExampleGobi NavaNo ratings yet

- Deep ScreeningDocument41 pagesDeep ScreeningSuciu FlorinNo ratings yet

- Sem 2 2 Track RenewalDocument9 pagesSem 2 2 Track RenewalShah SudAaisNo ratings yet

- Odc GuidelineDocument7 pagesOdc GuidelineCDO RourkelaNo ratings yet

- Cost Estimates - ChauraghatDocument81 pagesCost Estimates - ChauraghatAicons Engineering Pvt. Ltd.No ratings yet

- 20 Ch-20 PDFDocument8 pages20 Ch-20 PDFMANJEET SINGHNo ratings yet

- R. S. Engineering Company Latur Rate For Embankment, Subgrade, Shoulder, GSB,& WMM SR - NO Description of Item Unit RateDocument4 pagesR. S. Engineering Company Latur Rate For Embankment, Subgrade, Shoulder, GSB,& WMM SR - NO Description of Item Unit RateMaipalsingh ThakurNo ratings yet

- CH 3Document30 pagesCH 3abdullahchoudhary4No ratings yet

- Research Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDADocument4 pagesResearch Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDAAyush GoyalNo ratings yet

- Annexure-I of Schedule G Contract Price WeightagesDocument3 pagesAnnexure-I of Schedule G Contract Price WeightagesChristopher SwansonNo ratings yet

- Tute 08 Road Construction & MotorcycleDocument1 pageTute 08 Road Construction & Motorcycleyu yanNo ratings yet

- Kuwsd Board SR 2019-20Document128 pagesKuwsd Board SR 2019-20Kumaraswamy 143kummi100% (1)

- CombinedDocument41 pagesCombinedSaif MohdNo ratings yet

- Indian Railways Key Stats 1970-71 to 2012-13Document109 pagesIndian Railways Key Stats 1970-71 to 2012-13Tanvi RastogiNo ratings yet

- Mumbai Nagpur Expressway ProjectDocument4 pagesMumbai Nagpur Expressway ProjectOwais KadiriNo ratings yet

- Draft Indonesian Track Standard Part 1Document2 pagesDraft Indonesian Track Standard Part 1sukamtoNo ratings yet

- Chapter 6Document10 pagesChapter 6sde psd9No ratings yet

- BMBS wagonsDocument9 pagesBMBS wagonssibaranjandash2007No ratings yet

- Schedule - G 1Document6 pagesSchedule - G 1A RajaNo ratings yet

- Schedule - B: (See Clause 2.1)Document18 pagesSchedule - B: (See Clause 2.1)HimanhsuNo ratings yet

- PwayQBDocument49 pagesPwayQBHemantSharmaNo ratings yet

- Design of Rigid Pavement For TunnelsDocument19 pagesDesign of Rigid Pavement For TunnelsHemant YesajiNo ratings yet

- Finalexambfc31802sem 1 2022 2023 QuestionDocument14 pagesFinalexambfc31802sem 1 2022 2023 Questionliehans.santosoNo ratings yet

- Ca 1Document6 pagesCa 1Sumit Kumar SinhaNo ratings yet

- SOR (SH&MDR) 2013 14 (Do)Document93 pagesSOR (SH&MDR) 2013 14 (Do)Akash MahantaNo ratings yet

- APWD NH 20-21 (1) - MergedDocument111 pagesAPWD NH 20-21 (1) - MergedRidip DuttaNo ratings yet

- Apwd NH 20-21Document97 pagesApwd NH 20-21Ridip DuttaNo ratings yet

- KM KM KM Nos KM KM KM KM KMDocument6 pagesKM KM KM Nos KM KM KM KM KMABCI MIZORAM-4No ratings yet

- Concept of Class 9 EqvtDocument2 pagesConcept of Class 9 EqvtBijay Krishna DasNo ratings yet

