Professional Documents

Culture Documents

EIL Planning Manual

Uploaded by

Ravichandran SundaramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EIL Planning Manual

Uploaded by

Ravichandran SundaramCopyright:

Available Formats

Document No.

PROCEDURE FOR 5-2744-0115

PROGRESS MEASUREMENT Rev. No. 0

Page 1 of 9

PROCEDURE FOR PROGRESS MEASUREMENT

(PLANNING & SCHEDULING DEPARTMENT)

0 31.01.03 Issued for implementation DDC DRC HOD

Rev. No Date Purpose Prepared by Reviewed by Approved by

Template No. 5-0000-0001-T1 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 2 of 9

Abbreviations:

CPS Construction Planning System (Computer Package)

DFR Detailed Feasibility Report

EPCC Engineering, Procurement, Construction and Commissioning Contractor

ETDD Engineering Technology & Development Department

FEED Front End Engineering and Design

FOI Fax of Intent

GPC Group Planning Coordinator

HMTD Heat & Mass Transfer Department

HO Home Office

ITB Invitation to Bids

MR Material Requisition

MSR Material Status Report

PMC Project Management Consultancy

POSD Plant Operation & Safety Department

PPMS Project Progress Measurement System (Computer Package)

SMMS Specialists, Material and Maintenance Services

SOQ Schedule of Quantities

TBA Technical Bid Analysis

WBS Work Breakdown Structure

Document Drafting Committee Members:

Mr. SC Jain

Mr. A Datta

Mr. SP Sinhachoudhary

Mr. Subhash Chandra

Mr. D Deb

Mr. RN Singh

Mr. DV Singh

Document Review Committee Members

Mr. JP Kabra

Mr. SV Narasimham

Mr. VL Rajani

Mr. SS Kaushal

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 3 of 9

CONTENTS

Clause Title Page No.

1.0 PURPOSE 4

2.0 SCOPE 4

3.0 REFERENCE 4

4.0 DEFINITIONS 4

5.0 METHODOLOGY AND CONTROLS 4

5.1 INPUTS REQUIRED 4

5.2 OVERALL PROGRESS 5

5.3 WORK BREAKDOWN STRUCTURE 5

5.4 FUNCTIONWISE PROGRESS 5

5.5 COMPUTATION OF ACTUAL PROGRESS 7

5.6 PROGRESS MEASUREMENT - EIL AS PMC 8

5.7 PROGRESS MEASUREMENT - EIL AS EPCC CONTRACTOR 9

5.8 EIL SERVICES FOR TURNOVER PURPOSES 9

6.0 DOCUMENTATION & RECORDS 9

ANNEXURE.

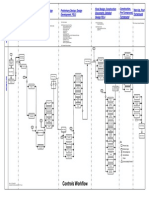

I. Overall Project Progress 2 sheets

II. Progress Milestones for Process Design & POSD 3 sheets

III. Progress Milestones for HMTD 5 sheets

IV. Progress Milestones for Environment 1 sheet

V. Progress Milestones for Engineering (Conventional) 11 sheets

VI. Progress Milestones for Engineering (PMC JOB) 7 sheets

VII. Progress Milestones for Procurement & Tendering 3 sheets

VIII. Progress Milestones for Others 1 sheet

IX. Progress Measurement for Construction 13 sheets

X. WBS for Progress Measurement 3 sheets

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 4 of 9

1.0 PURPOSE

The purpose of this procedure is to define the methodology to be followed to compute schedule

and actual progress percentage of the project during its execution.

2.0 SCOPE

The procedure is applicable for all types of projects.

3.0 REFERENCE

NIL

4.0 DEFINITIONS

NIL

5.0 METHODOLOGY AND CONTROLS

EIL system of progress measurement is based upon the: -

§ Concept of roll-on-off planning as per WBS

§ Weight factor based on effort (manhour or cost)

§ Milestones with prefixed %age progress

Progress Measurement is based on the concept of roll-on-off where weight factor based on effort/

cost is assigned to each activity. Activities are broken into various milestones. Progress

measurement follows the WBS of the project and progress is measured at various levels of WBS.

5.1 INPUTS REQUIRED

Sl. Input Description When required & Source

No Frequency

1 Detailed Feasibility Report Immediately after award Project Manager

indicating cost break up Once

2 Control Manhour of various Within 2 weeks and as & Project Manager

division/ disciplines when revised

3 Drawing & Requisition First issue: within 4 weeks Engineering, Process,

schedule / status Update: Monthly POSD, HMTD,

Environment

4 Execution Methodology/ Within 2 weeks Project Manager

Philosophy / List of Tenders

5 Updated Status of Ordering & Monthly Purchase, Contract

Tendering

6 FOI of order, award of contract As and when ordered / Purchase, Contract

and change awarded

orders/amendments

7 Updated Status of Monthly Inspection

Manufacturing & Delivery

8 Inspection / Expediting report Regular Inspection

9 Contract Document / SOQ As and when prepared Contract

10 Contractor Progress Report Weekly Construction

11 Progress Report from package Monthly Project / Inspection

Vendor / LSTK contractor

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 5 of 9

Sl. Input Description When required & Source

No Frequency

12 Cost data of each requisition / At the beginning & as and Cost Engg.

equipment & Work Contract when updated

based on Feasibility Report

13 Copy of EIL contract with As and when prepared Project

Client

5.2 OVERALL PROGRESS

Two types of Overall Progress are measured.

§ EIL Services Progress

§ Overall Physical Progress

5.2.1 EIL Services Progress

EIL services progress reflects progress of the services provided by EIL and does not include efforts of

any external agencies. Annexure-I gives the guidelines for considering weight factors of various

functions. These weight factors are applicable for grass root plants. In case of modification/ renovation

job, weight factor for functions shall be assigned in the ration of control manhours allocated to each

function by Projects. In case, project consists of multiple units, EIL services progress shall be rolled up

from EIL services progress of individual unit. The weight factor contribution of the units shall be based

on EIL effort and not on unit cost.

5.2.2 Overall Physical Progress

In Overall physical progress of the project, all the efforts contributing to execution/ progress of the

project including the effort of other agencies e.g. vendors, contractors are considered. To calculate the

overall physical progress, weight factors of various functions for different types of projects are given in

Annexure I. In case the event of a project having multiple units, overall physical progress shall be rolled

up from progress of individual unit. The weight factor contribution of each unit to overall physical

progress of the project/complex shall be derived from the estimated cost of the unit.

5.3 WORK BREAKDOWN STRUCTURE

Typical WBS for progress calculation for conventional as well as PMC jobs are attached as Annexure X.

5.4 FUNCTIONWISE PROGRESS

Progress measurement of HO functions (except manufacturing & delivery) is based on direct effort.

Direct efforts in respect of Home Office activities shall be considered for Process, POSD, HMTD,

General Civil, Structural, Architectural Piping, Mechanical Equipment, Rotating Equipment, Pressure

Vessels, Electrical, Instrumentation, Pipeline, Environmental Group, Purchase, and Contracts etc.

These departments constitute majority of Home Office Technical Manhours. Balance technical

departmental manhours viz. Projects, Project Services, HO Construction, SMMS, ETDD etc. shall be

considered as indirect effort and shall not be considered for progress measurement.

5.4.1 Process, HMTD & Engineering

Progress for Process, HMTD and Engineering disciplines are calculated based on deliverables & control

manhour. The Drawing Schedule & Requisition Schedule provided by each department/ discipline shall

be used. Control Manhour allocated to the discipline shall be divided amongst the activities/

deliverables. These activities shall be further broken down to milestones to evaluate the progress of an

activity. Milestones details for various disciplines are given in the Annexure II to VI. The updated

“Drawing Schedule and Requisition Schedule” shall be made available to planning department by

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 6 of 9

respective department/ discipline based on which the progress shall be calculated. The effort of Process

& POSD shall be considered for measuring Process progress while for Engineering, the effort of all

Engineering disciplines and Environment shall be taken into consideration.

When a project comprises of multiple units and a common deliverable is produced, the same shall be

reflected against all concerned units, distributing the effort proportionately, so that realistic progress

against the units is calculated. However, the number of common deliverables may be mentioned against

the unit which contribute the maximum weightage in quantitative status reports to avoid the error in

reporting total deliverables.

5.4.2 Ordering

The list of Material Requisitions shall be provided to Purchase Department by the departments whose

are coordinating/generating the requisition. Purchase Department shall indicate the manhour of each

requisition based on the control manhour. Any additional activities e.g. development of project specific

procedures, vendor list shall also be included and manhour shall be allocated. The progress of each

requisition & other deliverable shall be calculated based on the milestones progress indicated in the

Annexure-VII.

