Professional Documents

Culture Documents

Process Equipment Design - II (QB)

Uploaded by

Kartik ChaddarwalaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Equipment Design - II (QB)

Uploaded by

Kartik ChaddarwalaCopyright:

Available Formats

Process Equipment Design –II (QB)

1. Discuss the classification of equipments, mechanical design pointof view. Also discuss 07

classification of unfired pressure vessels.

2. Explain in detail basic properties of material. 04

3. Define (i) Elasticity (ii) Toughness (iii) Fatigue (iv) Creep (v) Poisson’s ratio 07

(vi) Moment of inertia (vii) Welding joint efficiency factor.

4. Define the terms: Stress, Strain, Ductility, Rigidity, Elasticity, Creep, Resilience 07

5. Discuss various methods of fabrication and welding of chemical equipments. 07

6. Discuss welding joint efficiency factor. Also discuss Non-destructive examination and repairs of 07

welded seams.

7. Give the full name of ASTM, ASME & HTRI. 03

8. What is design stress and factor of safety? Explain in brief. 03

9. What do you mean by weld joint efficiency factor? Discuss in brief. 04

10. Describe in brief about design pressure & design temperature. 04

11. Define the two most important stresses generated in a thin cylindrical shell and discuss the 07

classification of the unfired pressure vessel as per IS – 2825.

12. Write a short note on corrosion allowance. 04

13. Discuss analytical method for thickness calculation of shell subject to external pressure. 03

14. Discuss about stresses in combined loadings. 07

15. Discuss about design of Elliptical head. 04

16. Discuss about mechanical design of Hemispherical head. 03

17. Discuss about mechanical design of Torispherical head 03

18. Discuss about different types of Flange facings. 04

19. Discuss about different types of standard flanges. 04

20. State and discuss the various types of flanges used in industries. 07

21. Why are gaskets used? Write in brief on various types of gaskets. 07

You might also like

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Dme - QB (Q & A) - Portion After Iat 2 - Unit 3 & 5Document40 pagesDme - QB (Q & A) - Portion After Iat 2 - Unit 3 & 5mnsk mechNo ratings yet

- AssignmentDocument3 pagesAssignmentAviral Sansi0% (1)

- 13 - Introduction To Machine DesignDocument4 pages13 - Introduction To Machine DesignGaikwad AniketNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- DSS QB Unit-3 PDFDocument14 pagesDSS QB Unit-3 PDFDhaladhuli ChekravartyNo ratings yet

- Assignment1pdf 2024 01 09 09 30 35Document1 pageAssignment1pdf 2024 01 09 09 30 35Yash MehtaNo ratings yet

- 1-3-Lubrication-Journal BearingsDocument161 pages1-3-Lubrication-Journal Bearingsfaruk ucarNo ratings yet

- L-4/T-l/MME - Date: 17/02/2018Document12 pagesL-4/T-l/MME - Date: 17/02/2018Utsho DasNo ratings yet

- ME3393 IQ 02 - by LearnEngineering - inDocument10 pagesME3393 IQ 02 - by LearnEngineering - inUrbhi SahaNo ratings yet

- 7083 6799 Cast Bronze Bearing Design ManualDocument72 pages7083 6799 Cast Bronze Bearing Design ManualguilleaguadoNo ratings yet

- NAME-355 Syllabus First HandoutDocument4 pagesNAME-355 Syllabus First HandoutMoynul Hasan RonyNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Anonymous HYxnR9No ratings yet

- Process Equipment Design-I (Mechanical Aspect) : (CET-305) Lecture-7Document33 pagesProcess Equipment Design-I (Mechanical Aspect) : (CET-305) Lecture-7Kakashi 12No ratings yet

- DRCS Important QuestionsxDocument26 pagesDRCS Important QuestionsxcsaNo ratings yet

- Question BankDocument48 pagesQuestion Banksanjai kumarNo ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: InstructionsMamuye Busier YesufNo ratings yet

- Dme-2 byDocument81 pagesDme-2 byHauaisnNo ratings yet

- Unit WI04: Welding Joints, Positions and Symbols: Session 3Document22 pagesUnit WI04: Welding Joints, Positions and Symbols: Session 3danNo ratings yet

- Question Bank: Unit:4 Process Design of AbsorbersDocument1 pageQuestion Bank: Unit:4 Process Design of AbsorbersHitesh VariyaNo ratings yet

- Level VII CE CoursesDocument38 pagesLevel VII CE CoursesGSGSGNo ratings yet

- ME8491 IQ 02 - by LearnEngineering - inDocument10 pagesME8491 IQ 02 - by LearnEngineering - inDr.A.Maniram KumarNo ratings yet

- ME407E - M - DSGNDocument9 pagesME407E - M - DSGNAyush LolusareNo ratings yet

- Welding General ConsiderationsDocument13 pagesWelding General ConsiderationsAbdulhmeed Mutalat100% (1)