- Share Revised Question Bank For JE PWAY With Chapter NameDocument87 pagesShare Revised Question Bank For JE PWAY With Chapter NameGaganNo ratings yet

- Bridge RuleDocument85 pagesBridge RuleHimanshu GuptaNo ratings yet

- Civil Engineering Interview QuestionsDocument11 pagesCivil Engineering Interview QuestionsVishnu Nandakumar100% (1)

- Chapter 2 Rolling Stock Functional RequirementsDocument56 pagesChapter 2 Rolling Stock Functional Requirementsdyka89No ratings yet

- Chapter - 5 - Design of Bridge and ApproachesDocument3 pagesChapter - 5 - Design of Bridge and ApproachespraveenNo ratings yet

- Railways - Practice Sheet - 01Document3 pagesRailways - Practice Sheet - 01Prateek PalNo ratings yet

- Class PPT Delhi Metro Airport Express Line (SESSION 3)Document23 pagesClass PPT Delhi Metro Airport Express Line (SESSION 3)Hemant GopinathNo ratings yet

- Railway Track - DPP 01Document3 pagesRailway Track - DPP 01Adarsh RathoreNo ratings yet

- Venkat FlexiblePavement DesignDocument86 pagesVenkat FlexiblePavement DesignV Venkata Narayana100% (5)

- B.O.Q B&R OfficeDocument6 pagesB.O.Q B&R OfficeEngr Nissar KakarNo ratings yet

- Highway Engg. New Ocr FormatDocument41 pagesHighway Engg. New Ocr FormatIES-GATEWizNo ratings yet

- 24 Ch-24 PDFDocument33 pages24 Ch-24 PDFMANJEET SINGHNo ratings yet

- Pati TulihallanDocument28 pagesPati Tulihallanhakim imtiyazNo ratings yet

- Vertical Live Load (L)Document4 pagesVertical Live Load (L)Raymond CiaoNo ratings yet

- Highway Engineering Unit Test QuestionsDocument5 pagesHighway Engineering Unit Test QuestionsBalaji vNo ratings yet

- INFORMATION BOOK 2019 (PDF Version)Document134 pagesINFORMATION BOOK 2019 (PDF Version)Rashedul HasanNo ratings yet

- Hotmix and mechanical methods for 1km roadDocument3 pagesHotmix and mechanical methods for 1km roadPrashant VermaNo ratings yet

- JimmaaDocument9 pagesJimmaaRun Fast100% (1)

- 9113 Boq-1 3 04Document10 pages9113 Boq-1 3 04Anonymous wosn1lyNo ratings yet

- Question Bank Pway PDFDocument114 pagesQuestion Bank Pway PDFuday patel90% (39)

- Saudi Aramco Rigger-1, 2 Examination Choose The Best Answer and Mark With Circle LineDocument11 pagesSaudi Aramco Rigger-1, 2 Examination Choose The Best Answer and Mark With Circle LineFun PointNo ratings yet

- Saudi Aramco RiggerDocument11 pagesSaudi Aramco RiggerShabbir Hussain85% (13)

- Calculation of Carriage Cost As Per SPR (2016) GuidelinesDocument1 pageCalculation of Carriage Cost As Per SPR (2016) GuidelinesPayal MondalNo ratings yet

- Common Schedule of Rates-PbDocument534 pagesCommon Schedule of Rates-PbKulbir Thakur60% (5)

- Electrical Rates of CSR Punjab PDFDocument85 pagesElectrical Rates of CSR Punjab PDFanushkabhardwaj50% (2)

- 29 Ch-29 PDFDocument29 pages29 Ch-29 PDFMANJEET SINGHNo ratings yet

- 03 Ch-3 PDFDocument16 pages03 Ch-3 PDFMANJEET SINGHNo ratings yet

- 30 Ch-30 PDFDocument26 pages30 Ch-30 PDFMANJEET SINGHNo ratings yet

- Chapter No. 18 Steel and Iron Work: Plains Sub-Mountainous Sr. No. Description UnitDocument8 pagesChapter No. 18 Steel and Iron Work: Plains Sub-Mountainous Sr. No. Description UnitMANJEET SINGHNo ratings yet