5.4.3 Tendering

Project Manager shall provide the list of the tenders to contract department based upon execution

philosophy. Contract Department shall indicate the manhour allocation against each Tender based on

the control manhour. Any additional activities e.g. development of project specific procedures, pre

qualification of bidders shall also be included and manhour shall be allocated. The progress of each

Tender and other deliverables shall be calculated as per the milestones progress indicated in the

Annexure-VII.

5.4.4 Manufacturing/ Delivery

Manufacturing and delivery progress is calculated based on weighted value on estimated cost. Cost

Engineering Department shall provide the cost data to planning department. Inspection department shall

indicate the list with manhour for project specific. In order to rationalize the weighted value, a factor of

0.6 shall be used for plates, structural steel & bulk materials. The progress of each item & other

deliverable shall be calculated based on the milestones progress indicated in the Annexure-VII.

5.4.5 Progress for Package Items

Progress measurement methodology described here is applicable for vendor package (requisition) as

well as contract package (tender). Overall effort of each package unit is divided into five components

namely Residual Basic Engineering, Engineering, Ordering, Manufacturing & delivery, Construction &

Commissioning. Since the package are treated as a procurement item, hence to integrate the package

progress into overall Progress of the Project, the engineering, ordering and Manufacturing & delivery

progress shall be included in overall Manufacturing & delivery Progress. Construction & Commissioning

progress shall be included in overall construction progress. The weight factor of manufacturing &

construction shall be based on cost and shall be finalised with package contractor during kick-off

meeting.

5.4.6 Construction

For computation of overall construction progress, the weight factors of various contracts shall be

decided based on estimated cost. In case, cost data is not available, weight factors given in Annexure

IX for the construction disciplines may be considered. It is recommended that initially around 5~8% may

be kept as miscellaneous depending upon clarity of construction workload.

For computation of contractor progress, SOQ given in the contract document or estimated quantity (in

case of package contractor) and the manhour data given in Annexure – IX shall be the basis for

calculating the work item wise weighted value of the contractor. The weighted value normally shall not

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 7 of 9

be revised until there is a major change in construction workload / contractor’s scope. Around 5 ~ 10%

of contract weighted value may be kept as miscellaneous depending upon clarity of construction

workload to accommodate any variance in estimated construction workload and the same shall be

adjusted progressively in line with actual progress.

The manhour data given in Annexure – IX shall be used to calculate manhour required for performing

the activity. To calculate weight factor, manhour required shall be converted into standard manhour by

multiplying a conversion factor which is discipline dependent. The manhour of Mechanical works is

treated as standard effort. The manhours of other disciplines are converted into standard effort by

multiplying with the conversion factor as given in Annexure-IX.

The mobilisation by the contractor, which includes construction of office, warehouse, construction water,

construction power, construction equipment, etc., shall be considered in the contractor progress. The

weight factor for mobilisation shall be restricted to 5% of the contractor progress.

The progress of soil investigation, survey by the contractor shall not be considered as progress of

construction. If these activities are prerequisite to engineering activities, the same shall be considered

under engineering progress.

In the item rate contract, the progress of material supply by the contractor such as equipment, piping

materials, electrical/ instrument items shall be included in the construction.

Pre-commissioning & commissioning of the utility package items shall be considered in the construction

progress of the contractor. The weight factor shall be 3~8% of construction progress of the contractor

depending upon complexity.

5.4.7 Pre-commissioning & Commissioning

The progress for pre commissioning/ commissioning shall be reported as per EIL’s scope. The weight

factor shall be around 3% to overall progress. The POSD group shall identify the systems and Planning

Department shall assign weight factor to each system in consultation with POSD. Milestones given in

Annexure-VIII shall be used for progress calculation.

5.5 COMPUTATION OF ACTUAL PROGRESS

Overall progress of process, HMTD & engineering are calculated based on the updated drawing/

requisition schedule. The progress of Ordering, Tendering & Manufacturing / Delivery shall be

calculated based on the milestone achieved. The actual progress is assigned to an activity based on the

quantity/ milestones achieved. The activities not yet started shall have actual percentage progress equal

to 0, where as the completed activities shall have 100% actual progress. If activity has crossed one

milestone and not reached the next milestone, an assessment of percentage progress value can be

made. But in no case, the assessed percentage progress shall be more than the pre-assigned

percentage of next milestone. PPMS (Project Progress Monitoring System) software package shall be

used for HO department/ Disciplines.

Quantity oriented progress measurement is applicable for construction activities. When partial quantities

have been realised, actual progress for work item/ activity shall be percentage ration of the quantity

realised and total quantity. CPS (Construction Planning System) software package shall be used for

construction.

5.5.1 Change in scope

Change in weight factors due to scope change or change in estimated workload will impact actual

progress. In the event of actual progress of a discipline/contractor getting reduced up to 5%, the same

may be adjusted during next 2 to 3 months period. If the reduction in actual progress is more, the same

shall be reported with the approval of the project management. In case of increase in actual progress, it

shall be reflected in the same month with appropriate reason. In case a deliverable with some actual

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 8 of 9

progress has been deleted from the scope, the deliverable shall be retained in the list with weight factor

equivalent to earned value.

5.5.2 Work Front Computation

During construction phase, the work front is computed based on availability of various inputs e.g.

drawings, matching materials, access. For package and LSK contractor, where the engineering and

material supplies are in the scope of the contractor then the front for the same shall be treated as

available, however status of input availability of contractor’s scope shall be obtained from the contractor

for monitoring. The sequence of construction shall not form criteria for reducing work front if the

preceding work is to be carried out by the same agency. The availability of materials like cement, rebar

etc shall not be considered in evaluation the work front availability.

5.6 PROGRESS MEASUREMENT - EIL AS PMC

Where EPCC contractors execute the job and EIL role is PMC, Progress measurement comprises of

two distinct phases:

§ Pre Award Phase

§ Post Award Phase

Pre award and post award are having weightages in the range of 5~10% and 90~95 % respectively for

project physical progress. Progress of EPCC contractor shall be taken for Post award phase. When

more than one EPCC contractors are executing a project, the weighted contribution to overall shall be

factored based on the cost.

Project where development of infrastructure facilities are in the scope of EIL as PMC, Overall progress

may be divided first in categories like, pre project activities & project activities. The weightages of pre

project & project shall be decided based on cost. A typical WBS for the job where EIL is PMC is

attached as Annexure - X

5.6.1 Pre Award Phase

The progress till award of the EPCC shall be considered as the progress of Pre award phase. The effort

during this phase shall be categorised as follows

§ Basic Engineering & Process Design

§ Preparation of FEED (Front End Engineering & Design) package

§ Prequalification of bidders

§ Award of LSTK contract

The progress of process design is to be obtained from Licensors if the process package is being

supplied by licensors and part of the project scope. The progress of EIL process department shall be

considered for the units where EIL is the licensor. The contribution of Process in the pre award stage

may be varying from 25%~40% depending on the scope of EIL in preparing process package. If no

process package is to be developed by EIL and EIL’s scope is limited to the review of process package

received from client the contribution may be taken as around 15%.

The contribution of FEED preparation in the pre award phase shall be considered as 20% ~ 40%

depending upon the scope of EIL. The activities with milestones for progress measurement for various

engineering disciplines during pre award and post award phase are attached as Annexure-VI.

Engineering disciplines progress shall be calculated based on these milestones. The contribution of

contract department during ITB document preparation shall be considered as 15% ~ 20%.

Award of contract for EPCC work contributes around 30% ~ 40% of pre award phase. If pre qualification

of the bidders is to be done, the same can be considered as 15% ~ 20% of pre award phase.

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Document No.

PROCEDURE FOR

5-2744-0115

PROGRESS MEASUREMENT

Rev. No. 0

Page 9 of 9

5.6.2 Post Award Phase

The weight factor of various functions for EPCC contractors shall be finalized in the kick off meeting.

Annexure I may be used for finalizing the same. The progress at execution shall be the same as the

progress of EPCC contract.

5.6.3 Progress of EIL Service s

EIL service progress is to be calculated keeping in mind the effort being put by EIL vis-à-vis its scope of

work. As substantial effort is put by EIL till the award of the contract, pre award phase is around 35% ~

40% whereas post award phase is 60% ~ 65%. Progress of EIL Services shall be measured based

upon control manhours assigned to each department and milestones defined in Annexure- VI.

5.7 PROGRESS MEASUREMENT - EIL AS EPCC CONTRACTOR

The percentage contribution of various functions & the milestones attached in the Annexure may be

used for calculating the percentage progress for the project where EIL is the EPCC contractor.

However, the same shall be finalized with the client during the kick off meeting.