- ME3393 IQ 01 2 MARK - by LearnEngineering - inDocument5 pagesME3393 IQ 01 2 MARK - by LearnEngineering - inUrbhi SahaNo ratings yet

- T.E. (Mechanical Engineering) Semester VDocument5 pagesT.E. (Mechanical Engineering) Semester Vmanil patilNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPrabhat SinghNo ratings yet

- Unit WI04: Welding Joints, Positions and Symbols: Session 1Document21 pagesUnit WI04: Welding Joints, Positions and Symbols: Session 1danNo ratings yet

- D.E.I. Faculty of Engineering MEM-103: M P - IDocument6 pagesD.E.I. Faculty of Engineering MEM-103: M P - Ikapil sharmaNo ratings yet

- FDocument58 pagesFAlper DedeNo ratings yet

- Design of Jigs, Fixtures and Press Tools - Department of Mechanical EngineeringDocument8 pagesDesign of Jigs, Fixtures and Press Tools - Department of Mechanical EngineeringLoga Nath100% (2)

- DACDocument180 pagesDACBilly Tan67% (3)

- Question BankDocument7 pagesQuestion Bankjaimin777No ratings yet

- Engg Metallurgy Assign - 10.04.2020 PDFDocument2 pagesEngg Metallurgy Assign - 10.04.2020 PDFGopalakrishnan BalajiNo ratings yet

- T-Sheet 1 - RCDDocument1 pageT-Sheet 1 - RCDHemantNo ratings yet

- 4-Iii Me-Mee214-FmpDocument5 pages4-Iii Me-Mee214-FmpAgnivesh SharmaNo ratings yet

- SDI Steel Deck On Cold-Formed Steel Framing Design ManualDocument16 pagesSDI Steel Deck On Cold-Formed Steel Framing Design ManualWilmerNo ratings yet

- Course Title: Material Science and Strength of Materials Course Code: 4053 Course Category: B Periods/Week: 6 Periods/Semester: 84 Credits: 6Document4 pagesCourse Title: Material Science and Strength of Materials Course Code: 4053 Course Category: B Periods/Week: 6 Periods/Semester: 84 Credits: 6VaisakVenugopalNo ratings yet

- Machine DesignDocument2 pagesMachine DesignRam Sharan PrajapatiNo ratings yet

- Analysis and Design of Joist-GirderDocument42 pagesAnalysis and Design of Joist-Girderadnan-651358No ratings yet

- Pnuematic Riveting MachineDocument49 pagesPnuematic Riveting MachineMAHAMMADRAFEEQ MANVINo ratings yet

- 4 Hours / 100 Marks: Seat NoDocument25 pages4 Hours / 100 Marks: Seat NoPandit BarelaNo ratings yet

- 6.1 Steel Structures Design L T P Period/Week 6 0 0 RationaleDocument23 pages6.1 Steel Structures Design L T P Period/Week 6 0 0 RationaleVishakha PatelNo ratings yet

- Kings: Me1252-Manufacturing Technology - IiDocument7 pagesKings: Me1252-Manufacturing Technology - IiMohan Prasad.MNo ratings yet

- At6601 QBDocument12 pagesAt6601 QBpceautohod100% (1)

- Machine Design EDocument5 pagesMachine Design Eveerendra0% (1)

- Irjet V3i2175Document1 pageIrjet V3i2175AbhayNo ratings yet

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Theory Questions On Machine DesignDocument2 pagesTheory Questions On Machine DesignSushil Kumar SinghNo ratings yet

- B. V. M. Engineering College: Structural Engineering Department SE302 - Basic Structural Design Assignment # 1Document1 pageB. V. M. Engineering College: Structural Engineering Department SE302 - Basic Structural Design Assignment # 1Niyati KoratNo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Machine Design-I 4+1: MEC602 Common With Automobile Engineering ObjectivesDocument1 pageMachine Design-I 4+1: MEC602 Common With Automobile Engineering Objectivesnavneetkpatil8409No ratings yet

- PR8592 WT QB - by WWW - Easyengineering.net IQ QB 1Document7 pagesPR8592 WT QB - by WWW - Easyengineering.net IQ QB 1Payal PatilNo ratings yet

- Dmm1 Lesson PlanDocument65 pagesDmm1 Lesson Planrkadiraj7011100% (1)

- MT I Question BankDocument10 pagesMT I Question BankAnonymous ZB6qyhD6No ratings yet

- Manufacturing Process 1 Question BankDocument11 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Petroleum Refining and Petrochemicals Petroleum Refining and PetrochemicalsDocument9 pagesPetroleum Refining and Petrochemicals Petroleum Refining and PetrochemicalsKartik ChaddarwalaNo ratings yet

- Q.No. Type Section Key/Range MarksDocument3 pagesQ.No. Type Section Key/Range MarksKartik ChaddarwalaNo ratings yet

- Admit Card: Examination Centre: Centre CodeDocument1 pageAdmit Card: Examination Centre: Centre CodeKartik ChaddarwalaNo ratings yet