- 24 Ch-24 PDFDocument33 pages24 Ch-24 PDFMANJEET SINGHNo ratings yet

- Chapter No. 22 Bridges - Super Structure & Protection Work: Sr. No. Description Sub-Mountainous Plain UnitDocument13 pagesChapter No. 22 Bridges - Super Structure & Protection Work: Sr. No. Description Sub-Mountainous Plain UnitMANJEET SINGHNo ratings yet

- 28 Ch-28 PDFDocument38 pages28 Ch-28 PDFVarun JainNo ratings yet

- 21 Ch-21 PDFDocument24 pages21 Ch-21 PDFMANJEET SINGHNo ratings yet

- Chapter No. 31 Maintenance of Buildings and Furniture: NotesDocument11 pagesChapter No. 31 Maintenance of Buildings and Furniture: NotesMANJEET SINGHNo ratings yet

- Chapter No. 27 Quantities of Materials: NoteDocument14 pagesChapter No. 27 Quantities of Materials: NoteMANJEET SINGHNo ratings yet

- Chapter No. 4 Loading and Unloading: NotesDocument5 pagesChapter No. 4 Loading and Unloading: NotesMANJEET SINGHNo ratings yet

- 16 Ch-16 PDFDocument9 pages16 Ch-16 PDFMANJEET SINGHNo ratings yet

- Chapter No. 13 Hoisting and Roofing: NotesDocument9 pagesChapter No. 13 Hoisting and Roofing: NotesMANJEET SINGHNo ratings yet

- 14 Ch-14 PDFDocument33 pages14 Ch-14 PDFMANJEET SINGHNo ratings yet

- PrefaceDocument8 pagesPrefaceGurpreet SinghNo ratings yet

- Chapter No. 1 Daily Wages: NotesDocument3 pagesChapter No. 1 Daily Wages: NotesVarun JainNo ratings yet

- 11 Ch-11 PDFDocument8 pages11 Ch-11 PDFMANJEET SINGHNo ratings yet

- 17 Ch-17 PDFDocument24 pages17 Ch-17 PDFMANJEET SINGHNo ratings yet

- Common Schedule of Rates 2010: Public Works DepartmentDocument1 pageCommon Schedule of Rates 2010: Public Works DepartmentMANJEET SINGHNo ratings yet

- 32 Ch-32 PDFDocument6 pages32 Ch-32 PDFMANJEET SINGHNo ratings yet

- 26 Ch-26 PDFDocument5 pages26 Ch-26 PDFMANJEET SINGHNo ratings yet

- 10 Ch-10 PDFDocument12 pages10 Ch-10 PDFMANJEET SINGHNo ratings yet

- Chapter 19 Lining RatesDocument9 pagesChapter 19 Lining RatesMANJEET SINGHNo ratings yet

- Chapter No. 25 Maintenance of Canals & DrainsDocument4 pagesChapter No. 25 Maintenance of Canals & DrainsMANJEET SINGHNo ratings yet

- Chapter No. 12 Stone Masonry: NotesDocument6 pagesChapter No. 12 Stone Masonry: NotesMANJEET SINGHNo ratings yet

- 02 Ch-2 PDFDocument5 pages02 Ch-2 PDFanushkabhardwajNo ratings yet

- 06 Ch-6Document8 pages06 Ch-6Rajesh KaplishNo ratings yet

- Swype ReportDocument8 pagesSwype ReportNagarjuna ReddyNo ratings yet

- 1 Catalyst FundamentalsDocument17 pages1 Catalyst FundamentalsSam AnuNo ratings yet

- Exam Unit 1 Out and About 1º BachilleratoDocument5 pagesExam Unit 1 Out and About 1º Bachilleratolisikratis1980No ratings yet