The progress measurement system, where EIL is the LSTK contractor, shall be the same as that of

conventional system described above except the engineering progress measurement. Generally, client

desires to get engineering progress rolled up from the progress of each identifiable deliverables, hence

only the progress of those deliverables to be considered while calculating engineering progress. The

manhour for the activities, where deliverables are not produced (e.g. site visit, coordination etc.), shall

be distributed to the identifiable deliverables by engineering disciplines. The progress of various

deliverables being produced by other departments (e.g. planning documents, project procedures etc)

may also be considered as a part of engineering progress. Milestones for these deliverables are given

in Annexure-VIII.

To avoid any ambiguity at a later date, progress measurement system along with weighted value of

each function & milestones shall be finalized with the client.

5.8 EIL SERVICES FOR TURNOVER PURPOSES

Methodology for computation of EIL services progress by Projects is described in the guideline 8-7700-

0501 for the purpose of working out turnover for lump sum fees, conventional Jobs and PMC jobs by

Account Department.

6.0 DOCUMENTATION & RECORDS

Nil

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Annexure I Document No.

OVERALL PROJECT PROGRESS 5-2744-0115

Rev. No. 0

Page 1 of 2

A. Process Unit

Weighted %age

S.No. Function

Physical Progress EIL Services

1. Process 2 4

2. HMTD 2 4

3. Engineering 10 46

4. Ordering 2 6

5. Manufacturing & delivery 53 7

6. Tendering 1 3

7. Construction 30 30

Total 100 100

B. Utilities & Offsites

Weighted %age

S.No. Function

Physical Progress EIL Services

1. Process 2 4

2. Engineering 10 50

3. Ordering 2 3

4. Manufacturing & delivery 30 5

5. Tendering 1 3

6. Construction 55 35

Total 100 100

C. Pipeline Projects

Weightage %age

S.No. Function Physical Progress EIL Services

1. Process 2 4

2. Engineering 10 50

3. Ordering 2 6

4. Manufacturing & delivery 45 7

5. Tendering 1 3

6. Construction 40 30

Total 100 100

D. Offshore Oil & Gas Projects

Physical Progress (Weightage %age)

S.No. Function Revamp Jobs New Platforms

1. Engineering 9-12% 5-7%

2. Procurement 20-35% 35-45%

3. Fabrication 10-25% 25-35%

4. Transportation 2-5% 2-5%

5. Installation/hook-up/commissioning. 30-50% 15-25%

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

Annexure I Document No.

OVERALL PROJECT PROGRESS 5-2744-0115

Rev. No. 0

Page 2 of 2

E. INFRASTRUCTURE/ ENABLING WORKS

Weightage %age

S.No. Function Physical Progress EIL Services

1. Engineering 3 12

2. Ordering - -

3. Manufacturing & delivery - -

4. Tendering 1 4

5. Construction 96 85

Total 100 100

In case Infrastructure / enabling works involves procurement of materials such as construction

equipments, construction weight factor shall be modified to assign weight factor to procurement

activities.

F. PMC JOBS

S.No. Phase/ Function LSTK Package Engineered Package

Physical EIL Services Physical EIL Services

Progress Progress

1 Pre Award Phase 8 40 11 50

2 Post Award Phase 92 60 89 50

Total PMC Progress 100 100 100 100

S.No. Description Weighted %age

1 Pre Award Phase

Basic Engineering & Process Design 25~40%

Preparation of FEED 20~40 %

Prequalification of Bidders 5~10%

ITB/Award of work 30~40%

2 Post Award Phase

Process & Engineering 8~12%

Ordering 2~3%

Manufacturing/ Delivery 50~55%

Tendering 1%

Construction 25~30%

Commissioning 3~5%

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure II Document No.

PROCESS 5-2744-0115

Pp DESIGN & POSD

Rev. No. 0

Page 1 of 3

S No Activity / Milestones Percentage

1.0 PROCESS DESIGN

1.1 Preparation of Design Basis

- Preliminary draft prepared & issued for internal comments 50

- Internal comments incorporated & final draft for client's approval 70

- Client's approval received & comments incorporated 90

- Final design basis prepared 100

1.2 Preparation of PFDs

- Simulation 50

- Prepare draft PFDs & issued for internal comments 70

- Comments incorporated & issued for client's comments/ approval 90

- Client's comments incorporated & issued for detailed engineering 100

1.3 Preparation of P&IDs

- Issued for internal comments 50

- Comments incorporated & issued for client's comments/ approval 75

- Comments incorporated & issued for engg. 90

- P&IDs signed by client 95

- Updation of P&IDs after HAZOP 100

1.4 Preparation of Data Sheet for Critical Equipments

- Data sheet issued for internal comments 50

- Internal comment incorporated & issued for client's comments 75

- Client's comment incorporated & issued for Engg 95

- Order for equipments placed 100

1.5 Preparation of Data Sheet for Balance Equipment / Instruments

- Preliminary data sheet for comments 80

- Issued for detailed Engg 90

- Revise datasheet after detailed Engg 95

- Order for equipments placed 100

1.6 Equipment List

- Preliminary issued 90

- Equipment list updated during detailed Engg 100

1.7 Preparation of Line List

- Prepare preliminary line schedule 75

- Data w.r.t. Piping specs/ insulation added & issued for Engg 90

- Line schedule updated & issued for construction 100

1.8 LP Modelling for Configuration

- Finalise design philosophy 25

- LP modelling & report 75

- Client's comment incorporation 90

- LP modelling report finalised 100

1.9 Process Package

- Utility summary 10

- Chemical/catalyst consumption 20

- Effluent summary 30

- Process description write up 50

- Supervisory operating instruction 70

- Compile process documents 85

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure II Document No.

PROCESS 5-2744-0115

Pp DESIGN & POSD

Rev. No. 0

Page 2 of 3

S No Activity / Milestones Percentage

- Final process package issued 100

1.10 Process Licensor's Selection

- Prepare NIT 40

- Received Bids 50

- Technical evaluation of bids 75

- Finalise process licensor 100

1.11 Review of Process Package of Licensors

- Finalise design basis 10

- Review of PFD 25

- Review critical data sheets 35

- Review & discussion P&IDs 75

- Review process package 100

1.12 Review of LSTK's documents (EIL as PMC)

- Review basic engineering documents 100

1.13 Coordination 100

2.0 POSD

2.1 Preparation of Design Basis

- Preliminary draft prepared & issued for internal comments 50

- Internal comments incorporated & final draft for client's approval 70

- Client's approval received & comments incorporated 90

- Final design basis prepared & issued for implementation 100

2.2 Preparation of P&IDs (Offsites)

- Issued for internal comments 50

- Internal Comments incorporated & issued for client's approval 75

- Client’s Comments incorporated & issued for Engg 90

- Updation as per detailed Engg 100

2.3 Preparation of Data Sheet for Equipment

- Data sheet issued for comments 75

- Comment incorporated & issued for Engg 95

- Vendor/ engineering comments incorporated 100

2.4 Preparation of Data Sheet for Instruments

- Preliminary data sheet issued for comments 80

- Revision in datasheet after detailed Engg feed back 95

- Revision based on quotation received 100

2.5 Equipment List

- Preliminary issued 75

- Equipment list updated & issued for package 100

2.6 Preparation of Line List

- Prepare line schedule & issued for engg 90

- Line schedule updated based on feed back 100

2.7 Preparation Operating Manual

- Draft operating manual & issued for client's comments 75

- Incorporation of client's comments & final issue 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure II Document No.

PROCESS 5-2744-0115

Pp DESIGN & POSD

Rev. No. 0

Page 3 of 3

S No Activity / Milestones Percentage

2.8 Offsites Package

- Process description write up 40

- Preparation of Utility, Flare & Effluent Summaries 75

- Compile process documents 90

- Final process package issued 100

2.9 HAZOP Study

- Identification of Nodes 10

- Study & draft report issued to client 75

- Review client's comments 80

- Final report issued to client 100

2.10 Risk Analysis (*)

- Internal review & finalisation of modalities 15

- Data Collection, Simulation & Risk Estimation 45

- Issue draft report 75

- Review & incorporate comments 85

- Issue final report 100

(*): Progress distribution would vary case to case basis

2.11 Review of Process P&IDs (Licensor's)

- Review of P&IDs 80

- Discussion for finalisation of comments 100

2.12 Review of LSTK's Documents (EIL as PMC)

Review basic engineering documents for offsites

- P&IDs 5

- Datasheets 10

- Layouts 55

- Operating Manuals 100

2.13 Safety Audit

- Study & Initial preparation 10

- Site Visit 50

- Draft Report 50

- Final Report 100

2.14 Engineering Interaction (Miscellaneous Activities) 100

2.15 Pre-commissioning/ commissioning assistance

- System identification & mark up Progress break

up would

- Preparation of pre commissioning manual including flush in schemes

depend on

- System check listing (issue format II)

number of

- Checklist against format III systems & units

- Pre commissioning coordination (format IV) and site

- Commissioning coordination (format V) conditions

Legends: - Format I: Intimation regarding system completion

Format II: Check list

Format III: Ready for Precommissioining certificate

Format IV: Ready for Commissioning certificate

Format V: Completion of Commissioning Certificate

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure III Document No.