- Pressure DropDocument4 pagesPressure DropKartik ChaddarwalaNo ratings yet

- Paulo Correa and Alexandra Correa - Introduction To Experimental Aetherometry - Volume IIB: New Energy Physics and The Discovery of Ambipolar EnergyDocument12 pagesPaulo Correa and Alexandra Correa - Introduction To Experimental Aetherometry - Volume IIB: New Energy Physics and The Discovery of Ambipolar EnergySonyRedNo ratings yet

- Mechanical EngineeringDocument9 pagesMechanical EngineeringbilqistazNo ratings yet

- XJTLU - Steelwork CW - Portal Frame (2019-20)Document3 pagesXJTLU - Steelwork CW - Portal Frame (2019-20)FanisNo ratings yet

- 286 293, Tesma409, IJEASTDocument8 pages286 293, Tesma409, IJEASTPavaniNo ratings yet

- Solution Manual For Manufacturing Processes For Engineering Materials 6Th Edition Kalpakjian Schmid 0134290550 9780134290553 Full Chapter PDFDocument36 pagesSolution Manual For Manufacturing Processes For Engineering Materials 6Th Edition Kalpakjian Schmid 0134290550 9780134290553 Full Chapter PDFnick.fleming516100% (17)

- 25 IdeasDocument2 pages25 IdeasAnan BarghouthyNo ratings yet

- Measurement of Force and TorqueDocument33 pagesMeasurement of Force and TorqueKimberly Jade VillaganasNo ratings yet

- Thermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsDocument39 pagesThermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsGregory MacLeodNo ratings yet

- Design HitsDocument45 pagesDesign HitsLuisa Pérez LunaNo ratings yet

- Weight of Block + Weight Added vs. Weight of Pan + Weight AddedDocument1 pageWeight of Block + Weight Added vs. Weight of Pan + Weight AddedJohnoricks Ace Camarillo CatlingNo ratings yet

- Question EngaaDocument32 pagesQuestion EngaaxingchenNo ratings yet

- Figure 1. Drag Coefficient As A Function of SphericityDocument9 pagesFigure 1. Drag Coefficient As A Function of SphericityPAULA ANDREA CARO BAEZNo ratings yet

- Progress Report Week#9 UlubeluDocument6 pagesProgress Report Week#9 UlubelutiantaufikNo ratings yet

- Full ThesisDocument163 pagesFull ThesisRidwan Mohammed NurNo ratings yet

- Tutorial Chapter 02 - AnswerDocument8 pagesTutorial Chapter 02 - AnswerFateh Hakeem100% (4)

- Study The Effect of Angle Dorsiflexion On Bending Stress of Prosthetic PylonDocument18 pagesStudy The Effect of Angle Dorsiflexion On Bending Stress of Prosthetic Pylonsar0000No ratings yet

- ME Chapter 2Document1 pageME Chapter 2allovid50% (2)

- Literature ReviewDocument29 pagesLiterature ReviewAzmil Fishol67% (3)

- Sat Physics Subject Test PDFDocument20 pagesSat Physics Subject Test PDFYash GuptaNo ratings yet

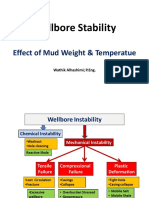

- Wellbore Stability Effect of Mud Weight 1645782860Document27 pagesWellbore Stability Effect of Mud Weight 1645782860Muhammad Husein MahfudzNo ratings yet

- Surface Defects: Grain Boundaries External Surfaces Stacking FaultsDocument14 pagesSurface Defects: Grain Boundaries External Surfaces Stacking FaultsAjeshSomanPulladNo ratings yet

- Problem 3.31 PDFDocument1 pageProblem 3.31 PDFKauê BrittoNo ratings yet

- Reinforced Concrete Structures Design and Drawing: Lecture NotesDocument84 pagesReinforced Concrete Structures Design and Drawing: Lecture Notesshambel asfawNo ratings yet

- Experiments Physics Form 4Document52 pagesExperiments Physics Form 4cikgusya67% (3)

- Vibration Analysis of Rolling BearingsDocument99 pagesVibration Analysis of Rolling BearingsDaniel_Ali_bNo ratings yet

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDocument8 pagesSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- Design of Magneto-Optical Traps For Additive ManufDocument7 pagesDesign of Magneto-Optical Traps For Additive ManufCRISTIAN ROJAS BELTRANNo ratings yet

- UNIT III Properties of Steam and Steam Power CycleDocument8 pagesUNIT III Properties of Steam and Steam Power CycleamdevaNo ratings yet

- Physics Yasir Academy Test (Full Book)Document2 pagesPhysics Yasir Academy Test (Full Book)Dawar ali bhattiNo ratings yet

- Parameters of The PT1 ElementDocument7 pagesParameters of The PT1 Elementputra sandiNo ratings yet