- F2 IS Exam 1 (15-16)Document10 pagesF2 IS Exam 1 (15-16)羅天佑No ratings yet

- Mikes ResumeDocument2 pagesMikes Resumeapi-312645878No ratings yet

- 5.test Report - RFU-C-7Ghz IP10 Extract VersionDocument42 pages5.test Report - RFU-C-7Ghz IP10 Extract Versionminhdung.pham4713No ratings yet

- S7 - Q2 - Answer KeyDocument11 pagesS7 - Q2 - Answer KeyRaniel LacuarinNo ratings yet

- Unit 5: Structural Modelling: Block II: From Analysis To DesignDocument76 pagesUnit 5: Structural Modelling: Block II: From Analysis To DesignPatrick FarahNo ratings yet

- Direct Marketing: Mcgraw-Hill/IrwinDocument30 pagesDirect Marketing: Mcgraw-Hill/IrwinJunaid KhalidNo ratings yet

- Holy Week Labyrinth GuideDocument4 pagesHoly Week Labyrinth GuideEileen Campbell-Reed100% (1)

- Process Planning and Cost Estimation Question BankDocument13 pagesProcess Planning and Cost Estimation Question BanksanthoshjoysNo ratings yet

- The Dogon Tribe of The Sirius MysteryDocument5 pagesThe Dogon Tribe of The Sirius MysteryLaron Clark100% (1)

- Chapter 24 Study QuestionsDocument3 pagesChapter 24 Study QuestionsAline de OliveiraNo ratings yet

- But Virgil Was Not There": The Lasting Impact of Dante's Homosocial HellDocument7 pagesBut Virgil Was Not There": The Lasting Impact of Dante's Homosocial HellЮлия ЧебанNo ratings yet

- SOP 01 Criteria For Donor SelectionDocument9 pagesSOP 01 Criteria For Donor Selectionهشام الشهيميNo ratings yet

- Keto Food List for BodybuildingDocument8 pagesKeto Food List for Bodybuildingharris81No ratings yet

- Study Note 1 Fundamental of AccountingDocument54 pagesStudy Note 1 Fundamental of Accountingnaga naveenNo ratings yet

- 6.4 Permutations and CombinationsDocument14 pages6.4 Permutations and CombinationsAns SembiringNo ratings yet

- BCG ReportDocument9 pagesBCG Reportjlgjlj ljglkhNo ratings yet

- The Impact of Spiritual Intelligence, Gender and Educational Background On Mental Health Among College StudentsDocument22 pagesThe Impact of Spiritual Intelligence, Gender and Educational Background On Mental Health Among College StudentsBabar MairajNo ratings yet

- MKTM028 FathimathDocument23 pagesMKTM028 FathimathShyamly DeepuNo ratings yet

- Developing Website Information ArchitectureDocument39 pagesDeveloping Website Information ArchitectureBizuNo ratings yet

- ID26Document21 pagesID26Ashish BaidyanathanNo ratings yet

- What is phonicsDocument244 pagesWhat is phonicsNelly FernandezNo ratings yet

- Combining Singing and PsycologyDocument6 pagesCombining Singing and PsycologyAna luciaNo ratings yet

- Integrated Marketing Communication PlanDocument5 pagesIntegrated Marketing Communication Planprojectwork185No ratings yet

- Accounting For Non Specialists Australian 7th Edition Atrill Test BankDocument26 pagesAccounting For Non Specialists Australian 7th Edition Atrill Test BankJessicaMitchelleokj100% (49)

- Man 400eDocument324 pagesMan 400eLopez Tonny100% (1)

- Value YourselfDocument7 pagesValue YourselfTalha KhalidNo ratings yet

- Semiconductor Optical AmplifierDocument40 pagesSemiconductor Optical AmplifierVikas ThakurNo ratings yet