HMTD 5-2744-0115

Rev. No. 0

Page 1 of 5

PERCENTAGE

CONVENTIONAL MRs

S. No ACTIVITY / MILESTONES LSTK PMC

Uneng- JOB JOB

Engineered

ineered

I. HEAT TRANSFER GROUP

EQUIPMENT: EXCHANGERS, AIR COOLERS,

A Design Basis

- Prepare & issue for Comments 75 75 75

- Issued for Client's Approval 90 90 90

- Final issue 100 100 100

B Interface Activities

- Review of Process Data Sheets 100 100 100 100

- Input related to Equipment Layout Purposes 100 100 100 100

- Squad Check (Piping and Structural Drawings) 100 100 100 100

C Equipment Design & Drawings

Thermal Design & Data Sheets.

- Issued For Internal Comments 70 70 70

- Issued for review by Process/Collaborator/ PMC 90 90 90

- Issued For Engg. 100 100 100

Mechanical Design & Drawings

- Issued for Comments 90 90

- Drawings issued for Engg 100 100

D Procurement Activities

- Preparation of Material Requisition, Spec. Feed Package 20 20 20 20

Input

- Issue TQ/ Pre bid Meeting & Issue Of Addenda (In case 30 35 30 35

of PMC Job)

- Issue Of TBA & Addenda (in case of PMC Job) 35 45 35 45

- Issue Purchase Requisition 40 50 - -

Issue Purchase Spec (in case of LSTK Jobs - for PMC - - 50 -

-

Approval)

Issue Purchase Spec (in case of LSTK Jobs - Final - - 60 -

-

issue)

- Review of Contractors Purchase Spec (PMC Job) Code 2 - - - 55

- Review of Contractors Purchase Spec (PMC Job) Code 1 - - - 60

- Vendor Document Review

Calculations - Code 2 - 65 - 65

Calculations - Code 1 - 70 - 70

Drawing Code 2 85 85 85 85

Drawing Code 1 95 95 95 95

Verification of final documents For Completeness and as- 100 100 100 100

built incorporation

E Site Review, Co-ordination & Misc. Activities 100 100 100 100

II. MASS TRANSFER GROUP

EQUIPMENT: TRAYS & TOWER INTERNALS

A Design Basis

- Prepare & issue for comments 75 75 75

- Issued for client's approval 90 90 90

- Final issue 100 100 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure III Document No.

HMTD 5-2744-0115

Rev. No. 0

Page 2 of 5

PERCENTAGE

CONVENTIONAL MRs

S. No ACTIVITY / MILESTONES LSTK PMC

Uneng- JOB JOB

Engineered

ineered

B Interface Activities

- Review of process data sheets 100 100 100 100

- Squad check (Piping and Pr. Vessel drawings) 100 100 100 100

- Input related to equipment layout purposes 100 100 100 100

C Equipment Design & Drawings

Hydraulic Design & Data Sheets.

- Issued for internal comments 70 70

- Issued for review by Process/Collaborator/PMC 90 90

- Issued for Engg. 100 100

Mechanical Design and Drawings

Tray Support Rings (TSR) & Bolting Bar Drawings

- Prepare drawing & issued for comments 70 70

- Release drawings for procurement 90 90

- Updation of drawing & final issue 100 100

General arrangement drawings (GAD)

- Prepare GA drawing & issued for comments 65 65

- Release drawings for procurement 95 95

- Updation of drawing & final issue 100 100

D Procurement Activities

- Preparation of material requisition/ spec/ feed package 20 20 20 20

input

- Issue TQ/ Pre bid meeting & issue of addenda (in case of 30 35 30 35

PMC job)

- Issue of TBA & addenda (in case of PMC job) 35 45 35 45

- Issue Purchase Requisition 40 50 - -

- Issue purchase spec (in case of LSTK jobs - for PMC - - 50 -

approval)

- Issue purchase spec (in case of LSTK jobs - Final issue) - - 60 -

- Review of contractors purchase spec (PMC job) code 2 - - - 55

- Review of contractors purchase spec (PMC job) code 1 - - - 60

- Vendor Document Review/Approval

Calculations - Code 2 - 65 - 65

Calculations - Code 1 - 70 - 70

Drawing Code 2 85 85 85 85

Drawing Code 1 95 95 95 95

- Verification of final documents for completeness and as- 100 100 100 100

built incorporation

E Site Review, Co-Ordination and Misc. Activities 100 100 100 100

III. SYSTEM GROUP

EQUIPMENT: EJECTORS, WASTE HEAT RECOVERY BOILER

A Design Basis

- Prepare & issue for comments 75 75 75

- Issued for client's approval 90 90 90

- Final issue 100 100 100

B Interface Activities

- Review of process data sheets 100 100 100 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure III Document No.

HMTD 5-2744-0115

Rev. No. 0

Page 3 of 5

PERCENTAGE

CONVENTIONAL MRs

S. No ACTIVITY / MILESTONES LSTK PMC

Uneng- JOB JOB

Engineered

ineered

- Input related to equipment layout purposes 100 100 100 100

- Squad check (Piping and structural drawings) 100 100 100 100

C Equipment Design & Drawings

Thermal Design & Data Sheets.

- Issued for internal comments 70 70 70

- Issued for review by Process/Collaborator/PMC 90 90 90

- Issued for Engg. 100 100 100

Mechanical Design And Drawings

- Issued for comments 90 90

- Drawings issued for Engg 100 100

D Procurement Activities

- Preparation of material requisition/ spec/ feed package 20 20 20 20

input

- Issue TQ/ Pre Bid meeting & issue of addenda (in case 30 35 30 35

of PMC job)

- Issue of TBA & addenda (in case of PMC job) 35 45 35 45

- Issue Purchase Requisition 40 50 - -

- Issue purchase spec (in case of LSTK jobs - for PMC - - 50 -

approval)

- Issue purchase spec (in case of LSTK jobs - Final issue) - - 60 -

- Review of contractors purchase spec (PMC job) code 2 - - - 55

- Review of contractors purchase spec (PMC job) code 1 - - - 60

- Vendor Document Review

Calculations - Code 2 - 65 - 65

Calculations - Code 1 - 70 - 70

Drawing Code 2 85 85 85 85

Drawing Code 1 95 95 95 95

- Verification of final documents for completeness and as- 100 100 100 100

built incorporation

E Site Review, Co-Ordination And Misc. Activities 100 100 100 100

IV. HEATER GROUP

EQUIPMENT: FIRED HEATERS, BURNERS, APH

A Design Basis

- Prepare & issue for comments 75 75 75

- Issued for client's approval 90 90 90

Final issue 100 100 100

B Interface Activities

- Review of process data sheets 100 100 100 100

- Input related to equipment layout purposes 100 100 100 100

- Squad check (Piping and structural drawings) 100 100 100 100

Equipment Design & Drawings

C

Thermal Design & Data Sheets.

- Release of API datasheets for comments 45 45 45

- Release of APH P&IDs (if applicable) for comments 55 55 55

- Release of auxiliary datasheets for comments 65 65 65

- Release of utility and gaseous effluent data 75 75 75

- Release of above docs for Process/ Licensor PMC 85 85 85

approval

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure III Document No.

HMTD 5-2744-0115

Rev. No. 0

Page 4 of 5

PERCENTAGE

CONVENTIONAL MRs

S. No ACTIVITY / MILESTONES LSTK PMC

Uneng- JOB JOB

Engineered

ineered

- Final issue of above docs 90 90 90

- Final issue of operating manual 100 100 100

Mechanical / Structural Design

- Mechanical Design 30 20

- Heater Design, Structural Design, Duct Design & FLP 100 100

Engg Drawings

- Issued for Tender/Comments 60 60

- Issued for Engg/AFC drawings with hold 80 80

- AFC with B.O. details 95 95

- Updated AFC 100 100

MR Without MR With

D Procurement Activities

VPC VPC

- Preparation of Material Requisition/Spec/Feed Package 50 30 30 30

input

Issue TQ/ Pre bid meeting & issue of addenda (in case of 70 40 40 40

-

PMC job)

- Issue of TBA & addenda (in case of PMC job) 90 45 45 45

- Issue Purchase Requisition 100 50

Issue purchase spec (in case of LSTK jobs - for PMC - - 50 -

-

approval)

- Issue purchase spec (in case of LSTK jobs - Final issue) - - 55 -

- Review of contractors purchase spec (PMC job) code 2 - - - 55

- Review of contractors purchase spec (PMC job) code 1 - - - 60

- Vendor Document Review

Calculations - Code 2 - 70 - 70

Calculations - Code 1 - 75 - 80

Drawing Code 2 - 85 85 85

Drawing Code 1 - 95 95 95

Verification of final documents for completeness and as- - 100 100 100

-

built incorporation

E Site Review, Co-ordination and Misc. Activities 100 100 100 100

V. SYSTEMS

Systems: Flue Gas Desulphurisation, Water De-oxygenation System, Gas Dehydration, De-aerator,

Separators, De-NOx, Heater Treater, Desalter, Water Bath Heater, SRU Incineration System And Mixing

Chamber

A Design Basis

- Prepare & issue for comments 75 75 75

- Issued for client's approval 90 90 90

Final issue 100 100 100

B Interface Activities

- Review of process data sheets 100 100 100 100

- Input related to equipment layout purposes 100 100 100 100

- Squad check 100 100 100 100

C Equipment Design & Drawings

Thermal Design & Data Sheets.

- Equipment Data Sheets for Comments 45 45

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure III Document No.

HMTD 5-2744-0115

Rev. No. 0

Page 5 of 5

PERCENTAGE

CONVENTIONAL MRs

S. No ACTIVITY / MILESTONES LSTK PMC

Uneng- JOB JOB

Engineered

ineered

- PFD, P&IDs for comments 60 60

- Process Data Sheets for Instruments and Line List 75 75

Release of above docs for Process/ Licensor/ PMC

- approval 85 85

- Final issue of above docs 90 90

- Issue of operating manual 100 100

Mechanical Design/ Drawings

- Issued for comments 70 70

- Final issue 100 100

D Procurement Activities

Preparation of material Requisition/Spec/Feed Package

- 20 20 20 20

input

Issue TQ/ Pre Bid meeting & issue of addenda (in case of

- 30 35 30 35

PMC job)

- Issue of TBA & addenda (in case of PMC job) 35 45 35 45

- Issue Purchase Requisition 40 50 - -

Issue purchase spec (in case of LSTK jobs - for PMC

- - - 50 -

approval)

- Issue purchase spec (in case of LSTK jobs - Final issue) - - 60 -

- Review of contractors purchase spec (PMC job) code 2 - - - 55

- Review of contractors purchase spec (PMC job) code 1 - - - 60

- Vendor Document Review/ Approval

Calculations - Code 2 - 65 - 65

Calculations - Code 1 - 70 - 70

Drawing Code 2 85 85 85 85

Drawing Code 1 95 95 95 95

Verification of final documents for completeness and as-

- 100 100 100 100

built incorporation

E Site Review, Co-ordination and Misc. Activities 100 100 100 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure IV Document No.

ENVIRONMENT 5-2744-0115

Rev. No. 0

Page 1 of 1

S.NO. ACTIVITY/MILESTONES PERCENTAGE

A WASTE WATER TREATMENT

Process Package

- Design Basis Formulation 25

- Approval of Design Basis by Client, if Required 35

- Prepare Process Package 100

Tendering

- Prepare Technical Part of Bid Document 15

- 1st TQ and Addendum 40

- Prepare TBA 70

- Award of Contract 75

- Review of Vendor Drawing/Documents 100

B WATER TREATMENT

Process Package

- Design Basis Formulation 25

- Approval of Design Basis by Client, if Required 35

- Prepare Process Package 100

Tendering

- Prepare Technical Part of Bid Document 15

- 1st TQ and Addendum 40

- Prepare TBA 70

- Award of Contract 75

- Review of Vendor Drawing/Documents 100

C EIA STUDIES

- Collection of Inputs 10

- Engage Agency for Study 25

- Compilation of Data 40

- Preparation of Impact Assessment Report – Draft 85

- Finalise Impact Assessment Report 90

- Participation in Public Hearing 95

- Presentation to the Ministry/ Pollution Board 100

D SOLID WASTE MANAGEMENT

Process Package

- Inventory Management (Identification, Quantify Etc.) 30

- Prepare Process Package 100

Tendering

- Prepare Technical Part of Bid Document 15

- 1st TQ and Addendum 40

- Prepare TBA 70

- Award of Contract 75

- Review of Vendor Drawing/Documents 100

E COMMISSIONING ASSISTANCE 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 1 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

1.0 PIPING DEPARTMENT

1.1 ENGINEERING FOR CONSTRUCTION

1.1.01 Design Basis for Units & Offsite

- Drafting/Study Completed 60

- Preparation & Issue for Comments/Internal Review 90

- Incorporation of Comments & issue for Engg/ Modelling 100

1.1.02 P&ID Review for Units & Offsite

- Checking/Review Completed 100

1.1.03 Equipment Layouts & Elevations for Unit

- Drafting/Study Completed for Package input completed 60

- Checking/Review Completed 75

- Preparation & issue for Comments/Internal Review 85

- Issued for Construction Withhold 90

- Issued for Construction Without Hold 100

1.1.04 Key Plan for Units & Offsite

- Drafting/Study completed for Package input compiled 60

- Checking/Review Completed 75

- Issued for Engineering Without Hold 100

1.1.05 Escape Routes & Safety Equipment Layouts (For Platforms)

- Drafting/Study completed for Package input compiled 60

- Checking/Review Completed 75

- Issued for Engineering Without Hold 100

1.1.06 Piping Studies for Units/Platform/Offsite

- Drafting/Study completed for Package input compiled 60

- Checking/Review Completed 75

- Incorporation of Comments & issue for Engg/ Modelling 100

1.1.07 Nozzle Orientation

- Preparation Review And Comments (Where Applicable) 75

- Incorporation of Comments & issue for Engg/ Modelling 100

1.1.08 Piping Gads for Units/Offsite

- Extraction and Labelling Completed 70

- Checking/Review Completed 90

- Issued for Construction With Hold 95

- Issued for Construction Without Hold 100

1.1.09 Underground Piping/Unit (On AutoCAD)

- Drafting/Study completed for Package input compiled 60

- Checking/Review Completed 75

- Incorporation of Comments & issue for Engg/ Modelling 100

1.1.10 Support GAD’s for Platforms

- Drafting/Study completed for Package input compiled 75

- Issued for Construction Without Hold 100

1.1.11 IBR Steam System ISO/Package Preparation For Units & Offsite

- Extraction and Labelling Completed 40

- Checking/Review Completed 60

- Preparation & Issue for Approval 80

- Final Issue 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 2 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

1.1.12 Steam Tracing (Incl. System Study) For Units & Offsite

- Drafting/Study completed for Package input compiled 40

- Checking/Review Completed 65

- Modelling Completed 85

- Issued for Construction Without Hold 100

1.1.13a Pipe Support including Specials for Units & Offsite

- Preparation & Issue for Comments/Internal Review 80

- Incorporation of Comments & issue for Engg/ Modelling 100

1.1.13b Pipe Supports Cleats for Units & Offsite

- Preparation & issue for Comments/Internal Review 80

- Incorporation of Comments & issue for Engg/ Modelling 100

1.1.14 Piping Specs & Catalogues Creation for Units/Platform/Offsite

- Spec Loading Completed 50

- Remaining 50% shall be linked with progress of line modelling 100

1.1.15 Equipment Modelling (Computerised)

- Modelling Completed 100

1.1.16 Line Modelling

- Modelling Completed 100

1.1.17 Line ISOS/Vessel Trims

- Review & Support Marking 50

- Support Marking & Comments Incorporated* 100

1.1.18 Isometrics – Jacketed Lines

- Drafting/Study completed or Package input compiled 60

- Checking/Review Completed 75

- Support Marking & Comments Incorporated 90

- Issued for Construction Without Hold* 100

* (Including Process Comments if Required)

1.1.19 Interference Checking

- To be linked with Line Modelling Progress

1.1..20 Package Units Coordination

- Package Input Compiled 20

- Checking/Review Completed 90

- Final Review 100

1.2.0 ENGINEERING FOR PROCUREMENT

1.2.01 Material Specification 100

- Issued for Engineering Without Hold

1.2.02 MRs (No. Piping TBA) For Units/Offsite/Platforms

- Preparation of Requisition 100

1.2.03 MR, TQ, TBA, PR & Drawing Approvals

- Preparation of Requisition 45

- Technical Evaluation Completed 70

- Preparation of PR 85

- Vendor Drawing Review Completed 100

1.2.04 MTO Summary & IPMCS Data Management & Reporting

- MTO - Preliminary 30

- MTO - Intermediate 70

- MTO - Final 90

- Reconciliation Completed 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 3 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

1.2.05 Tenders-Fabrication/Erection Insulation & Painting

Fabrication/Erection (40%)

- Input given 60

- Technical Evaluation Completed 80

- First Revised SOQ given 90

- Second Revised SOQ given 100

Insulation Tender (30%)

- Input given 60

- Technical Evaluation Completed 80

- First Revised SOQ given 90

- Second Revised SOQ given 100

Painting Tender (30%)

- Input given 60

- Technical Evaluation Completed 80

- First Revised SOQ given 90

- Second Revised SOQ given 100

1.2.06 Input to Tender Civil/Structural/ U/G Piping

- Input Given 100

1.2.07 MTO for Piping Supports for Units/Offsite/Platforms

Material List Prepared/ Input Given 100

1.3.0 Piping Stress for Units/Offsite/Platforms

1.3.01 Flexibility Analysis, Spring Support Design & Other 100

1.4.0 Others

1.4.01 Weight Control Report for Platforms 100

1.4.02 Field Engineering & S.B. ISO Checking 100

1.4.03 As Built (GAD’s & Isometrics) 100

1.4.04 Site Visits – To be linked with Overall Progress 100

1.4.05 Supervision – To be linked with Overall Progress 100

2.0 MECHANICAL EQUIPMENT DEPARTMENT

2.1 Engineering for Procure ment

2.1.01 Requisition for Any Item/Package

- Issue of MR 40

- Issue of TBA 65

- Issue of PR 75

- Vendor Drawing Review (Review Code-2) 90

- Vendor Drawing Review (Review Code-1) 100

2.1.02 Layout Drawings

- Study and Drafting 50

- Checking 60

- Issue for Internal Coordination 70

- Issued for Engineering 90

- Issued for Construction 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 4 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

3.0 ROTATING EQUIPMENT DEPARTMENT

3.1.0 Engineering for Procurement

- Issue of MR 25

- Issue of TBA 65

- Issue of Purchase Requisition 80

- Vendor Drawing Review (Review Code-2) 90

- Vendor Drawing Review (Review Code-1) 100

4.0 PRESSURE VESSEL DEPARTMENT

4.1 Reactors, Towers, Vessels etc.

- Design 10

- Drafting of mechanical data sheet 20

- Issue of MR 30

- Issue of TBA 45

- Issue of Purchase Requisition 50

- Issue of Nozzle Orientation 60

- Vendor drawing review (pipe/strl. Cleats under Hold) (Review Code-2) 85

- Vendor drawing review (Without Holds) (Review Code-2) 95

- Vendor drawing review (Review Code-1) 100

4.2 Tanks and Spheres.

- Design (with MTO requirement) 20

- Design (without MTO requirement) 30

- MTO & Issue of MR for Plates 35

- Drafting of tender drawing 40

- Issue of drawings with Tender/ Package 45

- Issue of Tender/Package Specification 50

- Issue of TBA 60

- Issue of Nozzle Orientation 65

- Vendor drawing review (Pipe/ Strl. Cleats under hold)(Review Code-2) 85

- Vendor drawing review (Without holds) (Review Code-2) 95

- Vendor drawing revi ew (Review Code-1) 100

4.3 Double walled Storage Tanks

- Drafting of drawing 10

- Issue of Drawings for tender 15

- Issue of Tender Specification 35

- Issue of TBA 50

- Issue of Construction Drawings and agreed variations 55

- Vendor drawing review (Review Code-2) 95

- Vendor drawing review (Review Code-1) 100

4.4 Package – Un Engineered

- Issue of tender Specifications 60

- Issue of TBA 80

- Design Review Complete 100

4.5 Engineered Package 25

- Drafting of drawing 45

- Issue of Drawings for package 60

- Issue of Package Specifications 70

- Issue of TBA 80

- Vendor drawing review (Review Code-2) 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 5 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

5.0 GENERAL CIVIL DEPARTMENT

5.1 Engineering for Construction

5.1.1 Overall Plot Plan

- Study & Issue for Inter Department Coordination 50

- Presentation to Plot Plan Committee 75

- Presentation to HAZOP Committee 80

- Issued for Client’s Approval 85

- Issued for Engineering/Construction (With Hold) 90

Issued for Engineering/Construction (Without Hold) 100

5.1.2 Basic Engg/P&IDs, Layout/Drawings & Detailed Engg.

Study & Issue for Inter Department Coordination 60

Issued for Engineering/Construction (With Hold) 80

Issued for Engineering/Construction (Without Hold) 100

5.1.3 Offsite Area Drawings

Road, Tankages KS, Bldg, Comp. Wall, CW Drg, Cable TR, S/S, TKPD. 35

Cable Layout, ERCS/IRC and Pipe ways 45

Fire Water, Drinking water, Service Water, Cooling Water (WF, WDK, 65

WCS & WS Lines)

OWS System, Sanitary Waste System & Chemical Sewer System 85

Approach, FT Path, Parking & Building Drawing Hook Up 95

Issue Incorporating Field Changes 100

5.1.4 Statutory Approvals

Package Submitted For Approval 70

Discussion With Statutory Bodies 80

Comments Incorporated And Issue For Engineering & Construction 100

5.2 Engineering For Procurement

5.2.1 Requisition Tender

Issue of MR 50

Issue of TBA 60

Issue of PR 70

Vendor Drawing Review (Review Code-2) 90

Vendor Drawings Review (Review Code-1) 100

5.2.2 Material Take-Off

MTO – 0 30

MTO – Preliminary 60

MTO – Intermediate 90

MTO – Final 100

5.2.3 Item Rate Tenders

Issue of Specification and Schedule of Rates 80

Technical Acceptance of Bids 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 6 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

6.0 STRUCTURAL DEPARTMENT

6.1 Engineering for Construction

6.1.1 Drawing Without 3D With 3D

Modelling Modelling

- Conceptual Study 5 5

- Modelling for Analysis 25 25

- Analysis & design 30 30

- Model Updation (from Staad) - 40

- Drawing Extraction - 45

- Drafting Complete/AUTOCAD editing 60 60

- Checking Complete 65 65

- Issued for Comments 80 80

- Issued for Construction (with holds) 85 85

- Issued for Construction (without holds) 100 100

6.2 Engineering For Procurement

6.2.1 Material Take-Off 30

- MTO – 0 60

- MTO – Preliminary 80

- MTO – Intermediate 100

- MTO – Final

6.2.2 Packages OED Other Project

- Issue Of Package Specification 45 25

- Issue TBA 50 30

- Contractor’s Drawing Review (Code-2) 90 90

- Contractor’s Drawing Review (Code-1) 100 100

6.2.3 Item Rate Tender

- Issue of Specification and Schedule of Rates 90

- Technical acceptance of Bids 100

6.3 Geo Technical

6.3.1 Soil Investigation

Study of available information and Planning 10

- Issue of Tender Specification 20

- Issue of TBA 30

- Technical Support during field Work 50

- Review of report and formulation of Foundation Design 75

- Interaction with other Disciplines during Engineering 100

6.3.2 Piling / Ground Treatment

- Preliminary Engineering and Planning 20

- Issue of Tender Specification 30

- Issue of TBA 40

- Interaction with other Disciplines during Engineering 65

- Technical Support during Field Installations, Load Testing and 100

Performance Monitoring

6.3.3 Foundation Engineering

- Preliminary Engineering & Concept ional Design 20

- Issue of Tender Specification 40

- Detailed Engineering and Design Review 80

- Technical Support during Construction and Installation 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 7 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

7.0 ARCHITECTURE DEPARTMENT

7.1 Engineering for Construction

7.1.1 Basic Drawings

- Preliminary Design Drawings Issued to Client for Comments/Approval 60

- Client Approval Received, Comments Incorporated & Issued for Internal 80

Comments

- Comment Incorporated & Issued for Tender 100

7.1.2 Detailed Drawings

- Drafting Completed 60

- Checking Completed 70

- Back Marking & Issue for Comments/Engineering 90

- Comments Incorporated & Issued for Construction 100

7.1.3 Statutory Approvals

- Package Submitted for Approval 80

- Comments Incorporated & Issued for Engg. & Construction 100

7.2 Engineering For Procurement

7.2.1 Tenders

- Issue of Specification and Schedule of Rates 90

- Technical Acceptance of Bids 100

7.2.2 Packages

- Issue of Package Specification 50

- Issue of TBA 70

- Contractor’s Drawing Review (Code-2) 90

- Contractor’s Drawing Review (Code-1) 100

7.3.0 Architectural Drawings for Pipeline

- Issued for Client’s approval 20

- Client Approval Received, Comments Incorporated & Issued for Internal 30

Comments

- Comment Incorporated & Issued for Tender 40

- Issued for Detailed Engineering 70

- Issued for Construction 90

- Revised & issued for Construction 100

8.0 ELECTRICAL DEPARTMENT

8.1 Basic Engineering

8.1.1 Main Single Line Diagram (SLD), Relay Metering & Review Co-

Ordination Diagram

- Preliminary Issue 60

- Issued for Approval 75

- Issued for Engineering (With Holds) 90

- Issued for Engineering (Without Holds) 100

8.1.2 Load Summary

- Preliminary Issue 75

- Final Issue 100

8.1.3 System Studies

- Preliminary Issue 75

- Final Issue 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 8 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

8.1.4 Area Classification

- Issued for Approval 75

- Issued for Engineering (With Holds) 90

- Issued for Engineering (Without Hold) 100

8.1.5 Cable Schedules/Miscellaneous Schedules

- Drafting Completed 60

- Issued for Construction Planning 75

- Issued for Construction (With Holds) 90

- Issued for Construction (Without Holds) 100

8.1.6 Interconnection Diagram

- Drafting Completed 75

- Issued for Construction (With Holds) 90

- Issued for Construction (Without Holds) 100

8.1.7 Layouts

- Drafting Completed 70

- Checking and Issue for Coordination 80

- Issued for Construction (With Holds) 90

- Issued for Construction (Without Holds) 100

8.1.8 Switchgear SLD & Schematics

- Issued with MR 65

- Issued with PR (With Holds) 80

- Issued with PR (Without Holds) 100

8.2 Engineering for Procurement

8.2.1 Requisition/Package (With Vendor Drawings Review)

- Issued for Enquiry 40

- Issue of TQ 65

- Issue of TBA 70

- Issue of Purchase Requisition 80

- Vendor Drawing Review (Review Code-2) 90

- Vendor Drawings Review (Review Code-1) 100

8.2.2 Requisition/Package (Without Vendor Drawings Review)

- Issued for Enquiry 50

- Issue of TQ 70

- Issue of TBA 90

- Issue of Purchase Requisition 100

8.2.3 Package of Other Departments

- Issued of Inputs 40

- Issue of TQ 50

- Issue of TBA 60

- Issue of Purchase Requisition Inputs 80

- Vendor Drawing Review Complete 100

8.2.4 Tender Documents

- Issue of Tender Spec and Schedule Of Rates 90

- Technical Acceptance of Bids 100

8.2.5 Material Take Off (Purchase

- Preliminary Issue 75

- Final Issue 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 9 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

8.2.6 Material Take Off (Tender

- Estimate at Issue of Tender 80

- Issue at Contract Award 90

- Final Issue for Site Construction 100

9.0 INSTRUMENTATION DEPARTMENT

9.1 Engineering for Construction

9.1.1 Instrument Index

- P&ID Data Entry Complete 50

- Data Filled (Stage- I) 70

- Data Filled (Stage- II) 90

- Issued for Construction 100

9.1.2 Drawings/Documents Other Than Instrument Index

- Study Complete 20

- Drafting Complete 50

- Checking Complete 80

- Back Marking & Issue for Comments 90

- Issued for Construction 100

9.1.3 Job Installation Standards

- Draft Completed 95

- Issue for Construction 100

9.2 Engineering For Procurement

9.2.1 Requisition (With Vendor Drawing Review)

- Issue of MR 40

- Issue of TBA 70

- Issue of Purchase Requisition 80

- Vendor Drawing Review (Review Code-2) 90

- Vendor Drawings Review (Review Code-1) 100

9.2.2 Requisition (Without Vendor Drawing Review)

- Issue of MR 40

- Issue of TBA 70

- Issue of Purchase Requisition 100

9.2.3 Distributed Control System

- Issue of MR 40

- Issue of TBA 50

- Issue of Purchase Requisition 70

- Engineering Inputs to Vendor 80

- Vendor Drawing Review 95

- Completion of Factory Acceptance Tests 100

9.2.4 Bill Of Material/Material Take Off

- First MTO/BOM 50

- Second MTO/BOM 90

- Issue for Construction 100

9.2.5 Tenders

- Issue of Specification and Schedule of Rates 85

- Technical Acceptance of Bids 100

9.2.6 Packages

- Issue of Inputs 40

- Issue of TBA 60

- Drawing Review Complete 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 10 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

9.2.7 Drawings and Documents For Engineering

- Study Complete 20

- Drafting Complete 50

- Checking Complete 80

- Back Marking & Issue for Comments 90

- Issued For Engineering 100

10.0 PIPELINE ENGINEERING DEPARTMENT

10.1 Engineering for Construction

10.1.1 Pipeline Route Engineering/Route Maps

- Preliminary Location Marking on Paper Maps 25

- Reconnaissance 45

- Route Optimisation Report 60

- Final Marking 70

- Issue for Survey 80

Approval for Survey/Finalisation of Survey Report 100

10.1.2 Alignments Sheets/Crossing Drawings

Drafting Complete 75

Checking Complete 85

Back Marking & Issue for Comments 90

Issued for Construction 100

10.1.3 Study Drawings 80

Issue for Comments 100

Issued for Engineering

10.1.4 Nozzle Orientation

Issue for Comments 75

Issued for Engineering 100

10.1.5 Equipment Layout

Drafting Complete 50

Checking Complete 60

Back Marking & Issue for Comments 85

Issued for Engineering 90

Issued for Construction 100

10.1.6 General Arrangement Drawing/Riser Drawing

/ Miscellaneous Installation Drawing

Drafting Complete 50

Checking Complete 70

Back Marking & Issue for Comments 85

Updated & Issued for Construction 100

10.1.7 Analysis Report

Issue for Comments 80

Incorporation of Comments & Final Issue 100

10.2 Engineering For Procurement

10.2.1 Material Specification

st

Preparation & 1 Issue for Engineering 90

nd

Preparation & 2 Issue for Engineering 100

10.2.2 MTO

Preparation 80

Summary Output Generation and Issue 90

Material Reconciliation 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure V Document No.

ENGINEERING 5-2744-0115

(Conventional) Rev. No. 0

Page 11 of 11

S.NO. ACTIVITY/MILESTONES PERCENTAGE

10.2.3 Tenders

Issue of Specs and Schedule of Rates 90

Technical Acceptance of Bids 100

10.2.4 Requisition

- Issue of MR 40

- Issue of TQ 50

- Issue of TBA 60

- Issue of PR 70

- Vendor Drawing Review (Review Code-2) 90

- Vendor Drawing Review (Review Code-1) 100

10.2.5 Design Basis

- Issue for Comments 80

- Issued for Engineering 100

10.2.6 Support Index

- Issued for Construction 100

10.2.7 Pipeline Schematic

- Issue for Comments 80

- Issue for Engineering 100

10.2.8 Load Data

- Issue for Engineering 100

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure VI Document No.

ENGINEERING 5-2744-0115

(PMC JOB) Rev. No. 0

Page 1 of 7

S.No. Department/Activity PERCENTAGE

1 Discipline – Piping 100.0

1.1 Pre-Award Stage 28.0

1.1.A Basic Engineering & Design Basis 3.0

1.1.A.1 Engineering Design Basis 1.5

1.1.A.2 Review of Process Packages 1.5

1.1.B Preparation of FEED-Units 21.0

1.1.B.1 Scope of Work 1.5

1.1.B.2 PMS & VMS 5.0

1.1.B.3 Scope Drawing Showing Orientation / Broad Location of Tie-in Points

for Process / Utility Lines, Underground Facilities, Electrical / 1.5

Instrument Trays

1.1.B.4 Proposed Equipment Layout & Critical Piping Studies 10.0

1.1.B.5 Pipe Rack Size and Cross Section showing no. of Tiers and B.L.

3.0

drawings

1.1.B1 Preparation of FEED-Offsites 21.0

1.1.B1.1 Scope of Work 1.5

1.1.B1.2 PMS & VMS 5.0

1.1.B1.3 Scope Drawing Showing Orientation / Board Location of Tie-in Points

for Process / Utility Lines, Underground Facilities, Electrical / 1.5

Instrument Trays

1.1.B1.4 Hook Up Drawing for Process and Utility Lines 4.0

1.1.B1.5 Piping Corridor Layout Including Size of Sleepers & Cross Section of

4.0

Pipe Rack and Flare Trestle Layout

1.1.B1.6 Planimetric Layout of Major Process and Utility Lines (Off-Site) 5.0

1.1.C After Issue of FEED 4.0

1.1.C.1 Prebid Meeting / Queries 1.5

1.1.C.2 Evaluation of Bids Including Issue of Tech. Addendum / TQ / TBA 2.5

1.2 Post -Award Stage 72.0

1.2.A Approval of Engineering Drawings / Documents of contractor 10.0

1.2.A.1 System Design in code 2 1.2

1.2.A.2 Procurement Engineering in code 2 4.4

1.2.A.3 Detailed Engineering in code 2 2.4

1.2.A.4 Approval for above Drawings / Documents in code 2 2.0

1.2.B Review of Contractors Engg. Drawing / Documents 59.0

1.2.B.1 System Design in code 2 4.0

1.2.B.2 Procurement Engineering in code 2 4.8

1.2.B.3 Detailed Engineering in code 2 39.2

1.2.B.4 Review of above Drawing / Documents in code 2 11.0

Review of Final Documents and Drawings List with respect to

1.2.C 3.0

Completeness of Engineering

2 Discipline - Mechanical Equipment 100.0

2.1 Pre-Award Stage 45.0

2.1.A Basic Engineering & Design Basis 15.0

2.1.A.1 Engineering Design Basis 5.0

2.1.A.2 Review of Process Packages (Process Design Basis, Process Data

5.0

Sheets & Process P&ID'S)

2.1.A.3 Basic Engineering 5.0

2.1.A.3.i Furnishing of Preliminary Electrical Load, Utility Data etc. 5 (2)

2.1.A.3.ii Preliminary System Study (for Material Handling, Solid Sulphur

0 (3)

Disposal and other similar Packages etc) as applicable

2.1.B Preparation of FEED 20.0

2.1.B.1 Scope of Work 1.0

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure VI Document No.

ENGINEERING 5-2744-0115

(PMC JOB) Rev. No. 0

Page 2 of 7

S.No. Department/Activity PERCENTAGE

2.1.B.2 Job Specification, Data Sheets and Drawings 14.0

2.1.B.3 Technical Memorandum 1.0

2.1.B.4 Vendor Data Requirement 2.0

2.1.B.5 List of Mandatory Spares 2.0

2.1.C After Issue of FEED 10.0

2.1.C.1 Amendments to FEED, As Required 2.0

2.1.C.2 Prebid Queries / Pre-Bid Meeting / Clarifications 2.0

2.1.C.3 Evaluation of Bids Including Issue of Tech. Addendum 2.0

2.1.C.4 Preparation of Technical Bid Analysis 4.0

2.2 Post -Award Stage 55.0

2.2.A Review /Approval of Engineering Drawings / Documents of contractor 51.0

2.2.A.1 System Design 25.0

2.2.A.1.i Review and Approval of Purchase Requisitions for Critical

20.0

Equipment / Packages in code 2

2.2.A.1.ii Approval of above in code 1 5.0

2.2.A.2 Review of Purchase Requisition for Non-Critical Equipment 8.0

2.2.A.2.i Review in code 2 5.0

2.2.A.2.ii Approval in code 1 3.0

2.2.A.3 Review of Vendor Drawing for all Equipment 18.0

2.2.A.3.i Review in code 2 14.0

2.2.A.3.ii Approval in code 1 4.0

Verification of Final Documentation List with respect to Completeness of

2.2.B 2.0

Engineering

2.2.C Site Assistance and Co-ordination 2.0

3 Discipline - Rotating Equipment 100.0

3.1 Pre-Award Stage 45.0

3.1.A Basic Engineering & Design Basis 15.0

3.1.A.1 Engineering Design Basis 5.0

3.1.A.2 Review of Process Packages 7.0

3.1.A.3 Furnishing of Preliminary Electrical Load, Utility Data etc. 3.0

3.1.B Preparation of FEED 20.0

3.1.B.1 Scope of Work 1.0

3.1.B.2 Job Specification, Data Sheets and Drawings 12.0

3.1.B.3 Technical Memorandum 1.0

3.1.B.4 Vendor Data Requirement 2.0

3.1.B.5 Experience Record Performa 2.0

3.1.B.6 List of Mandatory Spares 2.0

3.1.C After Issue of FEED 10.0

3.1.C.1 Amendments to FEED, As Required 1.0

3.1.C.2 Prebid Queries / Pre-Bid Meeting / Clarifications 2.0

3.1.C.3 Evaluation of Bids & Issue of Tech. Memorandum, If Any 3.0

3.1.C.4 Preparation of Technical Bid Analysis and Preparation of Agreed

4.0

Variations (of Successful Bidder), as applicable

3.2 Post -Award Stage 55.0

3.2.A Review /Approval of Engineering Drawings / Documents of contractor 51.0

3.2.A.1 Review and Approval of Purchase Requisitions for Critical Rotating

25.0

Equipment / Packages

3.2.A.1.i Review in code 2 17.0

3.2.A.1.ii Approval in code 1 8.0

3.2.A.2 Review of Purchase Requisition for Non-Critical Rotating Equipment 8.0

3.2.A.2.i Review in code 2 6.0

3.2.A.2.ii Approval in code 1 2.0

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure VI Document No.

ENGINEERING 5-2744-0115

(PMC JOB) Rev. No. 0

Page 3 of 7

S.No. Department/Activity PERCENTAGE

3.2.A.3 Review of Vendor Drawing for all Equipment 18.0

3.2.A.3.i Review in code 2 14.0

3.2.A.3.ii Approval in code 1 4.0

Verification of Final Documentation List with respect to Completeness of

3.2.B 2.0

Engineering

3.2.C Site Assistance and Co-ordination 2.0

4 Discipline - Pressure Vessels 100.0

4.1 Pre-Award Stage 55.0

4.1.A Basic Engineering & Design Basis 10.0

4.1.A.1 Engineering Design Basis 5.0

4.1.A.2 Comments On Process Data Sheets 5.0

4.1.B Preparation of FEED 35.0

4.1.B.1 Scope of Work, standards, specifications 5.0

4.1.B.2 Design of Vessels, Columns and Tanks for Determination of Minimum

25.0

Thickness / Foundation Loading Data

4.1.B.3 Finalisation of Engineering Tables 5.0

4.1.C After Issue of FEED 10.0

4.1.C.1 Prebid Queries / Pre-Bid Meeting / Clarifications 4.0

4.1.C.2 Issue of Technical Amendments 3.0

4.1.C.3 Technical Bid Analysis 3.0

4.2 Post -Award Stage 45.0

Approval / Review of Contractors Engineering Drawing / Documents

4.2.A 40.0

Included In Work Instruction 4-7700-0110

4.2.B Approval/ Review of above Documents in code 1 10.0

Verification of Final Documentation List with respect to Completeness of

4.2.B 3.0

Engineering

4.2.C Site Assistance and Co-ordination 2.0

5 Discipline - General Civil-Units 100.0

5.1 Pre-Award Stage 40.0

5.1.A Basic Engineering & Design Basis 17.5

5.1.A.1 Finalisation of Engineering Design Basis 5.0

5.1.A.2 Review of Process Packages 2.5

5.1.A.3 Basic Engineering 10.0

5.1.B Preparation of FEED 15.0

5.1.B.1 Scope of Work 2.0

5.1.B.2 Job Specifications / Design Parameters 5.0

5.1.B.3 Specific Requirements 3.0

5.1.B.4 Construction Material Specification 2.0

5.1.B.5 Conceptual Sketches / Standards 3.0

5.1.C After Issue of FEED 7.5

5.1.C.1 Prebid Queries / Pre-Bid Meeting / Clarifications and Issue of

2.5

Addendum

5.1.C.2 Evaluation of Bids / TQ / TBA 5.0

5.2 Post -Award Stage 60.0

5.2.A Approval of Engineering Drawings / Documents of contractor 15.0

5.2.A.1 PFD's for A/G Piping & U/G Sewers in code 2 4.0

5.2.A.2 Fire Water Layouts & Design Calculation in code 2 3.0

5.2.A.3 Approval of Plot Plan & Layout As Per TAC / OISD / CCE in code 2 3.0

5.2.A.4 Approval of above in code 1 5.0

5.2.B Review of Contractors Engg. Drawing / Documents 37.0

5.2.B.1 Finalisation of Conceptual / General Arrangement and Design

15.0

Philosophy in code 2

Template No. 5-0000-0001-T2 Rev. 1 Copyrights EIL – All rights reserved

PROGRESS MILESTONES FOR Annexure VI Document No.

ENGINEERING 5-2744-0115

(PMC JOB) Rev. No. 0

Page 4 of 7

S.No. Department/Activity PERCENTAGE

5.2.B.2 Input Data, Analysis and Design of Systems / Pipe Rack in code 2 15.0

5.2.B.3 Review of above in code 1 7.0

Verification / Revision / Updation of Drawings Because of Change In

5.2.C 3.0

Vendor / Engg. Data

5.2.D Site Assistance and Co-ordination 5.0

5a Discipline - General Civil-Offsites 100.0

5a.1 Pre-Award Stage 75.0

5a.1.A Basic Engineering & Design Basis 52.5

5a.1.A.1 Engineering Design Basis 5.0

5a.1.A.2 Review of Process Packages 2.5

5a.1.A.3 Basic Engineering 45.0

5a.1.B Preparation of FEED 15.0

5a.1.B.1 Scope of Work 2.0

5a.1.B.2 Job Specifications / Design Parameters 5.0

5a.1.B.3 Specific Requirements 3.0

5a.1.B.4 Construction Material Specification 2.0

5a.1.B.5 Conceptual Sketches / Standards 3.0

5a.1.C After Issue of FEED 7.5